Professional Documents

Culture Documents

เส้นทางวิจัยกระบวนการผลิตน้ำส้มสายชูหมัก

Uploaded by

tar_suradesCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

เส้นทางวิจัยกระบวนการผลิตน้ำส้มสายชูหมัก

Uploaded by

tar_suradesCopyright:

Available Formats

1 1 - 2553

:

...

1 2 2

1)

10520

Email : kkwaranu@kmitl.ac.th

2)

99 7 72130

(Fermented Vinegar Production Process)

8%

..2544

14

0801005225 13 2551

3

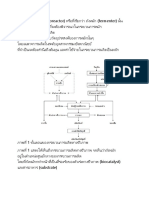

Orlean process

Slow process (Adams, 1985)

Quick process

http://riti.knit.or.th

1 1 - 2553

(Acetic acid bacteria)

Generator

(Inert material)

Ceramic Support (Ghommidh et al., 1982a;1982b)

Lipophilic fibrous support

Polypropylene, Polyethylene, Polystyrenes, Polyethylene

terephthalate Polyurethane (Okuhara, 1987)

(de Ory et al., 2003) (Kocher et al., 2006)

(Krusong et al., 2007)

Submerged process

Cavitator

Frings

acetator

(Adams, 1985)

5%

Frings acetator

8%

3

1) Acetobacter aceti

2)

3)

Acetobacter aceti

(2528) Potacharoen et al.,

(1999)

( )

Entani et al. (1987) US Patent

(US 4654306) Acetobacter altoacetigenes

MH-24 (FERM BP-491)

A. aceti 5

10%

9 (, 2545; 2547; 2550; 2551; 2552)

Cider

(Softly and Huang,1987; US Patent 4701336)

(Kubota et al.,1990; US Patent 4897272)

(Suresh and Ethiraj, 1991)

(Ethiraj and Suresh, 1992) (Garg et

al.,1995; , 2550) (Krishnankutty,

1995) Acid whey

(Tuckett et al.,1996) (Horiuchi et

al.,1999) (, 2545)

(, 2551)

http://www.frings-china.com/index1.2_en.html

http://riti.knit.or.th

15

1 1 - 2553

Heinrich Frings GmbH & Co KG Vinegar Infos The modern Vinegar

Plant-Planning and Realization pp. 4/4

Two stage

fermentation Continuous stirred tank

reactor (Aeschbach, 1982, US 4358463; Nodes, 1986,

US4569845) (Enenkel,

1988; US 4773315)

Lipophilic fibrous support

(Okuhara, 1987; US 4661356) Trickle Process

(Fleury et al.,1995; US Patent 5427803)

High cell density (Tamai et al.,

1997) Packed bed bioreactor (Horiuchi et al.,2000)

(Semi-continuous fermentation process)

(Adam, 1985;

Macias et al.,1997; Fregapane et al.,2001, 2003;

Arnold et al.,2002; de Ory et al.,2004)

(

) 30-40%

(Total concentration;

)

(60-70%) (Inoculum)

(Arnold et al.,2002; Garcia-Garcia

et al.,2007; Krusong et al.,2007)

16

-

() AGRO-ON

..2544 20-30

(Supplier)

..2535

..2544

2 Heinrich

Frings GmbH&Co.KG Frings

Bonn Frings

Frings

AGRO-ON

(.. 2544-2545)

(.)

http://riti.knit.or.th

1 1 - 2553

1 Heinrich Frings

GmbH & Co.KG Bonn

..2548

(Air lift fermentation process)

Acetobacter aceti 5

5

5 () (

, 2545)

5% 6-7

AGRO-ON

AGRO-ON

(..2546)

(By product)

AGRO-ON

( , 2547; 2550)

AGRO-ON

AGRO-ON

Frings .. 2548 ( 1)

http://riti.knit.or.th

Frings

1

Frings

Frings 4

Frings

.. 2548

Frings

(iTAP) (TMC)

(.)

