Professional Documents

Culture Documents

IS 3589 - 2003-10 - With Amd 1 To 4

Uploaded by

hhr2412Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IS 3589 - 2003-10 - With Amd 1 To 4

Uploaded by

hhr2412Copyright:

Available Formats

I S 3589 : 2001

Ed i t ion 4.2

(2003-10)

B U R E A U O F I N D I A N S T A N D A R D S

MANAK BHAVAN, 9 BAHADUR SHAH ZAFAR MARG

NEW DELHI 110002

P r i ce Gr ou p 7

BIS 2003

Indian S tandard

STEEL PIPES FOR WATER AND SEWAGE

(168.3 TO 2 540 mm OUTSIDE DIAMETER)

SPECIFICATION

( Third Revision )

(Incor por at ing Amendment Nos. 1 & 2)

ICS 77.140.30;41.140.60;91.140.80

Amendment 1_May' 2002

Amendment 2_Oct' 2003

Amendment 3_Mar' 2006

Amendment 4_June'2010

attached end of this spec

St eel Tubes, Pipes and Fit t ings Sect ional Commit t ee, MTD 19

FOREWORD

This Indian St andar d (Thir d Revision) was adopt ed by t he Bur eau of Indian St andar ds, aft er t he

dr aft finalized by t he St eel Tubes, Pipes and Fit t ings Sect ional Commit t ee had been appr oved by

t he Met allur gical Engineer ing Division Council.

This st andar d was or iginally published in 1966, fir st r evised in 1981 and subsequent ly in 1991.

While r eviewing t his st andar d in t he light of t he exper ience gained dur ing t hese year s, t he

commit t ee felt t o r evise t he same, t aking not e of t he pr esent pr act ices being followed in t he

count r y and also over seas st andar ds exist ing on t he subject . In t he r evision of t his st andar d t he

following main modificat ions have been made:

a) Pr ovision of out side diamet er s and t hicknesses of pipes have been r evised in accor dance wit h

t he pr ovisions, of Int er nat ional St andar ds.

b) Exhaust ive t ables for chemical composit ion of st eels t o be used and t ensile pr oper t ies of t he

pipes have been incor por at ed.

c) Annexes A t o D as t he guideline for Pr ot ect ion Against Cor r osion have been added which

r ecommend met hods of pr ot ect ing pipes against cor r osion. It cover s ext er nal as well as

int er nal pr ot ect ion. Separ at e Indian St andar ds incor por at ing var ious t ypes of pr ot ect ive

coat ings and mat er ials t her eof ar e expect ed t o be published in due cour se of t ime.

In t he for mulat ion of t his st andar d due weight age has been given t o int er nat ional coor dinat ion

among t he st andar ds pr evailing in differ ent count r ies in addit ion t o t he pr act ices in t he count r y.

This has been met by der iving assist ance fr om t he following publicat ions:

This edit ion 4.2 incor por at es Amendment No. 1 (May 2002) and Amendment No. 2 (Oct ober 2003).

Side bar indicat es modificat ion of t he t ext as t he r esult of incor por at ion of t he amendment s.

For t he pur pose of deciding whet her a par t icular r equir ement of t his st andar d is complied wit h,

t he final value, obser ved or calculat ed, expr essing t he r esult of a t est or analysis, shall be r ounded

off in accor dance wit h IS 2 : 1960 Rules for r ounding off numer ical values ( revised ). The number

of significant places r et ained in t he r ounded off value should be t he same as t hat of t he specified

value in t his st andar d.

ISO 559-1991 St eel t ubes for wat er and sewage ( second edit ion ), Int er nat ional

Or ganizat ion for St andar dizat ion.

ISO 4200 : 1991 Plain end st eel t ubes, welded and seamless Gener al t ables of dimensions

and masses per unit lengt h. Int er nat ional Or ganizat ion for st andar dizat ion.

BS 534 : 1990 St eel pipes and specials for wat er and sewage. Br it ish St andar ds Inst it ut ion.

I S 3589 : 2001

1

Indian S tandard

STEEL PIPES FOR WATER AND SEWAGE

(168.3 TO 2 540 mm OUTSIDE DIAMETER)

SPECIFICATION

( Third Revision )

1 SCOP E

This st andar d applies t o seamless and welded

car bon st eel pipes for wat er and sewage of

out side diamet er fr om 168.3 t o 2 540 mm.

2 REF ERENCES

The following Indian St andar ds cont ain

pr ovisions which t hr ough r efer ence in t his t ext

const it ut e pr ovisions of t his st andar d. At t he

t ime of publicat ion, t he edit ions indicat ed wer e

valid. All st andar ds ar e subject t o r evision and

par t ies t o agr eement s based on t his st andar d

ar e encour aged t o invest igat e t he possibilit y of

applying t he most r ecent edit ions of t he

st andar ds indicat ed below:

3 TERMI NOLOGY

For t he pur pose of t his st andar d, t he following

definit ions shall apply.

3.1 P i p e (Tu b e )

A long hollow open ended object of cir cular

cr oss-sect ion. The t er m t ube is synonymous

wit h t he t er m pipe.

3.2 Hyd r ost a t ic Te st P r e ssu r e

Test pr essur e for hydr aulic t est ing at t he

wor ks.

3.3 Ra n d om Len gt h s

The t er m r andom lengt h denot es t he nor mal

manufact ur ing lengt h falling wit hin a r ange

agr eed t o bet ween t he pur chaser and t he

manufact ur er .

3.4 Exa ct Le n gt h s

Pipes cut t o a specified lengt h on which only a

small t oler ance is allowed.

3.5 Effe ct ive Len gt h

The act ual lengt h t hat a pipe cont r ibut es when

cor r ect ly assembled in a r un of piping. This

dimension excludes t he addit ional lengt h

cont r ibut ed by a slip-on t ype coupling when

t hat is used.

4 I NF ORMATI ON TO BE SUP P LI ED BY

THE P URCHASER WHI LE P LACI NG

ORDER

4.1 Ma n d a t or y I n for ma t ion s

a) t he quant it y or der ed (t ot al t onnage, t ot al

lengt h or number of t ubes);

b) t he number of t his st andar d;

c) t he gr ade of st eel;

d) t he out side diamet er and t hickness;

e) t he lengt h of pipes;

f ) t he end pr epar at ion (bevelled ends or

special joint s); and

g) t he t ype of ext er nal coat ing and/or int er ior

lining as agr eed pr eviously wit h t he

manufact ur er .

4.2 Op t i on a l Req u i r emen t s

Cer t ain opt ional and supplement ar y

r equir ement s may also be specified as under :

a) t he st eel making pr ocesses and

deoxidat ion pr ocedur es;

b) t he t ube making pr ocess;

c) deliver y condit ion;

d) ladle analysis;

e) deliver y lengt hs; and

f ) end pr epar at ion.

IS No. Title

228 Met hods of chemical analysis of

st eels (issued in var ious par t s)

1608 : 1995 Met hods for t ensile t est ing of

st eel pr oduct s ( second revision )

2328 : 1983 Met hod for flat t ening t est on

met allic t ubes ( first revision )

3803 (Par t 1) :

1989/ISO 2566 :

1984

Met hod for elongat ion

conver sions for st eel: Par t 1

Car bon and low alloy st eels

( second revision )

4711 : 1974 Met hods for sampling of st eel

pipes, t ubes and fit t ings ( first

revision )

4736 : 1986 Hot -dip zinc coat ings on mild

st eel t ubes ( first revision )

I S 3589 : 2001

2

5 DESI GNATI ON

5.1 The pipes shall be designat ed by t he

met hod of manufact ur e followed by t he gr ade

number cor r esponding t o t he minimum

specified t ensile st r engt h in MPa following t he

symbol Fe as given in Table 1.

Example:

ERW Fe410 indicat es elect r ic r esist ance

welded or induct ion welded st eel pipe having a

minimum t ensile st r engt h of 410 MPa.

Ta b le 1 Desi gn a t i on of t h e Gr a d e s of t h e

P i p e s

5.2 The size of t he pipes shall be designat ed by

t heir out side diamet er s in mm.

6 QUALI TY OF STEEL

Pipes shall be manufact ur ed wit h t he st eel

pr oduced by t he open hear t h or elect r ic fur nace

or one of t he basic oxygen pr ocesses. Ot her

pr ocesses may be used by agr eement bet ween

t he pur chaser and t he manufact ur er .

7 MANUFACTURE OF THE P RODUCT

The pipes shall be manufact ur ed by one of t he

following pr ocesses.

7.1 Sea ml e ss P i p e s

The pipes shall be manufact ur ed by using a

seamless pr ocess and shall eit her be hot or cold

finished.

7.2 El ect r i c Resi st a n ce We ld ed P ip es

The pipes shall be manufact ur ed fr om plat e,

sheet or st r ip welded cont inuously by t he

passage of an elect r ic cur r ent acr oss t he

abut t ing edges longit udinally or spir ally. The

finished pipes shall not include welds used for

joining lengt hs of t he hot or cold, flat r olled

st r ips pr ior t o t ube for ming. The ext er nal weld

bead shall be r emoved complet ely.

7.3 Su b me r ge d Ar c We ld e d P ip e s

The pipes shall be manufact ur ed fr om plat e,

sheet or st r ip wit h eit her a single or double

longit udinal seam or a spir al seam and welded

acr oss t he abut t ing edges by an aut omat ic

submer ged ar c welding pr ocess using at least

t wo r uns, one of which shall be on t he inside of

t he pipes.

7.4 Rep a i r b y We l d i n g

7.4.1 Injur ious defect s in pipe wall, pr ovided

t heir dept h does not exceed one t hir d of t he

specified wall t hickness, shall be r epair ed by

welding.

7.4.1.1 Defect s in t he welds, such as sweat s and

leaks, unless ot her wise specified may be

r epair ed or piece r eject ed at t he opt ion of t he

manufact ur er for submer ged ar c welded pipes.

7.4.1.2 Welds of t he elect r ic r esist ance welded

pipes may be r epair ed only by agr eement

bet ween t he pur chaser and t he manufact ur er .

