Professional Documents

Culture Documents

Calculating Building Materials

Uploaded by

Herman Mwakoi0 ratings0% found this document useful (0 votes)

243 views6 pagesbuilding materials

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentbuilding materials

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

243 views6 pagesCalculating Building Materials

Uploaded by

Herman Mwakoibuilding materials

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 6

Wickes

ISSUE 12/09

CALCULATING BUILDING

MATERIAL QUANTITIES

Pua ea Rey

Pea

Pela uo isan

Peat ieee Snort

Rae Nm py

Pence Men tec Cy

cea k CRA Man sd

ten er aaa

Psat

KEEP INFORMED

* Look for ather Good Idea

Leaflets that could help you

with your current project.

*+ Check that your Good Idea

Leaflets are kept up to date.

Leatiets are regularly changed

to reflect product changes so

keep an eye on issue dates.

+ If you would like to be put on

‘our mailing ist for the Wickes

bbookdet, cal our Freephone

umber which is

0500 300 328

Viel our wensite at

TOC SU RCM Te CUA LTS

ecu RCo e URSA ce rc Nt tig

Cee Suk CEE ea

Re ee a eu Rett)

Pee un Ue Rac)

eae CRC me en aC

the length and the height, _through.

Cora ce Ty

Beer and

BRICKWORK

Brick sizes vary slightly because of the way they are made but for ease of calculation

the size of one brick is taken as 215 x 102.5 x 65mm and for normal brickwork the

joint between the bricks both vertically and horizontally is 10mm.

When deciding how many bricks are required the thickness of the mortar joint is.

included into the calculations, making the measurement ofthe brick

205 x 102.5 x 75mm. By adding the mortar joint thickness any slight variations in size

for the bricks i taken into account.

When determining how many bricks are required you should first work out the area of

the brickwork as follows:~ Length of wall say 4m, height of wall say 0.5m, multiply the

two figures together, 4m x 0.5m = 2 square metres. Square metres are often written

asm? or sqm

For an easy rule of thumb guide you should allow 60 bricks per square metre for the

building of a single skin wall. This is known as a half brick wall and is shown in

Diagram 1. The style is known as Stretcher Bond with only the long ‘Stretcher faces

ofthe bricks visible

Inthe example above for a 2 square metre wall you will need to mutiply 2 (area of

brickwork) x 60 (number of bricks per square motre) = 120 bricks.

I you intend constructing a one brick thick solid wall, as shown in Diagram 2, then

you should allow for 120 bricks per square metre. So for a one brick thick solid wall

you will need 2 (area of brickwork) x 120 (number of bricks per square metre) = 240

bricks. The visible ends of bricks are known as ‘Headers!

“These figures do not allow for wastage or breakage, so it would be advisable to add a

few extra to the order to make certain you do not run short. Normally 10% extra

should be sulficent.

Mortar

The next question to be answered is, how

‘much mortar will | need? Wickes bagged

bricklaying mortar is supplied to the

correct ratio for general bricklaying to

fensure a perfect mortar mix. (The weight

ff bags is approximately 25kq but this

does vary depending upon the moisture

content) With our bricklaying mortar all

that is necessary is for water to be added.

However, if large quantities are required

25kg bags of Masterorete cement and

[Major bags of building sand are available

for you to make your own mix.

A bag of Wickes bricklaying mortar is

sufficient for about 25 bricks, depending

fon the thickness of the mortar joints, so

for a square metre of brickwork (60 bricks)

2 8 bags will be required

So to find out how many bags of Wickes

bricklaying mortar mix are required for the

‘example wall measuring 4m long by 0.5m

high and using 120 bricks we need to

divide the total number of bricks (120) by

25 (coverage of one bag)

120

25 = 4.850 § bags of bricklaying

‘mortar are needed,

If the wall is to be built one brick thick

Using 240 bricks you would need:-

240

25 = 9.6 so 10 bags of bricklaying

‘mortar are needed,

Tolay say 1000 bricks (16.5 square metres)

fas a single skin wall, approximately 0.3

Cubic metres of mortar wil be needed, or

40 bags of bricklaying mortar. If the wall is

to be built as a one brick thick sold wall

then you wil need 60 bags of Wickes

bricklaying morta.

