Professional Documents

Culture Documents

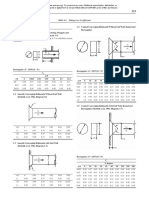

Figure - 1 Friction Loss For CLOSED Piping Systems: Schedule 40 Steel

Uploaded by

Suat YilmazOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Figure - 1 Friction Loss For CLOSED Piping Systems: Schedule 40 Steel

Uploaded by

Suat YilmazCopyright:

Available Formats

Design Criteria:

3 Frictional Pressure Drop per 100 Pipe Length with a Maximum Velocity of 10 ft/sec

Figure - 1

Friction Loss for CLOSED Piping Systems: Schedule 40 Steel

Source: Carrier Systems Design

Design Criteria:

3 Frictional Pressure Drop per 100 Pipe Length with a Maximum Velocity of 10 ft/sec

Figure - 2

Friction Loss for OPEN Piping Systems: Schedule 40 Steel

Source: Carrier Systems Design

Design Criteria:

3 Frictional Pressure Drop per 100 Pipe Length with a Maximum Velocity of 10 ft/sec

Figure - 3

Friction Loss for Copper Piping Systems: Types K, L, & M

Source: Carrier Systems Design

Example:

6800 lbs per hour of steam flow in a 2 inch pipe at 100 psig pressure. What is the pressure (psi) drop per 100 ft length of pipe and the flow velocity? Answer: psi/100 = 11 velocity = 32,000 fpm Steam Flow Rates at Various Pressures and Velocities for Schedule 40 Pipe Source:

Figure - 17 ASHRAE

Figure 18

Steam flow at 30 psig Source: ASHRAE

Design Criteria:

0.75 psi per 100 ft pipe Max Vel = 6,000 fpm

Figure 19

Steam flow at 50 psig Source: ASHRAE

Design Criteria:

1.0 psi per 100 ft pipe Max Vel = 8,000 fpm

Figure 20

Steam flow at 100 psig Source: ASHRAE

Design Criteria: 2.0 psi per 100 ft pipe Max Vel = 10,000 fpm

Figure 21

Steam flow at 150 psig Source: ASHRAE

Design Criteria: 2.0 psi per 100 ft pipe Max Vel = 10,000 fpm

Figure 20

Steam flow at 100 psig Source: ASHRAE

Design Criteria:

2.0 psi per 100 ft pipe Max Vel = 10,000 fpm

Figure 21

Steam flow at 150 psig Source: ASHRAE

Design Criteria:

2.0 psi per 100 ft pipe Max Vel = 10,000 fpm

You might also like

- Halton TsaDocument9 pagesHalton TsaNetri KrisztiánNo ratings yet

- ACH580 Drives For HVAC Catalog 3AUA0000186691 RevEDocument36 pagesACH580 Drives For HVAC Catalog 3AUA0000186691 RevESalaar AnsarNo ratings yet

- UCSB Chemical Fume Hood Guide Construction RequirementsDocument15 pagesUCSB Chemical Fume Hood Guide Construction RequirementsabaddownNo ratings yet

- Table of PropertiesDocument26 pagesTable of PropertiesFrancisco Escobar100% (1)

- Heat Gain From Electrical and Control Equipment in Industrial Plants, Part II, ASHRAE Research Project RP-1395Document4 pagesHeat Gain From Electrical and Control Equipment in Industrial Plants, Part II, ASHRAE Research Project RP-1395Michael LagundinoNo ratings yet

- ME 415 Energy Systems Design TutorialDocument54 pagesME 415 Energy Systems Design TutorialcmahendrNo ratings yet

- Designing Air Flow Systems GuideDocument3 pagesDesigning Air Flow Systems Guidemarcoo8No ratings yet

- E20s HAP50 ManualDocument144 pagesE20s HAP50 ManualMohammed TanveerNo ratings yet

- Ra9514 Natl Fire Code of The PhilippinesDocument475 pagesRa9514 Natl Fire Code of The PhilippinesZoom UserNo ratings yet

- Lift CalculationDocument3 pagesLift CalculationHussain JiffryNo ratings yet

- AHRI Standard 885-2008 Duct Discharge Calculation SpreadsheetDocument17 pagesAHRI Standard 885-2008 Duct Discharge Calculation SpreadsheetJagatjeetMNo ratings yet

- Experiment No. 1 Centrifugal PumpDocument30 pagesExperiment No. 1 Centrifugal PumpkeaneNo ratings yet

- Hydraulic CalculationsDocument6 pagesHydraulic CalculationsmehranNo ratings yet

- MEBS6008 Environmental Services II Air Diffusion PrinciplesDocument72 pagesMEBS6008 Environmental Services II Air Diffusion Principlesahtin618No ratings yet

- ORC Working Fluids Comparison ECOS PresentationDocument16 pagesORC Working Fluids Comparison ECOS Presentationoverlord5555No ratings yet

