Professional Documents

Culture Documents

All About TPI Inspection

Uploaded by

Aneesh JoseOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

All About TPI Inspection

Uploaded by

Aneesh JoseCopyright:

Available Formats

Table of Contents 1. 2. 3. 4. 5. 6. 7. 8. 9.

Purpose General Availability of Forms and Procedures Basic Inspection Duties Other Inspection Duties Inspection Procedure - General Welding Non Destructive Testing Hydrotest

10. Coating 11. Final Inspection 12. Static Process Equipment 13. Rotating Process Equipment. 14. Piping Fabrication and Valves 15. Structural Steel. 16. Electrical Equipment 17. Instruments 18. References 1.Purpose The purpose of this guide is to inform the Inspector regarding the extent of his reporting in relation to the assigned inspection level for purchase orders and requisitions in general, and assist in the performed inspections and tests by giving guidelines and specific information per type of equipment and materials. 2. General Company requisitions for materials and equipment are prepared by the engineering departments. 2.1 Based on the requisition, the purchase order and the available Vendor information, the Manager Inspection assigns the inspection level, and prepares the inspection schedule for the project. (See Reference 18.1) 2.2 This inspection schedule reflects all purchase orders for the project and its assigned inspection levels. The inspection level shall be one of the following: R - Resident Inspector IPC - Close prgressive inspection IP - Progressive inspection F - Final inspection N - No inspection 2.3 When necessary, the inspection level can be modified. This change can be initiated by the Inspector, the Manager Inspection or the Project Manager.

2.4 For all inspections the procedure for inspection activities shall be followed. See Reference 18.1. 2.5 The inspection level gives details regarding the scope of inspection. The following Table (2.6) is a guideline for the scope of inspection and the different reports in relation to the assigned inspection level. Regarding the levels and the timing of inspection the following should be considered: R - Resident Inspection. All intermediate inspection steps shall be monitored closely for the duration of residence. Residence Inspection is implemented for the whole or only part of the manufacturing period, when required contractually or when in the opinion of the Manager Inspection:

- the workload in one location warrants it; or when it is necessary to ensure specified quality requirements are met.

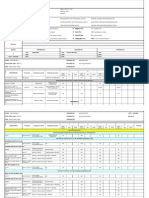

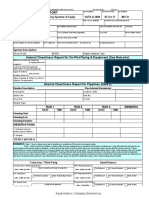

IPC - Close progressive inspection. Selected intermediate inspection steps shall be followed according to the inspection and test plan. IP - Progressive inspection. Limited intermediate inspections shall be witnessed according to the inspection and test plan. Other inspection points will be monitored. F - Final inspection. Only final inspection shall be carried out. N - No inspections carried out. 2.6 Inspection Level and Required Reports Required reports Inspection/Expediting Assignment Pre-inspection meeting Progressive inspection Final inspection Non Conformance Report Quality Control Memorandum Inspection Release Note Form No. 25013 25009 25009 25009 25010 25012 25011 R * * * * * * * IPC * * * * * * * IP * * * * * * * F * * * * *

2.6.1 2.6.2 2.6.3 2.6.4 2.6.5 2.6.6 2.6.7

Notes:

1. 2. 3. Inspection/Expediting Assignment is only used when an outside agency is employed. A common form 25009 is used to report the various types of inspection visits to the Vendor, the section headings in the text being adjusted accordingly. Each type of form used shall be numbered 001, 002 etc. per purchase order, the number being followed by the inspectors initials.

3. Availability of Forms and Procedures All existing reports/forms and applicable procedures can be found in Reference 18.1. Additional copies can be made available. 4. Basic Inspection Duties Normal Q.C. (inspection) duties for projects are outlined in par.6, but will also include the following: 4.1 Check the Vendor's understanding of the Purchase Order requirements concerning materials, fabrication testing and inspection by the means of a pre-inspection meeting (See Reference 18.1)

4.2 Check if Vendor furnished documents according to requisition and procedures have been approved by Company Home Office. 4.3 Check, witness or monitor fabrication and testing according the inspection and test plan, in particular respecting holdpoints. 4.4 Check all relevant documentation such as certificates, test reports etc. 4.5 Check manufacturing data books. 4.6 In case of deviations contact the procurement and or engineering department(s) for formal decisions. 5. Other Inspection Duties Inspectors will carry out surveys on Vendors' shops when required in order to determine Vendors' capabilities, experience and acceptability for work on Company projects, or re-surveys of Vendors shops if a considerable time has elapsed since the last experience with a particular shop. This is one aspect of the overall assessment of Vendor capabilities and performance conducted by several Company departments. See Reference 18.2. Inspectors will also continuously advise Company's Home Office on shop-loading developments in Vendors plants, trends in quality of workmanship, performance, etc. to assist buyers in selection of Vendors for new work. 6. Inspection Procedure - General This section covers basic activities for inspection of all equipment, parts of equipment or parts of package units covered by Company purchase orders. Additional information regarding specific inspections can be found in the following sections, where possible requirements inspections and test are split up per type of equipment and materials. It must be remembered that it is the Vendor himself who is in the first place responsible for the quality of his work using his own quality system. The inspector works through the Vendor system and would only assume a more proactive role in case of necessity, and in agreement with the Manager Inspection. Inspectors visits to sub-Vendors shall only normally be carried out accompanied by a representative of the Vendor. The Inspector shall not give direct instructions to the sub-Vendor. Each inspector has a personal rubber stamp with his name and boxes marked witnessed and checked. He shall use this on each quality record, ticking in one or other box, signing and dating it. 6.1 Acceptance Criteria/Governing Documents for Inspection 6.1.1 The basis of acceptance or rejection is defined by the purchase order requirements including the purchase order itself, the requisition, in combination with referenced codes, standards, specifications and drawings. 6.1.2 In case of contradiction in or incompleteness of the requirements, the inspector shall contact the Manager Inspection. 6.1.3 Vendors' shop drawings are only valid for details and dimensions not included in Company documents. 6.1.4 In the event of contradiction between Company and Vendor documents, Company documents govern unless specified by Company in writing. 6.1.5 Authority requirements shall prevail over Company general and project specifications, unless Company or project specifications are more stringent than the authority requirements.

