Professional Documents

Culture Documents

Total Middle East New Bitumen Terminal in Tlbu

Uploaded by

Damian LeonardoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Total Middle East New Bitumen Terminal in Tlbu

Uploaded by

Damian LeonardoCopyright:

Available Formats

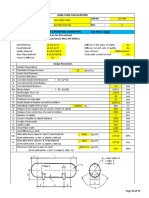

Design Calculation for T-109 tank

TOTAL MIDDLE EAST NEW BITUMEN TERMINAL IN TLBU

MECHANICAL DESIGN CALCULATION FOR SOFT STOCK STORAGE TANK (T-109)

Client

: Total Middle East

Contractor : Western Tanks & Pipes Company Ltd.

0

Rev. No.

Issued for Comments Description

30/04/09 Date

RS Prepared

SVR Checked

PS Appoved

Page 1 of 25

Design Calculation for T-109 tank

INDEX

S.NO. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 DESCRIPTION COVER INDEX DESIGN DATA YIELD & TENSILE STRENGTH OF MATERIAL SHELL THICKNESS BOTTOM PLATE THICKNESS ROOF PLATE ANNULAR BOTTOM PLATE -MINIMUM RADIAL WIDTH STABILITY CHECK AGAINST WIND VELOCITY CHECH OVERTURNING AGAINST WIDN LOAD SEISMIC ANALYSIS OVERTURNING MOMENT SHELL COMPRESSION TOTAL BASE SHEAR CALCULATION DYNAMIC HOOP STRESS DESIGN CHECK FOR FRANGIBLE JOINT COMPRESSION AREA CHECK FOR INTERNAL PRESSURE DESIGN OF ANCHOR BOLTS & ANCHOR CHAIRS VENT SIZE CALCULATION LOADING DATA PAGE NO. 1 OF 25 2 OF 25 3 OF 25 4 OF 25 4 OF 25 5 OF 25 5 OF 25 6 OF 25 7 OF 25 10 OF 25 12 OF 25 14 OF 25 15 OF 25 15 OF 25 16 OF 25 17 OF 25 18 OF 25 20 OF 25 23 OF 25 25 OF 25

Page 2 of 25

Design Calculation for T-109 tank

DESIGN DATA : Inside Diameter of tank Height of tank Number of tanks Product Design code Appendices Shell design Type of tank Maximum Liquid Level Design liquid height Specific Gravity Design Specific Gravity CA - Shell CA - Bottom CA - Roof Design Pressure (Positive) Design Pressure (Vacuum) Storage Pressure (Positive) Storage Pressure (Vacuum) Live load on roof Operating temperature (Max.) Operating temperature (Min.) Design Metal Temp. (Max.) Design Metal Temp. (Min.) Max. Filling Rate Max. Empting Rate Seismic design code Seismic Zone Factor Seismic Zone Importance factor Basic wind velocity Flash Point I Z = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = 18 18.8 One Soft Stock Tank API 650, 11th Edition + Add. 1, 2008 & API 2000 E,M,P & V One Foot Method Rafter Supported Cone Roof Tank 18.3 18.8 1.1 1.1 0 0 0 2.45 0.5 Atm. Nil 1 140 100 140 0 500 120 mm mm mm KPa KPa KPa KPa KPa C C C C m 3/hr m 3/hr

2 ( 25 G/cm )

m m

m m (1.1 to 0.9)

( 5 G/cm 2)

Appendix-E, API 650 0.075 Zone 1 (UBC) 1 45 > 200 m/sec oC

Page 3 of 25

Design Calculation for T-109 tank

YIELD & TENSILE STRENGTH OF MATERIAL Material Shell -1 SA 36 Shell -2 SA 36 Shell -3 SA 36 Shell -4 SA 36 Shell -5 SA 36 Shell -6 SA 36 Shell -7 SA 36 Shell -8 SA 36 Shell -9 SA 36 Bottom SA 36 Roof SA 36 Yield (MPa) Tensile (MPa) Sd (MPa) St (MPa) 250 400 147.5 171 250 250 250 250 250 250 250 250 250 250 400 400 400 400 400 400 400 400 400 400 147.5 147.5 147.5 147.5 147.5 147.5 147.5 147.5 147.5 147.5 171 171 171 171 171 171 171 171 171 171 = 0.885

Temperature factor at max. design temperature as per Table M-1

SHELL DESIGN : As per clause 5.6.3.2, The minimum thickness of shell plates shall be td = [(4.9 * D * (H-0.3) * G)/ Sd ] + C.A. tt = (4.9 * D * (H-0.3) )/ St Where, td = design shell thickness, in mm tt = hydrostatic test shell thickness, in mm D = Nominal tank diameter, in m = m (Inside Tank Dia. + First Shell Course Thk.) 18.014 H = design liquid level, in m = height from the bottom of course under consideration to the top of the shell including the top angle. G = Design specific gravity of the liquid to be stored, as specified by the purchaser C.A. Sd St = = = Corrosion Allowance, in mm Allowable stress for the design condition, in MPa Allowable stress for the hydrostatic test condition, in MPa t reqd. (mm) 12.18 10.53 8.89 7.57 6.25 4.94 3.62 2.30 2.30 t prov. (mm) 14.00 12.00 10.00 10.00 8.00 6.00 6.00 6.00 6.00 Wt.Wt.New Cor. (MT) (MT) 15.55 15.55 13.33 13.33 8.88 8.88 7.11 5.33 5.33 5.33 4.80 8.88 8.88 7.11 5.33 5.33 5.33 4.80

Course Shell -1 Shell -2 Shell -3 Shell -4 Shell -5 Shell -6 Shell -7 Shell -8 Shell -9 Total

Material SA 36 SA 36 SA 36 SA 36 SA 36 SA 36 SA 36 SA 36 SA 36

H (mm) 18.80 16.30 13.80 11.80 9.80 7.80 5.80 3.80 3.80

W (m) 2.50 2.50 2.00 2.00 2.00 2.00 2.00 2.00 1.80 18.80

td (mm) 12.18 10.53 8.89 7.57 6.25 4.94 3.62 2.30 2.30

tt (mm) 10.50 9.08 7.67 6.53 5.39 4.26 3.12 1.99 1.99

74.53 74.53 = 6.00 mm

Top shell course thickness

Page 4 of 25

Design Calculation for T-109 tank

BOTTOM PLATE THICKNESS : Bottom Sketch Plate Thickness : As per Clause 5.4.1, Minimum thickness required excluding C.A. Corrosion allowance (C.A.) Minimum thickness required including C.A. Thickness provided Annular plate thickness : As per API 650 Cl.5.5.3 & Table 5-1 Effictive Product height of Hence Table 5-1 is applicable Maximum Stress in the 1st shell course (Product) td = required thickness of first shell course t = Provided thickness less corrosion allowance Sd = Allowable stress Product Stress Hydrostatic Test Stress tt = required thickness of first shell course t = Provided thickness ( constructed) St = Allowable stress Hydrostatic Test Stress Maximum Stress in the first shell course ( Max. Product / Hydrostatic stress) Thickness for Product Design Plate thickness of first shell course to use Table 5-1 Add Corrosion allowance Thickness for Product Design Thickness for Hydrostatic Design Plate thickness of first shell course to use Table 5-1 Thickness for Hydrostatic Design Thickness of Annular Plate Provided Annular Plate thickness ROOF DESIGN : As per clause 5.10.2.2, Minimum nominal thickness required excluding C.A. Corrosion Allowance (C.A.) Minimum thickness including C.A. Thickness provided = = = = 5.00 mm 0.00 mm 5.00 mm 6.00 mm = = = = = = = = = = = = = = = = = = = = (td/t) * Sd 12.18 14.00 147.5 128.30 (tt/t) * St 10.50 14.00 171.00 128.30 128.30 mm mm Mpa Mpa mm mm Mpa Mpa Mpa Vs 128.30

