Professional Documents

Culture Documents

Range Width and Assortment Planning for Maximum Sales and Margins

Uploaded by

Ssk IndeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Range Width and Assortment Planning for Maximum Sales and Margins

Uploaded by

Ssk IndeCopyright:

Available Formats

Range Width and Assortment Planning

Putting together a profitable range..

Without a Range Plan..

Assortments are put together in an un-structured manner

Ranges are bought based on availability with supplier rather than to a specific plan

Space and volume of merchandise dont match Low margin products occupy more shelf space

Products bought are either too much or too less to meet the sales and margin plan

Main objectives

Get the sales and margin plan right for the planned area Each store to get a balanced range with sufficient width for sale all year round To plan full potential of each option and aim to maximize margins To plan the display and replenishment qty for each option so that each option is available for the planned duration without running out of stock.

The starting point..

Sales plan

Top down and Bottom up approach

Performance - last year same season and immediate prior season Growth % for in like-for-like stores Business from new stores

Estimates from Operations Market trends

Sales phasing

Analyse sales by week for last year same period Factor in new launches/ promotions

Plot sales over the current period

Buy Plan

Corresponding to the sales plan Taking into account lead times

Manufacturing Transit to warehouse Allocation to stores

Stock Covers to be maintained within control

Stock turn

Buyers aim is to convert stock into cash, the no. of times this can be done in a specific period is the Stockturn

Stock turn = Sales/ Avg Stock High weeks cover = lower stock turn, vice versa

Plan the closing stock in no. of weeks cover at any given time

Eg. 8 weeks (4 on floor, 2 in warehouse and 2 in transit)

Planned Margins

Intake margins at the time of purchasing product (Difference between MRP and Cost) / MRP Balance the high margin and low margin product to achieve overall planned margins Helps to work backwards from MRP

OTB

Simply,

OTB = Planned Closing Stock (Opening stock (Sales+Markdowns)) **

Jan Opg Stk Planned Sales Markdowns Closing Stock Planned Clsg Stk OTB Weeks Cover 450 200 0 250 370 120 7.4

Feb 370 170 10 190 350 160 8.2

Mar 350 180 10 160 340 180 7.6

Apr 340 160 0 180 350 170 8.8

May 350 190 15 145 410 265 8.6

Jun 410 220 30 160 220 60

Building the range

Good assortment is a balance of:

price color styles Fabrics

Price:

Determine the lead-in price, mid price and highest price. Limited number of prices = less confusion for the customer Overall margin should be achieved with lesser price points

Building the range

Color:

Balance the proportion of core colors and highlight colors Prevent overkill of any specific color Control your own preference consciously Involve designers in this process All colors only from the seasons color palette

Building the range

Styles:

Are the styles complimenting each other? Are there too many styles? Or too few? Are key styles available in key colors? Are we taking too much risk by introducing a new style in a new color? Are all key fabrics represented? Are all key styles presented in key fabrics (and key colors)

Fabrics

Planning the assortment

Decide the Average Selling Price:

On basis of last year same season ASP + Inflation If theres a conscious shift to have more expensive products then it should be factored here. Determine the sales per square foot required Check whether the SPF is feasible from the given area

Sales Density:

Planning the assortment

Determine the total qty required per option on an avg.

Find out the total qty sold per option in the last year same season Find out avg qty sold per outlet, extrapolate it to total outlets in the current planning period

Final outcome..

Inputs:

Output:

Sales plan Avg stock holding value

OTB / Avg selling price = Total qty to be bought Total qty / Avg qty per option = Total no. of options required

OTB for the entire period Avg selling price Avg no of pcs that we can sell per option

Range Width Planning

The challenge is to present the best offering in the space available Step 1 - Grade the stores

A, B or C based on size A largest, B Medium sized, C Smallest

Step 2 - Grade the categories in each store

Category Grade 1, 2 or 3 based on business potential

Product Priority Store Type A

Ladies Western 1

Ladies Ethnic 2

Winterwear 3

Home 2

Denims 1

Range Width Planning

Combination of store grade and category grade will determine the Assortment Grade i.e. number of options planned for each category at each location. Since the characteristics will be the same, each store with the same assortment grade will get exactly the same width and depth.