- Run Around Coil Loop Heat RecoveryDocument3 pagesRun Around Coil Loop Heat RecoveryesagcojrNo ratings yet

- HVAC Ducting - Principles and FundamentalsDocument56 pagesHVAC Ducting - Principles and FundamentalsRiddhi Patel100% (1)

- Duct Sizing ChartDocument1 pageDuct Sizing ChartHaji AliNo ratings yet

- Duct Design Friction ChartDocument4 pagesDuct Design Friction ChartSupawat RangsiwongNo ratings yet

- Ductulator - Air Duct CalculatorDocument1 pageDuctulator - Air Duct CalculatorCarlos R. SantiagoNo ratings yet

- ASHRAE-Psychrometric Chart PDFDocument2 pagesASHRAE-Psychrometric Chart PDFBrian MayNo ratings yet

- Sizing Chiller Water TankDocument4 pagesSizing Chiller Water TankDhetak Pramudiyawan Nugroho100% (1)

- The equal friction method for sizing ductsDocument8 pagesThe equal friction method for sizing ductsRamil BelmonteNo ratings yet

- CALCULATE ORIFICE DIAMETER FLOWDocument4 pagesCALCULATE ORIFICE DIAMETER FLOWNaseer HydenNo ratings yet

- Water Meter Design Criteria ManualDocument21 pagesWater Meter Design Criteria ManualAnonymous M0tjyWNo ratings yet

- System Head in Metric UnitsDocument7 pagesSystem Head in Metric UnitsrammysiNo ratings yet

- Ashrae - Ambient Conditions - AhmedabadDocument2 pagesAshrae - Ambient Conditions - AhmedabadDaniel BrownNo ratings yet

- AMCA Air Density Correction TableDocument36 pagesAMCA Air Density Correction Tabledirk leeNo ratings yet

- Heating Ventilation and Air ConditioningDocument38 pagesHeating Ventilation and Air ConditioningpraisethenordNo ratings yet

- Getting Started PDFDocument81 pagesGetting Started PDFMohammad NadimNo ratings yet

- Hydraulic Calculations Adjusted FlowDocument9 pagesHydraulic Calculations Adjusted FlowMd Shaidur Rahman100% (1)

- Slope Drainage PipingDocument1 pageSlope Drainage PipingRyan CarterNo ratings yet

- Fahu CalculationDocument1 pageFahu CalculationArul SankaranNo ratings yet

- RoadDocument59 pagesRoadlim saryNo ratings yet

- PSD CEU 194dec12 PDFDocument22 pagesPSD CEU 194dec12 PDFCesar Muñoz OssesNo ratings yet

- Air Duct CalculatorDocument1 pageAir Duct CalculatorRinaldy100% (9)

- Carrier Chapter 3 Piping DesignDocument22 pagesCarrier Chapter 3 Piping DesignAhmad Al-rifaiNo ratings yet

- Basic CalculationsDocument3 pagesBasic CalculationsMohammad J HaddadNo ratings yet

- Cleanroom and HVAC Design FundamentalsDocument46 pagesCleanroom and HVAC Design FundamentalsИван ШимчукNo ratings yet

- Performance Analysis of Backward Curved Centrifugal Fan in Heating Ventilation and Air-ConditioningDocument3 pagesPerformance Analysis of Backward Curved Centrifugal Fan in Heating Ventilation and Air-ConditioningIjsrnet Editorial100% (1)

- ACCA Reaffirms HVAC Design For Pool and Spa Manual 1Document2 pagesACCA Reaffirms HVAC Design For Pool and Spa Manual 1mefaisal75No ratings yet

- HVAC Load Calculation FundamentalsDocument3 pagesHVAC Load Calculation Fundamentalssivajirao70No ratings yet

- Module 10 Q&ADocument7 pagesModule 10 Q&ACorin FramptonNo ratings yet

- Compressed Air Distribution SystemsDocument5 pagesCompressed Air Distribution SystemsVarrit VejpongsaNo ratings yet

- Fluid MechanicsDocument35 pagesFluid MechanicsJohn Ely Collado Bantog0% (1)

- Pipe Sizing Charts TablesDocument35 pagesPipe Sizing Charts TablesMaxmore KarumamupiyoNo ratings yet

- Pipe Sizing for Optimal Steam FlowDocument6 pagesPipe Sizing for Optimal Steam Flowferdie14No ratings yet

- PipeFlow PracticeProblemsDocument23 pagesPipeFlow PracticeProblemsFawaz PartoNo ratings yet

- Calculating Minimum Pump Power for Transferring a Distillate Through PipingDocument2 pagesCalculating Minimum Pump Power for Transferring a Distillate Through PipingmohdnazirNo ratings yet

- Paxtonengineeringbulletin PipingDocument4 pagesPaxtonengineeringbulletin PipingMuhammadObaidullahNo ratings yet

