Professional Documents

Culture Documents

Operation & Maintenance Manual For Hypercomp CNG Compressor Model 3W815

Uploaded by

Asim RiazOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Operation & Maintenance Manual For Hypercomp CNG Compressor Model 3W815

Uploaded by

Asim RiazCopyright:

Available Formats

OPERATION & MAINTENANCE MANUAL

HYPERCOMP COMPRESSOR

MODEL: 3W815

HYPERCOMP (PVT) LTD.

HC-OMM-01 Version 00

THIS MANUAL IS AN INTEGRAL PART OF THE COMPRESSOR IT IS COMPULSORY TO READ IT BEFORE WORKING ON THE MACHINE

HYPERCOMP (PVT) LTD.

HC-OMM-01 Version 00

TABLE OF CONTENTS

1. INTRODUCTION .............................................................................................................................. 7 1.1. 1.2. 1.3. 1.4. 1.5. 1.6. 1.6.1. 1.7. 1.8. 1.9. 1.10. 2. 3. GENERAL ................................................................................................................................ 7 COMPRESSOR DESIGN ........................................................................................................... 7 COMPRESSOR CONFIGURATION............................................................................................ 8 CONTROL PANEL .................................................................................................................... 8 DRIVE ..................................................................................................................................... 9 LUBRICATION ......................................................................................................................... 9 OIL QUALITY ....................................................................................................................... 10 COOLING SYSTEM ................................................................................................................ 10 COMPRESSOR VALVES ......................................................................................................... 10 GAUGE PANEL ...................................................................................................................... 11 CONDENSATE DRAIN AND AUTOMATIC UNLOADING.......................................................... 11

SPECIFICATION & TECHNICAL DESCRIPTION................................................................................ 12 COMPRESSOR WARRANTY ........................................................................................................... 14 3.1. 3.2. 3.3. WARRANTY VOIDANCE .................................................. ERROR! BOOKMARK NOT DEFINED. WARRANTY EXCLUSIONS ............................................... ERROR! BOOKMARK NOT DEFINED. CAUTION .............................................................................................................................. 14

4.

INSTALLATION INSTRUCTIONS ..................................................................................................... 16 4.1. 4.2. 4.3. 4.4. 4.5. 4.6. GENERAL SAFETY PRECAUTIONS/ INSTRUCTIONS ............................................................... 16 INSTALLATION (GENERAL INSTRUCTIONS) .......................................................................... 17 PLACEMENT ......................................................................................................................... 17 PIPING .................................................................................................................................. 18 COOLING SYSTEM ................................................................................................................ 19 LUBRICATION ....................................................................................................................... 19

HYPERCOMP (PVT) LTD.

HC-OMM-01 Version 00

5.

COMMISSIONING ......................................................................................................................... 20 5.1. 5.2. START-UP PROCEDURE ........................................................................................................ 20 NOTES OF CAUTION ............................................................................................................. 21

6.

OPERATING INSTRUCTIONS ......................................................................................................... 22 6.1. 6.2. 6.3. 6.4. 6.5. 6.6. 6.7. 6.8. 6.8.1. 6.9. SAFETY PRECAUTIONS ......................................................................................................... 22 START-UP PROCEDURE ........................................................................................................ 23 RUNNING ON LOAD ............................................................................................................. 23 SAFETY CIRCUITS .................................................................................................................. 24 INSTRUMENTS & INDICATORS ............................................................................................. 25 LUBRICATION ....................................................................................................................... 26 SAFETY SHUT DOWN ............................................................................................................ 26 OIL QUALITY ......................................................................................................................... 26 LIST OF SUPPLIERS WITH SUITABLE OIL QUALITIES ........................................................... 27 COOLING .............................................................................................................................. 27

7. 8.

FAULT GUIDE ................................................................................................................................ 30 SERVICING/ MAINTENANCE INSTRUCTIONS ............................................................................... 34 8.1. 8.2. 8.3. 8.4. 8.5. 8.6. 8.7. 8.8. 8.9. GENERAL .............................................................................................................................. 34 DAILY INSPECTION AND MAINTENANCE .............................................................................. 34 50 HOUR RUN IN MAINTENANCE ......................................................................................... 35 3 MONTHLY OR 2000 HOUR INSPECTION AND MAINTENANCE ........................................... 35 4500 HOUR INSPECTION AND MAINTENANCE..................................................................... 35 9000 HOUR INSPECTION AND MAINTENANCE..................................................................... 36 GENERAL DAILY INSPECTION ............................................................................................... 36 DRIVE BELT TENSION AND ALLIGNMENT ............................................................................. 36 BASIC STEPS FOR V-BELT INTALLATION ................................................................................ 37

HYPERCOMP (PVT) LTD.

HC-OMM-01 Version 00

9.

REPAIR AND REPLACEMENT ......................................................................................................... 39 9.1. 9.2. 9.2.1. 9.2.2. 9.3. 9.3.1. 9.3.2. 9.4. 9.4.1. 9.4.2. 9.5. 9.5.1. 9.5.2. 9.6. 9.6.1. 9.6.2. 9.7. 9.7.1. 9.7.2. 9.7.3. 9.8. 9.8.1. 9.8.2. 9.9. 9.9.1. 9.9.2. 9.10. MAINTENANCE AND REPAIR PRECAUTIONS ........................................................................ 39 1ST STAGE SUCTION VALVE ................................................................................................. 40 REMOVAL ........................................................................................................................... 40 INSTALLATION .................................................................................................................... 40 1ST STAGE DELIVERY VALVE ................................................................................................. 40 REMOVAL ........................................................................................................................... 40 INSTALLATION .................................................................................................................... 40 1ST STAGE HEAD .................................................................................................................. 41 REMOVAL ........................................................................................................................... 41 INSTALLATION .................................................................................................................... 41 2ND STAGE VALVE AND HEAD.............................................................................................. 41 REMOVAL ........................................................................................................................... 41 INSTALLATION .................................................................................................................... 42 3RD STAGE VALVE AND HEAD .............................................................................................. 42 REMOVAL ........................................................................................................................... 42 INSTALLATION .................................................................................................................... 43 COMPRESSION CYLINDER .................................................................................................... 43 REMOVAL FOR 1ST, 2ND & 3RD STAGE ............................................................................. 43 COMPRESSION CYLINDER INSPECTION .............................................................................. 44 INSTALLATION FOR 1ST, 2ND & 3RD STAGE COMPRESSION CYLINDER ............................. 44 ROD SEAL CARRIER............................................................................................................... 45 REMOVAL ........................................................................................................................... 45 INSTALLATION .................................................................................................................... 45 GUIDE CYLINDER FOR 1 , 2 & 3 STAGE ............................................................................ 46 REMOVAL ........................................................................................................................... 46 INSTALLATION .................................................................................................................... 46 PISTON / PISTON RINGS FOR 1 , 2 & 3 STAGE ................................................................. 47 REMOVAL ...................................................................................................................... 47 INSTALLATION ............................................................................................................... 47

ST ND RD ST ND RD

9.10.1. 9.10.2. 9.11.

PISTON ROD ......................................................................................................................... 47 REMOVAL ...................................................................................................................... 47 INSTALLATION ............................................................................................................... 48

9.11.1. 9.11.2.

HYPERCOMP (PVT) LTD.

HC-OMM-01 Version 00

9.12.

GUIDE PISTON...................................................................................................................... 48 REMOVAL ...................................................................................................................... 48 INSTALLATION ............................................................................................................... 48

9.12.1. 9.12.2. 9.13. 9.14.

CONNECTING ROD BEARINGS REPLACEMENT / REINSTALLATION ....................................... 49 OIL PUMP ............................................................................................................................. 50 GENERAL ....................................................................................................................... 50 CAUTION ....................................................................................................................... 50 OIL PUMP REMOVAL ..................................................................................................... 50 OIL PUMP INSTALLATION .............................................................................................. 51

9.14.1. 9.14.2. 9.14.3. 9.14.4. 9.15.

CRANKSHAFT ....................................................................................................................... 51 GENERAL ....................................................................................................................... 51 CRANKSHAFT REMOVAL & INSTALLATION .................................................................... 52 CHECKING CRANKSHAFT END THRUST .......................................................................... 53

9.15.1. 9.15.2. 9.15.3. 9.16. 10. 11. 12.