= = = =

6 mm 0 mm 6 mm 10 mm

= =

HxG 20.68

23 23

14 6 mm 0.00 6 14 6 6 mm mm

Vs 128.30 mm mm

6 mm 12 mm

Page 5 of 25

Design Calculation for T-109 tank

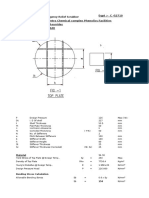

ANNULAR BOTTOM PLATE -MINIMUM RADIAL WIDTH : As per Cl.5.5.2, the minimum radial width of the annular plate at any point around the circumference of the 'tank shall be either Aw1 or Aw2, whichever is greater. Aw1 =Wr + t bot + Where, t bot =Thickness of the bottom shell course A proj =Projection of annular plate outside the shell A lap =Annular-sketch lap Wr =Minimum radial width between the inside of the shell and any lap welded joint in the remainder of the bottom Aw2 Where, tb H G = = = Thickness of the annular plate Design Liquid level Design specific gravity of product = = = 12 mm 19 m 1.1 = 215 tb (HG)^0.5 = 567 mm = = = = = 739 mm 14 mm 60 mm 65 mm 600 mm

As per clause E.6.2.1.1.2, the annular plate under the shell is thicker than remainder bottom plate , the width of the annular plate(L) , in m, measured radially inward from the shell shall be greater than or equal to 0.01723 ta x sqrt ( Fy/HGe): L = 0.01723 ta x sqrt ( Fy/HGe) Min. radial width at any point around the circumference Thicknness of annular is less than or equal to remainder of the bottom, Hence ta = Thickness of tank bottom under the shell extending at the distance, L from the inside of the shell( less corrosion allowance) Fy = Minimum specified yield strength of bottom annulas Min. radial width of Annular Plate at any point around the circum. Provided radial width of Annular Plate at any point around the circum. = = = = = = = 676 815.29 Not Applicable 12.00 mm 221.25 Mpa 739 mm 800 mm

Page 6 of 25

Design Calculation for T-109 tank

SHELL STABILITY CHECK AGAINST DESIGN WIND VELOCITY : Design wind velocity V = 45.00 m/s Calculate as per Appendix -V Design External Pressure( Vacuum) Total Design External Pressure for design of shell Ps Pe =

162.00 Km/hr.

0.500 Kpa

= Greater of Pe or W+0.4Pe = 1.26 Kpa

Where W = Maximum wind pressure consistent with the specified design wind velocity W= 0.0000333 ( V) (Kg) (Kh) V = Design Wind Velocity Kg = Wind Gust factor Kh = Wind Height factor W The transformed height of the shell Wtr = W x sqrt(t uniform/ t actual)^5 Where, Wtr = transposed width of each shell course, in mm W =actual width of each shell course, in mm t uniform = ordered thickness of the top shell course t actual = ordered thickness of the shell course for which the transposed width is being calculated Course Wtr (mm) Wactual(mm) t(Corroded mm) = = = = 162.00 Km/Hr. 1.1 1.1 1.06 Kpa

9 8 7 6 5 4 3 2 1

876.85 974.28 974.28 974.28 474.61 271.68 271.68 215.29 146.44 Total

1800 2000 2000 2000 2000 2000 2000 2500 2500 18800 Minimum 5.18 M = HTS

6.00 6.00 6.00 6.00 8.00 10.00 10.00 12.00 14.00 6.00

Height of transposed shell =

Check that buckling will occur elastically in the unstiffened cylindrical shell: ( D/ts min) 0.75 [(HTS/D)(Fy/E)0.5 ] > 0.00675 =

Page 7 of 25

Design Calculation for T-109 tank

Where D = Nominal tank Diameter ts min = Minimum thickness of thinnest shell course, mm(cord.) HTS - Height of the tranposed Shell H - Height of the tranposed Shell Fy - Yield strength of components E-Modulus of elasticity of roof plate material 0.018190 > Hence Buckling will be elastic

= = = = = = 0.000675

18.014 m 6.00 mm 5.179 m 18.80 m 147.5 Mpa 191714 Mpa

Design External Pressure for an unstiffened tank shell shall not exceed the following 2.5 Ps < E / 45609(HTS/D)(D/tsmin) Ps < 0.9360 > 1.25745

Hence Ok, shell will be stiffened Calculate the number of buckling waves : N = SQRT ( 445 D /ts min x HTS) N = 127.128 N = 11.2751 Say

< < 10 (Max)

100 100

End Stiffners Calculate the required properties of the top stiffner Radial Load imposed to the shell Vi = 250Ps H Vi = 5910.0 N/m Required Moment inertia of the top stiffner to be calculated as follows : Ireqd = 37.5 x Vi*D/E(N-1) 4 Ireqd = 53.58 cm Required area of the top stiffner region Areqd = ViD/2f Areqd = 109.76 mm f - Allowable tensile stress 485 Mpa t cone = 6.00 mm X shell = Length of shell with in tension/compression region = = = = = sin = 13.4 * sqrt (D*ts1) 139.31 mm Length of cone roof with in tension/compression region 13.4 x sqrt ( D* tcone/sin) 344 mm 0.1644

X roof

Provided Section X shell X roof

= =

835.866 mm 2061.52 mm > 109.76 mm

Area Avilable = 2897.38 mm Hence additional stiffener is not required

Page 8 of 25

Design Calculation for T-109 tank

Calculate the required properties of the bottom stiffner Wshell = = 13.4 * SQRT( D x tsn) 212.80 mm

Radial Load imposed to the shell Vi = 250Ps H Vi = 5910.0 N/m Required Moment inertia of the top stiffner to be calculated as follows : Ireqd = 37.5 x Vi*D/E(N-1) 4 Ireqd = 53.578 cm Required area of the bottom stiffner region Areqd = ViD/2f Areqd X shell tb = = 109.76 mm 14.7 * sqrt (D*tsn) 233.45 mm Thickness of bottom plate under the shell 12 mm Length of bottom with in tension/compression region 384 mm

= = = X bottom = =

233.45

60

384

Section Length (bWidth W Area (A) Distance (D) M=AD cm. cm. sq.cm. cm. cu.cm. 1 1.20 6 7.20 3.00 21.60 2 24.54 1.4 34.36 6.70 230.23 3 1.2 38.4 46.08 26.60 1225.73 SUM ( 1+2+3 ) Dx = sum(M) / sum(A) 45.80 87.64 = 1477.56

Iyy Ig cm.^4 cm.^4 64.80 21.60 1542.5 5.61 32604 5662.31 34212 5689.52

16.86 cm.

