Professional Documents

Culture Documents

KPST

Uploaded by

Anisatun Nafi'ahOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

KPST

Uploaded by

Anisatun Nafi'ahCopyright:

Available Formats

TASK OF SCIENCE CONCEPT DEVELOPMENT AND TECHNOLOGY

2nd Group

1. Riskita Bagus Perdhana (116120145) 2. Widyasari Oktaviani (116121150) 3. Anisatun Nafiah (116124161)

SI-36-04

Theory Study of Mixing Baking Soda and Acetic Acid

A. Basic Theory Volcano or volcanoes in general is a term that can be defined as a system of hot fluid channel (in the form of molten rock or lava) that extends from a depth of about 10 km below the surface of the earth to the earth's surface, including the accumulation of sediment material issued on when erupted. Volcano eruption is an event that occurs due to deposition of magma in the bowels of the earth is pushed out by high-pressure gas. Magma is the incandescent liquid contained in the layer of earth with a very high temperature, which is estimated at more than 1,000 C. Liquid magma coming out of the earth is called lava. The temperature of lava which issued could reach 700-1200 C. Volcanic eruptions that brought rock and ash can be sprayed as far as the radius of 18 km or more, while the lava could flood as far as 90 km radius. Magma is liquid or incandescent silicate solution formed by nature, a temperature between 9000-11000oC and derived from the lower crust or upper shell of the earth. The chemical composition of magma is very complex. 99% of the magma is composed of 10 chemical elements, namely silicon (Si), titanium (Ti), aluminum (Al), Iron (Fe), Magnesium (Mg), calcium (Ca), Sodium (Na), Potassium (K), Hydrogen (H) and oxygen (O). Lava is a solutionliquid of incandescent magma that flows out of the earth through the crater of a volcano or through a crack (fracture), which then freezes into rock many forms. When the liquid is diluted to melt away from the source to form the flow like rivers through the valley and freezes into rock like lava ropi or lava blocks (mostly in Indonesia form a lava blocks). When slightly thickened, will flow not far from its source to form a lava dome and on the sides to form blocks of frozen lava, but temperatures are still high, if the position is not stable will flow to form hot cloud frVolcanic eruptions are part of the volcanic activity is known by the term "eruption". Almost all volcanic activity associated with an active seismic zone caused associated with plate boundaries. On this plate boundary change in pressure and temperature is very high so as to melt the surrounding material which is an incandescent fluid (magma). Magma will intrusion surrounding rock or soil through cracks, fractures near the surface of the earth. Volcanic eruptions are part of the volcanic activity is known by the term "eruption". Mount that can erupt only existed as volcanic mountains alone, while the mountains are not all the status of volcano. Even usual mountain more than of the volcano. The cause of volcanic eruptions Almost all volcanic activity associated with an active seismic zone caused associated with plate boundaries. On this plate boundary change in pressure and temperature is very high so as to melt the surrounding material which is an incandescent fluid (magma). Magma will intrusion surrounding rock or soil through cracks, fractures near the surface of the earth.

Volcanoes are formed from magma, molten rock that is deepest in the earth. Magma is formed due to the heat inside the Earth's interior. At a certain depth, the temperature is very high heat so as to melt the rocks inside the earth. When this molten rock, was resulted gas which then mixes with the magma. Most of the magma formed at depths of 60 to 160 km below the earth's surface. Others are formed at depths of 24 to 48 km. Magma containing gas, gradually rising to the surface because of its mass is lighter than the solid rock around it. When the magma rises, the magma melts the nearby rocks, forming a large cabin at a depth of about 3 km from the surface. Cab magma (magma chamber) is what is the warehouse (reservoir) where volcanic eruptions originating materials. Magma containing gas in the cabin magma in state of magma under the pressure of heavy rocks that surround it. This pressure causes the magma erupts or melt conduit (channel) on the rocks brittle or cracked. Magma moves out through these channels leading to the surface. When magma approaches the surface, the content of gasin it regardless. Gas and magma exploded together and form a hole called the main hole (central vent). Most of the magma and other volcanic material and then gush out through this hole. After bursts of stops, the crater (crater) that resemble bowls usually formed at the peak of the volcano. While there are major holes in the bottom of the crater. Once the volcano is formed, not all magma that appears on the next eruption rises to the surface through the main hole. When the magma rises, some may break through walls or branched cracks through the smaller channels. Magma is through these channels may be out through another hole formed on the side of the mountain, or may also remain below the surface. In this experiment to make simulation volcanic eruption, there is chemical reaction. Chemical reactionis achemical change events of the reacting substances (reactants) transformed into substances the reaction products (products). Characteristic of chemical reaction are temperature changes, color changes, precipitate formation and the formation gas. Acetic acid is corrosive to many metals such as iron, magnesium, and zinc, forming hydrogen gas and acetate salts (called metal acetate). Metal acetates can also be obtained by reaction of acetic acid with a suitable base. Famous example is the reaction of baking soda (sodium bicarbonate) reacts with the vinegar. Almost all acetate salts dissolve well in water. The reaction of sodium bicarbonate and acetic acid: NaHCO3 + CH3COOH CO2 + H2O + CH3COONa Sodium bicarbonate can be used as a wash to remove any acidic. The reaction of sodium bicarbonate and acid resulted salt and carbonic acid, which easily breaks down into carbon dioxide and water. B. Main Materials 1. Acetic acid