COMPRESSOR REASSEMBLY ................................................................................................ 54

TORQUE WRENCH SETTING ......................................................................................................... 55 CLEARANCES/ TOLERANCES CHART ............................................................................................. 56 COMPRESSOR EQUIPMENT .......................................................................................................... 57 EXPLOSION PROOF ELECTRIC MOTOR ................................................................................. 57 PRESSURE SAFETY VALVES ................................................................................................... 82 WATER PUMP .................................................................................................................... 116 WATER FLOW SWTICH ....................................................................................................... 120 OIL FILTER .......................................................................................................................... 122 LUBRICATOR ...................................................................................................................... 128 SOLENOID VALVES ............................................................................................................. 137 TERMINAL BOX .................................................................................................................. 146 EXPLOSION PROOF SWITCH GAUGES ................................................................................ 152

12.1. 12.2. 12.3. 12.4. 12.5. 12.6. 12.7. 12.8. 12.9. 13. 14. 15.

P & I DIAGRAMS ......................................................................................................................... 186 PERIODIC MAINTENANCE CHART .............................................................................................. 187 PART LIST .................................................................................................................................... 188

HYPERCOMP (PVT) LTD.

HC-OMM-01 Version 00

1. INTRODUCTION

1.1. GENERAL

This manual has been prepared to assist the operators and service technicians to obtain optimum performance from the Hypercomp Compressor Model 3W815. It provides information required for the installation, commissioning, operation, servicing and troubleshooting faults of the compressor. Information contained in this manual corresponds to the details as on its publishing date. Minor differences may be observed on account of modifications in the compressor made afterwards. Such matters must be clarified from the compressor manufacturer explicitly so as to ensure safe and optimum performance of the machine. Please note that the Model and Serial No. must be quoted in all communications regarding the compressor. 1.2. COMPRESSOR DESIGN

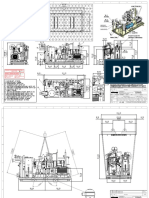

Hypercomp Compressor Model 3W815 is a W-type three (3) stage heavy duty machine designed for intermittent or continuous operation with minimal maintenance. This is apparent from the rugged water cooled cylinders and crosshead design. The standard design consists of a packaged unit mounted on a sturdy steel skid. The unit consists of the compressor, electric motor, flywheel, vee-belt drive, inter-stage coolers, oil separators / pulsation dampers for each stage, pressure relive valves, blowdown valves, condensate drains and automatic unloaders for each stage, optional low oil level safety switch and Control panel.

HYPERCOMP (PVT) LTD.

HC-OMM-01 Version 00

Hypercomp compressor utilizes a strong and robust crankcase frame design which provides efficient and reliable service under continuous duty applications. 1.3. COMPRESSOR CONFIGURATION

Hypercomp Compressor is a 3 cylinder 3 stage water-cooled compressor. The cylinders are mounted in a W type configuration to ensure well balanced operation. Each cylinder has tangential seals to prevent gas from pressurizing the crankcase. The crankshaft is dynamically balanced, counter-weighed and rides on two tapered roller bearings at each end. The pistons are crosshead guided. All connecting rods are forged steel. Connecting rod bearings are steel backed, Babbitt lined, shell type construction. The pulsation/filter chamber is placed on the inlet of the compressor with an adequate sized cartridge type filter positioned inside this tank. The threads in this tank are B.S.P. on the inlet. The gas passes through a solenoid valve, into the tank, through the enclosed filter and into the inlet manifold. 1.4. CONTROL PANEL

The compressor is supplied with an intrinsically safe control panel monitoring 1. 2. 3. 4. 5. 6. Oil pressure Inlet pressure Inter-stage Final stage pressures Lubricator flow rate (Optional) Final gas temperature and /or water temperature.

Other monitors can be added to system if required.

HYPERCOMP (PVT) LTD.

HC-OMM-01 Version 00

1.5.

DRIVE

The compressor is designed to be powered either by an electric motor or gas engine drive. The motor is of explosion proof category (Ex dIIBT4) and approved for use in hazardous areas. The electric motor is foot mounted and is driven with anti-static C section Vee belts. Protection for the motor is by thermistors and an over current device. 1.6. LUBRICATION

Oil is stored in the crankcase sump from which it is drawn by a plunger type oil pump. This oil pump is located on the front of the compressor adjacent to the intercooler. The oil pump is driven off an integral cam of the compressor crankshaft. Normal operating oil pressure is 20 to 60 psi. The oil is drawn through a screen located in crankcase sump through a check valve and passes through oil pump plunger to the oil pressure chamber. From this point the oil is under pressure and is fed through drilled passages in the crankshaft to the connecting rod and main bearings. The crosshead pistons and cylinders are splash lubricated by throw-off from the connecting rod bearings. The compression cylinders are force-fed lubricated by a single pump through a divider block or multi pumps depending on the service conditions. The divider block has a flow sensor to monitor the output. The oil pump body is bolted and doweled to the compressor from retainer and carries a non-adjustable pressure relief valve that serves to by-pass excess oil to the crankshaft sump. The relief valve also serves as a pulsation eliminator for oil pressure peaks. Volume of oil contained in sump is 12 liters. Half liter oil is consumed per 50 running hours (depends on conditions).

HYPERCOMP (PVT) LTD.

HC-OMM-01 Version 00

1.6.1. i.

OIL QUALITY

Oil should be of uniform viscosity, non-detergent and super refined with rust and oxidation inhibitors. Oil should be of naphthenic base of a specially compounded type to minimize carbon formation and to produce carbon residue of a soft and fluffy nature. Oils having animal fat compounding are not recommended. ii. Use of following weight oils for the ambient temperature ranges as indicated below is recommended: Above 60 F : SAE 30 32 to 60 F : SAE 20 Below 32 F : SAE 10W iii. Viscosity according to ISO Classification ISO VG 100 i.e. 90-100 cst (mm2/s) at 40 C (Resp. 55-70 cst or 7-9 deg E at 50 C) iv. Viscosity index: min. 80 v. Flash point: min. 200 C vi. Stock point: max. 12 C resp. pour point: max 9 C vii. To achieve good water separation properties, the oil should not, or to a light degree only, contain dispersant additives. 1.7. COOLING SYSTEM

The compressor is equipped with Shell & tube type heat exchanger and jacketed compression cylinders. The cooling can be achieved by either open or closed circuit. The cooling system should have an adequate corrosion and scaling inhibitors for maintenance free operation for extended periods, such as 50% Glycol/water solution or similar preparation. Water level is maintained by daily Top up of the water tank, located on the top of water circuit. 1.8. COMPRESSOR VALVES

Valves assemblies for all stages are of flat plate, low lift, multiport concentric type except the 1st stage which are not concentric type but have individual suction and delivery valves. Easy access is provided to the valves for their removal and services.

10

HYPERCOMP (PVT) LTD.

HC-OMM-01 Version 00

1.9.

GAUGE PANEL

Hypercomp compressor incorporates a gauge panel which can be mounted either on the skid or on the floor depending on the site conditions. It is connected to the compressor through flexible hoses. The gauge panel includes Low/High Inlet gas pressure switch gauge 1st stage gas delivery pressure gauge 2nd stage gas delivery pressure gauge 3rd stage gas delivery pressure gauge incorporating stop/start switch Low oil pressure switch gauge Water flow switch (fitted on compressor piping) 1.10. CONDENSATE DRAIN AND AUTOMATIC UNLOADING Each stage of the compressor delivery is piped through a separator which is connected to a diaphragm drain valve that discharge into a common chamber from where it is piped back to the blow down recovery vessel. The drain valves are operated by an EX solenoid valve which is actuated automatically every time the compressor shuts down and after every 30 minutes of continuous operation. The same system provides for the unloaded startup of the compressor.

11

HYPERCOMP (PVT) LTD.

HC-OMM-01 Version 00

2. SPECIFICATION & TECHNICAL DESCRIPTION

Make and Model Compressor Configuration Compressor Design No. of Cylinders No. of Stages Gas Inlet Pressure (min-max) Gas Discharge Pressure Gas Discharge capacity@15 Psig Gas Discharge capacity@8 Psig Compressor Speed Piston Stroke Piston Speed Cylinder Bores 1st Stage 2nd Stage 3rd Stage Cylinder Jacket Cooling Inter Stage Gas Cooling Cooling System Electric Motor Size Hypercomp, 3W815 W- 60 Cross Head design, Atmospheric crankcase 03 03 08-15 Psig 3625 Psig 270 cu.m/hr 5% (at 30C) 225 cu.m/hr 5% (at 30C) 795-900 RPM 127mm 3.36 m/s @ 795 RPM 3.81 m/s @ 900 RPM 206.375mm 88.9mm 38.1mm Water Water Cooling Tower (70RT Min) Closed Circuit Optional 75KW (100hp) for 270Cu.m/hr @ 15Psig 75KW (100hp) for 225Cu.m/hr @ 8Psig Clockwise if viewed from drive end. Upto 50C Big end bearings are pressure fed. Main bearings, small end bearings and crosshead

Direction of Rotation

Ambient Temp. Range Crankcase Lubrication

12

HYPERCOMP (PVT) LTD.