6.2 Pre-Inspection Meeting (PIM) with Vendor 6.2.1 When applicable a complete review shall be made of the Purchase Order and its attachments, in order to confirm Vendor's proper understanding of all design, fabrication, inspection, and document requirements. Every effort shall be made to eliminate questions in the earliest possible stage in the execution of the purchase order. A PIM shall be held in accordance with reference 18.1, and reported on form 25009. 6.3 Material Delivered to Vendor's Shop 6.3.1 For major suborders the Inspector shall check in the first place that they have been placed with previously Company approved sub vendors. He shall then check that relevant requirements expressed in the Purchase Order have been mentioned on the sub-order. These could include:

Company Purchase Order number and item number material specification and any special test requirements certification requirements critical minimum dimension excess materials for tests inclusion of clause concerning the Contractor's and Client's inspection rights marking requirements

The Inspector will receive the relevant unpriced copies of suborders together with the Manager Inspection's recommendation for inspection coverage at source. 6.3.2 The type of materials shall be checked if required by PMI, marking of materials shall be identified against certificates as early as possible after arrival of materials at the Vendor's works. 6.3.2 The type of materials shall be checked if required by PMI, marking of materials shall be identified against certificates as early as possible after arrival of materials at the Vendor's works. 6.3.3 The dimensions and appearance shall be checked, paying particular attention to:

critical minimum dimensions radii of bending, forging and pressing on manufactured parts fabrication and handling damage to surfaces and edges

6.3.4 The material certificates shall be legible and suitable for xerox copying and shall specify the test results in accordance with the specified material standard. Normal expected statements are the following:

name of manufacturer and factory symbol. (as on material) purchase Order number and date of revision manufacturer's order number certificate registration number and date of issue material specification dimensions quantity and/or weight in kg

surface examination statement charge number, batch number or heat-lot number chemical composition from test results mechanical properties from test results when applicable, NDT methods and results when applicable, heat treatment procedure, furnace charge number and heat treatment records signatories and function supplementary or additional requirements as specified in the material specification, project specification purchase order as applicable.

Certificates checked and accepted by the Inspector shall be marked with his personal stamp and noted "checked" together with his signature and the date. Unless otherwise instructed the inspector shall only mark his stamp on the first page of the certificate. 6.4 Fabrication Procedures and Qualifications 6.4.1 The Inspector shall verify that all necessary approvals from Company's Home Office and Authorities have been obtained on Vendor furnished procedures and other documents. This can include the following:

vendor drawings/data sheets welding procedures and qualifications stress relief and other heat treatment procedures; all forming operations, either hot or cold, on materials other than plain carbon steel tube rolling procedures and rolling sequences non-destructive testing procedures.

6.4.2 The Inspector shall ensure that welders are qualified to the used welding procedures and qualifications. 6.5 Intermediate Inspections Basically all intermediate inspections either from Vendor, Company or Independent Authority are laid down in the inspection plan. The inspector shall incorporate the assigned inspection level when marking up the hold points in the inspection plan. The advised legend for marking up the inspection plan is as follows: R W H Review Witnesses Holdpoint

This legend can also be used when completing the inspection report. Examples of hold points in the manufacturing stage are the following: 1. 2. 3. 4. 5. 6. receipt material inspection; location and dimensions of cut-outs before cutting; fit-up of nozzles or other connections; full dimensional and visual inspection before heat-treatment and/or pressure testing, including acceptance of NDE; witness insert of bundle for heat-exchangers; pressure testing; leak testing; PMI on final fabricated equipment and any other special NDE method;

7. 8. 9.

shotblasting/coating/lining; final inspection; manufacturing data book including shipping provisions or any other transport requirements; witness transport and/or reloading of equipment.

Regarding possible holdpoints the next chapters (6.6 thru 6.16) give keywords as a reference for use during the inspections. For welding see Chapter 7. 6.6 Receipt Inspection

suborder special tests certification minimum wall thickness marking storage

6.7 Location and Dimensions on Cut-outs

approved drawings reference lines shell course marking hand or machine cutting restamping material on cut-out for tests weld configuration template available start points of cutting.

6.8 Fit-up of Nozzles/Shell Courses

applied welding procedure proper grinding and cleaning NDE for surface defects NDE for weld edge (U.S.) high-low distortion prevented orientation, elevation and stand-out material for fit-up cladding.

6.9 Dimensional and Visual Inspection

approved drawings tolerances level indicators; fixed tolerances base plate template on jobsite required in advance

proper measuring equipment PWHT to be carried out field connections flange facings and protection internals to be installed sharp edges on nozzles and clips clip dimensions trial fit up of vessels shipped in two or more parts for site welding trial fit up of attachments (ladders; platforms etc.).

6.10 Insert of Bundle

dimensions of shell (straightness and ovality) dimensions of bundle proper tackwelding number of baffle plates dummy available grease allowed internal grinding internal cleaning

6.11 Heat Treatment

procedure available type of oven, fuel type, avoid direct flames No. of thermocouple and temperature registration calibration of used equipment distortion prevented method of support, expansion is approximately CS 1,1 mm/m/100C SS 1,55 mm/m/100C sign of chart at start of cycle heating up/cooling down rates open oven at which temperature

6.12 Pressure Testing

Procedure available: test medium, pressure and duration flange facings check used gaskets type bolt tensioning equipment required proper blinding off

correct bolts/nuts in relation to flanges original bolts/nuts available number of pressure gauges and correct ranges and calibration correct venting block valve environment temperature temperature of test medium use of pressure recorder method of support; position for testing air test reinforcements correct emptying (avoid vacuum!) NDE after pressure testing.

6.13 Leak Testing

procedure available equipment and calibration work method false indications medium acceptance criteria.

6.14 Positive Material Identification (PMI)

procedure available Company standard specification equipment available detection ranges and identified elements incoming materials and final product welds to be checked/electrodes cladding restoring.

6.15 Shotblasting/Coating/Lining

testing methods for profile coating manufacturer data sheets environmental conditions (temperature, dewpoint coating thickness (wet, dry) recoating time (curing of zinc silicates) corners etc. not reached with shotblasting sparktesting of lining (general rule = 9 Volts/micron).

6.16 Final Inspection

manufacturing Data Book, early list of contents check Vendor furnished documents list and/or job specification for total contents packing/marking/shipping instructions internal cleanliness anti-corrosion measures (silica gel, nitrogen purge etc.) flange protection marking of "North" line or arrow marking of "Centre of Gravity" (COG) method of lifting (slings or chains etc.) method of transport inform Company traffic department and/or jobsite.

7. Welding When welding is involved on materials or equipment the following topics have to be taken into account:

code or non-code items specifications with additional requirements to code availability of WPS and PQR or requalify? welder and welding operator qualifications materials weldability thickness post weld heat treatment and/or soaking welding processes cladding joining unequal materials vendor experience with welding process in or outdoor welding welding consumable handling environmental conditions (temperature; humidity) cutting process pre-heating proposed non-destructive examinations weld configurations fit-up materials distortion prevention dimensional control. REQUIRED WELD TEST PLATES + PWHT + TESTING !!