Acetic acid (systematically named ethanoic acid) is an organic compound with the chemical formula CH3CO2H (also written as CH3COOH or C2H4O2). It is a colorless liquid that when undiluted is also called glacial acetic acid. Acetic acid is the main component of vinegar (apart from water; vinegar is roughly 8% acetic acid by volume), and has a distinctive sour taste and pungent smell. Besides its production as household vinegar, it is mainly produced as a precursor to polyvinyl acetate and cellulose acetate. Although it is classified as a weak acid, concentrated acetic acid is corrosive and attacks the skin. Acetic acid is one of the simplest carboxylic acids. It is an important chemical reagent and industrial chemical, mainly used in the production of cellulose acetate mainly for photographic film and polyvinyl acetate for wood glue, as well as synthetic fibers and fabrics. In households, diluted acetic acid is often used in descaling agents. In the food industry, acetic acid is used under the food additive code E260 as an acidity regulator and as a condiment. As a food additive it is approved for usage in the EU, USA and Australia and New Zealand. The global demand of acetic acid is around 6.5 million tons per year (Mt/a), of which approximately 1.5 Mt/a is met by recycling; the remainder is manufactured from petrochemical feedstock. As a chemical reagent, biological sources of acetic acid are of interest but generally uncompetitive. Vinegar is dilute acetic acid, often produced by fermentation and subsequent oxidation of ethanol. Nomenclature The trivial name acetic acid is the most commonly used and preferred IUPAC name. The systematic name ethanoic acid, a valid IUPAC name, is constructed according to the substitutive nomenclature. The name acetic acid derives from acetum, the Latin word for vinegar, and is related to the word acid itself. Glacial acetic acid is a trivial name for water-free (anhydrous) acetic acid. Similar to the German name Eisessig (ice-vinegar), the name comes from the ice-like crystals that form slightly below room temperature at 16.6 C (61.9 F) (the presence of 0.1% water lowers its melting point by 0.2 C). A common abbreviation for acetic acid is AcOH, where Ac stands for the acetyl group CH3C(=O). Acetate (CH3COO) is abbreviated AcO. The Ac is not to be confused with the abbreviation for the chemical element actinium. To better reflect its structure, acetic acid is often written as CH3C(O)OH, CH3C(=O)OH, CH3COOH, and CH3CO2H. In the context of acidbase reactions, the abbreviation HAc is sometimes used, where Ac instead stands for acetate. Acetate is the ion resulting from loss of H+ from acetic acid. The name acetate can also refer to a salt containing this anion, or an ester of acetic acid.