NOTE: All calculations and quantities

are approximate and the information

supplied should be used for guidance

only.

General

A bag of Wickes bricklaying mortar

contains all the necessary ingredients to

‘make a good quality mortar mix, which is

suitable for most general “purpose

brickwork or blockwork. However, i you

want to mix your own mortar the

proportions for most general bricklaying

purposes should be 1:5, that is one part

Mastererete cement to five parts building

ssand for bricklaying.

The mix may vary slightly depending on

12 type of structure being built, (See

chart at the end of this section). The

‘measurements can be by weight or, much

more easily, by volume, such as the

bucketful, but they must be constant for

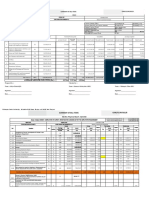

NUMBER OF BRICKS & AMOUNT OF MORTAR REQUIRED

(ingle skin of brickwork)

Sqm. of

brickwork

Number of

bricks needed

120

120

240

300

360

420

480

540

600

Bags of

bricklaying mortar

(ounded up)

24 (3)

4865)

728)

9.6 (10)

12

14.4 (15)

16.8(17)

19.2 (20)

21.6 (22)

24

NUMBER OF BRICKS & AMOUNT OF MORTAR REQUIRED

(oli one brick thick wall)

Sqm. of

brickwork

1

Number of

bricks needed

120

240

360

480

600

720

840

960

1080

1200

Bags of

bricklaying mortar

(ounded up)

4818)

9.6 (10)

14.4 (15)

192 (20)

24

28.8 (28)

33.6 (34)

38.4 (39)

49.2 (44)

48

For concrete blocks the calculations are a lot easier. Wickes medium density

‘concrete blocks and Wickes aerated concrete blocks measure 450 x 215 x

100mm - both types can be used above or below ground.

‘You will need roughly 10 blocks per square metre of wall, and 2 bags of

bricklaying mortar will be sufficient for 10 blocks. So for every square motre of

block work order 2 bags of bricklaying mortar mix.

NUMBER OF BLOCKS & AMOUNT OF MORTAR REQUIRED

(ingle skin 100mm thick blocks)

Sqm. of ‘Number of Bags of Wickes

blockwork blocks needed bricklaying mortar

1 10 2

2 20 4

3 30 6

4 40 a

5 50 10

6 60 12

7 70 14

8 20 16

9 90 18

10 100 20

(One 25kg bag of Mastorcrete cement

and 5 bags of building sand will make a

{general purpose mortar of 1:5 mix -

fenough to lay about 140 bricks or about

35 conerete blacks.

I you are laying your brickwork in the

cold weather, or are looking for greater

mixing water, in the amounts shown on

the packaging instructions. The

plasticiser produces tiny alr Bubbles in

the mortar to allow the water to expand

in freezing conditions and to reduce the

possibilty of the mortar cracking. The

plasticiser is the modern replacement for

lime that was once used in mortar mixes.

CHOOSING MORTAR MIXES FOR BRICKWORK

Type of construction

External walls above d.p.. level

External walls below dpc. level

Internal walls and inner leaf of cavity walls

Coping stones and sil,

Parapets and domestic chimneys

Retaining walls

External freestanding walls

Manholes

CHOOSING MORTAR MIXES FOR BLOCKWORK

Type of construction

External walls above 4.p.. level

External walls below dpc. level

Internal walls

Parapets

External freestanding walls

Manholes

CHOOSING A SUITABLE MORTAR MIX FOR RENDERING

Background material Mix

Low suation such as

hard dense clay bricks

dense conerate blocks

stone masonry

concrete

Normal suction such as

average types of bricks

clay blocks concrete

blocks aerated

conerete blocks

ALL RATIOS B)

Mastercrete cement /sharp sand

Mastererete cement ‘sharp sand

Proportions of Mastercrete

‘Cemenv/Building Sand

15

145

16

13

145

13

145

145

Proportions of Mastercrete

‘Cemenv/Building Sand

6

15

16

16

15

15

coat coat

194 15

18 16

3Y VOLUME

The amount of water needed to make a

perfect mortar mix is also important, For a

bag of bricklaying mortar about 2.5 litres

(of water will be required.