For Eg. From Nov to Jan, winterwear will get more space in all Northern stores than in Western region stores, irrespective of store size. So it will be treated as Grade 1 category even in a C grade store in Delhi and therefore get more space and therefore an appropriate number of options for a C1 Assortment Grade!

Combining the Range Width and Assortment plan

Look at planned footage at each store grade. For eg.

For store Grade A, Number of pcs that can be displayed using optimum fixturing

Combination of face-outs and side-outs Find out Average depth per option sold last year, arrive at total number of options that can be displayed this year. Compare that with the planned number of options as per the Assortment Grade Adjust the buy assortment and footage till the offering looks complete with the aim of maximising sales

You might also like

- Category ManagementDocument64 pagesCategory ManagementJyoti K KushwahaNo ratings yet

- Jagriti Mishra, NIFT GandhinagarDocument34 pagesJagriti Mishra, NIFT GandhinagarSaquib AhmadNo ratings yet

- Daily Management of Store OperationsDocument12 pagesDaily Management of Store OperationsDeepak KanojiaNo ratings yet

- Merchandise Planning & Management GuideDocument26 pagesMerchandise Planning & Management GuideSaurabh GargNo ratings yet

- Plan Merchandise Budgets & NeedsDocument5 pagesPlan Merchandise Budgets & NeedsArnun Kumar SahuNo ratings yet

- Merchandising ProcessesDocument17 pagesMerchandising ProcessesvijayasethiiNo ratings yet

- Assortment Planning & Model Stock Planning in RetailDocument10 pagesAssortment Planning & Model Stock Planning in RetailSWAPNIL KRISHNANo ratings yet

- Assortment PlanningDocument4 pagesAssortment PlanningRahul P SinghNo ratings yet

- Merchandising - Planning & OTBDocument65 pagesMerchandising - Planning & OTBpranjal100% (1)

- Merchandising PlanningDocument19 pagesMerchandising PlanningAnkitaGupte12No ratings yet

- Six Month Merchandising PlanDocument13 pagesSix Month Merchandising PlanAmisha SinghNo ratings yet

- Merchandising ManagementDocument41 pagesMerchandising ManagementVinodh ManiNo ratings yet

- Measure Key Retail Metrics to Track Product PerformanceDocument6 pagesMeasure Key Retail Metrics to Track Product PerformanceRajatNo ratings yet

- Retail Math FormulasDocument12 pagesRetail Math FormulasVinod Joshi50% (2)

- Assortmentplanning TechniquesDocument9 pagesAssortmentplanning TechniquesSankar DasNo ratings yet

- ACFrOgCcO424t-d2Tl2dU 7aZ4UrKv8wWzk7QLHGDAJq5w2Mkesu7TbzPjRdc4LGUrAZtFsrAtVycZ-SzmXu KiqrvV4QvEMqYpep8dXpuOm-swI9yH jOIFj KGcEaLRwX72Qo3t28x9IQpkkDocument89 pagesACFrOgCcO424t-d2Tl2dU 7aZ4UrKv8wWzk7QLHGDAJq5w2Mkesu7TbzPjRdc4LGUrAZtFsrAtVycZ-SzmXu KiqrvV4QvEMqYpep8dXpuOm-swI9yH jOIFj KGcEaLRwX72Qo3t28x9IQpkkabhayNo ratings yet

- Merchandise MixDocument7 pagesMerchandise MixANSHU KUMARINo ratings yet

- Retail FormulaDocument5 pagesRetail FormulavipinvermaseptNo ratings yet

- Acid-Test Ratio: Average InventoryDocument8 pagesAcid-Test Ratio: Average InventorymohsinnaveesNo ratings yet

- The Buying CycleDocument19 pagesThe Buying CyclesiewspahNo ratings yet

- Retail MerchandisingDocument62 pagesRetail MerchandisingVidush Mukesh Singh ChauhanNo ratings yet

- Mathematics For Retail Buying-Inventory ManagementDocument27 pagesMathematics For Retail Buying-Inventory ManagementBhavyata ChavdaNo ratings yet