HC-OMM-01 Version 00

Cylinder Lubrication (Optional) Oil capacity (crankcase) Oil capacity (lubricator) Ambient Temp. Range Recommended oil for ambient temperature ranges

cylinders are splash lubricated Through force feed lubricator 13 liter 1.5 liter Upto 50C Above 60F: SAE 30 32 to 60 F : SAE 20 Below 32F: SAE 10W 2135 x 1190 x 1730 (mm) Approx. 1750 Kg Approx. 2400 Kg

Overall Dimensions (LxWxH) Weight (without motor) Overall Weight

13

HYPERCOMP (PVT) LTD.

HC-OMM-01 Version 00

3. COMPRESSOR WARRANTY

Every Hypercomp Compressor is carefully inspected and test run before shipment is made from the factory and each new compressor is warranted to be free from defects in material and workmanship. If not otherwise specified in the terms of delivery, the compressor is warranted for a period of 12 months from date of startup or 18 months from date of dispatch from our works, whichever occurs first. The warranty covers at the manufacturers discretion the replacement or repair at his cost of any faulty material, parts, or workmanship but does not cover the financial and other losses to the business and is for the stated period, subject to full compliance of conditions stipulated in our O&M manual. 3.1. WARRANTY VOIDANCE

The warranty shall become null and void under following circumstances:i. If the compressor has been operated for capacity, medium or temperatures other than those specified in our offer / quotation. If the purchaser or a third party undertakes any remedial work or alteration without our written authorization. If routine inspection and maintenance as prescribed in this manual is not strictly followed by the purchaser If the purchaser does not immediately take steps to notify us of any defect or malfunction to prevent the fault from becoming more serious and causing damage. If the piping is not installed by the manufacturer or its recommended party as per his direction.

ii.

iii.

iv.

v.

14

HYPERCOMP (PVT) LTD.

HC-OMM-01 Version 00

vi.

If any damage occurs due to improper handling of compressor and its parts or use of lubricant other than those listed in this manual.

vii. If the compressor is operated for other RPMs, intake pressures and capacity as stated in our O&M manual. viii. If the Daily Log Sheet is not maintained properly. 3.2. WARRANTY EXCLUSIONS

This warranty does not cover following: i. Damage or excessive wear resulting from improper use or impurities contained in the gas or lubricants outside the normally accepted standards. Normal wear and tear of valves, seals, bearings and rings. Any liability for fires in the machinery or installation. Physical damage resulting from impact or similar accident including natural disasters. If any electrical safety setting is altered or by passed for any reason. Any damage due to high voltages from any source. 3.3. i. CAUTION

ii. iii. iv.

v.

Do not compress gas containing corrosive elements (e.g. sulphurous gases like SO2), which attack carbon steel, cast iron, aluminum alloys as well as non-ferrous metals. Do not exceed compressor specifications under any circumstances without the written approval of the manufacturer.

ii.

15

HYPERCOMP (PVT) LTD.

HC-OMM-01 Version 00

4. INSTALLATION INSTRUCTIONS

The following instructions serve for protecting the life and health of operators and maintenance personnel as well as for maintaining the operating reliability of the compressor unit. 4.1. GENERAL SAFETY PRECAUTIONS/ INSTRUCTIONS

Most accidents which occur during the operation and maintenance of any machine result from failure to observe basic rules and precautions. An accident can often be prevented by recognizing a situation that can lead to potentially hazardous conditions. 1. Highly compressed gases contain a large amount of energy and therefore are very dangerous if not handled correctly. 2. Installation, operation, maintenance and repair shall be carried out only by qualified personnel and in accordance with the corresponding regulations for operation and safety. 3. Carry out maintenance and repair works on entirely vented areas. 4. Rotating machine parts represent a special danger for accidents. Covers and guards must not be removed whilst the machine is operating. 5. Persons staying for long periods in the compressor room should use hearing protection. 6. Do not store flammable materials near the compressor unit, e.g. oily rags. 7. Smoking is strictly prohibited near the compressor and other gas storage system. 8. Supply pipe work and other components which may not include in our scope of supply must be suitable for the respective working pressure. 9. Never interrupt electrical protective conductors. 10.Electrical cables must be flame proof and must not be linked or get into contact with rotating parts. 11.Dont touch blank wires and live (current carrying) parts, when the electrical system is energized. 12.The switch board may be opened only by qualified and authorized persons. Even if the main switch is set to the OFF position, the poles

16

HYPERCOMP (PVT) LTD.

HC-OMM-01 Version 00

of the switch, the feed cables of the terminal strip are alive. Therefore do not touch anything on the switch board, and do not carry out work, when the main current supply is not disconnected. Before starting work check if the system is entirely free of power. 4.2. INSTALLATION (GENERAL INSTRUCTIONS)

1. The compressor is supplied on its own base and should be installed in a vented area allowing adequate room around for suitable access for maintenance. Every effort should be made to ascertain that ambient air around the compressor does not exceed 50C. 2. Generally the compressor should be mounted on a substantial concrete base or rigid iron fixture. 3. Anti vibration mountings can be used in situations where minimal vibration transmission is required. It is an advantage in these applications to increase the weight of the base by filling the spare areas with stressed concrete consultation with the factory can facilitate this at the manufacturing stage. 4. If the compressor is mounted on anti vibration mounts, the inlet, discharge gas and water piping should be flexible and these pipes should not be taut. 4.3. PLACEMENT

The compressor can be placed on the foundation and carefully leveled both crosswise and lengthwise. 1. Under normal circumstances, a special foundation for the compressor is not necessary but it must be verified first that the support floor is structurally adequate as well as flat and level. 2. The foundation structure should have o4 foundation bolts of 20mm diameters buried at least 150mm deep in to the concrete base and have a hole at the bottom to prevent them from rotating when the nut is tightened. 3. Alternatively 04 Nos x 20 mm Dyna bolts or equivalent can also be used.

17

HYPERCOMP (PVT) LTD.

HC-OMM-01 Version 00

4. The compressor can be placed on the foundation bolts and carefully leveled both crosswise and lengthwise. After the compressor is leveled, nuts on the foundation bolts should be tightened. 5. The control cabinet containing switch gauges and intrinsically safe circuits should be mounted free standing as close to the compressor as possible. The cabinet stand should be securely bolted to the floor. All control hoses and temperature probe cables are marked for attachment to the appropriate fitting on the compressor. All hoses can be freely laid across compressor ensuring they are clear of moving parts. 4.4. PIPING

1. In order to prevent vibrations being transmitted from the compressor to the fixed distribution piping in the plant room and to facilitate maintenance removal of pipe work, flexible piping must be fitted at the following points. a) b) c) d) e) f) Gas inlet Gas Discharge Cooling water in Cooling water out Blow down manifold OUT Pressure relief valves manifold out

2. Gas piping to and from the compressor must be entirely cleaned and free from dirt and scale from the inside (by blowing through with high pressure air) 3. Piping from the compressor to the storage must be at least (12mm) in diameter. Never reduce pipe size in the discharge line from a compressor, minimize bends and fittings in the discharge line. 4. Ensure that all piping to the inlet and from the discharge has been pressure tested to a minimum of one and half times the working pressure of each system. NOTE: Failure to do this could result in serious injury to nearby personnel.

18

HYPERCOMP (PVT) LTD.

HC-OMM-01 Version 00

5. Before completing pipe work assembly, ensure that all port protection plugs and blanks have been removed and suction piping is clear of jointing compound, scale, swarf, dirt, moisture or any other foreign substance. 4.5. COOLING SYSTEM

The compressor is cooled by a closed circuit system via the cooling tower. The cooling system should have an adequate corrosion and scaling inhibitors for maintenance free operation for extended periods, such as 50% Glycol/water solution or similar preparation. Water levels are maintained by daily Top up of the water tank, located on the top of water circuit. 4.6. LUBRICATION

1. Prior to initial operation, the crankcase of the compressor must be

filled with recommended lubricating oil. 2. It is important to use oil from a known reputable source. Use of inferior quality oil may create service problems with valves, bearings, oil pump etc. that will be costly to repair. 3. Check lubricator, flow rate is in accordance with recommended settings.

19

HYPERCOMP (PVT) LTD.