7.4.1.3 Repair s of t his nat ur e shall be made by

complet ely r emoving t he defect , cleaning t he

cavit y and t hen welding.

7.4.2 All r epair ed pipes shall be r et est ed

hydr aulically in accor dance wit h 10.

8 CHEMI CAL COMP OSI TI ON

8.1 La d l e An a lysis

The ladle analysis of st eel shall be as given in

Table 2. The analysis of st eel shall be car r ied

out eit her by t he met hod specified in IS 228 and

it s r elevant par t s or any ot her est ablished

inst r ument al/chemical met hod. In case of

disput e t he pr ocedur e given in IS 228 and it s

r elevant par t s, shall be t he r efer ee met hod.

However , wher e t he met hod is not given in

IS 228 and it s r elevant par t s, t he r efer ee

met hod shall be as agr eed t o bet ween t he

pur chaser and t he manufact ur er .

8.2 P r od u ct An a lysis

Per missible var iat ions in t he case of pr oduct

analysis fr om t he limit s specified in Table 2

shall be as given in Table 3.

9 MECHANI CAL P ROP ERTI ES

9.1 Te n sil e St r en gt h

The t ensile pr oper t ies of st r ip cut

longit udinally (excluding t he weld) fr om

select ed pipes shall show t he pr oper t ies as

given in Table 4 in r espect t o specific t ype of

pipes as manufact ur ed. The per cent age

elongat ion shall be det er mined on a gauge

lengt h of 5.65 . If ot her gauge lengt hs ar e

used conver sion shall be made as in IS 3803

(Par t 1).

9.2 F la t t e n i n g or Ben d Test

9.2.1 Flat tening Test for ERW Pipes

At t he opt ion of t he manufact ur er flat t ening or

bend t est shall be car r ied out depending upon

t he t hickness and out er diamet er of t he pipes.

Met h od of

Ma n u fa ct u r e of

P i p e

Refe-

r e n ce

St eel Gr a d e s

Ap p li ca b le

(1) (2) (3) (4) (5)

Seamless S Fe330 Fe410 Fe450

Elect r ic r esist ance

including induct ion

welded

ERW Fe330 Fe410 Fe450

Submer ged ar c

welded (including

spir ally welded)

SAW Fe330 Fe410 Fe450

NOTE Met hod of manufact ur e of pipe and st eel

gr ades ot her t han specified above shall be as agr eed t o

bet ween t he manufact ur er and t he pur chaser .

; )

S

o

I S 3589 : 2001

3

Ta b le 2 Ch e mi ca l comp osit i on

( Clauses 8.1 and 8.2 )

Ta ble 3 P e r mi ss i ble Va r i a t i on for

P r od u ct An a lys i s

( Clause 8.2 )

The t est shall be made on a r ing sample not less

t han 40 mm in lengt h cut fr om t he ends of

select ed t ubes which shall be flat t ened bet ween

par allel plat es keeping t he weld at 90 t o t he

dir ect ion of t he for ce. No opening shall occur by

fr act ur e in t he weld unt il t he dist ance bet ween

t he plat es is less t han 75 per cent of t he or iginal

out side diamet er of t he pipe and no cr acks or

br eaks on t he met al elsewher e t han in t he weld

shall occur unt il t he dist ance bet ween t he

plat es is less t han 60 per cent of t he or iginal

out side diamet er .

9.2.2 Bend Test for ERW Pipes

No bend t est is applicable t o ERW pipes.

Ta b le 4 Mech a n i ca l P r op er t i es a t Room

Temp er a t u r e

( Clause 9.1 )

9.2.3 Flat tening Test for S eamless Pipes

This t est shall be car r ied out in accor dance

wit h IS 2328. A r ing, not less t han 40 mm long,

cut fr om one end of each select ed pipe shall

when cold be flat t ened bet ween t wo par allel flat

sur faces wit hout showing eit her cr ack or flaw,

unt il t he dist ance bet ween plat es H (in mm)

measur ed under load, is not gr eat er t han t he

value given by t he following equat ion:

wher e

a = specified t hickness of t he pipe (mm),

St ee l

Gr a d e

Me t h od of

Ma n u fa ct u r e

Ch emi ca l Comp osi t i on (La d l e An a lysi s)

C

Max

Mn

Max

P

Max

S

Max

CE

Max

Fe 330

Fe 330

Fe 330

Fe410

Fe410

Fe 410

Fe 450

Fe 450

Fe 450

Seamless (S)

Welded (ERW)

Welded (SAW)

Seamless (s)

Welded (ERW)

Welded (SAW)

Seamless(s)

Welded (ERW)

Welded (SAW)

0.16

0.16

0.16

0.20

0.20

0.20

0.25

0.25

0.25

1.20

1.20

1.20

1.30

1.30

1.30

1.20

1.20

1.30

0.040

0.040

0.040

0.040

0.040

0.040

0.040

0.040

0.040

0.040

0.040

0.040

0.040

0.040

0.040

0.040

0.040

0.040

0.45

0.45

0.45

0.45

0.45

0.45

; )

Con st i t u en t Va r i a t i on Over Sp eci fi ed

Li mi t , P er ce n t , Max

(1) (2)

Car bon 0.02

Manganese 0.04

Sulphur 0.005

Phosphor us 0.005

St eel

Gr a d e

Met h od R

m

Ten s i l e

St r en gt h

MP a

Min

R

e

Yi el d

St r es s

MP a

Min

A

El on ga t i on

P er ce n t

GL5.65

Min

Fe330 ERW, Seamless

and SAW

330 195

1)

20

Fe410 ERW, Seamless

and SAW

410 235

1)

18

Fe450 ERW, Seamless

and SAW

450 275

1)

15

1)

Yield st r ess values ar e for design pur poses only eit her

t he upper yield st r ess ReH, or t he 0.5 per cent of pr oof st r ess

(t ot al elongat ion) ReH 0.5 is t o be det er mined.

S

o

H

1 C + ( ) a

C a/D +

------------------------ =

I S 3589 : 2001

4

D = specified out side diamet er of t he pipe

(mm),

C = a const ant dependent on t he st eel

gr ade value of C,

= 0.09 for Fe330

= 0.07 for Fe410 and Fe450.

NOTES

1 If any flaw appear s dur ing flat t ening t est , it may

be r emoved by gr inding or filing. In such cases if

t he r emaining wall t hickness is not less t han t he

minimum per mit t ed t hickness as per clause t he

sample shall be accept ed.

2 Super ficial r upt ur e r esult ing fr om sur face

imper fect ions shall not be a cause of r eject ion.

9.3 Gu i d e d Ben d Test (For SAW P i p e s)

St r ips not less t han 40 mm wide, cut

cir cumfer ent ially fr om pipes per pendicular t o

weld seam wit h t he weld near t he middle of t he

sample shall, wit hout fr act ur e, be doubled over

a r ound bar t he diamet er of which shall be

calculat ed as given below. The weld

r einfor cement shall be r emoved fr om t he faces.

9.3.1 One face bend and one r oot bend

specimen, bot h confor ming t o Fig. 1 shall be

bent appr oximat ely 180 in a jig subst ant ially

in accor dance wit h Fig. 2 for any combinat ion of

diamet er , wall t hickness and gr ade. The

maximum value for jig dimension A may be

calculat ed by t he for mula given below. The

manufact ur er shall use a jig based on t his

dimension or a smaller dimension at his opt ion.

wher e

9.3.2 The specimens shall not fr act ur e

complet ely. Cr acks 6.35 mm or less in lengt h at

t he edge of t he specimen or 3.18 mm or less in

lengt h in t he cent r e of t he specimen shall be

disr egar ded. Any cr ack gr eat er t han 3.18 mm

in lengt h and r egar dless of dept h locat ed wit hin

t he weld met al shall be a cause for r eject ion.

Any pop-out gr eat er t han 3.18 mm in lengt h

(6.35 mm at t he edge) and 12.5 per cent or less

of t he specified wall t hickness in dept h and

locat ed in t he par ent met al, t he heat affect ed

zone, or t he fusion line, shall not be t he cause

for r eject ion.

Any t est specimen t hat shows defect ive

pr epar at ion, or mat er ial imper fect ion unr elat ed

t o t he int ent of t he par t icular mechanical t est

whet her obser ved befor e or aft er t est ing, may

be discar ded and r eplaced by anot her specimen

fr om t he same lengt h of t he pipe.

9.3.3 On examinat ion of t he bent specimen,

opening out of a slight defect due t o incomplet e

r oot penet r at ion or lack of r oot fusion need not

be consider ed a cause for r eject ion pr ovided t he

defect has sound met al at t he back and on

eit her side of it . In bor der line cases, fur t her

t est s shall be made on specimens fr om t he

same weld adjacent t o t he or iginal t est

specimen.

10 HYDRAULI C P RESSURE TEST

Each pipe shall be hydr aulically t est ed at t he

manufact ur er s wor ks befor e t he pipe is coat ed,

wr apped and lined.

10.1 The hydr aulic t est pr essur e shall be t he

pr essur e calculat ed as per t he following

for mula:

wher e

10.1.1 The hydr aulic t est pr essur e shall be

applied for 5 s.

10.2 The hydr aulic t est may be subst it ut ed by a

Non-Dest r uct ive Test at t he opt ion of t he

manufact ur er .

10.2.1 Met hod of NDT and t he accept ance level

shall be as agr eed t o bet ween t he manufact ur er

and t he pur chaser .

11 DI MENSI ONS AND MASS P ER METRE

RUN OF P I P ES

11.1 Pr efer r ed out side diamet er and t hickness

of t he pipes ar e specified in t he Table 5. The

t able also pr ovides t he nominal mass per met r e

r un of t he pipes against each dimension.

NOTE Table 5 gives a select ion of pr efer r ed out side

diamet er s and t hicknesses, ot her sizes not included, in

t he t able may be supplied as specified by t he pur chaser .

1.15 = peaking fact or ,

D = specified OD in mm,

t = specified wall t hickness in mm,

and

e = st r ain in mm

= 0.132 5 for Gr ade Fe330,

= 0.127 5 for Gr ade Fe410 and Gr ade

Fe450.