- Block 10 Module 2Document18 pagesBlock 10 Module 2Sandra FerrellNo ratings yet

- Chilled Water Pipe DESIGNDocument22 pagesChilled Water Pipe DESIGNTanjim FakirNo ratings yet

- TugasDocument12 pagesTugasMatias Nicolas Ponce OyanedelNo ratings yet

- Head Loss in A PipelineDocument7 pagesHead Loss in A PipelineIlham FirmansyahNo ratings yet

- Intel compressor air piping and cooling water sizingDocument3 pagesIntel compressor air piping and cooling water sizingmohamedbadawyNo ratings yet

- Pressure Drop Across PipelinesDocument4 pagesPressure Drop Across PipelinesDavid LambertNo ratings yet

- NFPA Pipe Sizing EXAMPLEDocument4 pagesNFPA Pipe Sizing EXAMPLEMatt AndersonNo ratings yet

- HazenwilliamsDocument3 pagesHazenwilliamsSherif A-fattah FouadNo ratings yet

- Basic of Hydronics SystemsDocument7 pagesBasic of Hydronics SystemskzyahtunNo ratings yet

- Sound ReductionDocument11 pagesSound ReductionWilliam GrecoNo ratings yet

- Pipe Sizing ChartsDocument8 pagesPipe Sizing ChartsSuat YilmazNo ratings yet

- Heat Load Calculation (Cold Storage Plant)Document3 pagesHeat Load Calculation (Cold Storage Plant)Kenny Graiven81% (26)

- Air Flow CorrectionDocument127 pagesAir Flow CorrectionantonwelgemoedNo ratings yet

- ElevatorDocument27 pagesElevatorSuat Yilmaz100% (2)

- Steam Reformer Design and ConstructionDocument9 pagesSteam Reformer Design and ConstructionBaher Elsheikh89% (9)

- Pipe Sizing ChartsDocument8 pagesPipe Sizing ChartsSuat YilmazNo ratings yet

- Energy Efficiency: Power Quality and Utilisation GuideDocument11 pagesEnergy Efficiency: Power Quality and Utilisation Guidedavid.spiderweb3961100% (6)

- Fans & Blowers-Calculation of PowerDocument20 pagesFans & Blowers-Calculation of PowerPramod B.Wankhade92% (24)

- Pipe Sizing ChartsDocument8 pagesPipe Sizing ChartsSuat YilmazNo ratings yet

- Pipe Sizing ChartsDocument8 pagesPipe Sizing ChartsSuat YilmazNo ratings yet

- ElevatorDocument27 pagesElevatorSuat Yilmaz100% (2)

- Pipe Sizing ChartsDocument8 pagesPipe Sizing ChartsSuat YilmazNo ratings yet

- ElevatorDocument46 pagesElevatorSuat YilmazNo ratings yet

- These Changes Are Highlighted in Pale Yellow in The Updated Draft ManuscriptDocument69 pagesThese Changes Are Highlighted in Pale Yellow in The Updated Draft ManuscriptSuat YilmazNo ratings yet

- These Changes Are Highlighted in Pale Yellow in The Updated Draft ManuscriptDocument69 pagesThese Changes Are Highlighted in Pale Yellow in The Updated Draft ManuscriptSuat YilmazNo ratings yet

- Pipe Sizing ChartsDocument8 pagesPipe Sizing ChartsSuat YilmazNo ratings yet

- Pipe Sizing ChartsDocument8 pagesPipe Sizing ChartsSuat YilmazNo ratings yet

- These Changes Are Highlighted in Pale Yellow in The Updated Draft ManuscriptDocument69 pagesThese Changes Are Highlighted in Pale Yellow in The Updated Draft ManuscriptSuat YilmazNo ratings yet

- Pipe Sizing ChartsDocument8 pagesPipe Sizing ChartsSuat YilmazNo ratings yet

- Pipe Sizing ChartsDocument8 pagesPipe Sizing ChartsSuat YilmazNo ratings yet

- Pipe Sizing ChartsDocument8 pagesPipe Sizing ChartsSuat YilmazNo ratings yet

- Pipe Sizing ChartsDocument8 pagesPipe Sizing ChartsSuat YilmazNo ratings yet

- Pipe Sizing ChartsDocument8 pagesPipe Sizing ChartsSuat YilmazNo ratings yet

- ElevatorDocument46 pagesElevatorSuat YilmazNo ratings yet

- Pipe Sizing ChartsDocument8 pagesPipe Sizing ChartsSuat YilmazNo ratings yet

- Pipe Sizing ChartsDocument8 pagesPipe Sizing ChartsSuat YilmazNo ratings yet

- Fire Alarm Sprinkler GuideDocument56 pagesFire Alarm Sprinkler GuideBrandon PacsNo ratings yet

- Pipe Sizing ChartsDocument8 pagesPipe Sizing ChartsSuat YilmazNo ratings yet

- Calculating Relief Valves Under The New ASHRAEDocument2 pagesCalculating Relief Valves Under The New ASHRAEchandrashekharsNo ratings yet