HC-OMM-01 Version 00

5. COMMISSIONING

Before starting up the compressor for the first time, ensure that one is familiar with the safety devices and type of controls. 1. Fill the crankcase with oil up to the half way mark on the sight glass. (Approx. 12 liter) 2. Fill water circuit through cooling tower and bleed air from water pump as well as the air bleeding points on the compressor. 3. Check for correct voltage and phase sequence; if the phase sequence is not correct then the phase failure relay will not allow motor to start. 4. Check V-belts for correct alignment and tension; adjust if necessary. 5. Rotate compressor manually by rotating the fly wheel few full turns to achieve pre lubrication and to ensure that it is rotating smoothly. 5.1. START-UP PROCEDURE

1. Disconnect the inlet manifold pipe and all inlet pipes to all three compression cylinders for initial startup 2. By activating the solenoid valve purge the pulsation tank of air until gas is adequately present. (Caution must be taken during this procedure to have adequate ventilation and ensure that there are no ignition sources for at least 10 meters. 3. Disconnect the oil lubricator pipe from all cylinders and pump each lubricator pump by hand until the oil appears at the discharge end of each pipe. Reconnect the pipes and continue pumping for another twenty full strokes. 4. Check that the final discharge valve is open and that the pipe is free from obstruction. 5. Start/Stop the compressor until discharge gas noise is heard and check the direction of the rotation. Rotation should be such that the water pumps are rotating correctly. 6. Replace the inlet pipe to the first stage. Check that all pipe connections are securely tightened. 7. Check that all pressure switch settings are as recommended in the manual.

20

HYPERCOMP (PVT) LTD.

HC-OMM-01 Version 00

8. Start the compressor and allow it to run for no longer than 30 seconds during which time oil pressure should be checked to ensure that it has risen and that gas has flowed through the first stage in sufficient quantity and to ensure that any foreign matter has been blown clear. 9. Replace the inlet pipe to the second stage and repeat to clear any foreign matter. Continue in this manner until all piping is back in position and securely tightened. The compressor is now ready for final startup. 10.Having done an initial startup satisfactorily, restart the compressor and observe the interstage pressures are as recommended in the operating settings. 11.Check that the receiving vessels to be filled have their valves open. 5.2. NOTES OF CAUTION

1. The discharge pipes from each stage should not be touched during running as a painful burn can result. 2. Ensure that the cooling system has had sufficient anti-freeze added to the coolant for the climatic conditions that prevail. 3. A shut-off valve is installed in the high pressure discharge line; the operator should make certain that this valve is open before starting the compressor. In addition, a relief valve is also included in the line between compressor and the shut-off valve. 4. Do not allow the motor to rotate in the wrong direction for more than a few seconds. If incorrect rewire immediately. 5. For the first start (or after any maintenance repairs have been performed), make sure adjustments are made if bearing run hot or if the drive belts do not run true on their respective pulleys. Observe and obey all safety precautions. 6. The compressor controller gauges should read as indicated in the table of operation controls and indicators after the discharge pressure reaches 3600 psi. 7. Safety valves have been set at the factory to relieve at the proper pressure. Do not change or alter these settings.

21

HYPERCOMP (PVT) LTD.

HC-OMM-01 Version 00

6. OPERATING INSTRUCTIONS

The commissioning procedures described in the previous sections should be followed for the first time commissioning operation, after a compressor overhaul or after the compressor has been idle for long periods (over 4 weeks) The compressor and its surrounding area should be kept clean at all times. The exterior of the compressor, especially pipes connections and joints should be kept clean. If oil film and condensate is wiped clean regularly, any leaks that occur will be more readily identified. It is good to monitor and record the interstage gas pressures, temperatures, currents, hour meter reading, etc. This information is as per sample Daily log sheet attached. This information gives a good indication of machine operation and can give advanced warning of malfunction. The readings vary with ambient temperature and final discharge pressure but are usually within 5%. A useful visual indication can be obtained if the gauge glass is marked at the normal readings. 6.1. SAFETY PRECAUTIONS

1. Read all starting & operating instructions before running compressor. 2. Do not work over compressor without ensuring that all equipment is isolated from the electrical supply and will remain isolated whilst work is in progress. 3. Always open high pressure gas line valves slowly. 4. Never attempt to stop leakage or tighten joints or loose parts when compressor is running and parts are under pressure 5. Never operate the compressor with a malfunction in the oil or cooling water system. Should a fault develop in either of these, the compressor must be stopped immediately and the fault investigated and remedied.

22

HYPERCOMP (PVT) LTD.

HC-OMM-01 Version 00

6.2.

START-UP PROCEDURE

1. Before starting the compressor, the operator should be familiar with the type of controls and all the safety devices fitted to the compressor. 2. Check oil level in crankcase and top up if necessary using recommended oil until level in sight glass is on maximum. 3. Check water level in sight glass and top up if necessary. 4. Check Vee-belts are in good condition and correctly tensioned. 5. Check main isolator switch is ON, the Emergency Stop button is unlatched and fault circuits are Reset. 6.3. RUNNING ON LOAD

1. Press Start button. 2. If the storage cascade pressure is below the Re start set point of switch gauge, the compressor motor will start up immediately on STAR and then change over to DELTA after the time set time delay of approx. 5-8 seconds (Note: Motor will not start if any of the overload circuits i.e. compressor motor current overload, thermistor (for Ex motors), phase failure relay, cooling tower fan motor overload, water pump motor overload OR temperature fault circuits are activated). 3. Immediately after the starter contactors change over to DELTA, the gas inlet solenoid will be activated. However, at this stage the unload valve is still de-energized and will not allow the compressor to build up to its full operating pressures. 4. The timer T1 set at approx. 20 seconds (Condensate blowdown) and timer T4 set at approx. 30 seconds (oil safety By pass) are activated when the Start button is pushed. 5. The timer3 is set at approx. 20 seconds (Safety bypass) is activated after the compressor comes on Load. 6. Hence after a lapse of 20 seconds from the time the Start button was pushed, the compressor goes on Load. The indicator light on the electric control panel will also show this condition. 7. After a lapse of 40 seconds from the time the Start button was pushed, the compressor gets into normal on load operation ensuring that all safety circuits are working correctly.

23

HYPERCOMP (PVT) LTD.

HC-OMM-01 Version 00

8. The compressor is fitted with an automatically fitted unloader to mechanically remove any oil and condensate from the compressor. This is controlled by timer T2 set at 30 minutes and timer T1 set at 20 seconds. The operation of the unloader is such that it will operate whenever the compressor is shut down, during start-up, and after every 30 minutes of continuous compressor operation for a period of 20 seconds. 9. The compressor will continue to operate until the final stage gas pressure reaches the set point for automatic shut down e.g. 250 bars. On reaching this set point, the compressor motor will be deenergized and the unloader will be energized to bleed gas from all the cylinders back to the Blow down Recovery vessel. This means that the compressor is ready and waiting for a signal to restart automatically as soon as the gas storage pressure falls to the set point. 10.As gas is used from the storage cascade and the final stage gas pressure reduces to the set point; e.g. 205 bars, then the compressor will automatically restart. It will now go through the same sequence as in steps 2-9 above. 11.During normal operation, the compressor can also, be stopped by pressing Stop button or the Emergency Stop Button on electric Control Panel OR the Emergency Stop Button fitted on the side or front of gauge panel. 6.4. SAFETY CIRCUITS

The compressor operating conditions that are monitored under which the compressor will be shut down on a Fault are as follows: 1. Low gas inlet pressure 2. High gas inlet pressure 3. Low oil pressure 4. 3rd stage high gas discharge temperature after cooler 5. Water flow failure 6. Electric motor current overload (overload indication) 7. Electric motor thermistor (Overload indication) 8. Cooling tower fan motor overload (overload indication) 9. Water pump motor overload (overload indication) if fitted 10.Phase failure (overload indication)

24

HYPERCOMP (PVT) LTD.

HC-OMM-01 Version 00

11.Low oil level (optional) 12.High vibration (optional) 13.Gas leak detector (optional) 6.5. INSTRUMENTS & INDICATORS

The electric control panel has the following indicator lights 1. 2. 3. 4. 5. 6. 7. Low/High gas inlet pressure Low oil pressure Discharge gas temperature Overload Ready On load Water flow switch

The Electric control panel has the following switches 1. 2. 3. 4. 5. Reset push button stoop push button Start push button Emergency stop (latch-in-type) Load break isolating switch (with door interlock)

The Electric control panel has the following instruments 1. Voltmeter 2. Ammeter 3. Hours Run The Gauge panel is fitted with the following 1. 2. 3. 4. 5. 6. Oil pressure switch gauge Low/High gas inlet pressure switch gauge 1st stage gas discharge pressure 2nd stage gas discharge pressure 3rd stage gas discharge pressure Stop-Start switch gauge 3rd stage gas temperature after cooler switch gauge

25

HYPERCOMP (PVT) LTD.