- Session 11 13Document41 pagesSession 11 13sameeksharaj24No ratings yet

- Merchandise Planning: What Is A Six-Month Merchandise Plan?Document7 pagesMerchandise Planning: What Is A Six-Month Merchandise Plan?Varun SharmaNo ratings yet

- Part 1: 1-2 Terminology For Six Month Merchandise PlanDocument3 pagesPart 1: 1-2 Terminology For Six Month Merchandise PlansiewspahNo ratings yet

- Retailpricingv3 PDFDocument20 pagesRetailpricingv3 PDFSupratik DattaNo ratings yet

- Otb & Gmroi PlanningDocument13 pagesOtb & Gmroi PlanningElhamNo ratings yet

- Retail Planning Topics and Performance AnalysisDocument51 pagesRetail Planning Topics and Performance AnalysisriteshgadaNo ratings yet

- Report On Lamson Game (Group-19) : Challenges Faced in Decision MakingDocument2 pagesReport On Lamson Game (Group-19) : Challenges Faced in Decision MakingSiddhant sharmaNo ratings yet

- Depth (Also Known As Product Assortment or Merchandise Depth) - This Is The Number of Each Item or Particular Styles ThatDocument5 pagesDepth (Also Known As Product Assortment or Merchandise Depth) - This Is The Number of Each Item or Particular Styles ThatSWAPNIL KRISHNANo ratings yet

- The Buying CycleDocument17 pagesThe Buying CycleSudipta SinhaNo ratings yet

- Fashion MerchandisingDocument15 pagesFashion MerchandisingsalonivoraNo ratings yet

- Lesson 2-Merchandising Terminology, Marketing Vs MerchandisingDocument20 pagesLesson 2-Merchandising Terminology, Marketing Vs Merchandisingjhenefer3No ratings yet

- Mathematics of Retail BuyingDocument38 pagesMathematics of Retail BuyingMuskaanKanodiaNo ratings yet

- Break Even SalesDocument48 pagesBreak Even SalesAaria Jayaraj AnishNo ratings yet

- What Is Merchandise Mix ?: Process of Developing, Securing, Merchandise OfferingDocument18 pagesWhat Is Merchandise Mix ?: Process of Developing, Securing, Merchandise OfferingBuhroy R BuhroyNo ratings yet

- Combined TTLS Retail Merchandising IIDocument137 pagesCombined TTLS Retail Merchandising IIinzmam100% (1)

- Sales and DistributionDocument65 pagesSales and DistributionKabo Lucas100% (1)

- # KPI Area KPI Name Technical Name What It Tells You Logical Formula Dimensions Required by This KPI? Dimensions This KPI Wont Work With? 1 2 3Document4 pages# KPI Area KPI Name Technical Name What It Tells You Logical Formula Dimensions Required by This KPI? Dimensions This KPI Wont Work With? 1 2 3SandeepNo ratings yet

- Whats Your OTB Purchase Planning Made Easy.17143105Document2 pagesWhats Your OTB Purchase Planning Made Easy.17143105ramjee prasad jaiswalNo ratings yet

- Merchandising MixDocument27 pagesMerchandising MixAeshna SoniNo ratings yet

- Product Assortment Strategies: Written ReportDocument10 pagesProduct Assortment Strategies: Written ReportMiguel FloresNo ratings yet

- Retail Math'Sppt1Document40 pagesRetail Math'Sppt1nataraj105100% (8)

- Concepts of Retail Price & PricingDocument14 pagesConcepts of Retail Price & Pricingpradeepsingh_204uNo ratings yet

- Retail Merchandising - IIDocument10 pagesRetail Merchandising - IIMohita SalujaNo ratings yet

- Merchandising Calender: By: Harsha Siddham Sanghamitra Kalita Sayantani SahaDocument29 pagesMerchandising Calender: By: Harsha Siddham Sanghamitra Kalita Sayantani SahaSanghamitra KalitaNo ratings yet

- Retail Industry KPI's: ThemeDocument30 pagesRetail Industry KPI's: ThemeHFB50% (2)

- Process of MerchandisingDocument25 pagesProcess of MerchandisingAmisha SinghNo ratings yet