History Vinegar was known early in civilization as the natural result of air exposure to beer and wine, because acetic acid-producing bacteria are present globally. The use of acetic acid in alchemy extends into the 3rd century BC, when the Greek philosopher Theophrastus described how vinegar acted on metals to produce pigments useful in art, including white lead (lead carbonate) and verdigris, a green mixture of copper salts including copper(II) acetate. Ancient Romans boiled soured wine to produce a highly sweet syrup called sapa. Sapa that was produced in lead pots was rich in lead acetate, a sweet substance also called sugar of lead or sugar of Saturn, which contributed to lead poisoning among the Roman aristocracy. In the Renaissance, glacial acetic acid was prepared through the dry distillation of certain metal acetates (the most noticeable one being copper(II) acetate). The 16th-century German alchemist Andreas Libavius described such a procedure, and he compared the glacial acetic acid produced by this means to vinegar. The presence of water in vinegar has such a profound effect on acetic acid's properties that for centuries chemists believed that glacial acetic acid and the acid found in vinegar were two different substances. French chemist Pierre Adet proved them identical. In 1847 German chemist, Hermann Kolbe synthesized acetic acid from inorganic compounds for the first time. This reaction sequence consisted of chlorination of carbon disulfide to carbon tetrachloride, followed by pyrolysis to tetrachloroethylene and aqueous chlorination to trichloroacetic acid, and concluded with electrolytic reduction to acetic acid. By 1910, most glacial acetic acid was obtained from the "pyroligneous liquor" from distillation of wood. The acetic acid was isolated from this by treatment with milk of lime, and the resulting calcium acetate was then acidified with sulfuric acid to recover acetic acid. At that time, Germany was producing 10,000 tons of glacial acetic acid, around 30% of which was used for the manufacture of indigo dye. Because both methanol and carbon monoxide are commodity raw materials, methanol carbonylation long appeared to be an attractive precursors to acetic acid. Henry Dreyfus at British Celanese developed a methanol carbonylation pilot plant as early as 1925. However, a lack of practical materials that could contain the corrosive reaction mixture at the high pressures needed (200 atm or more) discouraged commercialization of these routes. The first commercial methanol carbonylation process, which used a cobalt catalyst, was developed by German chemical company BASF in 1963. In 1968, a rhodium-based catalyst (cis[Rh(CO)2I2]) was discovered that could operate efficiently at lower pressure with almost no by-products. US chemical company Monsanto Company built the first plant using this catalyst in 1970, and rhodium-catalysed methanol carbonylation became the dominant method of acetic acid production (see Monsanto process). In the late 1990s, the chemicals company BP Chemicals commercialized the Cativa catalyst ([Ir(CO)2I2]), which is promoted by ruthenium for greater efficiency. This iridium-catalysed Cativa process is greener and more efficient and has largely supplanted the Monsanto process, often in the same production plants. Acetic acid was discovered in the interstellar medium in 1996 by a team led by David Mehringer who detected it using the former Berkeley-Illinois-Maryland Association array at the

Hat Creek Radio Observatory and the former Millimeter Array located at the Owens Valley Radio Observatory. It was first detected in the Sagittarius B2 North molecular cloud (also known as the Sgr B2 Large Molecule Heimat source). Acetic acid has the distinction of being the first molecule discovered in the interstellar medium using solely radio interferometers; in all previous ISM molecular discoveries made in the millimeter and centimeter wavelength regimes, single dish radio telescopes were at least partly responsible for the detections. Chemical properties Acidity The hydrogen center in the carboxyl group (COOH) in carboxylic acids such as acetic acid can separate from the molecule by ionization: CH3CO2H CH3CO2- + H+ Because of this release of the proton (H+), acetic acid has acidic character. Acetic acid is a weak monoprotic acid. In aqueous solution, it has a pKa value of 4.75. Its conjugate base is acetate (CH3COO). A 1.0 M solution (about the concentration of domestic vinegar) has a pH of 2.4, indicating that merely 0.4% of the acetic acid molecules are dissociated.

Structure In solid acetic acid, the molecules form pairs (dimers), being connected by hydrogen bonds. The dimers can also be detected in the vapour at 120 C (248 F). Dimers also occur in the liquid phase in dilute solutions in non-hydrogen-bonding solvents, and a certain extent in pure acetic acid, but are disrupted by hydrogen-bonding solvents. The dissociation enthalpy of the dimer is estimated at 65.066.0 kJ/mol, and the dissociation entropy at 154157 J mol1 K1. Other lower carboxylic acids dimerize in a similar fashion. Solvent properties Liquid acetic acid is a hydrophilic (polar) protic solvent, similar to ethanol and water. With a moderate relative static permittivity (dielectric constant) of 6.2, it dissolves not only polar compounds such as inorganic salts and sugars, but also non-polar compounds such as oils and elements such as sulfur and iodine. It readily mixes with other polar and non-polar solvents such as water, chloroform, and hexane. With higher alkanes (starting with octane), acetic acid is not completely miscible anymore, and its miscibility continues to decline with longer n-alkanes. This dissolving property and miscibility of acetic acid makes it a widely used industrial chemical. Its solvent properties are mainly of value in the production of dimethyl terephthalate. Chemical reactions o Organic chemistry