HC-OMM-01 Version 00

The compressor is fitted with the following 1. Oil level sight glass 2. Water level sight glass (only in close circuit system) 6.6. LUBRICATION

The plunger type oil pump with internal by pass relief valve is fitted on front of the compressor. It draws oil from crankcase through strainer through a check valve via full flow replaceable filter and passes through the oil pump plunger to the oil pressure chamber. From this point the oil is under pressure and is fed through the drilled passages in the crankshaft to the connecting rods and main bearings. The cross head pistons and cylinders are splash lubricated by throw-off from the connecting rod bearings. Non-adjustable pressure relief valve that bypass excess oil to the crankcase sump. The relief valve also serves as a pulsation eliminator for oil pressure peaks. The lubrication circuit is shown on the attached P&I diagram. An oil pressure switch gauge is fitted as standard which indicates the oil pressure in the system as well as provides a safety on low oil pressure. 6.7. SAFETY SHUT DOWN

An oil level sight glass allows for easy inspection of oil level in the crankcase. An option is available to add a low oil level shut down safety switch to monitor the oil level in the compressor crankcase. 6.8. OIL QUALITY

1. Oil should be of uniform viscosity, non-detergent and super refined with rust and oxidation inhibitors. Oil should be of naphthenic base of a specially compounded type to minimize carbon formation and to produce carbon residue of a soft and fluffy nature. Oils having animal fat compounding are not recommended.

26

HYPERCOMP (PVT) LTD.

HC-OMM-01 Version 00

2. Use the following weight oils for the ambient temperature ranges as indicated below is recommended: a. Above 60 F : SAE 30 b. 32 to 60 F : SAE 20 c. Below 32 F : SAE 10W 3. Viscosity according to ISO Classification ISO VG 100 i.e. 90-100 cst (mm2/s) at 40 C (Resp. 55-70 cst or 7-9 deg E at 50 C) 4. Viscosity index: min. 80 5. Flash point: min. 200 C 6. Stock point: max. 12 C resp. pour point: max 9 C To achieve good water separation properties, the oil should not, or to a light degree only, contain dispersant additives. 6.8.1.

BP CALTEX CASTROL ESSO GULF Mobil Shell Texaco Valvoline

LIST OF SUPPLIERS WITH SUITABLE OIL QUALITIES

Energol RC 100 (ISO) RPM Compressor Oil 100 Aircol PD 100 Compressor oil S 100 Compressor oil 100 Rarus 429 Corena H 100 or or or or or or or or or TH-100 HB (ISO) Regal Oil R+0 100 Perfecto T100 Nuto 100 Harmony 100 DTE 103 Turbo oil T100 Regal oil100(R+O) R-506 TOS

Compressor oil VD-L 100 compressor oil 62

6.9.

COOLING

Satisfactory compressor operation depends on effective cooling which requires positive circulation of cool, clean water, free from suspended particles. The compressor is water cooled through centrifugal pump which is driven off compressor crankshaft pulley and cooling tower installed in the safe

27

HYPERCOMP (PVT) LTD.

HC-OMM-01 Version 00

zone. A closed type circuit is also recommended where cooling water purity and quality is difficult to achieve. However, it should be done with factory consultation.

28

HYPERCOMP (PVT) LTD.

HC-OMM-01 Version 00

Operational Parameters

Parameters *Normal Working Pressure (Psig) Maximum Working Pressure (Psig) Normal Inlet Working Temperature (C) Maximum Working Inlet Temperature (C) Normal Outlet Working Temperature (C) Maximum Working Outlet Temperature (C) Power Requirement = Motor Installed = 184 881 4530 Stage 1 Stage 2 Stage 3

147

705

3625

40

35

35

50

50

50

140

120

160

200

200

200

68 KW 75KW

Note: * All Working Pressures and Temperatures are within 5% Tolerance.

29

HYPERCOMP (PVT) LTD.

HC-OMM-01 Version 00

7. FAULT GUIDE

S. No. Symptoms Fault Insufficient oil in crankcase Relief valve spring broken Relief valve held open with dirt Oil pump ball valves held open with foreign matter Faulty oil pressure gauge Restriction in inlet line Blocked inlet filter line Insufficient gas supply Faulty inlet pressure gauge 3 4 5 High inlet pressure High 1st stage pressure High 2nd stage pressure Supply regulator failure Faulty gasket on 2nd stage inlet valve Faulty 2nd stage inlet valve Faulty 3rd stage inlet valve OR gasket 1st stage valves leaking or faulty Compressor capacity down with low 1st stage pressure 1st stage unloader valve diaphragm leak Replace diaphragm Recommendations Fill crankcase to oil level Replace spring Disassemble & clean Disassemble & clean Replace gauge Remove restriction Replace filter Contact gas supply authority Replace inlet pressure gauge Contact gas supply authority Check gasket for signs of leakage and replace Repair/ replace valve Repair/ replace valve Repair/ replace 1st stage valves after checking. Can be inlet or discharge valve

Oil pressure is incorrect

Low inlet pressure

30

HYPERCOMP (PVT) LTD.

HC-OMM-01 Version 00

S. No.

Symptoms Compressor capacity down, with normal inter stage pressure ( but very hot blow by on 3rd stage Capacity down with low 2nd stage pressure ( but very hot blow by on 2nd stage

Fault

Recommendations

Final stage rings worn excessively

Replace final stage rings

2nd stage rings worn excessively Damaged pressure gauges Damaged discharge valve of the forgoing stage or 1st stage High leakage rate across the piston rings back to forgoing stage and very hot blow by pipes Low suction pressure Closed or clogged shut off device in discharge piping of compressor Stage pressure too high Damaged seat of safety valve or wrong setting Faulty high pressure switch gauge

Replace 2nd stage rings

Replace gauge Repair/ replace valve

Intermediate pressure too low

Check and replace piston rings Contact gas supply authority Locate & repair Check gaskets and valves , also for high inlet pressure Check & replace

10

Safety valve blow off

Check electric & snubbers

31

HYPERCOMP (PVT) LTD.

HC-OMM-01 Version 00

S. No.

Symptoms

Fault

Recommendations

Too high ambient temperature Compressor temperature too high Insufficient intermediate cooling (damaged fan, wrong flow direction of cooling air, fouled cooler) Damaged suction & discharge valves Damaged part inside compressor (seizure of piston, corroded cylinder) Several oil leaks Wiper seals are worn Oil level too high in Crankcase Damaged gaskets or crankcase seals Clogged venting device causing too high pressure in crankcase Worn piston rod seals causing over pressure Damaged bearings Insufficient lubrication Too much axial clearance of crankshaft Contamination in bearings

Increase air flow

11

Correct or repair Repair/ replace valves

Replace seals

12

Oil consumption too high

Lower oil & gain level Replace Check crankcase relief valve Check & replace Check & replace Check & replace oil level Check clearances as per chart Check & replace, also replace oil filter Check fly wheel and key retighten 1360 NM ( 1000 Ft-lb)

13

Oil leakage from crankcase

Noisy or hot crankcase 14

Loose fly wheel

32

HYPERCOMP (PVT) LTD.

HC-OMM-01 Version 00

Too much clearance in the bearings of crankshaft, crankpin, piston pin 15 Compressor knocks ( stop immediately) Broken valve parts or foreign particles in cylinder Piston clearance wrong

Investigate & repair Identify foreign particles and replace clean affected parts Identify which piston increase clearance as specified

33

HYPERCOMP (PVT) LTD.

HC-OMM-01 Version 00

8. SERVICING/ MAINTENANCE INSTRUCTIONS

8.1. GENERAL

Regular inspections along with proper corrections of any fault found will prolong the useful life of your compressor. A regular inspection and service schedule is outlined in the following paragraph. Please bear in mind that this schedule is flexible and depending on the type of service, location, weather condition etc. It may be changed to suit individual conditions. 8.2. DAILY INSPECTION AND MAINTENANCE

It is useful to record stage pressures, temperatures, oil used in a log against hours run, as this builds up a detailed record of machine condition. It can also provide a trend and indication of a possible problem. 1. Before starting OR while machine is idle & unloaded check oil level. Fill to full mark, if oil level is low. Oil level must be kept between high and low level marks on sight glass. 2. Drain condensate from blowdown manifold by opening drain cock. 3. Check water levels and refill if necessary. Warning Compressed gas is very dangerous. It must be treated with respect and handled with care. The utmost caution should be observed when opening any valve after the gas has been compressed. Make certain that no person or object, that could be moved or damaged, located in the path of the compressed gas discharge from valve. This gas travels at an extremely high velocity and should be considered as dangerous as a gun.