AGRO-ON

( Agronegar)

(..25482550)

High Speed Agitation 600 (..25502551)

600 (..

2551-2552) Acetobacter aceti

5 10-12%

High Speed Agitation 600 (..

2552-) (, 2550; , 2551;

2552)

10% 36-48

5% 8% 10%

10-12%

(Stress condition)

17

1 1 - 2553

()

()

2 Frings

() 100 ; () 600

Frings 4

100 ( 2) 600

Frings

600

Agronegar

9

Spontaneous Mutation

(Total Concentration)

18

4-6

A. aceti 5, A. aceti WK A. aceti FT

9 7 5 A. aceti

5

AGRO-ON

Agronegar

Agronegar

A. aceti WK A. aceti FT

A. aceti WK

(, 2551)

GMO (Genetically Modified Micro

organism) Frings

(Dissolved

Oxygen)

Frings

Agronegar

http://riti.knit.or.th

1 1 - 2553

08010

05225 13 2551

3

(..

2551) iTAP .

4 2553

http://riti.knit.or.th

AGRO-ON/Agronegar

. .

Agronegar

19

1 1 - 2553

[1] . 2528.

.

. ,

, .

[2] . 2545.

.

(.)

2545-2545. 113 .

[3] . 2547.

.

-

() ..2546. 30 .

[4] . 2550.

.

2549-2550. 25 .

[5]

2550.

.

(.) ..2548-2550.53 .

[6] . 2550.

.

. 32

[7] . 2551.

High Speed Agitation

600 .

() ..2548-2550. 23 .

[8] . 2551.

.

() ..2550-2551. 26 .

[9] . 2552.

600 .

20

() ..2548-2550. 16 .

[10] A. Enenkel, Control arrangement for a vinegar

fermentation process, US4773315,1988.

[11] A. Okuhara, Production of vinegar with bacteria on

support, US4661356, 1987.

[12] B.J. Softly, A.S. Huang, Cider vinegar flavor, US

4701336, 1987.

[13] C. Ghommidh, J.M. Navarro, G. Durand, A study

of acetic acid production by immobilized Acetobacter

cells: oxygen transfer, Biotech Bioeng, 24 (1982a), pp.

605-617.

[14] C. Ghommidh, J.M. Navarro, R.A. Messing, A

study of acetic acid production by immobilized

Acetobacter cells: product inhibition effects, Biotech

Bioeng, 24 (1982b), pp. 1991-1999.

[15] E. Entani, S. Fujiyama, S. Ohmori, H. Masai,

Novel bacterium, Acetobacter altoacetogenes MH-24,

useful for the fermentation production of vinegar, US

4654306, 1987.

[16] E.R. Suresh, S. Ethiraj, Utilization of overripe

bananas for vinegar production, Tropical Sci, 31

(1991), pp. 317-320.

[17] F. Nodes, Process for the batchwise preparation

of vinegar, US4569845, 1986.

[18] G. Fregapane, H. Rubio-Fernandez, M.D.

Salvador, Influence of fermentation temperature on

semi-continuous acetification for wine vinegar

production, Eur Food Res Tech, 213 (2001)

pp. 61-66.

[19] G. Fregapane, H. Rubio-Fernandez,

M.D. Salvador, Continuous production of wine vinegar

in bubble column reactors of up to 60-litre capacity,

Eur Food Res Tech, 216 (2003), pp. 63-67.

[20] G.S. Kocher, K.L. Kalra, R.P. Phutela,

Comparative production of sugarcane vinegar

by different immobilization techniques,

J Inst Brew 112 (2006), pp. 264-266.

[21] H.A. Aeschbach, Method for the production of

fermentation vinegar, US4358463, 1982.

http://riti.knit.or.th

1 1 - 2553

[22] I. de Ory, L.E. Romero, D. Cantero, Optimization

of immobilization conditions for vinegar production.

Siran, wood chips and polyurethan foam as carriers for

Acetobacter aceti, Process Biochem 39 (2003), pp.

547-555.