However, water should be added first in

sufficient quality to allow it to be absorbed

by the mix, then itis added litle by litle

Until the mix has the consistency of butter

+ slipping easily from the shovel but firm

‘enough forthe sides not to collapse when

a hollow is made in the centre of the mix.

Mortar should be used within two hours of

‘mixing, so only mix sufficient to be used

Within that time. A rule of thumb estimate

is that it takes about 2.5 minutes to lay

fone brick. I the mortar stiffens slightly

while you are working, bring the

consistency back by adding a litle water.

Ifthe micis too dry it will not adhere to the

bricks propery, if itis too wet the mortar

will simply 0020 from the joint under the

\woight of the bricks.

In the mixes above, note the use of

different types of sand.

Types of sand & aggregates

‘Sand and aggregates are graded by the

size and shape of their particles. A well

graded sand for example, will have

Particles of dierent sizes - not all large

‘and not all small

Sharp sand

A rather coarse and gritty material. It is

normally used with other, coarse

aggregates for making concrete and floor

soreeds,

Soft sand

Known as builders or bricklayers sand this

hhas smoother particles and is of a finer

grade than sharp sand. It is mixed with

“Mastercrete cement to produce bricklaying

mortar,

The test of a good quality sand is that it

should not stain your hands when you

squeeze it.

Coarse aggregate (Not stocked on its

own by Wickes).

Basically this is gravel or crushed stone of

sufficient size to be retained by a mm

siove up to a maximum size of 20mm. itis

used to form concrete when mixed with

Ballast

known as ‘combined’ or ‘all-in’ aggregate,

this 1s a mix of sharp sand and coarse

aggregate and is used for making

concrete. The proportions of sand to

{gravel are not normally guaranteed but

‘are acceptable for use in a general

purpose concrete mix.

Storage

Sand and aggregates should always be

stored in a neat pile on a board or plastic

sheet and should always be protected

from dirt and rain by covering with a

plastic sheet. This should be weighted

‘down with bricks or similar heavy objects

to prevent it bowing away.

Conerete

Gonerete is one of the most useful

materials that can be used around the

home. It can be used to create a paved

area such as a path or driveway, of used

{as foundations to support a wall. Concrete

is normally made from three basic

materials - Mastororete cement, sharp

sand and coarse aggregate. Mixed

together the three ingredients form a

strong and solid structural materia

A mix is generally expressed as, for

‘example, 1:2:4, which indicates 1 part

Mastercrete Cement, 2 parts sharp sand

and 4 parts ballast (gravel). There are

varying mixes for dlfferent purposes and

these are indicated shortly.

When the sharp sand and gravel are

‘promixed this is known as allin ballast (or

alin aggregate). In the example just

described the mix would be expressed as

1:6 meaning 1 part Mastercrete Cament

to 6 parts all-in ballast

For convenience and to ensure a perfect

mix, a bagged Wickes concrete mix is

available. This has the correct amount of

‘coment and all-in ballast and all that is

necessary is for clean water to be added.

Between two and three litres of water will

'be needed for each bag of concrete mix.

‘As a rule of thumb, one bag of Wickes

concrete mix will cover an area of

approximately 0.0125 m*. It is difficult

to give exact figures as the sub-base for

concrete work, which is normally

hardeore or broken bricks, varies so much

in shape and has voids to be fille.

Mixing

The ballast should be thoroughly mixed

betore the cement is added, Mix in the

‘cement until the dry pile has an even

‘colour. Then the water can be added trom

‘a watering can, The mix is correct when

you can make a series of ridges in the top

‘surface by dragging the back ofthe shovel

across. The surface of the concrote

‘should be fiat and even and the ridges

You might also like

- Building Materials for College Engineering ProjectDocument40 pagesBuilding Materials for College Engineering ProjectMark Anthony Mores FalogmeNo ratings yet

- CE6704 Pec - EQS PDFDocument115 pagesCE6704 Pec - EQS PDFNIROB KUMAR DASNo ratings yet

- Rates Analysis for Building WorksDocument8 pagesRates Analysis for Building WorksyogeshNo ratings yet

- Chapter No. 27 Quantities of Materials: NoteDocument14 pagesChapter No. 27 Quantities of Materials: NoteMANJEET SINGHNo ratings yet