A

1.15 D 2t ( )

eD

t

------- 2e 1

----------------------------------- =

P = hydr aulic t est pr essur e MPa,

D = specified out side dia of t he pipe in

mm,

T = specified t hickness of t he t ube in mm,

and

S = st r ess 60% of t he specified minimum

yield st r ess in MPa. Th e ma xi mu m

t e st p r es s u r e t o b e li mi t ed t o 5

MP a wh e r e ve r a p p li ca b le .

P

2S T

D

------------ =

I S 3589 : 2001

5

FIG. 1 GUIDED BEND TEST SPECIMEN

FIG. 2 J IG FOR GUIDED BEND TEST

11.1.1 Mass per met r e r un of t he pipes can also

be wor ked out by t he for mula as under :

M = ( D T ) T 0.024 661 5

wher e

12 TOLERANCES

12.1 Tole r a n ce on Ma ss

The t oler ance on mass per car t load of 10

t onnes or above shall be 7.5 per cent on t he

nominal t heor et ical mass of t he t ubes.

12.2 Ge n er a l

The t oler ance on t he dimensions of t he pipes

shall be as specified in 12.3 and 12.4.

M = mass of t he pipe kg/met r e,

D = nominal out side diamet er of t he t ube

in mm, and

T = Nominal t hickness of t he t ube in mm.

I S 3589 : 2001

6

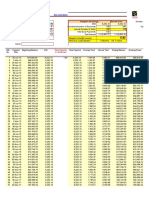

Ta b le 5 P r efer r ed Di men si on s a n d Ma ss p e r Me t r e Len gt h of P i p e s

( Clause 11.1 )

12.3 Ou t si d e Di a met e r , Th i ck n e ss a n d

He igh t of I n t er n a l We ld Be a d or

Rei n for cemen t

12.3.1 The t oler ance on out side diamet er shall

include ovalit y except for submer ged ar c

welded pipes.

The t oler ance on t he specified out side diamet er

of pipe wall shall be as given in Table 6.

Ta b le 6 Tol er a n ce s on Ou t sid e Di a me t e r

of P i p e s

12.3.2 Thickness

The t hickness t oler ance shall not apply t o t he

weld ar ea. The maximum height of t he weld

bead on t he int er nal sur face of t he pipe shall

not exceed 60 per cent of nominal wall

t hickness. The t oler ance on t he specified wall

t hickness shall be as follows:

12.3.3 Ovality

12.3.3.1 Ovalit y shall not exceed 1 per cent of

t he specified out side diamet er for pipes having

diamet er t o t hickness r at io not exceeding 100.

Wher e t he diamet er t o t hickness r at io exceeds

Ou t si d e

Di a met er

OD

Th i ck n es s Ma s s Ou t si d e

Di a met er

OD

Th i ck n es s Ma s s Ou t si d e

Di a met er

OD

Th i ck n e s s Ma s s

mm mm kg/m mm mm kg/m mm mm kg/m

168.3

219.1

273

323.9

355.6

406.4

457

2.6

3.2

4.0

4.5

2.6

3.6

4.5

6.3

3.6

4.0

5.0

6.3

4.0

4.5

5.6

7.1

4.0

5.0

5.6

8.0

4.0

5.0

6.3

8.8

4.0

5.0

6.3

10.0

10.6

12

16.2

18.2

13.9

19.1

23.8

33.1

23.9

26.5

33

41.1

31.8

35.4

44

55.5

34.7

43.2

48.3

68.6

39.7

49.5

62.2

86.3

44.7

55.7

70

110

508

610

711

813

914

1 016

1 067

1 118

5.0

5.6

6.3

11.0

5.8

6.3

12.5

6.3

7.1

14.2

7.1

8.0

18.0

8.0

8.8

10.0

17.5

8.8

10.0

20.0

8.8

10.0

11.0

8.8

10.0

11.0

62

69.4

77.9

135

83.5

93.8

184

109

123

244

141

159

314

179

196

223

387

219

248

491

230

251

286

241

273

300

1 219

1 422

1 626

1 829

2 032

2 235

2 540

10.0

11.0

12.5

12.5

14.2

14.2

16.0

14.2

16.0

17.5

16.0

17.5

20.0

17.5

20.0

22.2

20.0

22.2

25.0

298

328

372

435

493

564

635

634

715

782

795

869

992

957

1 093

1 211

1 243

1 379

1 551

Ou t s i d e Di a

(F or Al l Si ze s )

Toler a n ce

(1) (2)

For seamless pipes 1%

For ERW & SAW pipes 0.75%

ERW pipe 10%

SAW and seamless

pipe

%

+ 20

12.5

,

_

I S 3589 : 2001

7

100 t he t oler ance on ovalit y is not specified and

should be agr eed bet ween t he manufact ur er

and t he pur chaser .

12.4 Ra n d om Le n gt h

12.4.1 St eel t ubes shall be supplied in single

r andom lengt hs fr om 4 t o 7 m or double r andom

lengt h of 7 t o 14 m. For or der s over 200 m of

any one size of pipes, it shall be per missible t o

supply shor t r andom lengt hs fr om 2 t o 4 m for

single r andom lengt hs and 4 t o 7 m for double

r andom lengt hs pr ovided t he t ot al of such

lengt hs does not exceeds 7.5 per cent of t he t ot al

lengt h.

12.4.2 Wher e lengt h is specified as exact or

cut lengt hs t he per missible var iat ions shall be

mm for lengt h up t o and including 6 m.

12.4.3 Supply in any lengt h and t he t oler ances

ot her t han t he above specified shall be

mut ually agr eed t o bet ween t he manufact ur er

and t he pur chaser .

12.5 St r a i gh t n e ss

12.5.1 Finished pipe shall not deviat e fr om

st r aight ness by mor e t han 0.2 per cent of t he

t ot al lengt h.

12.5.2 Checking shall be car r ied out using a

t aut st r ing or wir e fr om end t o end, along t he

side of t he pipe t o measur e, t he gr eat est

deviat ion.

13 NUMBER, SELECTI ON AND P REP AR-

ATI ON OF SAMP LES AND TEST P I ECES

13.1 Unless ot her wise agr eed t o bet ween t he

manufact ur er and t he pur chaser t he pr ocedur e

for sampling of pipe for var ious t est s and

cr it er ia for confor mit y shall be as given in

IS 4711.

13.1.1 The t est samples shall be cut fr om pipes

in t he final condit ion of supply.

13.1.2 One set of mechanical t est s as specified

in 9 shall be car r ied out fr om samples t aken of

each t ube.

13.1.3 For t he t ensile t est , t he dimensions of

t he t est piece shall comply wit h t he appr opr iat e

r equir ement s of IS 1608. For welded pipes t he

t ensile t est piece shall not include t he weld

unless t he pipe is t est ed in full sect ion.

NOTE For t he t ensile t est , t he piece may be t aken

eit her longit udinally or t r ansver sely fr om t he pipe at

t he opt ion of t he manufact ur er .

13.1.4 For a bend t est on t he weld, t wo pieces

shall be pr epar ed, one for a face bend t est and

one for a r oot bend t est . Bot h t est pieces shall

be not less t han 40 mm wide and cut

per pendicular t o t he weld line fr om one end of

each select ed pipe so t hat t he weld is in t he

middle of t he t est piece and 90 t o t he longer

sides. The weld r einfor cement shall be r emoved

fr om bot h faces. The lengt h of t he t est pieces

shall be select ed by t he manufact ur er t o suit

t he equipment used for t he t est .

NOTE The t est pieces may be flat t ened befor e

t est ing.

14 VI SUAL I NSP ECTI ON, AP P EARANCE

AND WORKMANSHI P

14.1 The pipes shall be clean and fr ee fr om

such defect s as can be est ablished by visual

inspect ion in accor dance wit h t his st andar d.

14.2 It shall be per mit t ed t o dr ess by gr inding

or machining sur face mar ks and imper fect ions

such as scabs, seams, t ear s, laps, sliver s or

gouges pr ovided t hat t he t hickness of t he t ube

aft er dr essing does not fall below t he nominal

t hickness by mor e t han t he t oler ance specified

in t his st andar d.

14.3 All dr essed ar eas shall blend smoot hly

int o t he cont our of t he pipe.

14.4 For pipes which have a t hickness t o

diamet er r at io equal t o or less t han 0.03,

isolat ed dent s shall not be cause for r eject ion

pr ovided t hat t hey do not exceed a dept h

gr eat er t han 6 mm maximum for pipes below

610 mm OD and not exceed 1 per cent of OD for

pipes over 610 mm OD measur ed as a gap

bet ween t he point of t he dent and a

pr olongat ion of t he or iginal cont our of t he pipe.

The lengt h of t he dent in any dir ect ion shall not

exceed one half t he pipe diamet er .

14.5 The ends shall be cut nominally squar e

wit h t he axis of t he pipe and shall be fr ee fr om

excessive bur r s.

15 CONDI TI ON OF SUP P LY

Subject t o t he agr eement bet ween t he

manufact ur er and t he pur chaser t he pipes may

be supplied bar e or wit h ant i r ust coat ings.

16 GUI DELI NES OF COATI NG

16.1 Any t ype of pr ot ect ive coat ing, if r equir ed,

may be agr eed t o bet ween t he manufact ur er

and t he pur chaser . Guidelines for t he t ypes of

coat ing ar e given in Annexes A t o D.

16.2 Wher e t ubes ar e r equir ed t o be galvanized

t he zinc coat ing on t ubes shall be in accor dance

wit h IS 4736.

17 J OI NTS AND ENDS

17.1 The t ype of joint s and ends of pipes shall

be specified by t he pur chaser . The t ypes of

joint s and ends r ecognized under t his st andar d

ar e:

a) Plain ends or bevelled ends for but t

welding ( see Fig. 3A and 3B ) unless

ot her wise agr eed, bevelled ends shall be

bevelled t o an angle of 30 degr ee

measur ed fr om a line dr awn

+ 10

0

+ 5

0

I S 3589 : 2001

8

per pendicular t o t he axis of t he pipe. The

r oot face shall be 1.6 0.8 mm.

b) J oint s wit h sleeves joint or swelled and

plain ends for welding ( see Fig. 4 ).