D1 = sum(W) - Dx = 28.94 cm. I = Iyy + Ig - (sum(M)^2)/A = 14991.2 cu.cm The corner joint comprised of a portion of the shell and the bottom plate has a calculated moment of inertia of is not required 14991.2 cu.cm and will satisfy the inertia requirement. Hence additional stiffner

Page 9 of 25

Design Calculation for T-109 tank

CHECK FOR OVERTURNING AGAINST WIND LOAD : As per clause 5.11.2 The wind load or pr. acting on projected areas of cylindrical surface The wind load or pr. acting on projected area of conical curved surface for a wind velocity of 190 Km/hr

= =

0.86 Kpa 1.44 Kpa

The modified wind pressure can be calculated by multiplying (V/190) ^2 to the wind pressure Wind pressure on the projected area of the cylindrical surface = P1 Wind pressure on projected area of the conical curved surface Wind force on the cylindrical surface Wind force on the conical surface Where, D = tank diameter, in m R = tank radius, in m H = tank height, in m h = perpendicular height of roof, in m Roof Slope F1 F1 F2 F2 = = = = = = = = = =

0.625 kPa 1.047 kPa N N

P2 = D * H * P1 * 1000 211733.4 N * R * P2 * 1000 266806.0 N

2

18.014 m 9.007 m 18.80 m 1.50 m 1.00 : 6.00

Unanchored tanks shall satisfy both of the following uplift criteria: 1. 0.6Mw + MPi < MDL /1.5

8260192

>

5508765

2. Mw + 0.4MPi < (MDL + MF)/2

6643072

<

10206742

where, MPi where, Mw

= moment about the shell-to-bottom joint from design internal pressure, Design Pressure Pi = 2.45 Kpa 2 Uplift force due to internal pressure = 5624143 N-m Pi**D /4*R = = overturning moment about the shell-to-bottom joint from horizontal plus vertical wind pressure, = F1 * (H/2) + F2 * (D/2) = 4393415 N-m moment about the shell-to-bottom joint from the weight of the shell and roof supported by the shell, W*D/2 = 8,263,147 N-m 917414 N moment about the shell-to-bottom joint from liquid weight. The liquid weight (wL) is the weight of a band of liquid at the shell using a specific gravity of 0.7 and a height of one-half the design liquid height H. wL shall be the lesser of 1.4HD or the following: = Wa*D/2 = N N 12150337 N-m

= = Where, W = MF =

MDL

where, Wa where, WL WL

= = = = =

WL x * D 1348988.209 59tb sqrt (Fby x H) 38052 N/m 140.77*H/2*D

23836.81 N/m

Page 10 of 25

Design Calculation for T-109 tank

where, Fby H D tb

= = = =

minimum specified yield stress of the bottom plate under the shell Mpa design liquid height, m tank diameter, m required thickness (not including corrosion allowance) of the bottom plate under the shell in mm that is used to resist wind overturning

Weight Details UN CORRODED MT Shell -1 Shell -2 Shell -3 Shell -4 Shell -5 Shell -6 Shell -7 Shell -8 Shell -9 Total Shell Weight Roof weight Roof Roof Structure Top Curb Angle = Ladders & Handrails Shell Nozzle Weight Roof Nozzle Weight Shell Insulation Weight Roof Insulation Weight Total Weight N MT 15.55 152481.94 13.33 130684.29 8.88 87113.19 8.88 7.11 5.33 5.33 5.33 4.80 74.5 12.60 6.00 0.42 1.50 1.00 0.60 10.00 2.50 87113.19 69682.81 52256.30 52256.30 52256.30 47030.67 730875.01 123606.43 58839.90 4092.60 14709.98 9806.65 5883.99 98066.50 24516.63 CORRODED N 15.55 152482 13.33 130684 8.88 87113.2 8.88 7.11 5.33 5.33 5.33 4.80 74.5 12.60 6.00 0.42 1.50 1.00 0.60 10.00 87113.2 69682.8 52256.3 52256.3 52256.3 47030.7

109.15 1070397.69

730875 123606 58840 4092.60 14710.0 9806.7 5884.0 98066.5 (Considered Rock Wool insulation for 2.50 24516.6 shell & roof @ 180 mm thk. of 50 kg/sq.m 109.15 1070398 density)

TANK IS UNSTABLE FOR WIND AND HENCE TANKS ARE REQUIRED TO BE ANCHORED

Page 11 of 25

Design Calculation for T-109 tank

SEISMIC ANALYSIS As per API 650, Appendix E D = Site Classification II Z H Zone I I SDS = = = = = = = = = = Sp So = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = Seismic Use Group (SUG) Seismic Zone Factor Maximum Liquid Level Seismic Zone Importance Factor 1 The design, 5% damped, spectral response acceleration parameter at short periods (T = 0.2 secs.), %g (E.4.6.1-1) 2.5 Q Fa So = 0.30 Mapped, maximum considered earthquake, 5% damped, spectral response acceleration parameter at short periods (0.2 sec), %g 2.5 Sp = 0.1875 Design level peak ground acceleration parameter 0.075 (Seismic Zone 1)

Mapped, maximum considered earthquake, 5% damped, spectral response acceleration parameter

(Table E-5) = =

0.075 18.300 m

Ss

(E.4.3-1)

S1

Q Fa Fv Rwc Rwi TL Tc K Ks Av Ts Ai

at a period of zero seconds (peak ground acceleration for a rigid structure), %g (E.4.6.1) 0.4Ss = 0.075 Mapped, maximum considered earthquake, 5% damped, spectral response acceleration parameter at a period of one second, %g (E.4.3-2) 1.25 Sp = 0.094 Scaling factor from the MCE to the design level spectral accelerations. (E.4.6.1) 1 Acceleration-based site coefficient (at 0.2 sec period) (Table E-1) 1.6 Velocity-based site coefficient (at 1.0 sec period) (Table E-2) 2.4 Force reduction coefficient for the convective mode using allowable stress design methods 4 (Table E-4) (Mechanically Anchored) Force reduction factor for the impulsive mode using allowable stress design methods 2 (Table E-4) (Mechanically Anchored) Regional-dependent transition period for longer period ground motion, seconds (E.4.6.1) 4 secs. Natural period of the convective (sloshing) mode of behavior of the liquid, seconds 1.8 Ks * sqrt (D) = 4.42 Coefficient to adjust the spectral acceleration from 5% 0.5% damping 1.5 Sloshing period co-efficient (E.4.5.2-c) 0.578 / sqrt [tanh*(3.68 H / D)] = 0.578 (E.6.1.3) (E.4.5.2-a)

The maximum vertical seismic acceleration parameter 0.14 SDS = 0.042 Fv S1 / Fa Ss = 0.750

Impulsive design response spectrum acceleration coefficient, %g SDS (I/Rwi) 0.007 2.5 Q Fa So (I/Rwi) 0.150 > 0.007

(E.4.6.1-1)