7.1 Basically the requisition and/or job specifications are the documents where the requirements for welding are laid down. For code items Company will normally require that the Vendor transmits the Welding Procedure Specification (WPS) and the applicable Procedure Qualification Record (PQR).

Note:

WPS PQR - Weld configuration + position + consumable + equipment etc. as proposed for welding. - Record of tests done to prove WPS meets code requirements.

The WPS/PQR will be reviewed by Company Home Office using the same system as for drawings. 7.2 Review Codes F 1 2 3 Final approved Approved without comments Approved with comments (production may start when comments are incorporated) Not approved (resubmit before start production).

7.3 It should be noted that sometimes Vendors do not have the required PQR to cover the proposed WPS and propose to qualify the WPS on a weld coupon which is attached to the longitudinal seam. 7.4 It is always the duty of Inspector to check whether welders are qualified in accordance with approved procedures (validity qualification records).> 7.5 Except when otherwise stated in the job specifications Company Inspectors do not normally witness welding tests. It is the sole responsibility of the Vendors and the applicable authorities. 7.6 It is the duty of the Inspector to ensure that all welding procedures and their qualifications are strictly adhered to by the Vendor. Note changes in geometry, position and welding process or consumable. For example: a Vendor had his WPS/PQR. approved for the welding of circumferential seams using SAW in 1 G position (on rollers), but is in fact welding with SMAW (hand electrode) in the 2 G position (side). The applicable WPS/PQR should be transmitted to the Company home office, and if necessary be requalified in accordance with the required code. In the following chapters some keywords are given per subject related to welding in general. 7.7 Fit-up for Welding

reference lines for dimensional control joint alignment; high/low root gaps shrinkage (= +/- rootgap) fit up material tackwelds in bevel or external (bridge plates) removal of backwelds NDE of tackwelds pre-heating for tackwelds thick materials.

7.8 Distortion Prevention

proper stiffening/supporting by spiders, strongbacks etc.

number of passes symmetrical welding backwelding pre-setting to reach desired dimension after shrinkage large + heavy nozzle on edge of plate large + heavy nozzle in relatively thin shell plate.

7.9 Pre-heating

flame cutting on air hardening materials used method - electric or gas area of pre-heating heating up time minimum and maximum pre-heat temperature minimum interpass temperature cooling method (environment) method of checking temperature.

7.10 Visual Weld Examination

porosity starts/stops old tackwelds unequal a-height incomplete filling overfilling run out length weld spatter cracks weld cap finish weaving (max. 2,5 x d electr.) arc - strikes marks from lifting clamps.

7.11 Joints in Clad Material

approved welding procedure and qualification bonding of clad material sufficient cut away of cladding transition electrode type clad restoring surface finish PMI on electrodes

possible NDE (transition of U/S waves causing misinterpretations).

7.12 Post Weld Heat-Treatment

type of heat-treatment min/max temperature for material according to specification Method of support CS: elongation = 1,1 mm/100C SS: elongation = 1,6 mm/100C visual and dimensional already 100% accepted type of oven max. temperature variation through whole oven type of fuel and availability position of burners calibrated thermocouples and recorder method of attaching thermocouples minimum: 1 x on thickest piece 1 x on thinnest piece 1 x on test plate 1 x extra hand or remote controlled oven oxidation of materials any stiffening required heating up time/holding temperature/cooling down time complete recording chart available ( mind the scales ) re-check critical dimensions after PWHT.

7.13 Welding Consumables

acceptable list applicable (controlas etc.) storage handling procedure quivers required holding ovens special electrodes for project.

8. Non Destructive Testing

separate procedure required acceptance criteria type of ndt possible qualification of operators subcontracted NDT NDT after visual acceptance of welds

minimum "setting time" after last welding before NDT PWHT involved or not any NDT specified after pressure testing are all welds accessible after fabrication up to date NDT lists own qualified film interpreters or rely on Vendors.

9. Hydrotest Regarding the hydrotest, the following topics have to be considered:

hydrotest procedure available/required all NDE completed visual and dimensional acceptable method of support testing liquid temperature testing liquid contamination (chlorides stainless steel) correct gaskets installed (hydrotest gaskets or specified type) bolt tensioning equipment required/applied correct bolting in relation to flanges (DIN flanges with DIN bolting as they are less stiff than ANSI flanges) airpockets prevented correct calibrated pressure gauges and ranges minimum 2 pressure gauges pressure recorder required (calibration) block valve between pump and vessel first pressurise to operating pressure then after setting rise to hydrotest pressure test pressure and minimum holding time pressure difference in two or more compartments during testing note any deformation proper venting after test (vacuum!) drying and cleaning any NDE specified after hydrotest.

10. Coating Regarding coating and lining following topics should be considered. 10.1 General

coating system according to requisition/specification in-house or subcontracted approved manufacturers of paint coating procedure necessary

applicable data sheets available maximum operating temperature of equipment in relation to maximum temperature allowable for paint approved coating system on drawings all NDE/PWHT etc. carried out visual and dimensional accepted corners rounded off.

10.2 Shot-Blasting

type of grit in relation to material or equipment type of grit in relation to required blasting profile method of checking blasting profile cleanliness of blasting (SA 2; 2-1/2; etc.) standard on site. temperature of surface minimum 5 degrees above dewpoint grit recycled or not (mean particle size) flange facings suitably protected method of support.

10.3 Coating Application

correct equipment/nozzle type all dust from shotblasting removed coating consistency coating contamination maximum wet film thickness applied (drips, sags) pre strike difficult areas overspraying time temperature of surface.

10.4 Coating Inspection

calibrated coating thickness equipment uniform application proper illumination check minimum 5 points per square metre drips/sags/holidays intermediate thickness total thickness.

10.5 Lining and Lining Inspection

applicable specification applicable procedure

corner rounded off (min: r = 3 mm) manufacturers data sheets available minimum surface temperature method of application check thickness with calibrated equipment spark testing minimum voltage = 9V per micron when no spec. etc. available repair procedure

11. Final Inspection

nameplate as built drawing available all possible deficiencies cleared flange facings re-check packing/marking/shipping and invoicing instructions for project issued and complied with all drawings final approved all calculations final approved all procedures final approved transport drawings approved transport/lifting marks on equipment spare parts and interchangeability records and/or cards filled in and transmitted to Company Home Office any other outstanding documents according to vendor furnished documents list from requisition traffic department informed expediting department informed site informed.

