Professional Documents

Culture Documents

Automatic Air Maintenance Device Technical Specs

Uploaded by

Ngô Khoai SắnOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Automatic Air Maintenance Device Technical Specs

Uploaded by

Ngô Khoai SắnCopyright:

Available Formats

Technical Services: Tel: (8 0 0 ) 3 8 1-9 3 12 / F ax : (8 0 0 ) 7 9 1-550 0

Customer Service/Sales: Tel: (4 1 4 ) 5 7 0 -5 0 0 0 / (8 0 0 ) 5 5 8 -5 2 3 6 F a x : (4 1 4 ) 5 7 0 -5 0 1 0 / (8 0 0 ) 8 7 7 -1 2 9 5

M o d el A M D -1 A u to m atic A ir M aintenanc e D ev ic e P res s u re R ed u c ing T y p e W ith F ield A d ju s tab le P res s u re R eg u lato r General D es c rip t io n

The Model AMD -1 Autom atic Air Maintenance D evice is an autom atic, fieldadjustable device of the pressure reducing type. It is used to control the pressure in a dry pipe sprink ler system , preaction system , or dry pilot line system of a dry pilot actuated deluge or preaction valve. The AMD -1 is utilized in applications where there is a com pressed air (or nitrogen) source which is controlled at a higher pressure than the desired system pressure. P ressure sources include plant air supplies having their own autom atic com pressor controls, or nitrogen supplies having single-stage cylinder m ounted pressure regulators. The Model AMD -1 Autom atic Air Maintenance D evice is a redesignation for the C entral Model D -2, G em Model F 3 24 , and S tar Model S 4 60 .

T ec h nic al D at a

Ap p rovals U L and U LC Listed. F M Approved. M ax im u m Inlet Air ( or Nit rog en) Su p p ly P ressu re 20 0 psi (13 ,8 bar) F ield Ad ju stab le Ou tlet P ressu re Rang e 5 to 7 0 psi (0 ,4 to 4 ,8 bar) Assem b ly Major com ponents illustrated in F igure 1 are factory assem bled with galvanized steel nipples and m alleable iron pipe fittings.

Ins t allat io n

The Model AMD -1 Autom atic Air Maintenance D evice m ust be installed in accordance with the following instructions:

NOTE S uitable consideration m ust be given to the rem oval of ex cessive m oisture from the com pressed air supply.

WARNING The Model AMD -1 Autom atic Air Maintenance D evice described herein m ust be installed and m aintained in com pliance with this docum ent, as well as with the applicable standards of the N ational F ire P rotection Association, in addition to the standards of any other authorities having jurisdiction. F ailure to do so m ay im pair the integrity of this device. The owner is responsible for m aintaining their fire protection system and devices in proper operating condition. The installing contractor or sprink ler m anufacturer should be contacted relative to any q uestions.

O p erat io n

The B y-P ass V alve in the AMD -1 is opened to fast fill the system during the initial pressurization. O nce the req uired system pressure has been reached, the B y-P ass V alve is closed and the Air S upply C ontrol V alve is left open to place the AMD -1 in autom atic operation. G iven a sm all leak in the system , the P ressure R egulator will autom atically m aintain system pressure at the preset level. The 1/8 inch (3 ,2 m m ) orifice in the R estrictor C heck V alve lim its the flow of air from the P ressure R egulator into the system to a value which is significantly less than that which will be ex hausted by the operation of a 5.6 K -factor sprink ler.

Step 1 . C onnections between the inlet air supply and the AMD -1, as well as between the AMD -1 and the system to be pressurized, are to be a m inim um of 1/2 inch (D N 15) pipe size. Step 2. A 1/2 inch (D N 15), non-spring loaded, rubber faced, swing type check valve m ust be located between the AMD -1 and the system to be pressurized. A check valve of this type is provided in the air supply trim of Tyco F ire P roducts dry pipe valves, preaction valves, and dry pilot trim .