Page 12 of 25

Design Calculation for T-109 tank

When Tc Ac

> = = =

TL Convective design response spectrum acceleration coefficient, %g (E.4.6.1-5) K SD1 (TL/Tc) (I/Rwc) = 2.5 K Q Fa So (TsTL/Tc) (I/Rw 0.076 < 0.150 Ai

Effective Weight of Product & Center of action D/H Ratio Wi Wp Wc Xi = 0.984 < 1.333 Effective impulsive weight of the liquid, in N (E.6.1.1-2) 39,515,676 N Wi = [1 - 0.218 D/H] Wp = Total weight of tank contents based on the Design Specific gravity, in N 50,312,355 N Effective convective (sloshing) portion of the liquid weight,N (E.6.1.1-3) 0.230 (D/H) tanh (3.67 H/D) Wp = 11377840 N Height from the bottom of shell to the center of action of lateral seismic force related to the impulsive liquid force for ring wall moment,m [0.5-0.094(D/H)] H 7.457 m (E.6.1.2.1-2)

= = = = = = = = =

Xc

= = = = = = =

Ws Wr

Height from the bottom of shell to the center of action of lateral seismic force related to the convective liquid force for ring wall moment,m (E.6.1.2.1-3) {1.0-[cosh(3.67H/D)-1]/[(3.67H/D)sinh(3.67H/D)]} H 13.62 m Total Weight of tank shell and appurtenances, N 759484 N Total Weight of fixed tank roof including framing and any permanemt attachment, N 188330 N

Center of Gravity of Shell Width (m) 2.500 2.500 2.000 2.000 2.000 2.000 2.000 2.000 1.800 1.5012 Thk. (mm) 14 12 10 10 8 6 6 6 6 6 Wt. (MT.) 15.549 13.326 8.8831 8.8831 7.1057 5.3287 5.3287 5.3287 4.7958 18.604 95.15

Part Shell -1 Shell -2 Shell -3 Shell -4 Shell -5 Shell -6 Shell -7 Shell -8 Shell -9 Roof Sum

EY 1.25 3.75 6.00 8.00 10.00 12.00 14.00 16.00 17.90 19.30

EXY

C.G.

497.94 953.85

6.5565 10.025

Approx. Misc. Weight Shell Appurtenances (1st Course) Curb Angle (Top Course) Roof Appurtenances = = = 1.00 MT 0.42 MT 0.60 MT

Page 13 of 25

Design Calculation for T-109 tank

Xs Xr

= = = =

Height from the bottom of the tank shell to the shell's center of gravity 6.556 m Height from the bottom of tank shell to the roof and roof appurtenances center of gravity 10.025 m

OVERTURNING MOMENT As per clause E.6.1.5 The overturning moment due to seismic forces applied to the bottom of the shell shall be determined as : Mrw Mrw = = SQRT {[ Ai (WiXi + WsXs + WrXr)] + [Ac(WcXc)]} 46,752,376 N-m (E.6.2.1.1.1 - 1) (E.6.1.5-1)

Anchorage requirement based on seismic load J = Anchorage Ratio = Mrw = Where, Wint Wt = = = = = = = = = = = = = S.No. 1) 2) 3) 4) 5)

D [ Wt ( 1-0.4Av) + Wa - 0.4 Wint] 1.86 > 1.54 Calculated design uplift load due to product pressure per unit circumferential length, N/m 11034 N/m Tank and roof weight acting at base of shell, N/m (E.6.2.1.1.1-2) [(Ws/d) + Wrs] 16748 N/m Roof load acting on the shell, N/m 3328 N/m Effective specific gravity including vertical seismic effects G(1-0.4Av) = 1.082 Resisting force of tank contents per unit length of shell circumference that may be used to resist the shell overturning moment, N/m (E.6.2.1.1) 99 ta x sqrt ( Fy H Ge) < 201.1 H D Ge (E.6.2.1.1 - 1a) 65,512 N/m < 71,698 65,512 N/m Requirement J < 1.86 > Ls N/A Fc 59.45 ta 10 > > < < < Remarks Not OK N/A OK OK OK

Wrs Ge Wa

Anchorge is not required if the below conditions are met Description Resisting force is adequate for tank stability Maximum width of annulus for determining the resisting force is 3.5% of tank diameter Ls = Required maximum width of Annular plate Shell compression satisfies the Clause E.6.2.2 The required annulus plate thickness does not exceed the thickness of bottom shell course Piping flexibility requirements are satisfied 1.54 1.54 0.035 D N/A c 14.32 ts 14.00

Piping system shall be designed for the min. displacement in Table E-8

FALSE

Hence, Anchor is required , tank is Mechanically Anchored

Page 14 of 25

Design Calculation for T-109 tank

SHELL COMPRESSION As per clause E.6.2.2 The maximum longitudinal shell compression stress at the bottom of the shell J = 1.857 > 1.54 (E.6.2.2.2 - 1a) Mechanically Anchored tanks c = (wt (1+0.4Av)+ (1.273 Mrw/D)) x (1/1000ts) c = 14.32 N/m As per clause E.6.2.2.3 Allowable longitudinal membrane compression stress in tank shell GHD/t < 44 33.33 < 44 Fc Fc Fc = = > ( Where t = 10 mm) 83 ts /(2.5*D) + 7.5 SQRT(G*H) < 59.45 MPa < c Hence Safe 0.5Fty 110.625

TOTAL BASE SHEAR CALCULATION The equivalent Lateral force base shear shall be determined as difined as below : V = Sqrt ( Vi + Vc) (E.6.1 - 1) = 6160861 N Where, Vi = Ai (Ws + Wr + Wf + Wi) (E.6.1 - 2) = 6099248 N Wf = Weight of the tank floor,N 198,163 N = Vc = Ac Wc = 869125 N Sliding Resistance Vs = ( Ws + Wr + Wf + Wp)(1 - 0.4 Av) (E.7.6 - 1) 20237533.03 = N Where, Vs = Average shear wave velocity at large strain levels 6160861 = = < Friction coefficient for tank sliding 0.4 20237533.0

Seismic shear V does not exceed Sliding resistence Vs - HENCE OK

Page 15 of 25

Design Calculation for T-109 tank

DYNAMIC HOOP STRESS DESIGN D/H Ratio Y = = 0.984 18.00 < > 1.333 13.51

0.75 D

Dynamic liquid Hoop force As per Clause E.6.1.4 Ni = Impulsive hoop membrane force in tank wall , N/mm Nc Y Nh Nh T = = = = = = = 2.6 Ai GD Convective hoop membrane force in tank wall , N/mm

(E.6.1.4 - 3a) (E.6.1.4 - 4a)

1.85 Ac GDcosh[3.68(H-Y)/D]/cosh(3.68H/D) Distance from liquid surface to analysis point ( 300 mm from Bottom),m Product Hydrostatic membrane stress, N/mm 4.9 GDY h s = Nh SQRT ( Ni + Nc + ( AvNh) t Nh N/mm 1747.72 1504.98 1262.24 1068.05 873.86 679.67 485.48 291.29 97.10 t corroded mm 14 12 10 10 8 6 6 6 6

2 2 2)

Course Shell -1 Shell -2 Shell -3 Shell -4 Shell -5 Shell -6 Shell -7 Shell -8 Shell -9