[23] I. de Ory, L.E. Romero, D. Cantero, Operation in

semi-continuous with a closed pilot plant scale acetifier

for vinegar production, J Food Eng, 63(2004),

pp. 39-45.

[24] I. Garcia-Garcia, D. Cantero-Moreno,

C. Jimenez-Ot, S. Baena-Ruano, J.Jimenez-Hornero,

I. Santos-Duenas, J.Bonilla-Venceslada, F. Barja,

Estimating the mean acetification rate via on-line

changes in ethanol during a semi-continuous vinegar

production cycle, J Food Eng, 80 (2007), pp. 460-464.

[25] J. Horiuchi, T. Kanno, M. Kobayashi, New

vinegar production from onions, J Biosci Bioeng,

88 (1999), pp. 107-109.

[26] J. Horiuchi, K. Tabata, T. Kanno,

M. Kobayashi, Continuous acetic acid production by a

packed bed bioreactor employing charcoal pellets

derived from waste mushroom medium, J Biosci

Bioeng, 89 (2000), pp. 126-130.

[27] J. Horiuchi, K. Tabata, T. Kanno,

M. Kobayashi, Continuous acetic acid production by a

packed bed bioreactor employing charcoal pellets

derived from waste mushroom medium, J Biosci

Bioeng, 89 (2000), pp. 126-130.

[28] K. Fleury, V. Kalina, J. Zell, Trickle process for

vinegar production, US5427803,1995.

[29] M. Macius, I. Caro, D. Cantero, Optimum

operating conditions in closed system industrial

acetifiers (semi-continuous operation): a study by

computer simulation, Chem Eng J, 65 (1997),

pp. 201-207.

[30] M.R. Adams, Vinegar, In J.B. Wood, Editor,

Microbiology of fermented food, Blackie Academic and

Professional, London (1985), pp. 1-44.

[31] M.Tamai, O. Maruko, T. Kado, Improvement of the

vinegar brewing process using bioreactor. VI. Effect of

medium feeding rate on continuous production of

vinegar at high acidity by partial discharging of cell

http://riti.knit.or.th

concentration broth, J Japanese Soc Food

Sci Tech, 44 (1997), pp. 862-870.

[32] N. Garg, D.K. Tandon, S.K. Kalra,

N. Garg, Production of mango vinegar by immobilized

cells of Acetobacter aceti, J Food Sci Tech Mysore, 32

(1995), pp. 216-218.

[33] S. Arnold, T. Becker, A. Delgado, F. Emde, A.

Enenkel, Optimizing high strength acetic acid

bioprocess by cognitive methods in an unsteady state

cultivation, J Biotechnology 97 (2002), pp. 133-145.

[34] S. Ethiraj, E.R. Suresh, Studies on the mango

processing wastes for production of vinegar,

J Food Sci Tech Mysore, 29 (1992), pp. 48-50.

[35] S. Krishnankutty, Products from matured coconut

water, Indian Coconut J, 26 (1995), pp.12-13.

[36] W. Krusong, A. Vichitraka,

S. Pornpakdeewattana, Luffa sponge as supporting

material of Acetobacter aceti WK for corn vinegar

production in semi-continuous process, KMITL Sci J,

7 (2007), pp. 63-68.

[37] W. Potachareon, R.R. Navarro, P. Budhaka,

K. Suzuki, K. Komagata, Isolation and identification of

acetic acid bacteria from fermented foods in Thailand,

Proceedings of international conference on asian

network on microbial research, Chiang Mai, Thailand

(1999).

[38] T. Kubota, I. Itoh, S. Tanijiri, Process for

producing rice vinegar, US4897272, 1990.

[39] H.M. Tuckett, A.W. Nichol, T.J. Harden,

Production of pickling vinegar from acid whey,

Australian J. Dairy Tech, 51 (1996), pp. 53-57.