Page 1 of 4

A PR IL , 2 0 0 3

T F P12 2 1

Page 2 of 4

TFP1221

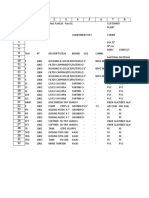

2" (50,8 mm) 1/4" NPT GAUGE TEST PORT

16-1/8"" (409,6 mm) BY -PASS VALVE (NORMALLY CLOSED) P/N 46-047-1-004

3-1/4" (82,6 mm)

1/2" NPT OUTLET CONNECTION (TO SY STEM)

8-1/2" (215,9 mm) LABEL

1/2" NPT INLET CONNECTION (FROM COMPRESSED AIR SUPPLY )

RESTRICTOR CHECK VALVE P/N 92-326-1-003 PRESSURE REGULATOR (ADJ USTABLE) P/N 92-324-1-012 STRAINER P/N 92-322-1-001 AIR SUPPLY CONTROL VALVE (NORMALLY OPEN) P/N 46-048-1-002

FIGU RE 1 MOD EL AMD -1 AU TOMATIC AIR MAINTENANCE D EV ICE

Setting Procedure

The Model AMD-1 Automatic Air Maintenance Device must be set in accordance with the following instructions: Step 1. Determine the pressure that meets the minimum requirements of the system to be pressurized. Step 2. Close the AMD-1 By-Pass Valve, and close the AMD-1 Air Supply Control Valve. Step 3 . Open the control valve in the air supply trim of the system to be pressurized and then reduce the system air pressure to 0 psig. Step 4. Close the control valve in the air supply trim of the system to be pressured. Step 5 . Remove the system pressure gauge from its connection and temporariliy install it in the 1/4 inch NPT AMD-1 Gauge Test Port.

pressure of the pressure regulator. Pull the knob out and away from the pressure regulator body and then slowly turn the knob clockwise, as viewed from the knob end of the pressure regulator, to increase pressure and counter-clockwise to decrease pressure.

Step 11. Open the Air Supply Control Valve in the AMD-1. Step 12. Open the By-Pass Valve in the AMD-1. Step 13 . Close the By-Pass Valve after the system has been pressurized to approximately 5 psi (0,4 bar) less than the minimum required system pressure determined in Step 1. Step 14. After the system pressure has stabilized, note the value and compare with the requirement. Readjust the Pressure Regulator, as require.

W hen decreasing pressure, the air pressure must be relieved downstream of the pressure regulator by temporarily opening the control valve in the air supply trim of the system to be pressurized (assuming that the system to be pressurized is at 0 psig).

After the pressure regulator is set, push the knob in and towards the pressure regulator body to snap it in a locked position. Step 8. Close the Air Supply Control Valve in the AMD-1. Step 9. Return the system air pressure gauge to its normal location. Re-install the 1/4 inch pipe plug in the the AMD-1 Gauge Test Port. Apply pipe thread sealant sparingly to the plug threads only.

NOTES If the system was over-pressurized during manual fill, a suitable connection to the system must be opened and the pressure manually reduced to the desired value. The AMD-1 will then automatically maintain the preset system pressure. The Restrictor Check Valve prevents the Pressure Regulator from bleeding down the system pressure. The system pressure should be set at the minimum required value, in order to minimize the time for system trip in the event of a sprinkler operation.

NOTE Make certain that the piping to which the AMD-1 Gauge Test Port is connected is at 0 psig before removing the plug.

Step 6 . Open the Air Supply Control Valve in the AMD-1. Step 7 . W hile observing the relocated pressure gauge, adjust the output

NOTE Make certain that the piping to which the AMD-1 Gauge Test Port is connected is at 0 psig before removing the pessure gauge.

Step 10 . Open the control valve in the air supply trim to the system being pressurized.

TFP1221

Page 3 of 4

Care and Maintenance

The following inspection procedure must be performed as indicated, in addition to any specific requirements of the NFPA, and any impairment must be immediately corrected. The owner is responsible for the inspection, testing, and maintenance of their fire protection system and devices in compliance with this document, as well as with the applicable standards of the National Fire Protection Association (e.g., NFPA 25), in addition to the standards of any authority having jurisdiction. The installing contractor or product manufacturer should be contacted relative to any questions. It is recommended that automatic sprinkler systems be inspected, tested, and maintained by a qualified Inspection Service.

4. Verify that the system pressure is essentially the same as the previously established requirement. If not, adjust the system pressure as follows: a. Close the systems main control valve and open the main drain valve. Close the Accelerator Control Valve, if the system is so equipped. b. Follow Steps 1 through 14 in the Setting Procedure. c. Slowly open the Accelerator Control Valve, as applicable. d. Slowly open the main control valve and after water begins to flow, slowly close the main drain valve and then completely open the main control valve. The AMD-1 Air Maintenance Device is now ready for service.