Y m 18.000 15.500 13.000 11.000 9.000 7.000 5.000 3.000 1.000

Ni N/mm 139.21 139.21 139.21 139.21 139.21 139.21 139.21 139.21 139.21

Nc N/mm 2.40 2.80 3.95 5.60 8.20 12.18 18.23 27.37 41.13

T Mpa 136.08 138.16 141.13 121.44 127.26 137.05 104.56 72.28 40.39

s Allow Mpa 196.18 196.18 196.18 196.18 196.18 196.18 196.18 196.18 196.18

Result OK OK OK OK OK OK OK OK OK

Freeboard For SUG II s = = When, Tc Af Af = = =

0.5 D Af 0.62 m

(E.7.2-1)

4.42 > 4 2.5 KQFaSoI(4Ts/Tc2) 0.07 = = 0.44 m 0.50 m (Table E-7)

Minimum Required Freeboard 0.7 s Provided Freeboard Height HENCE OK

Page 16 of 25

Design Calculation for T-109 tank

CHECK FOR SHELL-TO-ROOF FRANGIBLE JOINT REQUIREMENTS : As per Figure F-2, Detail-b

Top Angle 100 x 100 x 8 thk. Wh th

Wc

Rc tc tan = roof slope Area of Curb angle section plus the participating roof & shell Top angle provided Ac = Cross sectional area of top angle Wc = Max. width of participating shell Where, Rc tc Wh = 0.167

= = = = = = = = =

100 x 100 x 8 thk. 1550 sq.mm. 0.6(Rc tc)^0.5 139.43 mm 9000 mm 6 mm 0.3(R2 th)^0.5 or 300 mm (whichever is less) 171.94 mm 171.94 mm Rc/sin 54744.86 mm 6 Wc x tc 836.56 Wh x th mm sq.mm

= = =

Inside radius of tank shell Thickness of shell plate (uncorroded) Max. width of participating roof

Where, R2 = length of the normal to the roof, measured from the vertical centreline of the tank Thickness of roof plate (uncorroded) Participating area of shell plate = Participating area of roof plate Total area of roof-shell junction = = th As Ar At = = = = = = = = = = =

1031.62 sq.mm Ac + As + Ar

3418.18 sq.mm As per clause 5.10.2.6.d, The frangible roof joint for anchored tanks of any diameter, the tank shall meet the requirements of 5.10.2.6.a

Page 17 of 25

Design Calculation for T-109 tank

S.No 1

Requirement The slope of the roof at the top angle attachment does not exceed 2:12. The roof support members shall not be attached to the roof plate. The roof is attached to the top angle with a single continuous fillet weld on the top side (only) that does not exceed 5 mm (3/16 in.). No underside welding of roof to top angle (including seal welding) is permitted.

Actual Slope of the roof at the top angle attachment does not exceed 2:12 Roof support members are not attached to the roof plate. The roof is attached to the top angle with a single continuous fillet weld on the top side only and does not exceed 5 mm. No underside welding of roof to top angle (including seal welding) is provided. The roof-to-top angle compression ring is limited to 'detail-b' in Figure F-2.

Remarks OK

OK

OK

The roof-to-top angle compression ring is limited to details a - e in Figure F-2.

OK

As per clause 5.10.2.6, A = For frangible joint, the cross sectional area of the roof-to shell junction shall not exceed the following: W Ws Wrs = = = Total weight of the shell and any framing (but not roof plates) supported by the shell & roof Weight of the shell + miscellaneous items on shell Weight of roof structure

= = = = = =

W / (1390 tan ) 3499.57 Ws + Wrs 818324 759484 58840 sq.mm N N N

Total area of roof-to-shell junction, At < Area resisting the compressive force, A A > At & HENCE SHELL - TO - JOINT FRANGIBLE JOINT COMPRESSION AREA CHECK FOR INTERNAL PRESSURE Design Internal pressure Cross sectional area of tank Weight of the shell/roof/support Hence F.3 through F.6 shall apply = = = = = 2.450 kPa 0.0245 kg/cm2 2548650 Sq.cm 62441.92 kg 96650.19 kg

Required compression area as per F.5.1, A = 200 * D^2 (P - 0.08 th) Fy (tan q) Where D= P= th = Nominal tank Diameter Design internal pressure Nominal roof thickness = = = 18.014 m 2.450 kPa 6.00 mm

Fy = Minimum specified yield strength = 250 Mpa tan = Roof slope = 0.167 As per M 3.3 of API 650 the yield strength of material shall be multiplied by the ratio of the reduction factor

Page 18 of 25

Design Calculation for T-109 tank

Hence Material Yeiel strength ( MDT) Ratio Where, A =

= = =

250 x 221.25 Mpa 1.08 > 1

0.885 Hence ok

total required compression area at the roof to shell junction, in sq.mm = = = 3068.51 sq.mm 3068.51 sq.mm 3418.18 sq.mm

Required Compression Area Provided Compression Area

Provided compression area is adequate As per cl.F.4.1, the maximum design pressure, for a tank that has been constructed P: P = (A)Fy(Tan )/(200*D^2)+0.08th P = 2.67 Kpa As per cl.F.4.2, the maximum design pressure, limited by uplift at the base of shell, shall not exceed: Pmax Where, Pmax DLS = 0.00127DLS D^2 = = = = = = +0.08th 0.00425 M D^3

maximum design pressure, in Kpa Total weight of the shell & any framing (but not roof plates) supported by the shell & roof, in N. 916391 N Wind moment (Tank is provided with Ancharoge, hence M=0) 4393415 N-m 0 5845.62

M Pmax

1163.82 + 0.48 324.5 = 4.07 Kpa Pmax > Design Pressure Hence safe As per F.4.6,Calculated Failure Pressure

Pf Pf

= =

= As per Cl. F.4.3, the maximum design pressure for tank with a weak shell to roof attachment P max 0.8 Pf < 3.20 Kpa < Hence all the above conditions are meet for Appendix -F calculation

Calculated minimum failure pressure ( kPa) 1.6 P -0.047 th 4.00 Kpa

Page 19 of 25

Design Calculation for T-109 tank

DESIGN OF ANCHOR BOLTS & ANCHOR CHAIRS DESIGN OF ANCHOR BOLTS : Provide = Root area of bolt = Corrosion allowance Area available As per clause 5.11.3 The design tension load per anchor Overturning moment about the shell-to-bottom joint from horizontal plus vertical wind pressure Diameter of the anchor circle Number of anchors = =

48 mm. Dia. Bolts x 1458.00 sq.mm 0 mm 1458.000 sq.mm tb Mw d N W = = = = = =

36

nos.