- (New) Bhs Alejandro 2019Document39 pages(New) Bhs Alejandro 2019Juanito Dagasdas Jr.No ratings yet

- After Comment Jigjiga Citizen ChartersDocument44 pagesAfter Comment Jigjiga Citizen ChartersMame SomaNo ratings yet

- Data Rates-Dam Works-Part 8Document21 pagesData Rates-Dam Works-Part 8vpmohammedNo ratings yet

- Project Cost Estimation and Valuation GuideDocument32 pagesProject Cost Estimation and Valuation GuideYohannes HabeshawiNo ratings yet

- Description Unit Qty Rate Amount G+1 Multi Purpose Building: A-Sub StructureDocument7 pagesDescription Unit Qty Rate Amount G+1 Multi Purpose Building: A-Sub StructureYosiNo ratings yet

- Banquet Hall With KitchenDocument7 pagesBanquet Hall With KitchenPrabha khadkaNo ratings yet

- Ministry of Education construction contract summaryDocument51 pagesMinistry of Education construction contract summaryRock Man100% (1)

- 16 ClearingDocument1 page16 ClearingGreatHavokNo ratings yet

- Narayana Pet 400 (g+1) Houses-UrbanDocument103 pagesNarayana Pet 400 (g+1) Houses-UrbanK KARTHIKNo ratings yet

- 03 DITCH ScheduleDocument6 pages03 DITCH ScheduleMengstagegnew100% (1)

- StrengthDocument1 pageStrengthsutha_me20098282No ratings yet

- Interview On Construction Company: How To Cope With The PandemicDocument7 pagesInterview On Construction Company: How To Cope With The PandemicNicole Osuna Dichoso100% (1)

- Estimation AllDocument64 pagesEstimation AllAso GardiNo ratings yet

- Ethiopian Roads Project Progress ReportDocument32 pagesEthiopian Roads Project Progress ReportsamNo ratings yet

- Rate AnalysisDocument27 pagesRate AnalysisSRUTHI KNo ratings yet

- Quantity Surveying & Estimation-2Document17 pagesQuantity Surveying & Estimation-2Engr Nissar KakarNo ratings yet

- Geza Mixed BuilDocument20 pagesGeza Mixed BuilSisay chaneNo ratings yet

- RAYA UNIVERSITY PROJECT FINAL PAYMENT EXECUTED QTY JUSTIFICATIONDocument7 pagesRAYA UNIVERSITY PROJECT FINAL PAYMENT EXECUTED QTY JUSTIFICATIONzkalel_mNo ratings yet

- Break Down Cobble FinalDocument26 pagesBreak Down Cobble FinalAbinet ZewduNo ratings yet

- Basic Construction Training Manual Swiss Red Cross Skat FoundationDocument92 pagesBasic Construction Training Manual Swiss Red Cross Skat FoundationAnonymous M0tjyWNo ratings yet

- Civil Thumb RulesDocument8 pagesCivil Thumb RulesNasreen khushi muhammad NasreeNo ratings yet

- Technical Specifications and Measurements for Building Construction WorksDocument67 pagesTechnical Specifications and Measurements for Building Construction Workssamrawit aysheshimNo ratings yet

- Cost AnalysisDocument91 pagesCost AnalysisAbenezer TesfayeNo ratings yet

- SOR Road Works1!4!10Document95 pagesSOR Road Works1!4!10gagajainNo ratings yet

- IPC - 122 Shitoljhorna Khal RW DraftDocument73 pagesIPC - 122 Shitoljhorna Khal RW DraftArif AbedinNo ratings yet

- Formwork Is An Ancillary ConstructionDocument25 pagesFormwork Is An Ancillary ConstructionSarinNo ratings yet

- Compound WallDocument15 pagesCompound WallUday KumarNo ratings yet

- Hourly Labour Costs 2016Document14 pagesHourly Labour Costs 2016Anonymous VRspXsmNo ratings yet

- Specification and Quantity Surveying: COTM ProgramDocument27 pagesSpecification and Quantity Surveying: COTM ProgramTarmok HirpoNo ratings yet

- Rate AnalysisDocument28 pagesRate AnalysisRight TurnNo ratings yet

- Tender Process GuideDocument45 pagesTender Process GuideHany FathyNo ratings yet