NOTE The r oot face of t he bevel may be pr epar ed by

hand fit t ing, if r equir ed.

17.1.1 Pipe wit h sleeve welded joint s shall be

supplied wit h t he plain and par allel end and

sleeve and t aper ed t o appr oximat ely 3 mm per

100 mm. The ends shall be sized and gauged so

as t o ensur e t hat t he plain end will fr eely ent er

t he sleeve and t her eaft er be capable of being

for ced home.

17.2 All sleeves shall be made so t hat t he plain

end shall ent er t he specified minimum dept h

given in Table 7. The manufact ur er shall make

available t o inspect ion at t he wor ks met al

gauges of suit able dimensions t o enable t he

pur chaser or his r epr esent at ive t o ascer t ain

t hat t he sleeve and plain end comply wit h t he

r equir ement s of t he specificat ion.

Ta b l e 7 De p t h of sle e ve , X a n d clea r a n ce

Y for we ld e d t u b es

( Clause 17.2 )

18 MARKI NG

18.1 Each pipe shall be legibly mar ked wit h t he

following det ails:

a) Manufact ur er s name or t r ade-mar k;

FIG. 3 TYPES OF ENDS

Dep t h of Sle eve , X Ou t si d e Di a met e r

of P i p e

Toler a n ce

(1) (2) (3)

mm mm mm

50 168.3 upt o 406.4 6

60 457.0 upt o 1 219.0 6

75 1321.0 upt o 2 540.0 6

Clear ance Y, bet ween t he

plain ends, mm Max

4 168.3 upt o 1 219.0

6 1321.0 upt o 2 540.0

I S 3589 : 2001

9

FIG. 4 SLEEVE J OINT OR SWELLED AND PLAIN END FOR WELDING

b) Out side diamet er and specified wall

t hickness; and

c) Pipe designat ion.

Example:

For a pipe manufact ur ed under t r ade name

ABC having 508 mm out side diamet er 8 mm

specified wall t hickness confor ming t o SAW 410

gr ade shall be legibly mar ked as follows:

ABC 508.0 8 SAW 410

18.2 BI S St a n d a r d Ma r k

The pipes may also be mar ked wit h t he

St andar d Mar k.

18.2.1 The use of t he St andar d Mar k is

gover ned by t he pr ovisions of t he Bureau of

Indian S tandards Act, 1986 and t he Rules and

Regulat ions made t her eunder . The det ails of

condit ions under which a licence for t he use of

t he St andar d Mar k may be gr ant ed t o

manufact ur er s or pr oducer s may be obt ained

fr om t he Bur eau of Indian St andar ds.

ANNEX A

( Foreword and Clause 16.1 )

GUI DELI NES F OR P ROTECTI ON AGAI NST CORROSI ON

A-1 CEMENT-MORTAR P ROTECTI VE

LI NI NG AND COATI NG FOR STEEL P I P E

SHOP AP P LI ED

The inside of all pipe shall r eceive a

cement -mor t ar lining applied by cent r ifugal

spinning or by a met hod known t o pr ovide

equivalent r esult s.

The out side of pipe shall r eceive a r einfor ced

cement -mor t ar coat ing applied by mechanical

placement , pneumat ic placement , or a met hod

known t o pr ovide equivalent r esult s.

A-2 REI NF ORCEMENT

Spir al-wir e r einfor cement for pipe coat ing.

St eel wir e shall be a minimum size of 3 mm.

The wir e shall confor m t o t he r equir ement s of

IS 432 (Par t 1). Reinfor cing wir e need not be

galvanized unless ot her wise specified by t he

pur chaser .

Reinfor cement shall be 50 100 mm welded

wir e fabr ic. The wir e shall confor m t o t he

r equir ement s of IS 1566. Unless ot her wise

specified by t he pur chaser , wir e fabr ic

r einfor cement may be eit her cr imped or

uncr imped.

A-3 P ORTLAND CEMENT

Por t land cement shall confor m t o t he

r equir ement s of IS 269/IS 8041/IS 1489/IS 8112

for cement , or as ot her wise specified by t he

pur chaser . The minimum cement cont ent shall

be 330 kg/m

3

.

A-3.1 Sa n d

Sand shall consist of iner t mat er ials having

har d, st r ong, dur able uncoat ed gr ains

confor ming t o t he r equir ement s t o IS 2116.

A-4 MI XI NG WATER

Wat er shall be clean, colour less, and fr ee fr om

injur ious quant it ies of or ganic mat t er , alkali,

salt , or ot her impur it ies t hat might r educe t he

st r engt h, dur abilit y, or ot her desir able

qualit ies of t he mor t ar , t he maximum wat er

cement r at io shall not exceed 0.5:1.

A-5 SEAL COAT P AI NT

The paint or ot her wise mat er ials used t o

pr event t he r ust ing of st eel sur faces and

pr oviding seal coat of mor t ar lining or coat ing

befor e pipe inst allat ion shall be a quick dr ying,

cor r osion-r esist ant mat er ial wit h good bonding

pr oper t ies t o st eel and shall dr y t ackfr ee and

smoot h wit hin 4 h aft er applicat ion. The paint

I S 3589 : 2001

10

mat er ial applied t o t he int er ior of pipe or

fit t ings shall be fr ee fr om cont aminant s t hat

may be har mful t o t he end user of t he pot able

wat er .

A-6 LI NI NG

A-6.1 Ce me n t Mor t a r

Cement mor t ar shall be composed of cement ,

sand and wat er , well mixed and of pr oper

consist ency t o obt ain a dense, homogeneous

lining t hat will adher e fir mly t o t he pipe

sur face. Pr opor t ion 2 par t s of sand t o 1 par t

cement , by weight . The soluble chlor ide-ion (Cl)

cont ent of t he cement mor t ar mix shall not

exceed 0.15 per cent , expr essed as a per cent age

of cement weight .

A-6.2 Th i ck n ess of Li n i n g

Cement mor t ar lining shall be unifor m in

t hickness, except of joint s or ot her

discont inuit ies in t he pipe wall. Lining

t hickness shall be as list ed in Table 8 or as

specified by t he pur chaser . Ends of lining shall

be left squar e and unifor m wit h r egar d t o t he

longit udinal axis of t he pipe, and t he lining

holdback shall be as specified by t he pur chaser

for t he t ype of joint s r equir ed.

Ta b l e 8 Th ick n e ss of Ce me n t Mor t a r

Li n i n g

A-6.3 Eq u i p men t

A-6.3.1 Lining

St r aight sect ions of pipe shall be lined by use of

a spinning machine specifically designed and

built for t he pur pose of r ot at ing t he pipe sect ion

and cent r ifugally applying cement mor t ar

lining t o t he int er ior of st eel pipe or by a

met hod known t o pr ovide equivalent r esult .

A-6.3.2 Mixing

The mor t ar shall be mixed in bat ches. The

amount of cement and sand ent er ing int o each

bat ch shall be measur ed by weight . The

quant it y of wat er ent er ing t he mixer shall be

measur ed aut omat ically by an adjust able

device, or it shall be ot her wise measur ed t o

ensur e t hat t he cor r ect quant it y of wat er is

being added.

A-6.4 Ma ch i n e Lin i n g

A-6.4.1 Bracing

When r equir ed t o pr event dist or t ion or

vibr at ion dur ing t he spinning, each sect ion of

pipe shall be suit ably br aced wit h ext er nal or

int er nal suppor t s appr opr iat e t o t he

equipment .

A-6.4.2 Finish

Aft er t he mor t ar has been dist r ibut ed t o a

unifor m t hickness, t he r ot at ion speed shall be

incr eased t o pr oduce a dense mor t ar wit h a

smoot h sur face.

A-6.4.3 S urplus Water

Pr ovision shall be made for r emoval of sur plus

wat er by air blowing, t ilt ing of t he pipe or ot her

met hods appr oved by t he pur chaser .

A-6.5 De fe ct i ve Lin i n g

A-6.5.1 General

All defect s, including but not r est r ict ed t o sand

pocket s, voids, over sanded ar eas, blist er s, and

cr acking as a r esult of impact s, shall be cut out

and r eplaced by hand or pneumat ic placement

t o t he same t hickness as r equir ed for t he

mor t ar lining.

A-6.5.2 Lining Cracks

Temper at ur e and shr inkage cr acks in t he

mor t ar lining less t han 1.5 mm in widt h need

not be r epair ed.

A-6.6 Cu r i n g of Li n i n g

Immediat ely aft er complet ion of spinning, t he

pipe sect ions, may be moved t o a cur ing ar ea.

Car e shall be exer cised at all t ime t o pr event

damage t o t he lining. At t he opt ion of t he

manufact ur er , linings shall be eit her

acceler at ed cur ed or moist cur ed.

A-6.6.1 Moist Curing

On ar r ival at t he cur ing ar ea, but not lat er t han

30 min aft er complet ion of t he lining oper at ion,

pipe ends shall be cover ed wit h plast ic or wet

bur lap for a minimum per iod of 24 h befor e

applying t he ext er ior coat ing, if such coat ing is

specified. If a cement mor t ar ext er ior coat ing is

not specified, t he lining shall be kept moist for

four days befor e shipment . In eit her case, t he

lining shall be cur ed for a t ot al per iod of four

days befor e shipment . The ends of t he pipe

sect ions shall be kept closed dur ing t he cur ing

per iod, wit h plast ic end caps, except when

spr inkling hands ar e used, t he r einfor cement

and out side coat ings ar e being applied or

acceler at ed cur ing is being subst it ut ed. If t he

plast ic end caps ar e inst alled at t hat t ime, t hey

can be used for shipping t o t he jobsit e. The

manufact ur er shall exer cise car e and diligence

t o avoid dr ying t o or cr acking of t he lining.