Acetic acid undergoes the typical chemical reactions of a carboxylic acid. Upon treatment with a standard base, it converts to metal acetate and water. With strong bases (e.g., organolithium reagents), it can be doubly deprotonated to give LiCH2CO2Li. Reduction of acetic acid gives ethanol. The OH group is the main site of reaction, as illustrated by the conversion of acetic acid to acetyl chloride. Other substitution derivatives include acetic anhydride; this anhydride is produced by loss of water from two molecules of acetic acid. Esters of acetic acid can likewise be formed via Fischer esterification, and amides can be formed. When heated above 440 C (824 F), acetic acid decomposes to produce carbon dioxide and methane, or to produce ketene and water. Reactions with inorganic compounds Acetic acid is mildly corrosive to metals including iron, magnesium, and zinc, forming hydrogen gas and salts called acetates: Mg + 2 CH3COOH (CH3COO)2Mg + H2 Because aluminium forms a passivating acid-resistant film of aluminium oxide, aluminium tanks are used to transport acetic acid. Metal acetates can also be prepared from acetic acid and an appropriate base, as in the popular "baking soda + vinegar" reaction: NaHCO3 + CH3COOH CH3COONa + CO2 + H2O A colour reaction for salts of acetic acid is iron(III) chloride solution, which results in a deeply red colour that disappears after acidification. Acetates when heated with arsenic trioxide form cacodyl oxide, which can be detected by its malodorous vapours.

Production Acetic acid is produced industrially both synthetically and by bacterial fermentation. About 75% of acetic acid made for use in the chemical industry is made by the carbonylation of methanol, explained below. Alternative methods account for the rest. The biological route accounts for only about 10% of world production, but it remains important for the production of vinegar, as many food purity laws stipulate that vinegar used in foods must be of biological origin. As of 2003 - 2005, total worldwide production of virgin acetic acid was estimated at 5 Mt/a (million tons per year), approximately half of which was then produced in the United States. European production stood at approximately 1 Mt/a and was declining, and 0.7 Mt/a were produced in Japan. Another 1.5 Mt were recycled each year, bringing the total world market to 6.5 Mt/a. Since then the global production has increased to 10.7 Mt/a (in 2010), and further, however, slowing increase in production is predicted. The two biggest producers of

virgin acetic acid are Celanese and BP Chemicals. Other major producers include Millennium Chemicals, Sterling Chemicals, Samsung, Eastman, and Svensk Etanolkemi. Methanol carbonylation Most acetic acid is produced by methanol carbonylation. In this process, methanol and carbon monoxide react to produce acetic acid according to the equation: CH3OH + CO CH3COOH The process involves iodomethane as an intermediate, and occurs in three steps. A catalyst, metal carbonyl, is needed for the carbonylation (step 2). CH3OH + HI CH3I + H2O CH3I + CO CH3COI CH3COI + H2O CH3COOH + HI By altering the process conditions, acetic anhydride may also be produced on the same plant. Acetaldehyde oxidation Prior to the commercialization of the Monsanto process, most acetic acid was produced by oxidation of acetaldehyde. This remains the second-most-important manufacturing method, although it is usually uncompetitive with the carbonylation of methanol. The acetaldehyde may be produced via oxidation of butane or light naphtha, or by hydration of ethylene. When butane or light naphtha is heated with air in the presence of various metal ions, including those of manganese, cobalt, and chromium, peroxides form and then decompose to produce acetic acid according to the chemical equation 2 C4H10 + 5 O2 4 CH3COOH + 2 H2O The typical reaction is conducted at temperatures and pressures designed to be as hot as possible while still keeping the butane a liquid. Typical reaction conditions are 150 C (302 F) and 55 atm. Side-products may also form, including butanone, ethyl acetate, formic acid, and propionic acid. These side-products are also commercially valuable, and the reaction conditions may be altered to produce more of them where needed. However, the separation of acetic acid from these by-products adds to the cost of the process. Under similar conditions and using similar catalysts as are used for butane oxidation, the oxygen in air to produce acetic acid can oxidize acetaldehyde. 2 CH3CHO + O2 2 CH3COOH Using modern catalysts, this reaction can have an acetic acid yield greater than 95%. The major side-products are ethyl acetate, formic acid, and formaldehyde, all of which have lower boiling points than acetic acid and are readily separated by distillation. Ethylene oxidation Acetaldehyde may be prepared from ethylene via the Wacker process, and then oxidized as above. In more recent times, chemical company Showa Denko, which opened an ethylene oxidation plant in ita, Japan, in 1997, commercialized a cheaper single-stage conversion of ethylene to acetic acid.[28] The process is catalysed by a palladium metal catalyst supported on a heteropoly acid such as tungstosilicic acid. It is