UNDER ANY OTHER LEGAL THEORY, FOR INCIDENTAL, INDIRECT, SPECIAL OR CONSEQ UENTIAL DAMAGES, INCLUDING BUT NOT LIMITED TO LABOR CHARGES, REGARDLESS OF WHETHER TYCO FIRE PRODUCTS WAS INFORMED ABOUT THE POSSIBILITY OF SUCH DAMAGES, AND IN NO EVENT SHALL TYCO FIRE PRODUCTS LIABILITY EX CEED AN AMOUNT EQ UAL TO THE SALES PRICE.

TH E FOREGOING WARRANTY IS MADE IN LIEU OF ANY AND ALL OTH ER WARRANTIES EX PRESS OR IMPLIED, INCLUDING WARRANTIES OF MERCH ANTAB ILITY AND FITNESS FOR A PARTICULAR PURPOSE.

Ordering Information

Orders for the AMD-1 and replacement parts must include the description and Part Number (P/N). AMD-1: Specify: Model AMD-1 Automatic Air Maintenance Device, P/N 52-324-2-002 Replacement Parts for AMD-2 Air Maintenance Device: (Specify description) for use with Model AMD-1 Automatic Air Maintenance Device, P/N (see Figure 1).

NOTES Before closing a fire protection system main control valve for maintenance work on the fire protection system that it controls, permission to shut down the affected fire protection systems must first be obtained from the proper authorities and all personnel who may be affected by this decision must be notified. After placing a fire protection system in service, notify the proper authorities and advise those responsible for monitoring proprietary and/or central station alarms. It is also recommended that accumulated moisture be removed from air supply moisture filtration equipment, at least quarterly. More frequent inspections may be necessary in particularly humid environments

The Model AMD-1 Automatic Air Maintenance Device must be inspected quarterly in accordance with the following instructions: 1. Verify that the By-Pass Valve is closed. 2. Close the AMD-1 Air Supply Control Valve and clean out the 1/4 inch Strainer located at the inlet to the Restrictor Check Valve. Be sure to reinstall the strainer screen and tighten the cap securely. 3. Open the AMD-1 Air Supply Valve and verify that the control valve in the air supply trim to the system being pressurized is open.

L imited Warranty

Products manufactured by Tyco Fire Products are warranted solely to the original Buyer for ten (10) years against defects in material and workmanship when paid for and properly installed and maintained under normal use and service. This warranty will expire ten (10) years from date of shipment by Tyco Fire Products. No warranty is given for products or components manufactured by companies not affiliated by ownership with Tyco Fire Products or for products and components which have been subject to misuse, improper installation, corrosion, or which have not been installed, maintained, modified or repaired in accordance with applicable Standards of the National Fire Protection Association, and/or the standards of any other Authorities Having Jurisdiction. Materials found by Tyco Fire Products to be defective shall be either repaired or replaced, at Tyco Fire Products sole option. Tyco Fire Products neither assumes, nor authorizes any person to assume for it, any other obligation in connection with the sale of products or parts of products. Tyco Fire Products shall not be responsible for sprinkler system design errors or inaccurate or incomplete information supplied by Buyer or Buyers representatives. IN NO EVENT SHALL TYCO FIRE PRODUCTS BE LIABLE, IN CONTRACT, TORT, STRICT LIABILITY OR

Page 4 of 4

TFP1221

TYCO FIRE PRODUCTS, 451 North Cannon Avenue, Lansdale, Pennsylvania 19446

You might also like

- TFP1221 08 2015Document4 pagesTFP1221 08 2015JoshuaNo ratings yet

- cULus Listed FM Approved Pressure Maintenance DevicesDocument4 pagescULus Listed FM Approved Pressure Maintenance DevicesSavy PhanethNo ratings yet

- Models A & B Automatic Pressure Maintenance DevicesDocument4 pagesModels A & B Automatic Pressure Maintenance DevicesHIDRUCOL SASNo ratings yet

- 150 70-nm2 1Document12 pages150 70-nm2 1Eduardo JoseNo ratings yet

- LS20-100 Sullair Manual PDFDocument114 pagesLS20-100 Sullair Manual PDFJavier Miramontes100% (1)

- 25 90 00 Ahu-Vav-Rev4Document24 pages25 90 00 Ahu-Vav-Rev4PrestoneKNo ratings yet