21

You might also like

- 1-65-Buff Milk Team - ประเมินโครงการDocument24 pages1-65-Buff Milk Team - ประเมินโครงการkid789453No ratings yet

- สมบัติการยับยั้งเชื้อแบคทีเรียของฟิล์มไคโตซานผสมน้ำมันหอมระเหยจากเทพทาโร Antibacterial properties of chitosan film blended with essential oil from Cinnamomum porrectumDocument9 pagesสมบัติการยับยั้งเชื้อแบคทีเรียของฟิล์มไคโตซานผสมน้ำมันหอมระเหยจากเทพทาโร Antibacterial properties of chitosan film blended with essential oil from Cinnamomum porrectum405 Chalongrat MeeratNo ratings yet

- ผลของสภาวะอบแห้งและอายุการเก็บรักษาผลิตภัณฑ์จิงหรีดอบกรอบDocument12 pagesผลของสภาวะอบแห้งและอายุการเก็บรักษาผลิตภัณฑ์จิงหรีดอบกรอบSura C. JirNo ratings yet

- 2 ถังดักไขมัน+P18-34+Document17 pages2 ถังดักไขมัน+P18-34+Hathaitip BuangamNo ratings yet

- ใบงานที่ 1 เรื่อง ผลกระทบของเทคโนโลยีDocument3 pagesใบงานที่ 1 เรื่อง ผลกระทบของเทคโนโลยีploen.pimlaphatNo ratings yet

- ตัวอย่างงานวิจัย ชีวะ - เคมีDocument3 pagesตัวอย่างงานวิจัย ชีวะ - เคมีKanokon SurintranonNo ratings yet

- พัฒนาแอปพลิเคชันประมงDocument7 pagesพัฒนาแอปพลิเคชันประมงKunanon ArnonNo ratings yet

- มกษ 9000-2564Document60 pagesมกษ 9000-2564Anutep PhuttaraksaNo ratings yet

- 247494-Article Text-855515-1-10-20201024Document12 pages247494-Article Text-855515-1-10-20201024กิตติทัต ศรีพละธรรมNo ratings yet

- บทสรุปผู้บริหาร สถานภาพการผลิตหัวมันDocument283 pagesบทสรุปผู้บริหาร สถานภาพการผลิตหัวมันKUKUNo ratings yet

- 8800 25961 9 PBDocument19 pages8800 25961 9 PBArthit SomrangNo ratings yet

- การหมักเต้าหู้ยี้Document9 pagesการหมักเต้าหู้ยี้Chaiyasit SreerattanapitagNo ratings yet

- รายงานฝึกงานอุตสาหกรรมDocument31 pagesรายงานฝึกงานอุตสาหกรรมpichaya kumarnsitNo ratings yet

- KC5811003Document8 pagesKC5811003Arthit SomrangNo ratings yet

- วิจัยการกำจัดสีDocument11 pagesวิจัยการกำจัดสี63050201No ratings yet

- ArticleDocument12 pagesArticlecho cxdzvdsdbdfnfdhNo ratings yet

- มกษ. 6401-2560Document40 pagesมกษ. 6401-2560Chonakarn ChanboonsaiNo ratings yet

- ถังปฏิกรณ์Document18 pagesถังปฏิกรณ์Por BittyNo ratings yet

- บัญชีเบิกจ่ายDocument17 pagesบัญชีเบิกจ่ายTonychickNo ratings yet

- 422671Document204 pages422671wind-powerNo ratings yet

- รายงานวิศวกรรมประปาDocument13 pagesรายงานวิศวกรรมประปา108-0คณิน ยกเซ็นNo ratings yet

- IR20Document23 pagesIR20Nunnun NaezNo ratings yet

- tjst,+ ($userGroup) ,+9-2-7 บทความ+อ ดร วิจิตราDocument14 pagestjst,+ ($userGroup) ,+9-2-7 บทความ+อ ดร วิจิตราPAII KKNo ratings yet

- 6674-Article Text-38074-1-10-20190328Document5 pages6674-Article Text-38074-1-10-20190328DE NANo ratings yet