12. Static Process Equipment 12.1 Pressure Vessels 12.1.1 Specified code to be applied.

12.1.2 Check requisitions for:

applicable code(s) and additional requirements used materials and certification welding procedures and qualifications dimensional tolerances non destructive examinations post weld heat treatment authority inspection pressure testing surface preparation

service conditions

12.1.3 Points of specific importance during fabrication:

skirt-head connections reinforcement plates clips and supports level and indicators etc. weld test plates rounding off nozzles internally insulation rings davits aligning of internals (tray support rings) welds in heads flange facings marking of tangent-line ( in- and outside ) base ring template required? saddle fixed and sliding point positive material identification internal dimensional control " straightness O- thickness measurements.

12.2 Heat Exchangers Shell and tube-exchangers, double pipe exchangers. 12.2.1 Specified code to be applied. 12.2.2 Check requisitions for:

applicable code (s) and additional requirements used materials and certification welding procedures and qualifications dimensional tolerances non-destructive examinations post-weld heat treatment authority inspection pressure testing surface preparation and or lining service conditions

12.2.3 Points of specific importance during fabrication:

tube to tube-sheet connections

reinforcing plates dimensional control of bundle tackwelds and tie-rods check tie-rods for intermediate welds ( if so:NDE ) bundle dummy rounding off nozzles internally ovality of shell jack-bolts pulling of bundle lifting of bundle impingement plates partition plate welding weld test plates drilling of tubesheets dimensions stacked exchangers expanding percentage welding and rolling or rolling and welding internal sealing strips for longitudinal baffle type exchangers flange facings positive material identification.

12.3 Airfin Coolers Airfin coolers with headers of various designs such as plugged with loose covers fully enclosed, welded headers, cast headers with various air control systems etc. 12.3.1 Specified national/international specifications to be applied. 12.3.2 Check requisitions for:

applicable codes and additional requirements used materials and certification welding procedures and qualifications dimensional tolerances fin type and manufacturing (tightness and length) non-destructive examinations post weld heat treatment authority inspection pressure testing surface preparation and coating service conditions.

12.3.3 Points of specific importance during fabrication:

tube to tubesheet connections welding and rolling or rolling and welding drilling of tubesheet expanding " access for NDE plug type material and plug hole type restamping of tubes (prior to finning) prevent fin damage for structural steel see separate section 15.0 fit-up of header boxes welding sequence of header boxes positive material identification O measurements grooving of fin to end 15 mm after tubesheet gasket surface finish for cover type header boxes fabrication of swaged nozzles.

12.4 Heaters Fired heaters for refinery service. 12.4.1 Specified national/international specification to be applied. 12.4.2 Check requisition for:

applicable code(s) and additional requirements used materials and certification welding procedures and qualification dimensional tolerances non destructive examination (castings) post weld heat treatment authority inspection lining requirements pressure testing surface preparation fin type (studs) service conditions.

12.4.3 Points of specific importance during fabrication:

welding of hairpins and pipes restamping of pipes postweld heat treatment, supports etc casting technology and pilot castings

positive material identification RT acceptance criteria. Note: for structural steel see section 15.0

12.5 Atmospheric Tanks Shop and Field fabricated with fixed roof, floating roof etc. 12.5.1 Specified national/international code to be applied. 12.5.2 Check requisitions for:

applicable code(s) and additional requirements used materials and certification welding procedures and qualifications dimensional tolerances authority inspection non destructive examination pressure testing procedure surface preparation service conditions.

12.5.3 Points of specific importance during fabrication (for sake of completeness site erection points included):

soil survey soil consistency welding sequences lining " continuous dimensional survey(s) due to settlements automated RT examination fire monitoring system(s) seal for floating roof internal pipes and supports (heaters) trial assemblies gasket surfaces/flange facings internal hoses for draining (roof) skimmers applicable or not floor configuration (cone-down; cone-up; slope) any fixing with anchor bolts clips and structural steel. For structural steel see section 15.

12.6 Trays Trays for site and for shop installation in pressure vessels, reactors etc.

12.6.1 National/international specifications - not applicable. Manufacturers' standards, e.g. Koch, Glitsch Metawa. 12.6.2 Check requisition for:

used materials and certification welding procedures and qualifications dimensional tolerances non-destructive examinations surface preparation such as; (pickling, passivating etc) installation procedure hold down clamps etc filling of loose internals such as balls, catalyst etc service conditions.

12.6.3 Points of specific importance during fabrication and /or installation:

dimensional control (especially flatness) trial assembly tray holes, bubble caps, chimneys overlapping edges downcomers bolting down devices marking of tray numbers contamination with other materials positive material examination gaskets between tray and support rings installation through manhole possible spargers.

13. Rotating Process Equipment 13.1 Centrifugal Pumps Single and Multistage. 13.1.1 Specified national/international specification to be applied. 13.1.2 Check requisitions for:

applicable code(s) and additional requirements used materials and certification any welding involved dimensional tolerances

seal system accessories used driver baseplate type NPSH and performances service condition.

13.1.3 Point of specific importance during fabrication:

balancing of impeller(s) dimensional control installation of seal(s) flange facings finish testing procedure positive material identification non destructive examination results repairs carried out hydrotest procedure and liquid type head/flow testcurve from water calculated to specified liquid aligning pump and driver on base plate protection of couplings etc (coupling guard) grouting of baseplate on site involved vibration measurements flange facings.

13.2 Screw Pumps 13.2.1 Specified national/ nternational specification to be applied. 13.2.2 Check Requisitions for:

applicable code(s) and additional requirements used materials and certification any welding involved dimensional tolerances seal system accessories used driver baseplate type performance and other testing requirements service conditions.

13.2.3 Points of specific importance during fabrication:

welding of casing machining dimensional control seal installation testing procedure non destructive examination (access!) aligning pump and driver on baseplate baseplate grouting involved on site coupling guards testcurve from water calculated to specified liquid state and/or dynamic balancing vibration measurements flange facings.

13.3 Centrifugal Compressors Single and Multistage. 13.3.1 Specified national/international specification to be applied. 13.3.2 Check requisition for:

applicable code(s) and additional requirements used materials and certification any welding involved dimensional tolerances seal system driver testing requirements seal system accessories baseplate type casting requirements service conditions.

13.3.3 Points of specific importance during fabrication:

welding and/or repair by welding casting static and/or dynamic balancing pressure test requirements non-destructive examination aligning compressor and driver on baseplate

grouting of baseplate involved on site coupling guards etc. positive material identification testing procedure for impellers overspeed etc record of clearances shop/performance/string test vibration measurements internal examination after flange facings.