- Wk2-1 Marketing & MerchandisingDocument4 pagesWk2-1 Marketing & MerchandisingthararameshnairNo ratings yet

- Omni Channel Buying and Planning - Assignment 2Document9 pagesOmni Channel Buying and Planning - Assignment 2MuskaanKanodiaNo ratings yet

- Retail FormulasDocument5 pagesRetail FormulasAnil Kumar KashyapNo ratings yet

- Retail merchandising strategies and planningDocument22 pagesRetail merchandising strategies and planningSubhrajit GuhaNo ratings yet

- 3.zara Home Product Assorment.Document6 pages3.zara Home Product Assorment.Eugenio Pavon Gutierrez100% (2)

- The Green Line: How to Swing Trade the Bottom of Any Stock Market Correction: Swing Trading BooksFrom EverandThe Green Line: How to Swing Trade the Bottom of Any Stock Market Correction: Swing Trading BooksRating: 1 out of 5 stars1/5 (1)

- Marketing Management for Beginners: How to Create and Establish Your Brand With the Right Marketing Management, Build Sustainable Customer Relationships and Increase Sales Despite a Buyer’s MarketFrom EverandMarketing Management for Beginners: How to Create and Establish Your Brand With the Right Marketing Management, Build Sustainable Customer Relationships and Increase Sales Despite a Buyer’s MarketNo ratings yet

- Market Profile Basics: What is the Market Worth?From EverandMarket Profile Basics: What is the Market Worth?Rating: 4.5 out of 5 stars4.5/5 (12)

- Categories Topics Page No: Arts & CultureDocument104 pagesCategories Topics Page No: Arts & CultureZyesha KaifNo ratings yet

- Assignment On Supply Chain ManagementDocument3 pagesAssignment On Supply Chain ManagementSsk IndeNo ratings yet

- GA-History of IndiaDocument233 pagesGA-History of IndiaRuchita RanjanNo ratings yet

- MathFundas WWW - Qmaths.inDocument64 pagesMathFundas WWW - Qmaths.inRobin VermaNo ratings yet

- Retail MathematicsDocument2 pagesRetail MathematicsSsk IndeNo ratings yet

- Knitting by SamirDocument13 pagesKnitting by SamirSsk IndeNo ratings yet

- Squares TableDocument1 pageSquares TableSsk IndeNo ratings yet

- Clerk Competition BoosterDocument70 pagesClerk Competition Boosterdheeru0071No ratings yet

- The History of Bandhani or Tie and DyeDocument3 pagesThe History of Bandhani or Tie and DyeSsk Inde100% (1)

- NAFTADocument9 pagesNAFTASsk IndeNo ratings yet

- Article 2 Chemical Finishing and Its MechanismsDocument6 pagesArticle 2 Chemical Finishing and Its MechanismsSsk IndeNo ratings yet

- Fashion MarketingDocument3 pagesFashion MarketingSsk IndeNo ratings yet

- GlobalDocument9 pagesGlobalSsk IndeNo ratings yet

- Retail MathematicsDocument2 pagesRetail MathematicsSsk IndeNo ratings yet

- ITC InfotechDocument1 pageITC InfotechSsk IndeNo ratings yet

- ITC InfotechDocument1 pageITC InfotechSsk IndeNo ratings yet

- Retail PPT - FinalDocument24 pagesRetail PPT - FinalSsk IndeNo ratings yet

- Presentation 4Document1 pagePresentation 4Ssk IndeNo ratings yet

- Fashion MarketingDocument3 pagesFashion MarketingSsk IndeNo ratings yet

- Marketing Strategy-LG ElectronicsDocument28 pagesMarketing Strategy-LG ElectronicsSsk Inde80% (5)

- Fashion MarketingDocument3 pagesFashion MarketingSsk IndeNo ratings yet

- Request Travel Approval Email TemplateDocument1 pageRequest Travel Approval Email TemplateM AsaduzzamanNo ratings yet

- Safari - Nov 2, 2017 at 4:13 PM PDFDocument1 pageSafari - Nov 2, 2017 at 4:13 PM PDFAmy HernandezNo ratings yet