- โครางงานชานอ้อย 1Document26 pagesโครางงานชานอ้อย 106นายศุภวิชญ์ สิเนหะวัฒนะNo ratings yet

- เตาเผาถ่าน แม่โจ้ charcoal burnerDocument164 pagesเตาเผาถ่าน แม่โจ้ charcoal burnerpolysourceNo ratings yet

- 18Document24 pages18wind-powerNo ratings yet

- PTTGC Petrochemical Encyclopedia2011Document437 pagesPTTGC Petrochemical Encyclopedia2011Amonphan JitjindakulNo ratings yet

- CFP GuidelineDocument48 pagesCFP GuidelineWaraporn PantorlaoNo ratings yet

- เอกสารวิชาการ แมลง ไร ศัตรูทุเรียนDocument90 pagesเอกสารวิชาการ แมลง ไร ศัตรูทุเรียนJate SinthunontNo ratings yet

- Tese Esterificação Sogtham Photaworn EditDocument130 pagesTese Esterificação Sogtham Photaworn EditHugo CardosoNo ratings yet

- 259-1480-1-PB 2Document8 pages259-1480-1-PB 263030364No ratings yet

- 12 1584 00 XDocument15 pages12 1584 00 XTrirong KampoolNo ratings yet

- รายงานสมบูรณ์วิจัยถ่านกล้วย.6 ใหม่ จัดใหม่ PDFDocument74 pagesรายงานสมบูรณ์วิจัยถ่านกล้วย.6 ใหม่ จัดใหม่ PDFSaransiri WongsiriNo ratings yet

- บทที่ 5 การกำจัดสิ่งปฏิกูลและการจัดการที่เหมาะสมDocument35 pagesบทที่ 5 การกำจัดสิ่งปฏิกูลและการจัดการที่เหมาะสมComputer Center100% (1)

- แนวทางการประเมินคาร์บอนฟุตพริ้นท์Document76 pagesแนวทางการประเมินคาร์บอนฟุตพริ้นท์Viganda VarabuntoonvitNo ratings yet

- โปรเจค การออกแบบระบบเพิ่มประสิทธิภาพการผลิตก๊าซชีวภาพจากน้ำเสียในกระบวนการผลิตแป้งมันสำปะหลังดัดแปรDocument56 pagesโปรเจค การออกแบบระบบเพิ่มประสิทธิภาพการผลิตก๊าซชีวภาพจากน้ำเสียในกระบวนการผลิตแป้งมันสำปะหลังดัดแปรBoonsita NammanaNo ratings yet

- Pattern and Potential of Durian (Durio Zibethinus) Production in Tumbon Saikhao, Amphur Kokpho, Pattani ProvinceDocument205 pagesPattern and Potential of Durian (Durio Zibethinus) Production in Tumbon Saikhao, Amphur Kokpho, Pattani Provincewind-powerNo ratings yet

- À ¡.3 À À À À À Œ À Šà 2à À Žà À À ¡À À - À À ¡Document43 pagesÀ ¡.3 À À À À À Œ À Šà 2à À Žà À À ¡À À - À À ¡Stevens LouisNo ratings yet

- การประยุกต์ใช้เครื่องมือทางอุตสาหการDocument14 pagesการประยุกต์ใช้เครื่องมือทางอุตสาหการWeerssak AssnewutikornNo ratings yet

- เล่มโครงงาน beautiful flower towerDocument21 pagesเล่มโครงงาน beautiful flower towerParichika PhoomkhokrakNo ratings yet

- ดินไทยDocument99 pagesดินไทยAlek DunsNo ratings yet

- G01 Biosafety GuidelineDocument246 pagesG01 Biosafety GuidelineStuart GlasfachbergNo ratings yet

- 14bibliography AppendicesDocument85 pages14bibliography Appendicesitsa1993No ratings yet

- Fungi in BiotechDocument6 pagesFungi in BiotechPitrix HellNo ratings yet

- โครงการพัฒนาการผลิตปุ๋ยอินทรีย์ 2553Document9 pagesโครงการพัฒนาการผลิตปุ๋ยอินทรีย์ 2553free4bruceNo ratings yet