Never play with compressed gas! never point a Gas hose at ! someone ! Never treat compressed Gas lightly.

34

HYPERCOMP (PVT) LTD.

HC-OMM-01 Version 00

Start compressor, and record in your daily log book the following 1. 2. 3. 4. 5. 6. Oil pressure and amount used. Interstage gas pressures. Inlet gas pressure. Water temperature. Gas Company Meter Readings. Any Problem or fault on compressor. 50 HOUR RUN IN MAINTENANCE

8.3. 1. 2. 3. 4. 5. 6. 7. 8. 9.

Check interstage pressures. Retighten V-Belts Check for leaks. Check cylinder head bolts and re torque. Check compressor mounting bolts & motor mounting bolts. Check water temperature. Check interstage cooler discharge pipes. Check cooling water level. Change the crankcase oil and oil filter while the compressor is still warm. 3 MONTHLY OR 2000 HOUR INSPECTION AND MAINTENANCE

8.4.

1. Repeat all DAILY inspection and maintenance procedures as above. 2. While compressor is warm, drain and replace crankcase oil. Remove side cover from crankcase, inspect and clean the strainer screen. Remove and replace the oil filter cartridge. 3. Check and make certain that all gas connection are tight and secure. 4. Check vee belts on drive and water pump for tension and condition. 8.5. 4500 HOUR INSPECTION AND MAINTENANCE

1. Repeat all three monthly inspections and maintenance procedures.

35

HYPERCOMP (PVT) LTD.

HC-OMM-01 Version 00

2. Remove, clean and inspect all compressor intake and discharge valves. Repair or replace as necessary. 3. Check crankcase venting and distance piece for seal condition. 4. Check discharge capacity. 8.6. 9000 HOUR INSPECTION AND MAINTENANCE

1. Repeat all 4500 hours inspection. 2. Remove and recalibrate all pressure and temperature gauges, replace if necessary. 3. Check function of safety valves and recalibrate them. 8.7. GENERAL DAILY INSPECTION What to Inspect for Note dripping water, dust, chips or dirt On or about the compressor. See if any boards, canvas, paper or any foreign objects are left about that might jam any moving part or may interfere with proper ventilation. Motor or bearing block distress will often show up in unusual noises caused by abnormal metal to metal contact or odors from overheated insulation or grease. Feel bearing housings or pillow blocks for evidence or excessive heat.

What to Inspect Surroundings

Technical Conditions

Bearings

Warning Shut down compressor prior to checking for heat. 8.8. DRIVE BELT TENSION AND ALLIGNMENT

Checking parallel shaft alignment and axial groove alignment may be done simultaneously. To obtain accurate alignment, a straight edge should be used for this measurement, or when a straight edge is not available, a

36

HYPERCOMP (PVT) LTD.

HC-OMM-01 Version 00

taut line may be substituted. Perfect alignment proves to be impossible, a rough rule of thumb to determine permissible limit of misalignment is 0.4mm (1/54) out of line for each 300mm (12) between shaft centers. If drive belts are too loose, there will be slippage and rapid wear of belts. Slippage is usually indicated by a squealing or howling noise. Always refer to belt manufacturers catalogue for proper tension to be applied. Adjust tension by moving motor in direction necessary to increase or decrease tension. Tighten flywheel nut to 1356 Nm (1000 lbs ft) torque. Shaft must be in angular and parallel alignment and sheave grooves axially aligned to obtain proper performance of V-belt drives. Angular alignment is obtained by leveling shafts. 8.9. BASIC STEPS FOR V-BELT INTALLATION

1. Reduce centers so belt can be slipped on sheaves

2. 3. 4. 5. Have all belts slack on same side Tighten belts to eliminate slack Start unit and allow belts to seat in grooves Stop the unit then retighten to make sure belts have proper tension. 6. Recheck tension in 24 to 48 hours.

37

HYPERCOMP (PVT) LTD.

HC-OMM-01 Version 00

38

HYPERCOMP (PVT) LTD.

HC-OMM-01 Version 00

9. REPAIR AND REPLACEMENT

9.1. MAINTENANCE AND REPAIR PRECAUTIONS

1. Maintenance and repair may be carried out only on the shutdown and entirely vented compressor unit. If necessary, empty the receivers and coolers. First, the main switch in the switchboard of the unit has to be set to the OFF position. Erroneous switching on of the unit should be prevented by locking the main switch or by providing a corresponding instruction label. 2. Before starting the work, be sure by opening all manual drain valves, that the compressor is entirely pressure-less. 3. After modification or repair work on pressure vessels and safety equipment, all work must be tested and accepted by the inspection authority concerned. 4. Only use original spare parts and recommended products for maintenance and repair works on the compressor unit. 5. Never do work connected with heat production like welding near oil or gas systems. Before working on oil or gas tanks empty them and clean them carefully, e.g. by a steam jet or purge with nitrogen. 6. During maintenance and repair work observe strict cleanliness. Keep impurities away, by covering dismounted parts and free opening with a clean rag, paper or adhesive tape. 7. After having finished the works be sure that no tools, loose parts or cleaning rags have been left on or in the compressor unit. 8. Do not use easily flammable solving agents for cleaning of parts, until the unit has cooled thoroughly. After the use of solving agents carefully rinse the parts and clean them with compressed air. 9. Be very careful, use eye protection, when working with compressed air for cleaning equipment. 10.The manufacturer takes no responsibility for personal injury or damage on the unit, caused by the non-observance of the safety precautions during handling, operation, maintenance or repair of compressor units. 11.After modification or repair work to compressor and before power is applied to machine, always manually turn compressor over by hand using flywheel to ensure compressors running free.

39

HYPERCOMP (PVT) LTD.

HC-OMM-01 Version 00

9.2.

1ST STAGE SUCTION VALVE REMOVAL

9.2.1. 1. 2. 3. 4. 5. 6.

Remove 3x bolts on suction valve cover. Lift off valve cover. Remove and discard cover O ring. Remove lantern Remove valve from its seat. Remove metal gasket from seat in head and discard. 9.2.2. INSTALLATION

1. Carefully wipe any loose carbon from valve seat/ pocket ensuring that no carbon is left in the pocket or on top of the piston. 2. Apply thin smear of grease on valve gasket and place its position. 3. Rotate the valve back & forth to ensure proper seating. 4. Place lantern in valve pocket and rotate to check seating. 5. Place the cover and bolts in right position and gradually apply torque evenly to final torque value of 48 ft.lb 9.3. 1ST STAGE DELIVERY VALVE REMOVAL

9.3.1. 1 2 3 4 5 6

Remove 3x bolts on delivery valve cover. Lift off valve cover. Remove and discard cover O ring. Remove lantern Remove valve from its seat. Remove metal gasket from seat in head and discard. 9.3.2. INSTALLATION

1. Carefully wipe any loose carbon from valve seat/ pocket ensuring that no carbon is left in the pocket or on top of the piston. 2. Apply thin smear of grease on valve gasket and place its position. 3. Rotate the valve back & forth to ensure proper seating.

40

HYPERCOMP (PVT) LTD.

HC-OMM-01 Version 00

4. Place lantern in valve pocket and rotate to check seating. 5. Place the cover and bolts in right position and gradually apply torque evenly to final torque value of 48 ft.lb 9.4. 1ST STAGE HEAD REMOVAL

9.4.1. 1. 2. 3. 4. 5. 6.

Remove lubricator piping. Remove suction tank discharge tanks and piping. Remove gaskets and discard. Remove 04 bolts (90 degree apart) around head. Lift the head carefully. Remove the head to cylinder gasket and discard. 9.4.2. INSTALLATION

1. Place the new head to cylinder gasket with liberal amount of grease on both sides. 2. Place the head in right position. 3. Install the 04 bolts & torque them as per torque chart 2.37Nm/175Lb.Ft. 4. Install suction & discharge tanks with new gaskets greased on both sides. 5. Replace lubricator piping. 9.5. 2ND STAGE VALVE AND HEAD REMOVAL

9.5.1.

1. Remove lubricator piping from head. 2. Remove unloader piping from pulsation damper/ condensate collector on the suction side of the stage. 3. Remove 1st stage heat exchanger to 2nd stage head piping. 4. Check integrity of O ring at head end and replace as necessary. 5. Remove 2nd stage head to 2nd stage heat exchanger piping. 6. Check integrity of O ring at head end and replace as necessary. 7. Evenly loose head bolts and remove head. 8. Remove head to valve gaskets (Inner & Outer) and discard.