- Project 1Document20 pagesProject 1pandurang parkarNo ratings yet

- Damodaran PDFDocument79 pagesDamodaran PDFLokesh Damani0% (1)

- Industrial Visit ReportDocument6 pagesIndustrial Visit ReportgaureshraoNo ratings yet

- DaewooDocument18 pagesDaewooapoorva498No ratings yet

- Marico Over The Wall Operations Case StudyDocument4 pagesMarico Over The Wall Operations Case StudyMohit AssudaniNo ratings yet

- SPT, Cross, ForwardDocument38 pagesSPT, Cross, Forwardseagul_1183822No ratings yet

- 2nd Annual Latin America Rail Expansion SummitDocument16 pages2nd Annual Latin America Rail Expansion SummitenelSubteNo ratings yet

- Bid Data SheetDocument3 pagesBid Data SheetEdwin Cob GuriNo ratings yet

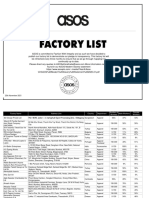

- ASOS Factory List November 2021 Final ListDocument45 pagesASOS Factory List November 2021 Final Listishika maluNo ratings yet

- Eco Bank Power Industry AfricaDocument11 pagesEco Bank Power Industry AfricaOribuyaku DamiNo ratings yet

- Nifty MasterDocument35 pagesNifty MasterAshok Singh BhatiNo ratings yet

- A4 - Productivity - City Plan 2036 Draft City of Sydney Local Strategic Planning StatementDocument31 pagesA4 - Productivity - City Plan 2036 Draft City of Sydney Local Strategic Planning StatementDorjeNo ratings yet

- Chris Cole Artemis Vega - Grants Interest Rate Observer Oct232012 - FINAL - v8Document34 pagesChris Cole Artemis Vega - Grants Interest Rate Observer Oct232012 - FINAL - v8augtour4977100% (1)

- Assumptions in EconomicsDocument9 pagesAssumptions in EconomicsAnthony JacobeNo ratings yet

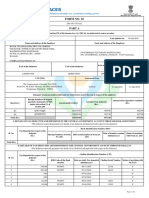

- Form 16 TDS CertificateDocument2 pagesForm 16 TDS CertificateMANJUNATH GOWDANo ratings yet

- Hotel Industry - Portfolia AnalysisDocument26 pagesHotel Industry - Portfolia Analysisroguemba87% (15)

- CareEdge Ratings Update On Tyre IndustryDocument5 pagesCareEdge Ratings Update On Tyre IndustryIshan GuptaNo ratings yet

- Extra Oligopolio PDFDocument17 pagesExtra Oligopolio PDFkako_1984No ratings yet

- India Inc's Baby Steps On Long Road To Normalcy: HE Conomic ImesDocument12 pagesIndia Inc's Baby Steps On Long Road To Normalcy: HE Conomic ImesShobhashree PandaNo ratings yet

- Ficha Tecnica y Certificado de Bituminoso MartinDocument2 pagesFicha Tecnica y Certificado de Bituminoso MartinPasion Argentina EliuNo ratings yet

- Final Report For Print and CDDocument170 pagesFinal Report For Print and CDmohit_ranjan2008No ratings yet

- Terms of TradeDocument3 pagesTerms of TradePiyushJainNo ratings yet

- Beli TGL 21 Sep 2021Document1 pageBeli TGL 21 Sep 2021Putri Marissa DilaNo ratings yet

- Fingal Housing Strategy AppendixDocument156 pagesFingal Housing Strategy Appendixdi TalapaniniNo ratings yet

- Print - Udyam Registration Certificate AnnexureDocument2 pagesPrint - Udyam Registration Certificate AnnexureTrupti GhadiNo ratings yet

- Infinity Hospitality - Wedding RatesDocument1 pageInfinity Hospitality - Wedding RatesgecogirlNo ratings yet

- AAEC 3301 - Lecture 5Document31 pagesAAEC 3301 - Lecture 5Fitrhiianii ExBrilliantNo ratings yet

- STIEBEL ELTRON Produktkatalog 2018 VMW Komplett KleinDocument276 pagesSTIEBEL ELTRON Produktkatalog 2018 VMW Komplett KleinsanitermNo ratings yet