13.4 Reciprocating Compressors 13.4.1 Specified national/international specification to be applied. 13.4.2 Check requisition for:

applicable code(s) and additional requirements used materials and certification any welding involved dimensional tolerances driver seal system testing requirements seal system accessories base plate service conditions.

13.4.3 Points of specific importance during fabrication:

welding and /or repair by welding casting static and/or dynamic balancing pressure testing non-destructive examination grouting involved on site coupling guards positive material identification performance testing procedure alignment of crank shaft other alignments driver/compressor etc. stripping test flange facings

"rod run-out" prior to test run.

13.5 Steam/Gas Turbines 13.5.1 Specified National/International Specification to be Applied. 13.5.2 Check requisition for:

applicable code(s) and requirements used materials and certification any welding involved dimensional tolerances used as driver for: seal systems testing requirements accessories baseplate service conditions.

13.5.3 Points of specific importance during fabrication:

welding and/or repair by welding casting static and/or dynamic balancing pressure testing non-destructive examination(s) performance testing procedure dimensional control/clearances alignments stripping test installation of rotor vibration measurements complete testing procedures:

14. Piping Fabrication and Valves 14.1 Pipespools 14.1.1 Specified national/international code shall be applied. 14.1.2 Check Requisitions for:

applicable code(s) and additional requirements used materials and certification welding procedures and qualifications

dimensional tolerances non destructive examination post weld heat treatment pressure testing surface preparation authority inspection service conditions

14.1.3 Points of specific importance during fabrication:

fit up materials compliance with welding procedures marking, restamping authority keep iso's up to date maintain traceability tracking of NDT records marking of fieldwelds welding of branch fittings and correct fit up flange facing protection O-thickness measurements threaded connections positive material identification:

14.2 Piping Materials Pipe, fittings, flanges, O-lets, bolts, nuts. 14.2.1 Check requisition for:

applicable code and/or specification and additional requirements non destructive examination welding involved heat treatments hardstamping requirements dimensional tolerances service conditions.

14.2.2 Other important notes:

approved manufacturers involved to meet code or authority requirements O-lets manufactured in accordance with approved drawings tolerances.

14.3 Valves

Gate, Globe, Check, Butterfly etc. 14.3.1 Specified national/international specifications shall be applied. 14.3.2 Check Requisitions for:

applicable codes and additional requirements material and certification welding involved/casting involved non-destructive examination tolerances special packing materials flange facing finish special testing requirements positive material examination any auxiliaries service conditions.

14.3.3 Points of specific importance during fabrication:

material marking/tracebility testing procedure control valve settings pilot castings.

15. Structural Steel 15.1 Specified national/international specification shall be applied. 15.1.1 Check requisition for:

applicable code(s) and additional requirements materials and certification welding procedures/qualifications non destructive examination tolerances service conditions.

15.1.2 Points of specific importance during fabrication:

keep track of all activities (any partial subcontracting for ladders, handrailing etc.) compliance with welding procedures mind large size trusses; nodes (lifting eye etc) inspection per defined lot (shipping lists etc) which is required also for next activities such as galvanising and then arrival at site.

16. Electrical Equipment 16.1 Electric Motors Three phase, squirrel cage, induction type. 16.1.1 Specified national/international specification shall be applied. 16.1.2 Check requisitions for:

applicable code(s) and additional requirements used materials and certification classification zone approved manufacturers specified tests service conditions accessories.

16.1.3 Points of specific importance during fabrication/testing:

winding resistance (temperature) insulation resistance bearings vibration tests high voltage test performance test efficiency/power factor/slip

Note: when Cos < 0.8 always contact Home Office Engineer

thermal constant time (Te time) running up time (Art) pull-up torque rotor inertia (GD2) cooling fan material motor enclosure certification (validity) test of windings terminal box (location and classification).

16.2 Generators AC 3 phase, air cooled, rotating. 16.2.1 Specified national/international specification shall be applied. 16.2.2 Check requisitions for:

used materials and certification service conditions power factor/voltage/frequency accessories (heater, cooling system) bearings.

16.2.3 Points of specific importance during fabrication and testing:

temperature rise of stator winding cooling air temperature efficiency momentary excess current overload short circuit requirements voltage variations during operation unbalanced loads wave form overspeed subtransient reactance noise level vibration critical speeds rating plate testing procedure.

16.3 Transformers Single phase/three phase power and distribution transformers:

up to 100 KVA above 100 KVA.

16.3.1 Specified national/international specification shall be applied. 16.3.2 Check requisition for:

applicable code(s) and/or additional requirements used materials and certification classification approved manufacturers specified tests.

16.3.3 Points of specific importance during fabrication and/or during fabrication:

full load test for temp, rise of oil 14 quid and HV ILV windings separate source voltage tests overvoltage test (+ increased frequency) no load test winding transformation and polarity test calculation of impedance voltage calculation of iron losses calculation of copper losses calculation of efficiency short circuit impedance dielectric strength of oil or synthetic liquid in transformer earthing.

16.4 Switchgear Switchgear for use in distribution of electrical energy:

low voltage switchgear high voltage switchgear

16.4.1 Specified national/international specification shall be applied. 16.4.2 Check requisitions for:

specified materials and certification approved manufacturers of components service conditions.

16.4.3 Points of specific importance during fabrication and/or testing:

testing procedure circuit breakers protective relays current and voltage transformers fuses draw-out units metering devices inspection of busbars and earthbars, size, connections and hole sizes marking of components (busbars, terminals etc) dielectric test insulation resistance test mechanical interlocks (doors etc) mechanical and electrical operation test interchangeability of components high voltage test for main circuits; control and auxiliary circuits/secondary circuits

insulation resistance test grounding continuity test for metal parts of switchboard to main earth bar and switching devices/busbar chambers to main earth bar. shutters test operation test security (screening) for live parts short circuit capacity test impulse test voltage drop test nameplate(s).