41

HYPERCOMP (PVT) LTD.

HC-OMM-01 Version 00

9. Remove valve. 10.Remove valve to cylinder gasket and discard. 9.5.2. INSTALLATION

1. Ensure all surfaces on cylinder and head are clean and free of imperfections. 2. Apply a thin smear of grease on the valve/cylinder gasket and place it in position. 3. Place piston on top dead center. 4. Check head clearance as per clearance chart. 5. Place valve in position and rotate back & forth to ensure correct seating. 6. Apply a thin smear of gasket cement to the cylinder side of the inner gasket and place in position on the valve. 7. Apply a thin smear of grease to the valve /head gasket and place in position in the head. 8. Carefully place head in position on the valve-beware of sudden movements that may disturb the inner gasket. 9. Apply anti-seize to head bolts, position and hand tighten. 10.Evenly apply gradual torque until the required torque as per torque chart. 11.Replace 2nd stage head/2nd stage heat exchanger piping. 12.Replace 1st stage heat exchanger/2nd stage head piping. 13.Replace suction tank piping. 14.Operate lubricator pump to expel all air from the lubricator piping. 15.Replace lubricator pipe. 16.Re-torque head bolts to original torque after 24 hours running. 9.6. 3RD STAGE VALVE AND HEAD REMOVAL

9.6.1.

1. Remove lubricator piping from head. 2. Remove un-loader piping from pulsation damper/condensate collector on the suction side of the stage. 3. Remove 2nd stage heat exchanger to 3rd stage head piping. 4. Check the integrity of O ring and replace as necessary.

42

HYPERCOMP (PVT) LTD.

HC-OMM-01 Version 00

5. 6. 7. 8. 9.

Remove 3rd stage head to 3rd stage heat exchanger piping. Check the O ring condition and replace if required. Evenly loosen head bolts and remove head. Remove head to valve gasket and step ring and discard. Remove valve to cylinder gasket and discard. 9.6.2. INSTALLATION

1. Ensure all surfaces on cylinder and head are clean and free of imperfections. 2. Apply a thin smear of grease on the valve/cylinder gasket and place it in position. 3. Place piston on top dead center. 4. Check head clearance as per clearance chart. 5. Place valve in position and rotate back & forth to ensure correct seating. 6. Apply a thin smear of grease to step ring, place in position, and rotate to ensure correct seating. 7. Apply a thin smear of grease to the valve /head gasket and place in position in the head. 8. Carefully place head in position on the valve-beware of sudden movements that may disturb the inner gasket. 9. Apply antiseize to head bolts, position and hand tighten. 10.Evenly apply gradual torque until the required torque as per torque chart. 11.Install lubricator piping (bleeding as required). 12.Install 3rd stage head to 3rd stage HEAT EXCHANGER piping. 13.Install 3rd stage head to 2nd stage HEAT EXCHANGER piping. 14.Retorque head bolts to original torque after 24 hours running. 9.7. COMPRESSION CYLINDER REMOVAL FOR 1ST, 2ND & 3RD STAGE

9.7.1.

1. Drain water from machine 2. Remove head as per section 9.4.1 for 1st, 9.5.1 for 2nd and 9.6.1 for 3rd stage. 3. Remove water piping from cylinders.

43

HYPERCOMP (PVT) LTD.

HC-OMM-01 Version 00

4. Rotate compressor to bring the piston on top dead center. 5. Unscrew piston locking nut. 6. Unscrew piston from piston rod, keeping rings in order of original assembly for inspection purpose. 7. Remove piston from cylinder. 8. Rotate compressor to bring piston rod at bottom dead center. 9. Equally loosen and remove cylinder nuts. 10.Carefully remove cylinder by lifting over rod, the threads on the rod can damage the cylinder bore if contact is made. 11.Remove and check the integrity of the cylinder to seal carrier O ring. 9.7.2. COMPRESSION CYLINDER INSPECTION

The compressor cylinders are precision honed for standard size pistons only. Inspect the cylinder bore closely. If a cylinder is out of round, worn, or deeply scratched, it must be replaced with a new one or the sleeve pressed out and a new sleeve fitted. The new sleeve should be honed to .4 microns to the diameter specified. A worn cylinder is indicated by visible ridging at the end of the ring travel, while an out of round cylinder can be determined as follows: Take micrometer reading at various positions along the length of bore of the cylinder. 9.7.3. INSTALLATION FOR COMPRESSION CYLINDER 1ST, 2ND & 3RD STAGE

1. Check the O ring on the seal carrier plate. 2. Apply smear of grease to seal carrier and underside of cylinder base. 3. Place piston rod at bottom dead center. 4. Place cylinder over rod and into position on seal carrier. 5. Place in position and torque to required torque guide cylinder/cylinder nuts. 6. Place piston rod at top dead center. 7. Apply a liberal amount of crankcase oil to cylinder bore.

44

HYPERCOMP (PVT) LTD.

HC-OMM-01 Version 00

8. Place piston and fittings in position on rod and screw in position, placing rings in position as piston enters bore. Remember stamped numbers on rings are placed towards pressure. 9. Install piston washer and nut and torque to required torqueusing special tools as required. 10.Install heads as per 9.4.2 for 1st stage, 9.5.2 for 2nd stage and 9.6.2 for 3rd stage. 9.8. ROD SEAL CARRIER REMOVAL

9.8.1.

1. Remove head as per 9.4.1 for 1st stage, 9.5.1 for 2nd and 9.6.1 for 3rd stage. 2. Remove cylinder as per 9.1.1. 3. Remove seal vent piping if present. 4. Place seal protector tool on piston rod threads. 5. Lift seal carrier from guide cylinder top and carefully remove by lifting seal carrier up the rod and over the seal protector. 6. Check the integrity of seal carrier to guide cylinder O ring seal and replace as necessary. 7. Remove cap screws from seal block flange. 8. Remove seal pack from seal carrier plate. 9. Remove nuts from seal pack studs. 10.Remove breakdown assembly, then oil rod seals, rod seals, O rings etc. 11.Note position of seals for inspection purpose. 12.Check the integrity of seals and O rings, replace as necessary. 13.Assemble seal pack. 14.Install seal pack into seal carrier plate. 9.8.2. INSTALLATION

1. Assemble seal pack and install into seal carrier. 2. Place rod thread protector in position and well oil with crankcase oil. 3. Ensure O ring in position in underside of seal carrier.

45

HYPERCOMP (PVT) LTD.

HC-OMM-01 Version 00

4. Carefully place seal carrier assembly over thread protector on to the guide cylinder in right position. 5. Install compression cylinder per 9.7.3. 6. Install head per 9.4.2, 9.5.2 and 9.6.2. 9.9. GUIDE CYLINDER FOR 1st, 2nd & 3rd STAGE REMOVAL

9.9.1.

1. Remove head as per 9.4.1 for 1st, 9.5.1 for 2nd and 9.6.1 for 3rd stage. 2. Remove cylinder as per 9.7.1. 3. Remove seal carrier as per 9.8.1. 4. Loosen guide cylinder/crankcase stud nuts, bolts and remove them. 5. Carefully lift crosshead cylinder from crankcase. 9.9.2. INSTALLATION

1. Place new guide cylinder/crankcase gasket at the lower end of the guide cylinder or on the crankcase at position where cylinder is to be installed with smear of grease on both sides. 2. Install the cylinder over the piston and into place. Tighten down cylinder with cap screws and nuts. 3. Turn the crankshaft slowly until the piston in the reinstalled cylinder reaches top dead center. 4. Tighten bolts and nuts securing the cylinder to 192Nm. Note: During this stage of assembly, adequate lubrication must be provided to reduce the chance of scuffing the cylinder walls. Use clean compressor oil and cover the inside walls of the cylinder and dip the piston in the clean oil so that both components are thoroughly lubricated.

46

HYPERCOMP (PVT) LTD.

HC-OMM-01 Version 00

9.10. PISTON / PISTON RINGS FOR 1st, 2nd & 3rd STAGE 9.10.1. 1. 2. 3. 4. REMOVAL

Remove head as per 9.4.1, 9.5.1 and 9.6.1. Place piston to be removed at top dead center. Unscrew piston locking nut and discard. Unscrew piston carefully from piston rod. Use special tolls as required. 5. As piston exits the cylinder, remove rings and note order and position of rings. 6. Remove piston spacer. INSTALLATION

9.10.2. 1. 2. 3. 4.

5. 6. 7. 8.