(4Mw/dN) - (W/N) 59539 N 4393415 N-m 18.227 m 36 nos. -1E+06 N

Weight of the shell plus roof supported by the shell (corroded) less 0.4 times the uplift from internal pressure. As per clause E.6.2.1.2 - Mechanically Anchored tank W AB = Calculated design uplift load on anchors per unit circumferential length, N/m 2 = [(1.273 Mrw / D ) - Wt (1-0.4 Av)] = 177972 N/m PAB = The anchor seismic design load = = W AB ( D/N) 279775 N

E.6.2.1.2-1

E.6.2.1.2-2

Uplift load as per table -5-21 a Uplift load Case Design Pressure Condition [(P 0.08th ) D] W1 Test Pressure [(Pt 0.08th ) D] W1 Failure Pressure [(1.5 x Pf - 0.08th) x D 2] - W3 Frangilbility Pressure (3 x Pf-0.08 th)x D2 -W3 Wind Load [4 Mw/D] W2 Seismic Load [4 Ms/D] W2 Design Pressure + Wind [(P 0.08th ) D] + [4 Mw/D] W1 Design Pressure + Seismic [(P 0.08th) D] + [4 Ms/D] W1 9465591.1 262933.1 180.3 200 OK Net Uplift, Load/Bolt U (N) (N) -915751.37 -915751.37 N/A N/A -94842.06 9,310,945 -25437.5 -25437.5 N/A N/A -2634.5 258637.4 Stress/Bolt (Mpa) Allowable Stress Remarks (Mpa) 105 140 N/A N/A 200 200 OK OK N/A N/A OK OK

-17.4 -17.4 N/A N/A -1.8 177.4

59804.27

1661.2

1.1

140

OK

Page 20 of 25

Design Calculation for T-109 tank

W1 W2 W3 P th Pf Pt

= = = = = = = = =

Dead load of shell less C.A. and any dead load other than roof plate acting on shell less C.A. in N 916391 N Dead load of shell less C.A. and any dead load including roof plate acting on shell less C.A. in N 1070398 N

Dead load of shell including C.A. and dead load other than roof plate acting on the shell including C.A. in N

916391 N Design pressure, Kpa Roof plate thickness, mm Calculated minimum failure pressure, Kpa Test Pressure kPa 279775.5 N

= = = =

2.45 kPa 6.00 mm 4.00 kPa 2.45 kPa

Max Governing Load at each bolt

AISI T-192 Volume II, Part VII- ANCHOR BOLT CHAIRS Minimum cross sectional area of bolt Ab = Yield strength of bolt (A 36) Fy = Design Load Top plate width Top plate length Top plate thickness Anchor Bolt Diameter Anchor Bolt eccentricity Distance from outside of top plates to edge of hole Distance between vertical plate Chair Height Vertical Plate Width ( Average) Vertical plate thickness Bottom plate thickness Bottom shell course thickness + RF Pad Annular/Sketch Plate Projection Pitch Circle Diameter Diameter of the tank Radius of Shell Weld Size Top Plate Design Critical stress in top plate, S P a b c d e f g h k J m t Q PCD D R w = = = = = = = = = = = = = = = = = =

2.26 inch2 250 N/mm 2 279775 N 7.87 inch 7.87 inch 1.18 inch 1.89 inch 4.00 inch 2.93 inch 3.94 13.78 5.12 0.55 0.39 inch inch inch inch inch

1458 mm 2 = 200 200 30 48 101.53 62.871 Ksi mm mm mm mm mm

74.47 mm 100 350 130 14 10 mm mm mm mm mm

0.94 inch 2.36 inch 717.60 inch 708.66 inch 354.33 inch 0.2362 inch

24 mm 60 mm 18227.05 mm 18000 mm 9000 mm 6 mm

= = =

2 P / f c * (0.375 g - 0.22 d) 16.30 Ksi

1146.18

<

1682.51 kg/cm 2

Bending plus direct stress in shell at top plate, Sb = P e / t2 * [(1.32Z / {(1.43ah 2/Rt + (4 a h 2)0.333} + (0.031 / (R t) 0.5) = 15.57 Ksi = Where, Z = Reduction Factor = = HENCE OK 1.0 / [{0.177 a m / (R t) 0.995

0.5

1094.85

<

1682.51 kg/cm 2 }*(m / t) + 1]

2

Page 21 of 25

Design Calculation for T-109 tank

Vertical Plate: Minimum Thk. is Greater of 0.5 inch or 0.04 (h-c)

= = = =

0.5 or 0.5 or 0.5039 inch 12.8 mm P/25 2.51

0.04( h - c) 0.50

jk 2.82

> > HENCE OK

g j b Radius RF Pad k h

Q PCD

Weld Size Calculation Wv = = = = = W = = P/(a+2h) 1.77 Ksi Vertical Load on wels Pe/(ah+0.667h) 1.07 Ksi (Wv 2 + W H2)0.5 2.07 < HENCE OK

WH

2.27 Ksi

Page 22 of 25

Design Calculation for T-109 tank

VENT SIZE CALCULATION As per API 2000, D = Tank Diameter in m H V Vi Vo = = = = Tank Height in m Tank Capacity in m 3 Maximum Filling Rate in m /hr Maximum Emptying Rate,m 3/hr Flash Point of Liquid

3

= = = = =

18.00 m 18.80 m 4784.02 m 3 500.00 m 3/hr 120.00 m 3/hr 0 > 200 C

= = = = =

59.06 feet 61.68 feet ###### bbl 3,145 bbl/hr 755 bbl/hr

Inbreathing (Vacuum Relief) (a) Required venting capacity for liquid movement out of the tank (clause 4.3.2.1.1) iQ1 = 0.94 Vo (b) iQ2 (c) iQt = 112.80 Nm3/hr Required venting capacity for thermal inbreathing (Table -2B, Notes a) = 0.169 V = 808.5 Nm3/hr Required venting capacity for inbreathing = iQ1 + iQ2 = 921.3 Nm3/hr

Outbreathing (Pressure Relief) (a) Required venting capacity for liquid movement into the tank (clause 4.3.2.2.1) oQ1 = 1.01 Vi = 505.00 Nm3/hr (b) Required venting capacity for thermal outbreathing (Table -2B, Notes b) oQ2 = 60 % of inbreathing = 485.1 Nm3/hr (c) Required venting capacity for outbreathing oQt = oQ1 + oQ2 = 990.1 Nm3/hr Size and Number of Free Vents D1 = Size selected, in inch D = Inside Diameter of Vent (a) Vent Flow Area without Screen (A1) 2 A1 = /4 * D (b) f1 A2 (c) Vm Vent Flow Area with Screen (A2) Wire Size = 60 meshes per sq.inches = Nominal screen area = f1*A1 = = = 6 Inch Schedule 40/Std. 155.96 mm 19104 mm 2 = 0.019 m 2

37% = 7068.4 mm 2 = 0.007 m 2

Mean Velocity Vm = 2*g*P f*d = 41.93 m/s = 2E+05 m/hr

Page 23 of 25

Design Calculation for T-109 tank

Where, P d f g = = = = Maximum difference venting pressure = Density of Vapour Total Resistance co-efficient Acceleration due to gravity 224.25 mmH2O = = = 224.25 kg/m 2 1.25 kg/m 3 2.00 9.8 m/s 2

(d) Inbreathing / Outbreathing Capacity, Q 1 - Without Screen Q1 = A1 * Vm = 2,884 m 3/hr

2 - With Screen Q2 =

A2 * Vm

1,067 m 3/hr

(e) Quantity of Free Vent required, N 1 - Without Screen N = Max. ( iQt or oQt) / Q1 2 - With Screen N = Provide 2

0.34335 SET(S)

Max. ( iQt or oQt) / Q2 SET(S) of 6

0.928 SET(S) Free Vent with Screen

Inch Schedule 40/Std.