17. Instruments 17.1 General Generally specific test and inspection requirements are stated in the requisitions and/or its applicable documents. Basically the inspection of the instruments will contain a full detailed review of the requisition with applicable documents and a performance test. This performance test shall be executed for a selected number of instruments, preferably minimum one instrument of each type. The results shall be compared with the calibration/test reports of the Vendor. 17.2 Scope 17.2.1 The following types of instruments will only be inspected if required by the terms of the Purchase Order and its attachments. In this event, the extent of inspection will be agreed between Inspection and Engineering in advance of request for quotation. (a) Conventional and miniature pneumatic and electronic receiver-indicators, recorders and controllers. (b) Electronic potentiometer instruments. (c) Locally mounted indicators, recorders, controllers and transmitters, excluding displacement type level instruments. (d) Thermocouples and other temperature measuring primary elements. (e) Minor instruments such as pressure gages, thermometers, rotameters, pressure and level switches etc. 17.2.2 For the above categories of instruments, the Vendor will normally only be requested to furnish certificates of conformity with the specification, unless otherwise specifically mentioned in the Purchase Order. 17.2.3 Prior to release of any instrument for shipping all test calibration and other certificates as required per requisition shall be checked and approved, whether they have been inspected or not. 17.3 For certain specialised instruments as analysers, sample conditioning systems, control panels, auxiliary cabinets etc., inspection (where called for in the requisition) may be jointly with a control systems engineer. In these circumstances the proposed inspection dates, as advised in expediting reports, will be communicated in advance to Engineering. In some cases it might be requested by Engineering to send instruments which are supplied by others, but actually forming a part of the system, to the Vendor of the system for an integral performance test. 17.4 In-Line Instruments as control valves, orifice flanges, turbine meters etc. shall, in addition to the specific instrument inspection procedure as described in this chapter, be inspected as described elsewhere in this guide.

17.5 Instruments on Package Units The inspection procedure for instruments on package units is identical to the inspection procedure as described above. In addition special attention shall be given to:

make and type of instrument range of instruments scale of instruments location visibility/accessibility durability of installation material certification enclosures.

If the instruments are wired/piped by Vendor:

type of cable/tubing: armoured/unarmoured thermocouple extension cable size and type of cable glands/unions durable fastening of wiring/tubing

17.6 In some cases relevant Authorities require certain tests and inspections of safety and relief valves or bursting discs. A combination of Company's and Authority inspection shall be considered to improved co-ordination and to facilitate Authority approval. 18. References Document number BN-IN-005 CM-PE-711 Title Vendor Inspection Procedure Vendor Quality System Requirements Level 3 2

18.1 18.2

You might also like

- THE THIRD PART INSPECTION FOR VALVES - OdtDocument8 pagesTHE THIRD PART INSPECTION FOR VALVES - OdtVelibor StokicNo ratings yet

- KBR Inspection Test Plan For Instruments: Level 1 Level 2 Level 3Document2 pagesKBR Inspection Test Plan For Instruments: Level 1 Level 2 Level 3kamlNo ratings yet

- Itp For Casing, Ducting, StackaaaaaaaaaaaDocument4 pagesItp For Casing, Ducting, Stackaaaaaaaaaaaaymanmalah100% (1)

- Saudi Aramco Test Report: Calibration Test Report - Pressure Gauge SATR-A-2002 22-Jan-18 MechDocument2 pagesSaudi Aramco Test Report: Calibration Test Report - Pressure Gauge SATR-A-2002 22-Jan-18 MechaneeshNo ratings yet

- Vendor's Inspection and Testing PlanDocument2 pagesVendor's Inspection and Testing Planrylar999No ratings yet

- E3. Sample Notification of Inspection (Noi) NOI No. VLV-NOI-381 Rev. 0Document1 pageE3. Sample Notification of Inspection (Noi) NOI No. VLV-NOI-381 Rev. 0Isaac EdusahNo ratings yet

- Inspection & Test Plan Key Valve Interlocks: To BS EN ISO 9001: 2008Document2 pagesInspection & Test Plan Key Valve Interlocks: To BS EN ISO 9001: 2008Charles RobiansyahNo ratings yet

- Hydrostatic Test ProcedureDocument8 pagesHydrostatic Test ProcedureNenad TomicNo ratings yet

- Safety Alert: Failure of Fabricated Test Blind Flange For Hydrostatic TestingDocument5 pagesSafety Alert: Failure of Fabricated Test Blind Flange For Hydrostatic TestingvietnampetrochemicalNo ratings yet

- Itp-Shop Fabricated PipingDocument4 pagesItp-Shop Fabricated PipingkamlNo ratings yet

- Method Statement OF Air Blowing / Water Flushing of PipesDocument19 pagesMethod Statement OF Air Blowing / Water Flushing of Pipesarun kumar100% (1)

- Procurement 6.1. Material List Requistion and InquiriesDocument3 pagesProcurement 6.1. Material List Requistion and InquiriesMercy EdemNo ratings yet

- PBI-ITP-QA-0001 Inspection and Test Plan Rev.0Document7 pagesPBI-ITP-QA-0001 Inspection and Test Plan Rev.0Tadaya KasaharaNo ratings yet

- Qualification Procedure No. 7: SSPC: The Society For Protective CoatingsDocument6 pagesQualification Procedure No. 7: SSPC: The Society For Protective CoatingsRinush SinagaNo ratings yet

- Ddaily Drift Calibration Procedure: 1. ScopeDocument1 pageDdaily Drift Calibration Procedure: 1. ScopeJohn DolanNo ratings yet

- Consultancy in Mechanical Integrity RBI, RCM, FFS, NDT & Vibration Analysis Services Training Based On API ASME and Other StandardsDocument6 pagesConsultancy in Mechanical Integrity RBI, RCM, FFS, NDT & Vibration Analysis Services Training Based On API ASME and Other StandardsShahbaz KhanNo ratings yet

- 2722-ME-007 - Piping Design, Fabrication & InstallationDocument42 pages2722-ME-007 - Piping Design, Fabrication & InstallationEngr Muhammad AliNo ratings yet

- Inspection and Test Plan For Storage Tank CompressDocument6 pagesInspection and Test Plan For Storage Tank CompressSmit BhivgadeNo ratings yet

- Structural Steel and Pipe Work ProcedureDocument5 pagesStructural Steel and Pipe Work ProcedureMohamed100% (2)

- Itp Line PipeDocument8 pagesItp Line Pipekaml100% (1)

- Itp Structural SteelDocument4 pagesItp Structural SteelkamlNo ratings yet

- Welding Inspector Job and ResponsilbilitiesDocument5 pagesWelding Inspector Job and ResponsilbilitiesFelix GomintongNo ratings yet

- Occpl: Hydro & Pneumatic Test ProcedureDocument3 pagesOccpl: Hydro & Pneumatic Test ProcedureNupesh katreNo ratings yet

- Procedure For WeldingDocument7 pagesProcedure For WeldingMecon Hyderabad100% (1)

- Storage Tank Foundation Settlement Quality Control and Inspection Report FormDocument1 pageStorage Tank Foundation Settlement Quality Control and Inspection Report FormKhepa BabaNo ratings yet

- QAP For Conical StrainerDocument2 pagesQAP For Conical StrainersatishchidrewarNo ratings yet