Ensure all surfaces are clean and free of imperfections. Place piston rod at top dead center. Place piston spacer on piston rod. Place piston in cylinder bore and screw in position- position rings as piston enters bore-note that any characters stamped on ring face cylinder pressure. Torque piston onto rod. Place piston washer in position, install piston nut and torque nut to required torque. Place piston to top dead center and check head clearance is within limits. Install head as per 9.4.2, 9.5.2 and 9.6.2.

9.11. PISTON ROD 9.11.1. 1. 2. 3. 4. 5. 6. REMOVAL

Remove head as per 9.4.1, 9.5.1 and 9.6.1. Remove cylinder as per 9.7.1. Remove seal carrier per 9.8.1. Remover guide cylinder cover plates. Loosen cap screws in crosshead piston. Unscrew rod from crosshead piston.

47

HYPERCOMP (PVT) LTD.

HC-OMM-01 Version 00

9.11.2. 1. 2. 3. 4.

INSTALLATION

Screw rod into crosshead piston. Install seal carrier per 9.8.2. Install compression cylinder per 9.7.3. Adjust head clearance by screwing rod into crosshead piston thread. 5. Torque up cap screws in crosshead piston. 6. Replace crosshead cylinder cover plates. 7. Replace seal carrier plate as per 9.8.2. 8. Replace cylinder as per 9.7.3. 9. Replace pistons as per 9.10.2. 10.Replace heads as per 9.4.2, 9.5.2 and 9.6.2.

9.12. GUIDE PISTON 9.12.1. REMOVAL

1. Remove head per 9.4.1, 9.5.1 and 9.6.1. 2. Remove cylinder per 9.7.1. 3. Remove seal carrier per 9.8.1. 4. Remove guide cylinder per 9.9.1. 5. Rotate crankshaft until the entire crosshead piston is exposed. 6. Tip piston to expose clamp screw. 7. Straighten lock washer tab. 8. Remove clamp screws and discard. 9. Remove tab washer and discard. 10.Push gudgeon pins out of bearings. 9.12.2. INSTALLATION

1. Check guide cylinder/guide piston clearance by placing piston in bore and using feeler gauge. 2. Place piston with installed bearings over small end of conrod and push gudgeon pin in position.

48

HYPERCOMP (PVT) LTD.

HC-OMM-01 Version 00

3. Place tab washer in position on bolt, position bolt rotating gudgeon pin to align slot in gudgeon as required. 4. Torque bolt to required torque. 5. Bend lock washer tabs over bolt flats to lock in position. 6. Install guide cylinder per 9.9.2. 7. Install seal carrier per 9.8.2. 8. Install compression cylinder per 9.7.3. 9. Install head per 9.4.2, 9.5.2 and 9.6.2. 9.13. CONNECTING ROD BEARINGS REPLACEMENT / REINSTALLATION 1. Drain the oil from crankcase. 2. Remove piping, tubing, cylinder head and cylinder. 3. Remove the crankcase hand hole cover on side opposite the oil level indicator by removing the eight cap screws and washers. 4. Remove guide piston per 9.12.1. 5. Remove screws and nuts holding connecting rod to crankshaft. 6. Remove cap and insert type bearings from connecting rod. 7. Install new inserts in connecting rod and reassemble rod. 8. Use a micrometer and take several readings of the bearing and crankpin diameter bearing at various points to determine the existing clearance. The use of perfect circle Plasti gauge is also recommended for measuring bearing clearance. 9. Disassemble conrod and lubricate. With proper inserts in place, reinstall rod onto crankshaft. Connect guide piston to rod, replace guide cylinder, seal plates, compression cylinder, cylinder head and piping. Note: Each connecting rod and cap is identified with a stamped number. Make sure the same rod and cap is reassembled on the same side. Under size bearings in sizes of 0.010 0.20 and 0.030 are available when the crankpins are ground to match. Shims are not used and are not available so that adjustment for wear is obtained only by the use of bearing inserts.

49

HYPERCOMP (PVT) LTD.

HC-OMM-01 Version 00

9.14. OIL PUMP 9.14.1. GENERAL

It is important to understand the operation of the pump and its relation to the lubrication system of the compressor. Lubricating oil pressure is provided by a plunger type oil pump driven off the crankshaft. Oil is drawn through a screen, located in the crankcase sump, through a check valve and to the pump. From this point lubrication is under pressure and is carried through drilled passages in the crankshaft to the connecting rod and main bearings. Guide cylinders and pistons are splash lubricated by throw-off from the connecting rod bearings. 9.14.2. CAUTION

Make-up oil may not be added to the crankcase while compressor is operating. A heavy oil mist will be blown out of the oil filler tube if the filler cap is opened while the compressor is operating. This is normal and should not e interpreted as blow-by. There is a small flapper type relief valve assembled in the filler tube cap, which is spring loaded towards the crankcase caused by the reciprocating motion of the pistons and crankcase. This valve in the cap allows gas pressure to escape from the crankcase and prevents air at atmospheric pressure from entering and maintains a partial vacuum during operation. 9.14.3. 1. 2. 3. 4. OIL PUMP REMOVAL

Remove water pump/lube drive pulley. Remove oil connection from oil filter assembly. Screw nuts down on dowel pins and remove tapered dowel pins. Remove pump body attaching bolts/nuts. Remove oil pump body. 5. Remove plunger and connecting rod assembly. 6. Remove check valve assembly.

50

HYPERCOMP (PVT) LTD.

HC-OMM-01 Version 00

9.14.4.

OIL PUMP INSTALLATION

1. Dip plunger in clean crankcase oil and insert into pump body. Be sure fulcrum pin does not extend beyond diameter of plunger. 2. Install the oil seal (lip facing inward) into pump body. Seal must be flush with outside of body so oil return passage will not be obstructed. 3. Re-install pump body to retainer. Exercise care with connecting rod and seal. 4. Shellac gasket to chamfered end of sleeve. Slip gasket side (toward compressor) over crankshaft and through oil seal. 5. Assemble cap screws finger tight. 6. Install dowel pins and tighten cap screws. 7. Install water drive pulley, washer and nut, if so equipped. Tighten nut securely and bend washer tabs on hex nut. Install lube pump pulley. 8. Reinstall oil connections to oil filter assembly. 9. Install water pump and lubricator belt and adjust. 9.15. CRANKSHAFT 9.15.1. GENERAL The compressor crankcase is cast in one piece and is closely machined to carry the crankshaft and cylinders. Tapered roller bearing outer race are a tap fit in the crankcase bore at the pulley (drive) end, and a press fit in the retainer located at the opposite end of the crankcase. Bearing caps at outer race are installed in the crankcase and retainer with the bearing surfaces facing the center of the crankcase. Metal shims are placed behind the bearing retainer to adjust the end thrust of the crankshaft. The main bearing is shrunk fit on the crankshaft. The one piece, Cast Iron crankshaft is counter balanced for smooth operation. It is rifle drilled to provide lubrication to the main and connecting rod bearings.

51

HYPERCOMP (PVT) LTD.

HC-OMM-01 Version 00

9.15.2.

CRANKSHAFT REMOVAL & INSTALLATION

To remove and replace the crankshaft, it will be necessary to completely disassemble the compressor. To do this, proceed as follows: 1. Remove all tubing from cylinder heads and between compressor and heat exchangers. 2. Remove cylinder heads. 3. Remove all pistons. 4. Remove all compression cylinders. 5. Remove all seal carrier plates. 6. Remove all cross head cylinders. 7. Drain oil from compressor crankcase. 8. Remove drive belts and flywheel from compressor. 9. Remove the oil tubing from the compressor oil pump. 10.Remove side plates on each side of crankcase. 11.Remove pistons and connecting rods. 12.Remove oil pump, oil connections and screen in crankcase of compressor. 13.Remove crankshaft. Use a bearing puller and remove the bearings from the crankshaft (only if replacement is needed!). 14.Inspect the condition of the crankshaft and bearings for indications of excessive wear, galling, pitting etc. 15.Tap out the main bearing outer race or cup from each end of crankcase. 16.The crankshaft connecting rod journals may be reground to a maximum removal of .76mm (0.030) of stock to remove scratches or other damage. 17.After grinding, polish the shaft with a crocus cloth. Use a micrometer to check the shaft diameter after grinding and polishing. 18.Insert new tapered roller bearing outer races into each end of the crankcase. The race, at pulley end, is a tap fit and a press fit at the retainer end of the crankcase. Make sure the races are installed with bearing surface facing the center of the crankcase. 19.The main bearings are tapered roller type and are shrink-fit to the crankshaft. To install the bearings, heat bearing in oil to 350 deg F (177 deg C), place it over the shaft until it rests on the

52

HYPERCOMP (PVT) LTD.

HC-OMM-01 Version 00