- The Sixth National Agricultural Systems Seminar Save The World To Save Life 2010Document16 pagesThe Sixth National Agricultural Systems Seminar Save The World To Save Life 2010wind-powerNo ratings yet

- สารสกัดจากใบแป๊ะก๊วยDocument13 pagesสารสกัดจากใบแป๊ะก๊วยWassachol SumarasinghaNo ratings yet

- การหาประสิทธิภาพหม้อไอน้ำDocument13 pagesการหาประสิทธิภาพหม้อไอน้ำKanit ChobNo ratings yet

- Application of Lean Manufacturing To Reduce The Production Cost of Collagen PowderDocument10 pagesApplication of Lean Manufacturing To Reduce The Production Cost of Collagen PowderTanatchaporn PrathomtongNo ratings yet

- Paper 021Document5 pagesPaper 021wind-powerNo ratings yet

- พลาสติกและสิ่งแวดล้อม-อ เหมี่ยวDocument6 pagesพลาสติกและสิ่งแวดล้อม-อ เหมี่ยวBeam NattapornNo ratings yet

- เอกสารฝึกอบรม 23 PDFDocument10 pagesเอกสารฝึกอบรม 23 PDFnongkem internetNo ratings yet

- 7.รายงานฉบับสมบูรณ์-ฟาร์มจิ้งหรีดDocument120 pages7.รายงานฉบับสมบูรณ์-ฟาร์มจิ้งหรีดVikornNo ratings yet

- Thailland4 0 PDFDocument112 pagesThailland4 0 PDFsc425000No ratings yet

- DownloadDocument20 pagesDownloadมิ้ม จรรยพรNo ratings yet

- นมวัวดัดแปลงพันธุกรรม ภัยใหม่ที่พ่อแม่ควรรู้Document4 pagesนมวัวดัดแปลงพันธุกรรม ภัยใหม่ที่พ่อแม่ควรรู้tar_suradesNo ratings yet

- การพัฒนากระบวนการผลิตน้ำบูดูสู่ตลาดโลกDocument3 pagesการพัฒนากระบวนการผลิตน้ำบูดูสู่ตลาดโลกtar_suradesNo ratings yet

- ผลของสารให้ความหวานต่อคุณภาพของโยเกิร์ตDocument10 pagesผลของสารให้ความหวานต่อคุณภาพของโยเกิร์ตtar_suradesNo ratings yet

- Workshop 21 7 50Document36 pagesWorkshop 21 7 50tar_suradesNo ratings yet

- ผลของสารให้ความหวานต่อคุณภาพของโยเกิร์ตDocument10 pagesผลของสารให้ความหวานต่อคุณภาพของโยเกิร์ตtar_suradesNo ratings yet

- ข้อมูลจุลินทรย์อีเอ็มเชิงวิชาการDocument5 pagesข้อมูลจุลินทรย์อีเอ็มเชิงวิชาการtar_suradesNo ratings yet

- หาลำดับเบสคัดจุดเด่นสายพันธุ์Document2 pagesหาลำดับเบสคัดจุดเด่นสายพันธุ์tar_suradesNo ratings yet

- ระบบความปลอดภัยทางชีวภาพ 4 ระดับDocument2 pagesระบบความปลอดภัยทางชีวภาพ 4 ระดับtar_suradesNo ratings yet

- Workshop 21 7 50Document36 pagesWorkshop 21 7 50tar_suradesNo ratings yet

- น้ำหมักชีวภาพDocument10 pagesน้ำหมักชีวภาพtar_suradesNo ratings yet

- เทคโนโลยีชีวภาพด้านอาหารDocument14 pagesเทคโนโลยีชีวภาพด้านอาหารtar_suradesNo ratings yet