- 1.1 Control Philosophy CAS-1 NMDCDocument36 pages1.1 Control Philosophy CAS-1 NMDCkoushik42000No ratings yet

- Air Dryyer PDFDocument15 pagesAir Dryyer PDFrajishrrrNo ratings yet

- Compresor SullairDocument86 pagesCompresor Sullairseze71100% (1)

- DRESSER Regulators FlowgridDocument12 pagesDRESSER Regulators Flowgridzalziza100% (1)

- Triplex Systems 3Document2 pagesTriplex Systems 3Eng.Gihad EladlNo ratings yet

- Aftercooler - Test: Shutdown SIS Previous ScreenDocument7 pagesAftercooler - Test: Shutdown SIS Previous ScreenKeron Trotz100% (1)

- LS-16 Sullair ManualDocument112 pagesLS-16 Sullair Manualbinhleduc36100% (2)

- Convertidor Neumatico Y695ADocument8 pagesConvertidor Neumatico Y695AALBERTONo ratings yet

- ISO 6772 - Impulse Test AereoDocument8 pagesISO 6772 - Impulse Test Aereomaurobruno1973No ratings yet

- 9/27/01 AC 43.13-1B CHG 1: Figure 12-5. Pitot/static System For A Small AircraftDocument5 pages9/27/01 AC 43.13-1B CHG 1: Figure 12-5. Pitot/static System For A Small Aircraftaerogem618No ratings yet

- User'S, Maintenance and Spare Parts Manual: Refrigerating Air DryerDocument67 pagesUser'S, Maintenance and Spare Parts Manual: Refrigerating Air DryerValentin Bogdan100% (1)

- Triplex Systems 4Document2 pagesTriplex Systems 4Eng.Gihad EladlNo ratings yet

- Duplex Systems 6Document2 pagesDuplex Systems 6Eng.Gihad EladlNo ratings yet

- Aftercooler - Test: Testing and AdjustingDocument6 pagesAftercooler - Test: Testing and AdjustingAbdoulaye Boua BERTHENo ratings yet

- LS20-100 Sullair Manual PDFDocument114 pagesLS20-100 Sullair Manual PDFJames Hanks50% (2)

- bl5389 PDFDocument22 pagesbl5389 PDFMurtaza ÇakaloğluNo ratings yet

- Operating Manual Manual de Instrucciones Manuel D'utilisationDocument16 pagesOperating Manual Manual de Instrucciones Manuel D'utilisationCarlos EscalonaNo ratings yet

- Proportional Reducing ValveDocument8 pagesProportional Reducing ValvediabalziabNo ratings yet

- FMC - Desairador VerticalDocument4 pagesFMC - Desairador VerticalFaull JackmanNo ratings yet

- 301 12 PDFDocument13 pages301 12 PDFEduardo VillatoroNo ratings yet

- Valvula Bendix PP-1 ManualDocument4 pagesValvula Bendix PP-1 Manualjgomez30No ratings yet

- HVAC System Tender Specification SheetDocument46 pagesHVAC System Tender Specification SheetAnkush Nayar100% (1)

- CAR-II - (R) - Constant Airflow Regulator - Prod Specs Tech DataDocument4 pagesCAR-II - (R) - Constant Airflow Regulator - Prod Specs Tech DataSantiago J. ramos jrNo ratings yet

- Atr72 Air PDFDocument34 pagesAtr72 Air PDFEhsan Ul HaqueNo ratings yet

- Duplex Systems 4Document2 pagesDuplex Systems 4Eng.Gihad EladlNo ratings yet

- Air Amplifier Models Aad 5 Aad 5 C ADocument20 pagesAir Amplifier Models Aad 5 Aad 5 C AOMiD QahqaieNo ratings yet

- AtlasDocument5 pagesAtlasSunil KumarNo ratings yet

- Instrument Air SystemDocument16 pagesInstrument Air SystemDony RamdhaniNo ratings yet

- Sullair Air Care Seminars provide hands-on compressor trainingDocument110 pagesSullair Air Care Seminars provide hands-on compressor trainingWaldemarDominguez0% (1)

- RTHC Svn02c enDocument16 pagesRTHC Svn02c enRicardo100% (1)

- HP by Pass System-ModifiedDocument21 pagesHP by Pass System-Modifiedsrigirisetty208100% (1)