Page 24 of 25

Design Calculation for T-109 tank

LOADING DATA : Shell Bottom plate Roof plate Roof Structural Top Curb Angle Ladder & Platform Shell appurtenances Roof appurtenances Anchor chair Misc. wt. Insulation Weight ( Shell)

74.53 Mt 20.31 Mt 12.60 Mt 6.00 Mt 0.42 Mt 1.50 Mt 1.00 Mt 0.60 Mt 2.80 Mt 0.45 Mt 12.50 Mt

Fabricated Weight Product wt. Test water wt. Operating Weight Hydrotest Weight Wind shear Wind moment Seismic shear Seismic moment Size and Number of anchor bolts Bolt Circle Diameter

132.7 Mt 5122 Mt 4784 Mt 5255 Mt 4917 Mt 49 Mt 448 Mt-m 628 Mt 4767 Mt-m

M 48 x 36 Nos.

18.23 m

Page 25 of 25

You might also like

- Southern Marine Engineering Desk Reference: Second Edition Volume IFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume INo ratings yet

- API 650 Tank Design 5Document44 pagesAPI 650 Tank Design 5Inamullah Khan93% (14)

- Storage Tanks CalculationsDocument21 pagesStorage Tanks Calculationsjimallen21288% (26)

- Design of an anchor chair for offshore structuresDocument1 pageDesign of an anchor chair for offshore structuresMohammed Faizal Nv100% (2)

- API 650 Tank Design CalculationsDocument8 pagesAPI 650 Tank Design Calculationsツ ツNo ratings yet

- API 650 Water Storage Tank - Xls 36Document71 pagesAPI 650 Water Storage Tank - Xls 36rudi 01No ratings yet

- Thickness Cal. Fo DM Water Storage Tank-API 650Document15 pagesThickness Cal. Fo DM Water Storage Tank-API 650Jose Rodriguez50% (2)

- Storage Tank CALC Api 650Document10 pagesStorage Tank CALC Api 650kuselanml100% (3)

- API 650 Design TanksDocument34 pagesAPI 650 Design TanksSyedZainAli100% (13)

- API 650 Tank Design 1Document5 pagesAPI 650 Tank Design 1Jose Ortiz100% (1)

- Storage Tank DesignDocument21 pagesStorage Tank Designravi456compNo ratings yet

- Storage Tank DesignDocument43 pagesStorage Tank DesignsamvendanNo ratings yet

- Design of anchor bolts and base plate for a fixed base columnDocument4 pagesDesign of anchor bolts and base plate for a fixed base columnSuryaSinghNo ratings yet

- Tank-API-650-SI-Manzanillo-30 mbls-API-650-Calculation-Report - 1Document52 pagesTank-API-650-SI-Manzanillo-30 mbls-API-650-Calculation-Report - 1Tony Lozada Mahuen100% (1)

- Tank Calc - Api650Document90 pagesTank Calc - Api650kamleshyadavmoney100% (3)

- Saddle Design at Operating ConditionDocument17 pagesSaddle Design at Operating ConditionGanesh Bhardwaj100% (2)

- Tank Design As Per IS803 and API650Document36 pagesTank Design As Per IS803 and API650Vikash Kumar Singh100% (1)

- Storage Tank Design Calculations for Hydrogen PeroxideDocument12 pagesStorage Tank Design Calculations for Hydrogen Peroxidechompink6900No ratings yet

- GS 158-1 Internal Floating Decks For Storage Tanks: March 1998Document38 pagesGS 158-1 Internal Floating Decks For Storage Tanks: March 1998Mohd KhairulNo ratings yet

- Inigneers India Lltvilteid: ElevationDocument7 pagesInigneers India Lltvilteid: ElevationSandip SurNo ratings yet

- Storage Tank Design Calculation - Api 650: Close Floating RoofDocument31 pagesStorage Tank Design Calculation - Api 650: Close Floating RoofNguyễn Duy HưngNo ratings yet

- Design As Per APIDocument82 pagesDesign As Per APINeeraj BhallaNo ratings yet

- Anchor Bolt Chairs - CalculationDocument8 pagesAnchor Bolt Chairs - Calculationchicaiza123No ratings yet

- Design Calculation TankDocument28 pagesDesign Calculation Tankibiceng100% (4)

- API 650 Storage Tank Load Computations With Ring Wall Foundation Design (8.7-m Diameter X 9.0-m Height)Document25 pagesAPI 650 Storage Tank Load Computations With Ring Wall Foundation Design (8.7-m Diameter X 9.0-m Height)AVBP100% (3)

- API 650 Tank Design CalculationDocument9 pagesAPI 650 Tank Design CalculationSunday PaulNo ratings yet

- Anchor Chair Design FinalDocument26 pagesAnchor Chair Design FinalLe Bacha Bacha100% (4)

- Best Tank Calculation SheetDocument88 pagesBest Tank Calculation Sheetchriscivil12No ratings yet

- Tank Shell DesignDocument4 pagesTank Shell Designgon972001No ratings yet

- Stress Relaxation and CreepDocument7 pagesStress Relaxation and CreepRaasik JainNo ratings yet

- 16.0 M Dia X 18.0 HT Fire Water Tank Rev 4 (2) - CommentedDocument29 pages16.0 M Dia X 18.0 HT Fire Water Tank Rev 4 (2) - CommentedKP SAHU100% (1)

- Tank Anchor Bolt DesignDocument9 pagesTank Anchor Bolt Designgon972001100% (1)

- PFS FWKO Tank EvaluationDocument12 pagesPFS FWKO Tank EvaluationkoyahassanNo ratings yet

- Design of Flat Head For HydrotestDocument12 pagesDesign of Flat Head For HydrotestSAGARNo ratings yet

- Self-Supported Cone Roof: Design of Steel Storage Tanks As Per Api-650 (Diameter 3M)Document29 pagesSelf-Supported Cone Roof: Design of Steel Storage Tanks As Per Api-650 (Diameter 3M)amokhta0% (1)

- PV Elite 2013 SP3 Licensee: ISGEC TubeSheet CalcDocument8 pagesPV Elite 2013 SP3 Licensee: ISGEC TubeSheet CalcMayank MittalNo ratings yet

- API 650 Storage Tank Design CalculationDocument14 pagesAPI 650 Storage Tank Design CalculationMohammed EljammalNo ratings yet

- API 650 Tank Design CalculationDocument8 pagesAPI 650 Tank Design CalculationNorazlan Shah Mahadi100% (1)

- External Floating Roof RequirementsDocument3 pagesExternal Floating Roof RequirementsSajeev NarayananNo ratings yet

- Design Calculation R1 PDFDocument14 pagesDesign Calculation R1 PDFJagankumarNo ratings yet

- API 650 Design TanksDocument39 pagesAPI 650 Design TanksAhmedAli25% (4)

- Double Deck - Floating RoofDocument7 pagesDouble Deck - Floating RoofDhia SlamaNo ratings yet

- Design Tanks Menurut API 650Document80 pagesDesign Tanks Menurut API 650irbar.darmansyah.alwiNo ratings yet