- นมวัวดัดแปลงพันธุกรรม ภัยใหม่ที่พ่อแม่ควรรู้Document4 pagesนมวัวดัดแปลงพันธุกรรม ภัยใหม่ที่พ่อแม่ควรรู้tar_suradesNo ratings yet

- โรงกลั่นชีวภาพแนวคิดเพื่อการแปรรูปชีวมวลอย่างมีประสิทธิภาพสูงสุดDocument7 pagesโรงกลั่นชีวภาพแนวคิดเพื่อการแปรรูปชีวมวลอย่างมีประสิทธิภาพสูงสุดtar_suradesNo ratings yet

- การพัฒนานมถั่วเหลืองสำหรับลิตโยเกิร์ตถั่วเหลืองDocument8 pagesการพัฒนานมถั่วเหลืองสำหรับลิตโยเกิร์ตถั่วเหลืองtar_suradesNo ratings yet

- ไบโอดีเซล (Biodiesel)Document19 pagesไบโอดีเซล (Biodiesel)tar_suradesNo ratings yet

- ศักยภาพของแบคทีเรียชอบเค็มต่อการพัฒนาอุตสาหกรรมน้ำปลาไทยDocument8 pagesศักยภาพของแบคทีเรียชอบเค็มต่อการพัฒนาอุตสาหกรรมน้ำปลาไทยtar_suradesNo ratings yet

- เส้นทางวิจัยกระบวนการผลิตน้ำส้มสายชูหมักDocument8 pagesเส้นทางวิจัยกระบวนการผลิตน้ำส้มสายชูหมักtar_suradesNo ratings yet

- นมวัวดัดแปลงพันธุกรรม ภัยใหม่ที่พ่อแม่ควรรู้Document4 pagesนมวัวดัดแปลงพันธุกรรม ภัยใหม่ที่พ่อแม่ควรรู้tar_suradesNo ratings yet

- Workshop 21 7 50Document36 pagesWorkshop 21 7 50tar_suradesNo ratings yet

- หาลำดับเบสคัดจุดเด่นสายพันธุ์Document2 pagesหาลำดับเบสคัดจุดเด่นสายพันธุ์tar_suradesNo ratings yet

- การสกัดสารจากพืชสมุนไพรเพื่อยับยั้งแบคทีเรียก่อโรคในอาหารDocument4 pagesการสกัดสารจากพืชสมุนไพรเพื่อยับยั้งแบคทีเรียก่อโรคในอาหารtar_suradesNo ratings yet

- ระบบความปลอดภัยทางชีวภาพ 4 ระดับDocument2 pagesระบบความปลอดภัยทางชีวภาพ 4 ระดับtar_suradesNo ratings yet

- โรงกลั่นชีวภาพแนวคิดเพื่อการแปรรูปชีวมวลอย่างมีประสิทธิภาพสูงสุดDocument7 pagesโรงกลั่นชีวภาพแนวคิดเพื่อการแปรรูปชีวมวลอย่างมีประสิทธิภาพสูงสุดtar_suradesNo ratings yet

- เทคโนโลยีชีวภาพด้านอาหารDocument14 pagesเทคโนโลยีชีวภาพด้านอาหารtar_suradesNo ratings yet

- การพัฒนานมถั่วเหลืองสำหรับลิตโยเกิร์ตถั่วเหลืองDocument8 pagesการพัฒนานมถั่วเหลืองสำหรับลิตโยเกิร์ตถั่วเหลืองtar_suradesNo ratings yet

- ข้อมูลจุลินทรย์อีเอ็มเชิงวิชาการDocument5 pagesข้อมูลจุลินทรย์อีเอ็มเชิงวิชาการtar_suradesNo ratings yet

- น้ำหมักชีวภาพDocument10 pagesน้ำหมักชีวภาพtar_suradesNo ratings yet

- ไบโอดีเซล (Biodiesel)Document19 pagesไบโอดีเซล (Biodiesel)tar_suradesNo ratings yet

- น้ำหมักชีวภาพDocument10 pagesน้ำหมักชีวภาพtar_suradesNo ratings yet