Ou t si d e Di a of

St e el P i p e

Mi n i mu m Th i ck n e ss

of Li n i n g

Tol er a n ce

mm mm mm

(1) (2) (3)

168.3 t o 323.9 6 + 2

0

355.6 t o 610 7 + 2

0

660 t o 1 219 9 + 2

0

1 321 t o 2 540 12 + 3

0

I S 3589 : 2001

11

A-6.6.2 Accelerat ed Curing

Acceler at ed cur ing may begin immediat ely on

ar r ival of t he pipe at t he cur ing ar ea, but t he

t emper at ur e of t he pipe shall not exceed for 3 h

or unt il t he mor t ar has t aken it s init ial set ,

whichever occur es fir st .

The ambient vapour shall t hen be maint ained at

a t emper at ur e bet ween 45C and 65C at a

r elat ive humidit y of not less t han 85 per cent for

a minimum cur ing per iod of 6 h, aft er which t he

ext er ior coat ing may be applied, if such coat ing

is specified. If cement mor t ar coat ing is not

specified, t he lining shall be cur ed for 18 h befor e

shipment . In eit her case, t he lining shall be

cur ed for a t ot al per iod of 18 h befor e shipment .

A-7 MORTAR LI NI NG TEST CYLI NDERS

A-7.1 Mor t a r Te st Cyli n d e r s

A set of at least t wo st andar d t est cylinder s,

50 mm in diamet er by 300 mm in lengt h, shall

be made each day. The t est cylinder s shall be

cur ed wit h t he pipe at t he same t emper at ur e

and for t he same t ot al lengt h of t ime. Ot her

sizes cylinder s, such as 50 mm 100 mm may

be used t o t est compr essive st r engt h. If t he

7-day t est r equir ement s, t hen t he 28-day t est

need not be complet ed.

A-7.2 Ce n t r i fu ga l Te st Cyl in d e r s

Cent r ifugally spun t est cylinder s may be

subst it ut ed for mor t ar t est cylinder s, at t he

opt ion of t he manufact ur er . Test cylinder s shall

be spun about t heir longit udinal axes in

150 mm diamet er by 300 mm long st eel molds

at a speed t hat will simulat e t he compact ion of

mor t ar in t he lining t o pr oduce a spun cylinder

wall t hickness of at least 35 mm. The net

cr oss-sect ional ar ea of t he hollow cylinder shall

be used t o det er mine it s compr essive st r engt h.

Damaged cylinder s shall not be t est ed.

A-7.3 St r en gt h of Mor t a r Li n i n g

Mor t ar t est cylinder s shall obt ain a minimum

compr essive st r engt h of 18 MPa in 7 days and

31 MPa in 28 days. Pipe made wit h mor t ar

lining t hat does not meet t he st r engt h

r equir ement s set for t h her ein shall be subject t o

r eject ion.

The aver age of any 10 consecut ive st r engt h

t est s of cylinder s r epr esent ing each mor t ar mix

shall be equal t o or gr eat er t han t he specified

st r engt h, and not mor e t han 20 per cent of t he

st r engt h t est s shall have values less t han t he

specified st r engt h. No cylinder t est r esult shall

be less t han 80 per cent of t he specified st r engt h.

A-8 COATI NG

A-8.1 Gen e r a l

When specified, t he ext er nal pr ot ect ion of st eel

pipe shall be a r einfor ced cement mor t ar

coat ing applied over t he out er sur faces of t he

pipe sect ions. If t he pipe has been mor t ar lined,

t he cur ing t imes specified above must elapse

befor e t he coat ing is applied.

A-8.2 Cemen t Mor t a r

Cement mor t ar applied by mechanical

placement or by t he st eampneumat ic pr ocess

shall consist of not mor e t han 3 par t s sand t o

1 par t cement , by weight . The wat er in t he

mixt ur e shall be car efully cont r olled so t hat t he

mor t ar will not r un, sag, or segr egat e.

The soluble chlor ide-ion (Cl) cont ent of t he

cement mor t ar mix shall not exceed 0.15 per cent ,

expr essed as a per cent age of cement weight .

A-8.3 Th i ck n ess

Cement mor t ar coat ing shall be unifor m in

t hickness except in joint s or ot her

discont inuit ies in t he pipe. Coat ings shall be

20 mm minimum t hickness for all sizes of pipe

up t o unless ot her wise specified by t he

pur chaser . Ends of coat ings shall be unifor m

and squar e t o t he longit udinal axis of t he pipe,

and t he coat ing holdback shall be as specified

by t he pur chaser for t he t ype of joint r equir ed.

A-9 REI NF ORCEMENT

A-9.1 Ge n er a l

Unless ot her wise specified by t he pur chaser ,

t he r einfor cement of t he coat ing of pipe sect ions

may be spir al wir e, wir e fabr ic, or wir e mesh

(r ibbon mesh). Reinfor cement shall be fr ee of

oil, gr ease, and ot her cont aminant s t hat might

r educe t he adher ence bet ween t he coat ing and

r einfor cement . All r einfor cement shall be

placed in t he middle t hir d of t he coat ing. When

cement mor t ar coat ing is applied over a

dielect r ic under coat , t he r einfor cement shall

not be at t ached t o or ot her wise be in cont act

wit h t he st eel pipe.

A-9.2 Sp i r a l Wi r e

At t achment of ends and splices in t he wir e

shall be by welding or ot her suit able means

accept able t o t he pur chaser . Maximum spacing

of t he wir e shall be 35 mm. The wir es on 50 mm

spacing on t he 50 mm 100 mm fabr ic shall

ext end cir cumfer ent ially ar ound t he pipe.

A-9.3 Wir e Me sh

At t achment of ends and splices in t he wir e

shall be as appr oved by t he pur chaser . When

25 mm 25 mm, 8 mm t he spir al lap shall be

35 mm and t he spliced lap 110 mm minimum.

A-10 AP P LI CATI ON OF MORTAR

COATI NG

A-10.1 Ap p li ca t i on

Mor t ar coat ing shall be applied by mechanical

I S 3589 : 2001

12

or pneumat ic placement t o t he specified

t hickness in one or mor e cont inuous

applicat ion(s). Allowance shall be made for

splices of r einfor cing wir e. If applied in mor e

t han one cour se, t he int er val bet ween t he fir st

and last cour se shall be not mor e t han 2 h. The

mor t ar shall be pr oject ed at high velocit y

against t he ext er ior sur faces of t he pipe or shall

be applied by an equivalent met hod t o pr oduce

a har d, t ight adher ing coat ing of t he specified

t hickness.

A-10.2 De fe ct i ve Coa t i n g

A-10.2.1 S and Pockets and Porous S pots

If any sand pocket s or por ous spot s occur , t hey

shall be complet ely cut out and r eplaced by

pneumat ic placement or hand applicat ion of

mor t ar in t he pr opor t ion of 2 par t s sand t o

1 par t cement , by weight .

A-10.2.2 Coating Cracks

Car e shall be exer cised t o minimize t he

occur r ence of cr acks in t he mor t ar coat ing.

However , hair line cr acks need not be r epair ed.

Repair pr ocedur es shall include t he br ushing or

wiping of neat cement int o t he cr acks,

aut ogenous healing of t he cr acks by addit ional

moist cur ing, t he paint ing of t he cr acks wit h an

epoxy coat ing, or a combinat ion of t hese

met hods.

NOTE Repair pr ocedur e involving ext ensive chipping

or r out ing of t he cr acks should be avoided as t his

pr ocedur e t ends t o deepen and lengt hen t he exist ing

cr acks and may damage t he bond or adhesion bet ween

t he coat ing and t he cylinder .

A-10.3 Cu r i n g of Coa t i n g

A-10.3.1 General

Aft er t he init ial set has t aken place, t he mor t ar

coat ing shall be cur ed by t he moist or

acceler at ed cur ing met hods or unless ot her wise

specified by t he pur chaser , a membr ane

mat er ial may be applied immediat ely following

t he coat ing applicat ion. Moist and acceler at ed

cur ing may be used int er changeably on a t ime

r at io basis of 5 h or moist cur ing t o 1 h of

acceler at ed cur ing, except cur ing t emper at ur es

shall not exceed t he maximum allowable for

dielect r ic under coat mat er ial.

The coat ing shall be kept cont inually moist by

int er mit t ent or cont inuous spr aying for a

per iod of at least four days. Moist cur ing may

be used only if t he minimum ambient

t emper at ur e exceeds 5C cont inuously dur ing

t he minimum r equir ed cur ing per iod, and no

cr edit shall be allowed for any t ime dur ing

which t he t emper at ur e dr ops below 10C.

A-10.4 Accel er a t e d Cu r i n g

Acceler at ed cur ing of t he pipe or special may

begin immediat ely aft er complet ion of t he

coat ing oper at ion or wit hin 6 h t her eaft er . The

t emper at ur e of t he pipe or special shall not

exceed 30C unt il t he cement mor t ar coat ing

has t aken it s init ial set or unt il a per iod of 3 h

has elapsed, whichever occur es fir st . The

r elat ive humidit y shall be not less t han 85

per cent at a t emper at ur e bet ween 45 t o 65C

for at least 18 h.

A-10.5 Me mb r a n e Cu r i n g

Membr ane cur ing shall consist of t he complet e

encapsulat ion of t he coat ing by applicat ion of a

mat er ial t hat will r et ain t he moist ur e of t he

applied cement mor t ar coat ing.

A-10.6 Ma n u fa ct u r e

Dur ing t he ent ir e per iod of t he applicat ion of

t he lining and coat ing and t he cur ing t her eof,

t he sect ion shall be car efully suppor t ed and

handled t o avoid damage t o t he mor t ar . If a

pipe sect ion must be moved, such oper at ion

shall be done wit h ever y r easonable pr ecaut ion

t o pr ot ect against damage. Any damaged

por t ion of t he lining or coat ing shall be cut out

and r eplaced.