- Cash Flow Summary For 3B+G+8 Mixed use apartment buildingDocument18 pagesCash Flow Summary For 3B+G+8 Mixed use apartment buildingÑatty MessawNo ratings yet

- Estimating Lesson Part 3-Estimating Lecture Notes (1) - Abcdpdf - PDF - To - WordDocument111 pagesEstimating Lesson Part 3-Estimating Lecture Notes (1) - Abcdpdf - PDF - To - WordSharrme ChandranNo ratings yet

- Estamiting and CostingDocument30 pagesEstamiting and CostingPramod RijalNo ratings yet

- Schedule - M - FORMULADocument148 pagesSchedule - M - FORMULAZainabu waziriNo ratings yet

- Time ScheduleDocument2 pagesTime ScheduleSanggalangi LatinroNo ratings yet

- Standard Coefficients For Building ProjectsDocument7 pagesStandard Coefficients For Building ProjectsrohitNo ratings yet

- Dire Dawa Housing Project Cost BreakdownDocument276 pagesDire Dawa Housing Project Cost BreakdownSolomonNo ratings yet

- Sor 2006Document54 pagesSor 2006Ram Narendra NathNo ratings yet

- SNNPRG South Omo Zone Construction DepartementDocument79 pagesSNNPRG South Omo Zone Construction DepartementIbrahim DawudNo ratings yet

- Description of Item of Work: C:/Users/Convert/Appdata/Local/Temp/1/Task-317813946Document4 pagesDescription of Item of Work: C:/Users/Convert/Appdata/Local/Temp/1/Task-317813946Abu MariamNo ratings yet

- Civil Site Data by DND ConstructionDocument35 pagesCivil Site Data by DND Constructiongowtham gowda100% (1)

- Project No - Agreement NoDocument10 pagesProject No - Agreement NoAlulaNo ratings yet

- Curriculm of Civil Engg& Allied DisciplineDocument21 pagesCurriculm of Civil Engg& Allied DisciplineAbbasabbasiNo ratings yet

- Rate Analysis Notes 3Document15 pagesRate Analysis Notes 3MADHU SUDAN H.N C-ENo ratings yet

- Activity 1Document2,866 pagesActivity 1Vincent Ronin SerratoNo ratings yet

- Analysis Book-2012Document4,514 pagesAnalysis Book-2012Muhammad Danish KhanNo ratings yet

- Quantitynotes 180816020109 PDFDocument73 pagesQuantitynotes 180816020109 PDFOm Krish RamNo ratings yet

- Rustomjee Realtors waterproofing rate analysisDocument4 pagesRustomjee Realtors waterproofing rate analysisAnis MushrifNo ratings yet

- Find Out The Following Quantities.: EXAMPLE:-2: The Figure Given Below Shows The Details of Septic TankDocument6 pagesFind Out The Following Quantities.: EXAMPLE:-2: The Figure Given Below Shows The Details of Septic TankAnkitNo ratings yet

- B S R - Buildings Dept - BatticaloaDocument263 pagesB S R - Buildings Dept - Batticaloaudithairesha100% (1)

- How Much Cement, Sand and Water Is Required For 12mm Thick Plastering - HapphoDocument7 pagesHow Much Cement, Sand and Water Is Required For 12mm Thick Plastering - HapphoJatinder BhatiaNo ratings yet

- 01 Introduction To EstimationDocument74 pages01 Introduction To Estimationkiran sreekumarNo ratings yet

- EARTH WORK VOLUME FROM 16+520-20+980: Station Cut Area (SQ.M.) Cut Volume (Cu.M.) Fill Area (SQ.M.) Fill Volume (Cu.M.)Document5 pagesEARTH WORK VOLUME FROM 16+520-20+980: Station Cut Area (SQ.M.) Cut Volume (Cu.M.) Fill Area (SQ.M.) Fill Volume (Cu.M.)Tewodros Tadesse100% (1)

- Brick MortarDocument6 pagesBrick MortarChris NaveenNo ratings yet

- Construction Material TermsDocument6 pagesConstruction Material TermsMuddassar FayyazNo ratings yet

- 9 Different Types of Fasts in The Bible - Glen Wolf PDFDocument1 page9 Different Types of Fasts in The Bible - Glen Wolf PDFHerman MwakoiNo ratings yet