- NOI Template-Source InspectionDocument2 pagesNOI Template-Source InspectionyuzwuzereNo ratings yet

- AIE-PR-PRJ-005 - in Service Pipework Inspection Procedure Rev 01Document20 pagesAIE-PR-PRJ-005 - in Service Pipework Inspection Procedure Rev 01faraz_muslimNo ratings yet

- SATR-J-6913 Rev 0 PDFDocument6 pagesSATR-J-6913 Rev 0 PDFAdel KlkNo ratings yet

- Positive Recall ProcedureDocument6 pagesPositive Recall ProcedureSiva RamNo ratings yet

- Electrode Test Record E6010Document9 pagesElectrode Test Record E6010Veeraraghavan GuruNo ratings yet

- Ain Tsila Development Main EPC Contract A-CNT-CON-000-00282: Visual Inspection Test Procedure B-QAC-PRO-210-39162Document14 pagesAin Tsila Development Main EPC Contract A-CNT-CON-000-00282: Visual Inspection Test Procedure B-QAC-PRO-210-39162ZaidiNo ratings yet

- B170 Aq SPC 70000 - 2Document41 pagesB170 Aq SPC 70000 - 2Mingyu Song100% (1)

- Sample WPS 1Document13 pagesSample WPS 1waqas pirachaNo ratings yet

- Quality Assurance & Standards in Lifting Equipment Inspection, Examination & TestingDocument21 pagesQuality Assurance & Standards in Lifting Equipment Inspection, Examination & TestingikponmwonsaNo ratings yet

- Itp Pipe SupportsDocument4 pagesItp Pipe SupportskamlNo ratings yet

- SAIC-W-2077 Weld Joint Identification SystemDocument1 pageSAIC-W-2077 Weld Joint Identification Systemkarioke mohaNo ratings yet

- Ir 0703Document3 pagesIr 0703sheikmoinNo ratings yet

- Contractor Quality Control Plan For Fix or Stationery Equipment Installation Inspection and Test Plan For Fix or Stationery Equipment InstallationDocument5 pagesContractor Quality Control Plan For Fix or Stationery Equipment Installation Inspection and Test Plan For Fix or Stationery Equipment InstallationSergey KichenkoNo ratings yet

- Welder Qualification Radiography Acceptance CriteriaDocument2 pagesWelder Qualification Radiography Acceptance CriteriaKamalnath KpNo ratings yet

- Inspection and Test Plan For Gas TurbineDocument5 pagesInspection and Test Plan For Gas TurbineLiu YangtzeNo ratings yet

- SAIC-W-2082 Validation of Welding Equipment (EE)Document4 pagesSAIC-W-2082 Validation of Welding Equipment (EE)karioke mohaNo ratings yet

- SGS IND Storage Tank A4 EN 14 PDFDocument8 pagesSGS IND Storage Tank A4 EN 14 PDFAjejejeNo ratings yet

- ITP For Hydraulic BarrierDocument4 pagesITP For Hydraulic Barriermoytabura96No ratings yet

- On Plot HydrotestingDocument14 pagesOn Plot HydrotestingShambu S VtkNo ratings yet

- QW-200 and QW-300Document1 pageQW-200 and QW-300Julio CastilhosNo ratings yet

- Welder Diameter Limitation ASME SEC IXDocument1 pageWelder Diameter Limitation ASME SEC IXkumarNo ratings yet

- C.S Piping Welding 20368E02Document37 pagesC.S Piping Welding 20368E02EL-Hamra Terminal projectsNo ratings yet

- PWHT Job Card For p91 Butt Weld 14'' SupportDocument2 pagesPWHT Job Card For p91 Butt Weld 14'' Support9703422499No ratings yet

- Saudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 30-Oct-17 MechDocument2 pagesSaudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 30-Oct-17 MechJagdishNo ratings yet

- Cable Tray InstallationDocument1 pageCable Tray InstallationNaeemNo ratings yet

- Sa 6717Document1 pageSa 6717biplabpal2009No ratings yet

- Itp Electrical SwitchgearDocument4 pagesItp Electrical SwitchgearpertmasterNo ratings yet

- Hydrostatic Test of Pandi WaterDocument7 pagesHydrostatic Test of Pandi WaterOscar C. GabinayNo ratings yet

- SAIC-A-2023 Rev 6 Prssure Test Air GasDocument5 pagesSAIC-A-2023 Rev 6 Prssure Test Air Gaspookkoya thangalNo ratings yet

- Inspection Capabilities - 2016Document4 pagesInspection Capabilities - 2016muhamadrafie1975No ratings yet

- SAIC & SATR - InstrumentationDocument4 pagesSAIC & SATR - InstrumentationAdel KlkNo ratings yet

- Inspection and Test Plan (Itp) For Control ValvesDocument15 pagesInspection and Test Plan (Itp) For Control ValveszakariaNo ratings yet

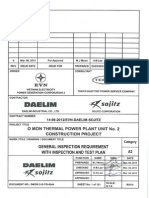

- 3.3.1 General Inspection Requirement With ITPDocument121 pages3.3.1 General Inspection Requirement With ITPĐình Nam100% (3)

- Inspection Level IV Is Invoked, This System Meets The Requirements of Former MIL-I-45208ADocument18 pagesInspection Level IV Is Invoked, This System Meets The Requirements of Former MIL-I-45208AAdrian Copa JNo ratings yet

- 9 Cswip 3.1 Question Answers SPECIMEN WRITTEN EXAMINATION QUESTIONS Question Answers Solved Past Papers Cswip 3.1Document32 pages9 Cswip 3.1 Question Answers SPECIMEN WRITTEN EXAMINATION QUESTIONS Question Answers Solved Past Papers Cswip 3.1Mohammed Amjad AliNo ratings yet

- Stainless Steel Wire - Ss316/316L: Product Data SheetDocument1 pageStainless Steel Wire - Ss316/316L: Product Data SheetAneesh JoseNo ratings yet

- Datasheet For Carbon Steel A333 Grade 6Document10 pagesDatasheet For Carbon Steel A333 Grade 6Aneesh JoseNo ratings yet

- Aluminium Coil / Sheet / Corrugated: Aluminium Alloy - AA 1100, 1050, 1060 - AA 3003 - AA 5005, 5052, 5754Document1 pageAluminium Coil / Sheet / Corrugated: Aluminium Alloy - AA 1100, 1050, 1060 - AA 3003 - AA 5005, 5052, 5754Aneesh JoseNo ratings yet

- Tillc-Doc004-Pds-Ss316 Screw PDFDocument1 pageTillc-Doc004-Pds-Ss316 Screw PDFAneesh JoseNo ratings yet