- API 650 Storage Tank TCA PreparationDocument86 pagesAPI 650 Storage Tank TCA PreparationBimal DeyNo ratings yet

- Mechanical Calculation For Crude Oil Storage Tanks (TK-6001 6020)Document38 pagesMechanical Calculation For Crude Oil Storage Tanks (TK-6001 6020)Hamid MansouriNo ratings yet

- Etank Full ReportDocument108 pagesEtank Full ReportFaizal SattuNo ratings yet

- Mechanical design of open top fire water tankDocument30 pagesMechanical design of open top fire water tankkpsahuNo ratings yet

- Design Calculations For V2703 Rev 0Document9 pagesDesign Calculations For V2703 Rev 0Dilip KatekarNo ratings yet

- Curb AngleDocument1 pageCurb Angle940623015859No ratings yet

- Premium TankDocument26 pagesPremium TankAnonymous p0iwBoNo ratings yet

- Hfo Service Tank - ht003 Data Sheet r1 PDFDocument4 pagesHfo Service Tank - ht003 Data Sheet r1 PDFsocomenin2013No ratings yet

- API 650-Water SS Tank-060914Document84 pagesAPI 650-Water SS Tank-060914A.K.M Shafiq MondolNo ratings yet

- Tank Stability 10.0: Shell Dimension, NewDocument4 pagesTank Stability 10.0: Shell Dimension, NewjonedNo ratings yet

- Calculation Storage Tank1000 KL PDFDocument58 pagesCalculation Storage Tank1000 KL PDFemre gedikli100% (1)

- Diesel Tank TaluksangayDocument70 pagesDiesel Tank TaluksangayBert EngNo ratings yet

- Heat Transfer Fluid Comparison Table: Key Properties and Temperature RatingsDocument58 pagesHeat Transfer Fluid Comparison Table: Key Properties and Temperature RatingsShiv Raj0% (1)

- Fresh HDO Storage TankDocument42 pagesFresh HDO Storage TankHgagselim SelimNo ratings yet

- EN Calculation of Storage TankDocument3 pagesEN Calculation of Storage TanknodyyyNo ratings yet

- Double Deck CalDocument18 pagesDouble Deck Calranjitpandey0% (1)

- Tugas Perancangan TankiDocument47 pagesTugas Perancangan Tankimuh irchamNo ratings yet

- Broadband Metamaterials in ElectromagneticsDocument399 pagesBroadband Metamaterials in ElectromagneticsFarhad AzadiNo ratings yet

- Design Calculation For Dirty Brackish Water Tank (129-0T2540)Document9 pagesDesign Calculation For Dirty Brackish Water Tank (129-0T2540)Dhakshina KNo ratings yet

- Applications of Nitinol Propulsion DeviceDocument4 pagesApplications of Nitinol Propulsion DeviceDeepak BhopeNo ratings yet

- Low Speed Aerodynamics (Aerodynamics-I) : Multiple Choice Questions Set 3Document4 pagesLow Speed Aerodynamics (Aerodynamics-I) : Multiple Choice Questions Set 3Harish MathiazhahanNo ratings yet

- Cast IronDocument12 pagesCast Irongaby908No ratings yet

- EN 10025 Grade S355J2C Normalized or Normalized Formed (+N)Document3 pagesEN 10025 Grade S355J2C Normalized or Normalized Formed (+N)melvin ekboteNo ratings yet

- Ecr Glassflake: Micronised Grade GF007CDocument1 pageEcr Glassflake: Micronised Grade GF007Capde06No ratings yet

- Experimental study of four-point bending test on CLT deep beamsDocument6 pagesExperimental study of four-point bending test on CLT deep beamsFergus GardnerNo ratings yet

- High Temp Furnace Bottom Loading Ceramics MetalsDocument4 pagesHigh Temp Furnace Bottom Loading Ceramics MetalsDekanat FizfakNo ratings yet

- Principal Application Fields Case Hardening Steel:: 20Mncr5Document1 pagePrincipal Application Fields Case Hardening Steel:: 20Mncr5Bhuvnesh VermaNo ratings yet

- IndxDocument50 pagesIndxsupriyo1970No ratings yet

- Fatigue Analysis of Pulley by Using Finite Element AnalysisDocument4 pagesFatigue Analysis of Pulley by Using Finite Element AnalysisTJPRC PublicationsNo ratings yet

- ME303 7 Head Loss 2 BranchedDocument39 pagesME303 7 Head Loss 2 BranchedtoshugoNo ratings yet

- Article: Fabricating A Low-Cost Raman SpectrometerDocument8 pagesArticle: Fabricating A Low-Cost Raman SpectrometerNeethu EmmanuelNo ratings yet

- Full Download Electric Circuits 10th Edition Nilsson Solutions Manual PDF Full ChapterDocument36 pagesFull Download Electric Circuits 10th Edition Nilsson Solutions Manual PDF Full Chapterpachyunmuzzleimshbk100% (15)

- MM235 - Phase Diagram - SMDocument18 pagesMM235 - Phase Diagram - SMUtkarsh MishraNo ratings yet

- CO1 HaysDocument4 pagesCO1 Hayso100% (1)

- Volumer Fraction and Weight Fraction by Rik Heslehurst PHD, MEng, BEng (Aero) FIEAust, FRAeS, CPEng PDFDocument3 pagesVolumer Fraction and Weight Fraction by Rik Heslehurst PHD, MEng, BEng (Aero) FIEAust, FRAeS, CPEng PDFM.Saravana Kumar..M.ENo ratings yet

- MECH 390 - PRACTICE 1 - FALL 2011Document5 pagesMECH 390 - PRACTICE 1 - FALL 2011Abeer AlnaqbiNo ratings yet

- PENGARUH SUDUT POTONG DAN KECAMATAN POTONG TERHADAP MESIN BUBUTDocument5 pagesPENGARUH SUDUT POTONG DAN KECAMATAN POTONG TERHADAP MESIN BUBUTDonnie Hafiz Prasetya RitongaNo ratings yet

- Optical Cavity Modes and Laser FrequenciesDocument70 pagesOptical Cavity Modes and Laser FrequenciesHung DauBiNo ratings yet

- Concrete Types in Morden ConstructionDocument7 pagesConcrete Types in Morden ConstructionAkshay Kumar Sahoo100% (2)

- Module 2 Compression MemberDocument10 pagesModule 2 Compression MemberMichael James ll Banawis100% (1)

- Connecting Rod B.E. BoltsDocument16 pagesConnecting Rod B.E. BoltsAnjaana PrashantNo ratings yet

- Lab 10 Diffraction and InterferenceDocument5 pagesLab 10 Diffraction and InterferenceMeowerNo ratings yet

- Fetter Ch6r PDFDocument11 pagesFetter Ch6r PDFAbdul SalamNo ratings yet

- FabricationDocument6 pagesFabricationhimansu palNo ratings yet

- ACTIVITY#2 Group Activity PDFDocument5 pagesACTIVITY#2 Group Activity PDFAlfaro, Jeff SimonNo ratings yet

- Alloy 827182 Welds PaperDocument21 pagesAlloy 827182 Welds PaperOscarCastilloNavaNo ratings yet