- Drill Bit Types Guide - HSS, Masonry, Brad Point & MoreDocument7 pagesDrill Bit Types Guide - HSS, Masonry, Brad Point & MoreHerman Mwakoi100% (1)

- Artisan Manual (Draft)Document18 pagesArtisan Manual (Draft)Herman MwakoiNo ratings yet

- CashflowDocument2 pagesCashflowTarif HaqueNo ratings yet

- Sage 50 Resource GuideDocument185 pagesSage 50 Resource GuideshubizNo ratings yet

- Types of Fasts:: Full FastDocument3 pagesTypes of Fasts:: Full FastHerman MwakoiNo ratings yet

- Basic Accounting SampleDocument37 pagesBasic Accounting SampleJihadah HayatiNo ratings yet

- What Is A Green BuildingDocument2 pagesWhat Is A Green BuildingHerman MwakoiNo ratings yet

- Beef Recipe - Kenyan Beef Stew - What's For Dinner KenyaDocument1 pageBeef Recipe - Kenyan Beef Stew - What's For Dinner KenyaHerman MwakoiNo ratings yet

- Jingle Bells LyricsDocument2 pagesJingle Bells LyricsHerman MwakoiNo ratings yet

- 9 Different Types of Fasts in The Bible - Glen WolfDocument1 page9 Different Types of Fasts in The Bible - Glen WolfHerman MwakoiNo ratings yet

- Dhobi Sinks ModelDocument1 pageDhobi Sinks ModelHerman MwakoiNo ratings yet

- CashflowDocument2 pagesCashflowTarif HaqueNo ratings yet

- What Is Green Building - ..Document1 pageWhat Is Green Building - ..Herman MwakoiNo ratings yet

- The KitchnDocument2 pagesThe KitchnHerman MwakoiNo ratings yet

- The Organic FarmerDocument9 pagesThe Organic FarmerHerman MwakoiNo ratings yet

- QSCad Trial Version TutorialDocument23 pagesQSCad Trial Version TutorialHerman Mwakoi0% (1)

- Windows 7 Desktop Icons ..Document11 pagesWindows 7 Desktop Icons ..Herman MwakoiNo ratings yet

- Safemode in Windows 8Document8 pagesSafemode in Windows 8Herman MwakoiNo ratings yet

- Homemade Chicken Feed. Organic and Soy-Free! The Elliott HomesteadDocument21 pagesHomemade Chicken Feed. Organic and Soy-Free! The Elliott HomesteadHerman MwakoiNo ratings yet

- From Archicad To Working DrawingsDocument12 pagesFrom Archicad To Working DrawingsAtif ShaikhNo ratings yet

- Total Station Setup and OperationDocument33 pagesTotal Station Setup and OperationMaskusHaryadiNo ratings yet

- 51 Fantastic Uses For Ba..Document10 pages51 Fantastic Uses For Ba..Herman MwakoiNo ratings yet

- Disk PartDocument4 pagesDisk PartHerman MwakoiNo ratings yet

- Estimating How Much Roofing Is RequiredDocument5 pagesEstimating How Much Roofing Is RequiredMark Alvin PunzalanNo ratings yet

- My Bucket Feeder - by Te... Yard Chickens Community PDFDocument5 pagesMy Bucket Feeder - by Te... Yard Chickens Community PDFHerman MwakoiNo ratings yet

- My Automatic Waterer - BackYard Chickens CommunityDocument10 pagesMy Automatic Waterer - BackYard Chickens CommunityHerman MwakoiNo ratings yet

- QS CD GuideDocument5 pagesQS CD GuideHerman MwakoiNo ratings yet

- Residential House Elevations and Floor PlansDocument1 pageResidential House Elevations and Floor PlansHerman MwakoiNo ratings yet

- Rock Core Logging For Engineering PurposesDocument17 pagesRock Core Logging For Engineering PurposesElaine Ramos100% (1)

- 2425 Techinical SpecificationDocument409 pages2425 Techinical SpecificationananditNo ratings yet

- RETAINING WALL (RR) 3m HeightDocument29 pagesRETAINING WALL (RR) 3m HeightHemam Prasanta100% (1)