I S 3589 : 2001

13

ANNEX B

( Foreword and Clause 16.1 )

LI QUI D-EP OXY COATI NG SYSTEMS F OR THE I NTERI OR AND

EXTERI OR OF STEEL P I P ELI NES

B-1 COATI NG AND LI NI NG SYSTEMS

Unless specified ot her wise by t he pur chaser ,

t he coat ing and lining syst ems may consist of

any of t he following t hr ee t ypes: (1) t wo-par t ,

chemically cur ed epoxy pr imer and one or mor e

coat ings of a differ ent t wo-par t , chemically

cur ed epoxy t opcoat ; (2) t wo or mor e coat s of t he

same t wo-par t , chemically cur ed epoxy coat ing,

in which case t he fir st coat shall be consider ed

as t he pr ime coat ; or (3) a single coat of a

t wo-par t , solvent fr ee, chemically cur ed epoxy

coat ing.

B-1.1 Liq u id -Ep oxy Coa t i n gs

The coat ings used shall be based on liquid,

chemically cur ed epoxies. The cur ing agent

may be an amine, amine-adduct , or polyamide;

and t he epoxy may be modified wit h t he coal

r at , phenolic, or ot her modifier s. Mat er ials used

in bot h t he pr imer and finish coat (s) shall be

pr oduct s of one manufact ur er .

B-1.2 Coa t in g Th i ck n e ss

Unless ot her wise specified by t he pur chaser ,

t he minimum dr y film t hickness DFT pr ovided

shall be at least 406 m.

Aft er cur ing but pr ior t o bur ial, t he coat ing

syst em shall be a cont inuous film, fr ee of t hin

spot s and ot her imper fect ions as defined and

shall pass elect r ical inspect ion.

B-1.3 Coa t in g Ap p li ca t i on

B-1.3.1 General

The pipe coat ing shall be applied in accor dance

wit h t he manufact ur er s r ecommendat ions.

Applicat ion by air less spr ay or cent r ifugal

wheel equipment is pr efer r ed.

B-2 P I P E P REP ARATI ON

B-2.1 Cl ea n i n g

Pr ior t o adbr asive blast cleaning, sur faces shall

be inspect ed and, if r equir ed, cleaned accor ding

t o r emove oil, gr ease, or ot her for eign mat t er .

Only appr oved solvent s t hat do not leave a

r esidue shall be used. Pr eheat ing t o r emove oil,

gr ease, mill scale, wat er and ice may be used

pr ovided all pipe is pr eheat ed in a unifor m

manner t o avoid dist or t ing t he pipe.

B-2.2 Ab r a si ve Bla st Cle a n i n g

The ext er ior pipe sur faces shall be abr asive

blast cleaned t o achieve a near whit e met al

sur face. The int er ior pipe sur faces shall be

abr asive blast cleaned t o achieve a whit e met al

sur face. Abr asive blast ing and coat ing shall

only be per for med when t he met al t emper at ur e

is mor e t han 3C above dew point .

B-2.3 Su r fa ce I n sp e ct i on

The ext er ior and int er ior pipe sur faces shall be

inspect ed for sur face imper fect ions, such as

sliver s, scabs, bur r s, weld spat t er , and gouges,

shall be r emoved by gr inding.

B-2.4 I n t e r i or Cle a n i n g

If abr asives or ot her loose for eign mat t er has

ent er ed t he int er ior of t he pipe, t hen clean, dr y

oil fr ee compr essed air shall be used t o r emove

t he loose for eign mat t er in a manner t hat does

not adver sely affect t he cleaned sur face.

Alt er nat ively, vacuum cleaning or ot her

met hods may be used in place of compr essed air .

B-2.5 P ip e En d s for Non -wel d e d F i el d

J oi n t s

When r ubber gasket ed joint s or mechanical

couplings ar e used, t he coat ing shall ext end t o

t he ends of t he pipe. The coat ing t hickness on

t he pipe sur faces t hat r eceive r ubber sealing

gasket s shall not exceed what is r ecommended

by t he manufact ur er of t he coupling. However ,

t he coat ing syst ems dr y film t hickness shall

not be less t han 406 m.

B-2.6 Ap p li ca t ion Te mp e r a t u r e

The t emper at ur e of t he mixed coat ing mat er ial

and of t he pipe at t he t ime of applicat ion shall

not be lower t han 10C. Pr eheat ing of t he

coat ing mat er ial, t he use of in line heat er s t o

heat t he coat ing mat er ial; or heat ing of t he

pipe, fit t ings or specials may be used t o

facilit at e t he applicat ion. Heat ing shall

confor m t o t he r ecommendat ions of t he coat ing

manufact ur er .

B-2.7 Ap p li ca t ion of Ep oxy Coa t i n g

Syst e m

If mor e t han one coat is applied, t he second coat

shall be applied wit hin t he t ime limit s, sur face

condit ions, and t emper at ur e r ecommended by

t he manufact ur er , if t he per iod bet ween coat s is

exceeded, t hen a r epair pr ocedur e shall be

obt ained fr om t he coat ing manufact ur er and it s

r ecommendat ions followed.

B-3 CURE

Aft er applicat ion, t he coat ing syst em shall be

t est ed for cur e.

I S 3589 : 2001

14

B-4 ELECTRI CAL I NSP ECTI ON F OR

CONTI NUI TY

Aft er cur ing, but pr ior t o inst allat ion, t he

coat ing syst em applied t o t he pipe shall be

t est ed for holidays accor ding t o t he pr ocedur es

and using t he volt age set t ings. Any holidays

indicat ed by t he det ect or shall be mar ked wit h

chalk or felt -t ip mar ker t o ident ify t he ar ea t o

be r epair ed.

B-5 COATI NG REP AI R

Accessible ar eas of pipe r equir ing coat ing

r epair s shall be cleaned t o r emove debr is and

damaged coat ing using sur face gr inder s or

ot her means accept able t o t he pur chaser . The

adjacent coat ing shall be feat her ed by sanding,

gr inding, or ot her met hods appr oved by t he

pur chaser . Accumulat ed debr is shall be

r emoved by vacuum, blowing, or wiping wit h

clean r ags.

Ar eas not accessible by coat ing r epair , such as

int er ior sur faces of small diamet er pipe, shall

be r epr ocessed and r ecoat ed. Repair s shall be

elect r ically inspect ed using a holiday det ect or .

The coat ed pipe shipped fr om t he plant shall be

holiday fr ee.

B-6 WELDED F I ELD J OI NTS

B-6.1 P r e p a r a t i on

The weld joint shall be cleaned so as t o be fr ee

fr om mud, oil, gr ease, welding flux, weld

spat t er , and ot her for eign cont aminant s. The

cleaned met al sur faces of t he weld joint shall

t hen be abr asive blast ed, vacuum blast ed, or

abr aded using r ot ar y abr ading pads. The

adjacent liquid epoxy coat ing shall be feat her ed

by adbr ading t he coat ing sur face for a dist ance

of 25 mm.

B-6.2 Ele ct r i ca l I n sp e ct i on

Aft er cur ing, t he coat ing syst em applied t o t he

welded joint s shall be holiday t est ed. Any

holidays indicat ed by t he det ect or shall be

mar ked wit h chalk or felt -t ip mar ker t o ident ify

t he ar ea for r epair .

B-6.3 Be e d i n g a n d Tr e n ch Ba ck fi ll

Wher e t he t r ench t r aver ses r ocky gr ound

cont aining har d object s t hat could penet r at e

t he pr ot ect ive coat ing, a layer of scr eened

ear t h, sand, or r ounded r iver r un gr avel not

less t han 150 mm t hick wit h a maximum

par t icle size of 20 mm shall be placed in t he

bot t om of t he t r ench pr ior t o inst allat ion of t he

coat ed ar t icle.

ANNEX C

( Foreword and Clause 16.1 )

FUSI ON-BONDED EP OXY COATI NG F OR THE I NTERI OR AND

EXTERI OR OF STEEL P I P ELI NES

C-1 MATERI AL

The epoxy powder shall consist of a one-

component , fusion bonded mat er ial consist ing

of epoxy r esin, cur ing agent s, cat alyst s, filler s,

colour ant s, flow cont r ol agent s, and ult r aviolet

light r esist ant agent s t hat when applied t o t he

pr eheat ed subst r at e, will unifor mly coalesce

and cur e t o pr oduce a homogeneous film t hat

complies wit h t he r equir ement s of t his

st andar d.

Applicat ion capabilit y, when applied by

elect r ost at ic spr ay, fluidized bed, or air spr ay t o

t he pr eheat ed ar t icle and subsequent ly cur ed,

t he epoxy powder shall pr oduce a unifor m

pr ot ect ive coat ing.

C-2 P I P E COATI NG AP P LI CATI ON

C-2.1 Ge n e r a l

When bot h an int er nal and an ext er nal coat ing

ar e t o be applied, it is pr efer able t o pr eheat t he

pipe t o t he specified t emper at ur e and apply t he

int er nal coat ing fir st , immediat ely followed by

t he ext er nal coat ing, since elevat ed

t emper at ur es ar e r equir ed dur ing pr ocessing,

fusion bonded epoxy coat ing must be applied

pr ior t o t he applicat ion of ot her coat ings or

linings unless t hose coat ings and linings ar e

r esist ant t o t he pr ocessing heat .

C-2.2 Su r fa ce Con d i t i on

Sur faces t o be coat ed shall be fr ee fr om mud,

mill lacquer , wax, coal t ar , asphalt , oil, gr ease,

chlor ides, or any ot her delet er ious mat er ial.

Pr ior t o blast cleaning, sur faces shall be

inspect ed and, if r equir ed, pr ecleaned, t o

r emove oil, gr ease, and loosely adher ing

deposit s. Heat ing t o r emove oil, gr ease, mill

scale, wat er , and ice may be used pr ovided t he

pipe sect ion, is pr eheat ed in a unifor m manner

t o avoid dist or t ion.

C-2.3 Bla s t Clea n i n g

The pipe sur faces t o be coat ed shall be blast

cleaned t o achieve a near whit e sur face.

C-2.4 Su r fa ce I n sp e ct i on

The cleaned ext er ior and int er ior pipe sur faces

shall be inspect ed for adequat e sur face

I S 3589 : 2001

15

pr epar at ion. Sur face imper fect ions such as

sliver s, scabs, bur r s, weld spat t er , and gouges

shall be r emoved by hand filing or gr inding t o

pr event holidays in t he applied coat ing.