- Pneumatic Test CertificateDocument1 pagePneumatic Test CertificateAneesh JoseNo ratings yet

- Tillc-Doc001-Pds-Ss316 Banding PDFDocument1 pageTillc-Doc001-Pds-Ss316 Banding PDFAneesh JoseNo ratings yet

- Interpreting What Your Voltmeter Is Telling You: Reading What Reading IndicatesDocument3 pagesInterpreting What Your Voltmeter Is Telling You: Reading What Reading IndicatesAneesh JoseNo ratings yet

- ABB-RL-3 918: Added Battery Limit Acoustic Insulation HCDocument1 pageABB-RL-3 918: Added Battery Limit Acoustic Insulation HCAneesh JoseNo ratings yet

- ABB Proposal Is Found Acceptable, Code-1. This Approval Does Not Relieve EPC Contractor From Any Responsibility As Stated in SOWDocument2 pagesABB Proposal Is Found Acceptable, Code-1. This Approval Does Not Relieve EPC Contractor From Any Responsibility As Stated in SOWAneesh JoseNo ratings yet

- Abb Rev AtionsDocument14 pagesAbb Rev AtionsAneesh JoseNo ratings yet

- Rounded Indication ChartDocument8 pagesRounded Indication ChartAneesh JoseNo ratings yet

- Controlvalvesandactuators 090617042347 Phpapp01Document34 pagesControlvalvesandactuators 090617042347 Phpapp01Vijaya LakshmiNo ratings yet

- Guide To Protective CoatingDocument118 pagesGuide To Protective CoatingAnilkumar Gurram100% (1)

- Inspection Test PlanDocument2 pagesInspection Test PlanAneesh JoseNo ratings yet

- Aramco Question 01 PDFDocument43 pagesAramco Question 01 PDFRaghu Kumar100% (1)

- Date: 15. 01. 2014 Time: 08.00 AMDocument1 pageDate: 15. 01. 2014 Time: 08.00 AMAneesh JoseNo ratings yet

- Painting DFT Rules-SSPC-PA-2Document16 pagesPainting DFT Rules-SSPC-PA-2Michael AlbuquerqueNo ratings yet

- THG Hooks Forged Hooks Catalogue Sheet PDFDocument5 pagesTHG Hooks Forged Hooks Catalogue Sheet PDFjhonNo ratings yet

- Din en 10152Document20 pagesDin en 10152rahul srivastavaNo ratings yet

- IRC Rigid Pavement Design: Atul Narayan, S. PDocument49 pagesIRC Rigid Pavement Design: Atul Narayan, S. PSudheendra HerkalNo ratings yet

- Dsr-2013 in Ms ExcelDocument672 pagesDsr-2013 in Ms ExcelSubrata PaulNo ratings yet

- Design of Tail LugDocument34 pagesDesign of Tail LugPrajwal Shetty100% (1)

- Stress Classification ASME DIV2 Sec5 V1Document13 pagesStress Classification ASME DIV2 Sec5 V1pajadhavNo ratings yet

- Part-9 PG 146-158Document15 pagesPart-9 PG 146-158cjmNo ratings yet

- Aramco StandardDocument17 pagesAramco StandardYam Balaoing67% (3)

- Specification Erection Static EquipmentDocument11 pagesSpecification Erection Static Equipmentagaricus67% (3)

- F1267Document6 pagesF1267pratishgnairNo ratings yet

- Allowable Stresses of Typical ASME Materials - Carbon SteelDocument3 pagesAllowable Stresses of Typical ASME Materials - Carbon SteelMSNo ratings yet

- Construction of Structural Steel Elevator Hoist Shaft at SR 16 Hostel at IIM - Indore PDFDocument23 pagesConstruction of Structural Steel Elevator Hoist Shaft at SR 16 Hostel at IIM - Indore PDFKrishnendu BanikNo ratings yet

- Adani Parsa Coal Washery - WriteupDocument7 pagesAdani Parsa Coal Washery - Writeupanon_211762843No ratings yet

- 1 PTBarsBrochure-Oct2015Document6 pages1 PTBarsBrochure-Oct2015Dong-Yong KimNo ratings yet

- TND - 072388 - 148909-Tech. Specs.Document569 pagesTND - 072388 - 148909-Tech. Specs.govindharajaluNo ratings yet

- Design Aspects of Gates of DamDocument6 pagesDesign Aspects of Gates of DamdheeruNo ratings yet

- ASME Sec VIII The Most Common Code Used For Designing Pressure Vessels in Oil & GasDocument19 pagesASME Sec VIII The Most Common Code Used For Designing Pressure Vessels in Oil & GasShieeplNo ratings yet

- Pipe SupportsDocument18 pagesPipe SupportsdwipaNo ratings yet

- Astm A573 - A573m - 13Document2 pagesAstm A573 - A573m - 13Panneer BalashanmuganNo ratings yet

- Schedule Price - Fire Proofing BSB's Scope - R.1Document6 pagesSchedule Price - Fire Proofing BSB's Scope - R.1Mj Edin100% (1)

- Steel-Album CatalogDocument62 pagesSteel-Album Cataloglifei2998No ratings yet

- Specification For Concrete WorkDocument35 pagesSpecification For Concrete WorkBalamuruganNo ratings yet

- Mapua Univeristy: Muralla ST., Intramuros, Manila Department of Civil, Environmental, and Geological EngineeringDocument43 pagesMapua Univeristy: Muralla ST., Intramuros, Manila Department of Civil, Environmental, and Geological EngineeringCha RobinNo ratings yet

- Architecturally Exposed Structural Steel PDFDocument8 pagesArchitecturally Exposed Structural Steel PDFJagatheesh RadhakrishnanNo ratings yet

- Sulphur Tank Paper Rev6 - BrimstoneDocument18 pagesSulphur Tank Paper Rev6 - BrimstonevikramNo ratings yet

- DO - 007 - s2018 Standard Specifications For Item 1406, Rubber Dock FendersDocument11 pagesDO - 007 - s2018 Standard Specifications For Item 1406, Rubber Dock FendersanbertjonathanNo ratings yet

- Classif AçosDocument7 pagesClassif AçoslavascudoNo ratings yet

- AASHTO Steel Bridge Bearing Design & GuidelinesDocument50 pagesAASHTO Steel Bridge Bearing Design & GuidelinesNils Antoine FreundNo ratings yet

- A 5.29 FCAW Consumables PDFDocument36 pagesA 5.29 FCAW Consumables PDFStephen LewellenNo ratings yet

- Section D2Document249 pagesSection D2KvvPrasadNo ratings yet