- Jockey Pump BrochureDocument8 pagesJockey Pump BrochuregbogboiweNo ratings yet

- Engineering Standard: IPS-E-IN-110Document21 pagesEngineering Standard: IPS-E-IN-110charleselitb92100% (1)

- Service & Maintenance ManualDocument44 pagesService & Maintenance ManualAnonymous 2iQ1B59No ratings yet

- Amd 75Document2 pagesAmd 75ROBERTONo ratings yet

- Blower TUTHILL ManualDocument48 pagesBlower TUTHILL ManualEd Ortiz100% (1)

- Ingersoll CompressorDocument68 pagesIngersoll CompressorTravis Merlo100% (4)

- Almig Pistons 'A' Range Operating ManualDocument22 pagesAlmig Pistons 'A' Range Operating ManualAndy MitchellNo ratings yet

- Design Requirements For Pressure Safety Relief Valves: Codes: Structure & ComparisonDocument5 pagesDesign Requirements For Pressure Safety Relief Valves: Codes: Structure & Comparisontss1372350% (2)

- Heavy Duty ManualDocument26 pagesHeavy Duty ManualErnesto Andres Guevara MalaveNo ratings yet

- Installation Instructions: OS52D & S52 Scroll Air CompressorDocument2 pagesInstallation Instructions: OS52D & S52 Scroll Air CompressorRui PedroNo ratings yet

- Wet System ManualDocument38 pagesWet System ManualLalit MalhotraNo ratings yet

- Bermad: AMD With Adjustable Regulator For Fusible Plug Loops Model AMD-76Document2 pagesBermad: AMD With Adjustable Regulator For Fusible Plug Loops Model AMD-76KittyNo ratings yet

- 4 - Purge Unit Technical DocumentationDocument34 pages4 - Purge Unit Technical DocumentationMohd Shahid100% (1)

- A380-Level I - Ata 36 PneumaticDocument26 pagesA380-Level I - Ata 36 PneumaticAbolfazl Mazloomi100% (3)

- Mini Diaphragm Vacuum Pump Operating InstructionsDocument5 pagesMini Diaphragm Vacuum Pump Operating InstructionsAleksxxNo ratings yet

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideFrom EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideRating: 4 out of 5 stars4/5 (8)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- 737 Performance Reference Handbook - EASA EditionFrom Everand737 Performance Reference Handbook - EASA EditionRating: 4.5 out of 5 stars4.5/5 (3)

- Job code 0-6495-20 page 177-178Document2 pagesJob code 0-6495-20 page 177-178Ngô Khoai SắnNo ratings yet

- MFR: Amot MODEL: 4BOSH13001-00-AZA CONN: 4" 150# RFWN Body Material: Carbon Steel Setpoint: 54.4 Deg CDocument1 pageMFR: Amot MODEL: 4BOSH13001-00-AZA CONN: 4" 150# RFWN Body Material: Carbon Steel Setpoint: 54.4 Deg CNgô Khoai SắnNo ratings yet

- Catalog For Bare Conductor PDFDocument35 pagesCatalog For Bare Conductor PDFSatay Chilly0% (1)

- Survey on Dream Team Project CollaborationDocument1 pageSurvey on Dream Team Project CollaborationNgô Khoai SắnNo ratings yet

- 07L5045 Decanter Maintenence Hoist Rev P1Document4 pages07L5045 Decanter Maintenence Hoist Rev P1Ngô Khoai SắnNo ratings yet

- VietnamDocument2 pagesVietnamNgô Khoai SắnNo ratings yet

- Mainline PPR LT.21.DDocument1 pageMainline PPR LT.21.DVictor AfandiNo ratings yet

- NTT data JKT3 New construction project valve and strainer BOQ identifies new sizes and quantities neededDocument17 pagesNTT data JKT3 New construction project valve and strainer BOQ identifies new sizes and quantities neededagung sudarsonoNo ratings yet

- Bolt Mto - 2Document330 pagesBolt Mto - 2Đinh Thiện SỹNo ratings yet

- Meson Gate Valve 620767Document1 pageMeson Gate Valve 620767syed aliNo ratings yet

- Pengadaaan PANEL Ruang Pompa: Satuan Harga Upah Kerja ItemDocument6 pagesPengadaaan PANEL Ruang Pompa: Satuan Harga Upah Kerja ItemALIF NAUFALNo ratings yet