C-2.5 I n t e r i or Clea n i n g

If abr asives or ot her loose for eign mat t er have

ent er ed t he int er ior of t he pipe, t hen clean, dr y,

oil-fr ee compr essed air shall be used t o r emove

t he loose for eign mat t er in a manner t hat does

not affect t he sur face of t he pipe t hat is t o be

coat ed. Vacuum cleaning or ot her met hods may

be used in place of compr essed air cleaning.

C-2.6 P r eh ea t i n g

Pr eheat t emper at ur e should be in accor dance

wit h t he coat ing manufact ur er s

r ecommendat ions but shall not exceed 250C.

C-2.7 P i p e En d s

Coat ing shall be held back in fr om t he ends of

pipe sect ions t o be joined by field welding. This

r equir ement applies t o bot h t he int er ior and

ext er ior sur faces of t he pipe. When r ubber

gasket ed joint s or mechanical couplings ar e

used, t he coat ing shall ext end t o t he ends of t he

pipe unless ot her wise specified by t he

pur chaser .

C-2.8 Th i ck n e ss

The coat ing powder shall be applied t o t he

pr eheat ed pipe at a unifor m cur ed-film

t hickness of not less t han 300 micr ons on t he

ext er ior and not less t han 375 micr ons on t he

int er ior .

C-2.9 Cooli n g

Aft er t he coat ing has cur ed in accor dance wit h

t he t ime/t emper at ur e r equir ement s of t he

coat ing manufact ur er , t he coat ing may be

cooled wit h air or wat er spr ay t o a t emper at ur e

below 90C t o facilit at e handling for inspect ion

and r epair .

C-2.10 I mp e r fe ct i on s

On complet ion of t he coat ing oper at ion, t he

coat ing shall be visually inspect ed for blist er s,

bubbles, voids, or ot her discont inuit ies. The

coat ings shall also be elect r ically inspect ed for

holidays. Inspect ion and r epair may commence

aft er t he pipe has cooled t o 90C or below.

C-3 COATI NG REP AI R

C-3.1 Mi n or De fect s

Coat ing r equir ing r epair due t o scar s, sliver s,

coat ing imper fect ions and ot her small defect s

shall be r epair ed using r epair mat er ials fr om

t he same manufact ur er as t he fusion bonded

epoxy or any ot her compat ible mat er ial

appr oved by t he pur chaser and t he applicat or .

C-3.2 Ma jor De fe ct s

Pipe sect ions wit h coat ing defect s, such as

par t icle coat ing, unbounded coat ing, or

inadequat e film t hickness, shall be r epr ocessed

st ar t ing wit h sur face pr epar at ion pr ocedur es.

C-3.3 F ie l d Wel d e d J oi n t s

The weld ar ea shall be heat ed t o a t emper at ur e

not t o exceed 260C using a cir cumfer ent ial

induct ion heat ing coil of sufficient size, widt h,

and power t o pr ovide t he r equir ed heat in t he

weld zone and 55 mm back under t he fusion

bonded pipe coat ing.

Immediat ely aft er heat ing, t he weld shall be

coat ed wit h a powder coat ing. The welded joint

coat ing shall over lap t he or iginal pipe coat ing

by no less t han 25 mm.

The ext er ior of field welded joint s may be

coat ed wit h hot applied t ape, cold applied t ape,

liquid epoxy, or heat shr inkable coat ings.

I S 3589 : 2001

16

ANNEX D

( Foreword and Clause 16.1 )

TAP E COATI NG SYSTEM

D-1 GENERAL

For cor r osion pr ot ect ion of met al pipes oft en

sever al out er wr aps, hot or cold applied ar e

used. For ver y cor r osive soil condit ion cold

applied t apes ar e used on st eel pipes at sit e. In

t he fact or y nor mally hot applied t ape coat ing

ar e used. Unless t he t r anspor t at ion is made

ver y car efully t hese fact or y applied t ape

coat ing may get damaged.

For nor mal const r uct ion consider at ions cold

applied t apes ar e applied as a t hr ee layer

syst em consist ing:

a) Pr imer ,

b) Cor r osion pr event ive t ape (inner layer ),

and

c) Mechanical pr ot ect ive t ape (out er layer ).

D-2 OUTER LAYER TAP E

The out er layer shall consist of polyolefin

backing wit h a laminat ed elast omer t ype

adhesive. The out er layer t ape shall be

compat ible wit h t he inner layer t ape. The

funct ion of t he out er layer t ape shall be

pr imar ily t o pr ovide mechanical and out door

weat her ing pr ot ect ion t o t he t ape syst em and

secondar ily, t o cont r ibut e t o t he over all

cor r osion pr ot ect ion pr oper t ies of t he syst em.

D-3 P RI MER

The pr imer shall be applied t o t he pr oper ly

pr epar ed pipe sur face befor e applicat ion of t he

inner layer t ape. The fusion bonding medium

bet ween t he pipe sur face and inner layer t ape.

D-4 I NNER LAYER TAP E

The inner layer t ape shall consist of a polyolefin

backing wit h a lament ed adhesive. The inner

layer t ape shall be applied aft er t he pr imer and

befor e t he out er layer t ape.

The pr imar y pur pose of t he inner layer t ape is

t o pr ovide t he cor r osion pr ot ect ion coat ing.

D-5 TOTAL COATI NG SYSTEM

The t ot al t hickness of t he syst em made up of

inner t ape and out er t ape may var y depending

on pipe diamet er oper at ing condit ion and

inst allat ion condit ions. In no case shall t he

t hickness be less t han t hose given below:

The t apes can be applied dir ect ly ont o t he

pr imed pipe sur face by means of mechanical

coat ing/wr apping equipment manually or by

machine. The inner layer t ape shall be specially

applied wit h over lap widt h and applicat ion

t ensions as r ecommended by t he

manufact ur er s. The minimum over lap shall be

not less t han 25 mm when a new r oll of t ape is

st ar t ed and t he ends shall be over lapped at

least 150 mm measur ed cir cumfer ent ially. The

over lap shall be smoot h and shall be locat ed t o

ensur e t he cont inuit y of t he inner layer coat ing.

The out er layer t ape shall be applied over t he

inner layer t ape using t he same t echnique.

The over lap of t he out er layer shall not coincide

wit h t he over lap of t he inner layer t ape. The

minimum over lap of t he applied t ape and

minimum end t ap of t wo r olls shall be same as

specified for inner t ape.

Bu r ea u of I n d i a n St a n d a r d s

BIS is a st at ut or y inst it ut ion est ablished under t he Bureau of Indian S tandards Act, 1986 t o pr omot e

har monious development of t he act ivit ies of st andar dizat ion, mar king and qualit y cer t ificat ion of goods and

at t ending t o connect ed mat t er s in t he count r y.

Cop yr i gh t

BIS has t he copyr ight of all it s publicat ions. No par t of t hese publicat ions may be r epr oduced in any for m

wit hout t he pr ior per mission in wr it ing of BIS. This does not pr eclude t he fr ee use, in t he cour se of

implement ing t he st andar d, of necessar y det ails, such as symbols and sizes, t ype or gr ade designat ions.

Enquir ies r elat ing t o copyr ight be addr essed t o t he Dir ect or (Publicat ions), BIS.

Revi ew of I n d i a n St a n d a r d s

Amendment s ar e issued t o st andar ds as t he need ar ises on t he basis of comment s. St andar ds ar e also

r eviewed per iodically; a st andar d along wit h amendment s is r eaffir med when such r eview indicat es t hat no

changes ar e needed; if t he r eview indicat es t hat changes ar e needed, it is t aken up for r evision. User s of

Indian St andar ds should ascer t ain t hat t hey ar e in possession of t he lat est amendment s or edit ion by

r efer r ing t o t he lat est issue of BIS Cat alogue and St andar ds : Mont hly Addit ions.

This Indian St andar d has been developed fr om Doc : No. MTD 19 (4194)

Amen d men t s I ssu ed Si n ce P u b li ca t i on

Amen d No. Da t e of I ss u e

Amd. No. 1 May 2002

Amd. No. 2 Oct ober 2003

BUREAU OF I NDI AN STANDARDS

Headquar t er s:

Manak Bhavan, 9 Bahadur Shah Zafar Mar g, New Delhi 110002.

Telephones: 323 01 31, 323 33 75, 323 94 02

Telegr ams: Manaksanst ha

(Common t o all offices)

Regional Offices: Telephone

Cent r al : Manak Bhavan, 9 Bahadur Shah Zafar Mar g

NEW DELHI 110002

323 76 17

323 38 41

East er n : 1/14 C. I. T. Scheme VII M, V. I. P. Road, Kankur gachi

KOLKATA 700054

337 84 99, 337 85 61

337 86 26, 337 91 20

Nor t her n : SCO 335-336, Sect or 34-A, CHANDIGARH 160022 60 38 43

60 20 25

Sout her n : C. I. T. Campus, IV Cr oss Road, CHENNAI 600113 235 02 16, 235 04 42

235 15 19, 235 23 15

West er n : Manakalaya, E9 MIDC, Mar ol, Andher i (East )

MUMBAI 400093

832 92 95, 832 78 58

832 78 91, 832 78 92

Br anches : AH ME DABAD. BAN GAL ORE . BH OP AL . BH U BAN E S H WAR. COI MBAT ORE .

F ARI DABAD. GH AZI ABAD. GU WAH AT I . H YDE RABAD. J AI P U R. KAN P U R.

LUCKNOW. NAGPUR. NALAGARH. PATNA. PUNE. RAJ KOT. THIRUVANANTHAPURAM.

VISHAKHAPATNAM.

'

'

'

'

'

AMENDMENT NO. 4 JUNE 2010

TO

IS 3589 : 2001 STEEL PIPES FOR WATER AND SEWAGE

(168.3 TO 2 540 mm OUTSIDE DIAMETER)

SPECIFICATION

( Third Revision )

(Page 3, Table 2, read with Amendment No. 1) Add the following

Note below the table.