- Feeder Type FCE-4NL GBDocument2 pagesFeeder Type FCE-4NL GBsameh ibrahemNo ratings yet

- Stowing What Is Stowing?Document19 pagesStowing What Is Stowing?Harsh SahuNo ratings yet

- Fun Faces of Wisconsin Agriculture: Soil Type and Vegetable ProductionDocument5 pagesFun Faces of Wisconsin Agriculture: Soil Type and Vegetable ProductionJhoanna Mission-EbroleNo ratings yet

- Sieve Analysis DataDocument2 pagesSieve Analysis DataAT NM100% (2)

- Residential Villas Soil ReportDocument10 pagesResidential Villas Soil ReportRakesh ReddyNo ratings yet

- Compression Test Pile (Debond 12m)Document3 pagesCompression Test Pile (Debond 12m)Anonymous S7Cq7ZDgPNo ratings yet

- Conveyor Belt Cleaner Types & ClassificationDocument26 pagesConveyor Belt Cleaner Types & ClassificationGaurav MakwanaNo ratings yet

- Guid PlasteringDocument2 pagesGuid PlasteringBozzay TamásNo ratings yet

- GEO PUB 1/93 - Review of Granular and Geotextile FiltersDocument133 pagesGEO PUB 1/93 - Review of Granular and Geotextile FiltersaescarameiaNo ratings yet

- Technical Specification for Hydraseal DPM Surface Damp Proof MembraneDocument2 pagesTechnical Specification for Hydraseal DPM Surface Damp Proof Membranebassem kooliNo ratings yet

- Soil Classification TableDocument3 pagesSoil Classification TableSon of projectNo ratings yet

- Calculation of Lateral Spring ConstantsDocument5 pagesCalculation of Lateral Spring ConstantsAndy AcousticNo ratings yet

- A Ground To 14th Floor: S. No. Description Unit RateDocument3 pagesA Ground To 14th Floor: S. No. Description Unit RateHarsh SathvaraNo ratings yet

- Centrifuge of Bamboo Crib WallsDocument8 pagesCentrifuge of Bamboo Crib WallsIndriati Martha PatutiNo ratings yet

- Sieving For Perfect Quality Control: MillingDocument12 pagesSieving For Perfect Quality Control: MillingAndri FitriyadiNo ratings yet

- Classification of Soils and Soil-Aggregate Mixtures For Highway Construction PurposesDocument10 pagesClassification of Soils and Soil-Aggregate Mixtures For Highway Construction PurposesweamNo ratings yet

- Staff Submittal Regarding Enforcement Action Against Punaluu Homeowner For Shoreline HardeningDocument123 pagesStaff Submittal Regarding Enforcement Action Against Punaluu Homeowner For Shoreline HardeningIan LindNo ratings yet

- Duane - OkDocument11 pagesDuane - OkLuciana VieiraNo ratings yet

- Pelly surficial geology map data from May 2015Document2 pagesPelly surficial geology map data from May 2015GrantNo ratings yet

- Kandhal - Recommended-Revisions-to-MORTH-Specifications-Section-500 PDFDocument44 pagesKandhal - Recommended-Revisions-to-MORTH-Specifications-Section-500 PDFJimmy ThomasNo ratings yet

- Cat Enclosure IngDocument40 pagesCat Enclosure IngJuan Pablo GonzálezNo ratings yet

- Instant Download Ebook PDF Exploring Earth Science 2nd Edition by Stephen Reynolds PDF ScribdDocument31 pagesInstant Download Ebook PDF Exploring Earth Science 2nd Edition by Stephen Reynolds PDF Scribdcheryl.howard822100% (36)

- Science 4 Worksheet No.: 1Document2 pagesScience 4 Worksheet No.: 1arellano lawschool100% (2)

- Lesson 2 MINERAL AGGREGATESDocument10 pagesLesson 2 MINERAL AGGREGATESDeniell Kahlil Kyro GabonNo ratings yet

- Guideline For Problem Soils in Sa June 2007Document75 pagesGuideline For Problem Soils in Sa June 2007Dian PageNo ratings yet

- Bubble Making 101 For New Learners by DW & KHDocument21 pagesBubble Making 101 For New Learners by DW & KHreggaemusicNo ratings yet