- 220 Vac/24 VDC 220-24 VacDocument22 pages220 Vac/24 VDC 220-24 Vacfernandez123456No ratings yet

- Kitz Bronze Gate ValveDocument9 pagesKitz Bronze Gate ValveRyte EchanoNo ratings yet

- Building Services - I (Water Supply and Sanitation) 15 ENG 4.3Document12 pagesBuilding Services - I (Water Supply and Sanitation) 15 ENG 4.3VarunNo ratings yet

- Exc 315L - 6ym DiagHydDocument2 pagesExc 315L - 6ym DiagHydLuis Eduardo Corzo EnriquezNo ratings yet

- High pressure steam system notes and detailsDocument1 pageHigh pressure steam system notes and detailszhangNo ratings yet

- Valve Assy, Control, P - N Yy30v00036f1Document3 pagesValve Assy, Control, P - N Yy30v00036f1刘奇雄No ratings yet

- Pressure Relief ValveDocument20 pagesPressure Relief ValveshaikhNo ratings yet

- Rehabilitasi Sistem Penyediaan Air Baku Rendang Payungan Di Kabupaten KlungkungDocument6 pagesRehabilitasi Sistem Penyediaan Air Baku Rendang Payungan Di Kabupaten KlungkungMade ArsanaNo ratings yet

- Lucius Learning Series - MOV Seismic Weak LinkDocument20 pagesLucius Learning Series - MOV Seismic Weak Linkcool_rdNo ratings yet

- 2-Way Cartridge Valves Pressure Functions Cartridge Valves Type LC... Control Covers Type LFA..Document68 pages2-Way Cartridge Valves Pressure Functions Cartridge Valves Type LC... Control Covers Type LFA..PrasantaKumarMallikaNo ratings yet

- Tinywow - PROEDI 1000 HWS + PW LOOP REVERSE OSMOSIS SYSTEM + DISTRIBUTION 2.2 - 5949721Document18 pagesTinywow - PROEDI 1000 HWS + PW LOOP REVERSE OSMOSIS SYSTEM + DISTRIBUTION 2.2 - 5949721Yacine MokhtariNo ratings yet

- L&T Valves API 600 BS 1873 1868 Gate Globe CheckDocument1 pageL&T Valves API 600 BS 1873 1868 Gate Globe CheckMunishTrichyNo ratings yet

- Spare Parts List Series L90LS: Code Part # Description RemarksDocument1 pageSpare Parts List Series L90LS: Code Part # Description RemarksfuchswebdeNo ratings yet

- SD22 Vue EclateeDocument12 pagesSD22 Vue Eclateejacques PerronNo ratings yet

- 1.19 Course Highlights - P&ID Valve SymbolsDocument39 pages1.19 Course Highlights - P&ID Valve SymbolsdadizNo ratings yet

- Different Types of Valves Used in PipingDocument9 pagesDifferent Types of Valves Used in PipingIrshad Siddiqui100% (1)

- Section 3 Hydraulic SystemDocument3 pagesSection 3 Hydraulic SystemRafał DworakNo ratings yet

- Globe, gate, check, relief valvesDocument12 pagesGlobe, gate, check, relief valvesAbdallah MansourNo ratings yet

- Vdocuments - MX Valves Valves Nozzle Check Valves 44 Swing Check ValvesDocument59 pagesVdocuments - MX Valves Valves Nozzle Check Valves 44 Swing Check ValvesKURAF MUHENDISLIK AŞ.No ratings yet

- Automatic Float Control ValveDocument2 pagesAutomatic Float Control ValveMohamed RaafatNo ratings yet

- 5303 - 5403 Ind.Document308 pages5303 - 5403 Ind.Edinaldo GuimaraesNo ratings yet

- Klinger Marine Bronze Valves: Globe & SDNR Valves - ThreadedDocument64 pagesKlinger Marine Bronze Valves: Globe & SDNR Valves - ThreadedPipolo PippoNo ratings yet

- Tabla de Bujias Champion 20234Document82 pagesTabla de Bujias Champion 20234alexander ortizNo ratings yet

- VADO Price List April 2013Document15 pagesVADO Price List April 2013Rasmus2410No ratings yet

- Valves: Types, Functions, Uses, Maintenance & TroubleshootingDocument68 pagesValves: Types, Functions, Uses, Maintenance & TroubleshootingToniNo ratings yet