NOTE For each reduction by 0.01 percent Carbon below the specified maximum, an increase of

0.05 percent above the maximum of manganese is permissible up to a maximum of 1.50 for grades

Fe410 and 450.

(MTD 19)

Reprography Unit, BIS, New Delhi, India

You might also like

- Review QuestionsDocument31 pagesReview QuestionsGerby PaaNo ratings yet

- Defects in Concrete Structures - Types Causes, Prevention PDFDocument11 pagesDefects in Concrete Structures - Types Causes, Prevention PDFvenkateswara rao Pothina100% (1)

- Back To Original Page: Quality System Requirements 9001 9000Document9 pagesBack To Original Page: Quality System Requirements 9001 9000Shreenivas ThakurNo ratings yet

- Is 7098 1 1988Document24 pagesIs 7098 1 1988Hriday AgarwalNo ratings yet

- Is Iec 41 1991Document214 pagesIs Iec 41 1991OmerfAta100% (1)

- Is 3589Document21 pagesIs 3589ajit singhNo ratings yet

- Cement & AdmixturesDocument64 pagesCement & AdmixturesVignesh RamalingamNo ratings yet

- Cellular Concrete Specifications Latest On 4-13Document3 pagesCellular Concrete Specifications Latest On 4-13diracmoutinhoNo ratings yet

- Mumbai Metro MapDocument1 pageMumbai Metro MapPareshNo ratings yet

- Topic 4 - Design of Steel Structures BS en 1993Document14 pagesTopic 4 - Design of Steel Structures BS en 1993Misgun SamuelNo ratings yet

- BIA - Technical Notes On Brick ConstructionDocument1,007 pagesBIA - Technical Notes On Brick ConstructionAdam Greenlaw100% (2)

- Charles E. Smith - Feasibility of Thermite Sparking With Impact of Rusted Steel Onto Aluminum Coated SteelDocument66 pagesCharles E. Smith - Feasibility of Thermite Sparking With Impact of Rusted Steel Onto Aluminum Coated SteelAlarmakNo ratings yet

- Predicting Ultimate Loads For Wind Turbine DesignDocument12 pagesPredicting Ultimate Loads For Wind Turbine Designcarra80No ratings yet

- Weld Imperfection Examination StandardDocument4 pagesWeld Imperfection Examination StandardMohd Akmal ShafieNo ratings yet

- KT Penstock PDFDocument24 pagesKT Penstock PDFKmi GutierrezNo ratings yet

- 5822 2004 PDFDocument19 pages5822 2004 PDFSuresh CNo ratings yet

- Mesauring Hydro TurbinesDocument8 pagesMesauring Hydro TurbinesJenny Cecilia Ureña ZuriNo ratings yet

- Load Calculation Spreadsheets: Quick Answers Without Relying On Rules of ThumbDocument7 pagesLoad Calculation Spreadsheets: Quick Answers Without Relying On Rules of ThumbMhil ParasNo ratings yet

- Parabolic Trough Collector PTCDocument2 pagesParabolic Trough Collector PTCCarloyos Hoyos100% (1)

- Is: 1239part 2 Mild Dteel Tube PipeDocument36 pagesIs: 1239part 2 Mild Dteel Tube PipeRathnakar NaikNo ratings yet

- Bs 7371 6 1998Document10 pagesBs 7371 6 1998sdd1965No ratings yet

- Asq What Is Statistical Process ControlDocument3 pagesAsq What Is Statistical Process ControlCloud RedfieldNo ratings yet

- Is 3589 - 2001Document21 pagesIs 3589 - 2001Aara MeghNo ratings yet

- E9d0' R""o .: Indian StandardDocument26 pagesE9d0' R""o .: Indian Standards_samirkumar1008100% (1)

- Seismic Design Code OverviewDocument125 pagesSeismic Design Code OverviewMarian Mihai VitaNo ratings yet

- Aa0850150-Residual Stress Measurement of GeneratorDocument4 pagesAa0850150-Residual Stress Measurement of GeneratorAnonymous gr5Pr9AV100% (2)

- Rdso Spec M C PCN 100 2006Document27 pagesRdso Spec M C PCN 100 2006Antony George Sahayaraj100% (1)

- Trashracks and Raking Equipment, Water Power PDFDocument16 pagesTrashracks and Raking Equipment, Water Power PDFJhony MedranoNo ratings yet

- Is 9523Document78 pagesIs 9523Anonymous XBq5J840% (1)

- IS 3589-2001 MS PipesDocument21 pagesIS 3589-2001 MS Pipesiampatanjali100% (5)

- IS 3589 - 2003-10 - With Amd 1 To 4Document25 pagesIS 3589 - 2003-10 - With Amd 1 To 4hhr2412No ratings yet

- Section 23 21 00 - Hydronic Valves and SundriesDocument22 pagesSection 23 21 00 - Hydronic Valves and Sundriesvaradarajck893No ratings yet

- Automatic Control ValvesDocument36 pagesAutomatic Control Valveshoxoxi1234No ratings yet

- Draft IS 4721Document10 pagesDraft IS 4721rajfabNo ratings yet

- Magnesium Ion BatteriesDocument6 pagesMagnesium Ion Batteriespkamboj4mbaprojects9345No ratings yet

- FEASIBILITY REPORTSDocument22 pagesFEASIBILITY REPORTSKrishna VishwakarmaNo ratings yet

- EJSE Special Issue: Loading Regulations and Standards in AustraliaDocument5 pagesEJSE Special Issue: Loading Regulations and Standards in Australiaabdul kareeNo ratings yet

- Is 4721Document7 pagesIs 4721dak2anshulNo ratings yet

- 04 100TR Vapour Compression System LNG Vapour Absorption System KochiDocument54 pages04 100TR Vapour Compression System LNG Vapour Absorption System Kochiraviraj gaikwadNo ratings yet

- Erw Pipe Sizes PDFDocument2 pagesErw Pipe Sizes PDFEliuNo ratings yet

- Is - Iso - 10816 (2) - 2001Document14 pagesIs - Iso - 10816 (2) - 2001sangitaghaisasNo ratings yet

- IS 2062 Rev 2011Document10 pagesIS 2062 Rev 2011Ganesh LohakareNo ratings yet

- HandbookDocument29 pagesHandbookShubham Mishra100% (1)

- BS EN 10224-2002 Non-Alloy Steel Tubes and Fittings For The Conveyance of Water and Other Aqueous Liquids - Technical Delivery ConditionsDocument62 pagesBS EN 10224-2002 Non-Alloy Steel Tubes and Fittings For The Conveyance of Water and Other Aqueous Liquids - Technical Delivery ConditionsKok WaiNo ratings yet

- Chinese Standards For ReferenceDocument3 pagesChinese Standards For ReferencenavinzhereNo ratings yet

- EN-62561-1 2011 AA 2012 Vot1eDocument6 pagesEN-62561-1 2011 AA 2012 Vot1epemanr1914No ratings yet

- Is 4759 1996 PDFDocument12 pagesIs 4759 1996 PDFSandeep SundriyalNo ratings yet

- Iso16077 2013Document40 pagesIso16077 2013ittsaNo ratings yet

- Protection Ground Electrodes With Injection of Bentonite Emulsion Under PressureDocument5 pagesProtection Ground Electrodes With Injection of Bentonite Emulsion Under PressureAbdulyunus AmirNo ratings yet

- 9a02306-Basic Electrical EngineeringDocument5 pages9a02306-Basic Electrical EngineeringsivabharathamurthyNo ratings yet

- Is 1730Document11 pagesIs 1730maheshkbandari0% (1)

- Is.4544.2000 0Document17 pagesIs.4544.2000 0Davorin IvićNo ratings yet

- Hydro PowerDocument12 pagesHydro PowerDaisy100% (2)

- Seamless Steel Pipes-2 PDFDocument60 pagesSeamless Steel Pipes-2 PDFNaveen ReddyNo ratings yet

- Basic Valve & SizingDocument8 pagesBasic Valve & SizingRio Ananda PutraNo ratings yet

- Solar Receiver Steam GeneratorDocument2 pagesSolar Receiver Steam GeneratorMohamed MeeranNo ratings yet

- Thermal Power Plant PresentationDocument36 pagesThermal Power Plant PresentationkkkkkkkkkkkkkkhAsFAIKSGEF0% (1)

- SR 1911-1998 Steel Bridges For Railway (En)Document184 pagesSR 1911-1998 Steel Bridges For Railway (En)Vlad AmarieNo ratings yet

- We 0303Document140 pagesWe 0303korie100% (1)

- WWW$W Qfi MGR : (168.3 1?! 2540 MM N I HIRE! 5%) - MDocument23 pagesWWW$W Qfi MGR : (168.3 1?! 2540 MM N I HIRE! 5%) - MocsspectroNo ratings yet

- Is 3589Document22 pagesIs 3589Otavio123100% (1)

- Specification For Steel Tubes, Tubulars and Other Steel FittingsDocument34 pagesSpecification For Steel Tubes, Tubulars and Other Steel FittingsDebesh PradhanNo ratings yet

- Astm B302 (1998)Document5 pagesAstm B302 (1998)Deepak JNo ratings yet

- Is 4270Document12 pagesIs 4270Narendra SinhaNo ratings yet

- Mildsteeltubes, Tubctlars Andother Wroughtsteel Fittings-SpecificationDocument17 pagesMildsteeltubes, Tubctlars Andother Wroughtsteel Fittings-Specificationnarasimhareddy415No ratings yet

- Wrought Carbon Steel Sleeve-Type Pipe Couplings: Standard Specification ForDocument5 pagesWrought Carbon Steel Sleeve-Type Pipe Couplings: Standard Specification ForDeen ew100% (1)

- HTL With Money ManagerDocument67 pagesHTL With Money Managerkishor.kokateNo ratings yet

- HTL With Money ManagerDocument67 pagesHTL With Money Managerkishor.kokateNo ratings yet

- HTL With Money ManagerDocument67 pagesHTL With Money Managerkishor.kokateNo ratings yet