thought to be competitive with methanol carbonylation for smaller plants (100 250 kt/a), depending on the local price of ethylene. Oxidative fermentation For most of human history, acetic acid bacteria of the genus Acetobacter have made acetic acid, in the form of vinegar. Given sufficient oxygen, these bacteria can produce vinegar from a variety of alcoholic foodstuffs. Commonly used feeds include apple cider, wine, and fermented grain, malt, rice, or potato mashes. The overall chemical reaction facilitated by these bacteria is: C2H5OH + O2 CH3COOH + H2O A dilute alcohol solution inoculated with Acetobacter and kept in a warm, airy place will become vinegar over the course of a few months. Industrial vinegar-making methods accelerate this process by improving the supply of oxygen to the bacteria. The first batches of vinegar produced by fermentation probably followed errors in the winemaking process. If must is fermented at too high a temperature, acetobacter will overwhelm the yeast naturally occurring on the grapes. As the demand for vinegar for culinary, medical, and sanitary purposes increased, vintners quickly learned to use other organic materials to produce vinegar in the hot summer months before the grapes were ripe and ready for processing into wine. This method was slow, however, and not always successful, as the vintners did not understand the process. One of the first modern commercial processes was the "fast method" or "German method", first practised in Germany in 1823. In this process, fermentation takes place in a tower packed with wood shavings or charcoal. The alcohol-containing feed is trickled into the top of the tower, and fresh air supplied from the bottom by either natural or forced convection. The improved air supply in this process cut the time to prepare vinegar from months to weeks. Nowadays, most vinegar is made in submerged tank culture, first described in 1949 by Otto Hromatka and Heinrich Ebner. In this method, alcohol is fermented to vinegar in a continuously stirred tank, and oxygen is supplied by bubbling air through the solution. Using modern applications of this method, vinegar of 15% acetic acid can be prepared in only 24 hours in batch process, even 20% in 60-hour fed-batch process. Anaerobic fermentation Species of anaerobic bacteria, including members of the genus Clostridium or Acetobacterium can convert sugars to acetic acid directly, without using ethanol as an intermediate. The overall chemical reaction conducted by these bacteria may be represented as: C6H12O6 3 CH3COOH These acetogenic bacteria produce acetic acid from one-carbon compounds, including methanol, carbon monoxide, or a mixture of carbon dioxide and hydrogen: 2 CO2 + 4 H2 CH3COOH + 2 H2O This ability of Clostridium to utilize sugars directly, or to produce acetic acid from less costly inputs, means that these bacteria could potentially produce acetic acid more efficiently than ethanol-oxidizers like Acetobacter. However, Clostridium bacteria are

less acid-tolerant than Acetobacter. Even the most acid-tolerant Clostridium strains can produce vinegar of only a few per cent acetic acid, compared to Acetobacter strains that can produce vinegar of up to 20% acetic acid. At present, it remains more cost-effective to produce vinegar using Acetobacter than to produce it using Clostridium and then concentrate it. As a result, although acetogenic bacteria have been known since 1940, their industrial use remains confined to a few niche applications. Uses Acetic acid is a chemical reagent for the production of chemical compounds. The largest single use of acetic acid is in the production of vinyl acetate monomer, closely followed by acetic anhydride and ester production. The volume of acetic acid used in vinegar is comparatively small. Vinyl acetate monomer The major use of acetic acid is for the production of vinyl acetate monomer (VAM). This application consumes approximately 40% to 45% of the world's production of acetic acid. The reaction is of ethylene and acetic acid with oxygen over a palladium catalyst. 2 H3CCOOH + 2 C2H4 + O2 2 H3CCOOCH=CH2 + 2 H2O Vinyl acetate can be polymerized to polyvinyl acetate or to other polymers, which are components in paints and adhesives. Ester production The major esters of acetic acid are commonly used solvents for inks, paints and coatings. The esters include ethyl acetate, n-butyl acetate, isobutyl acetate, and propyl acetate. They are typically produced by catalysed reaction from acetic acid and the corresponding alcohol: H3C-COOH + HO-R H3C-CO-O-R + H2O, (R = a general alkyl group) Most acetate esters, however, are produced from acetaldehyde using the Tishchenko reaction. In addition, ether acetates are used as solvents for nitrocellulose, acrylic lacquers, varnish removers, and wood stains. First, glycol monoethers are produced from ethylene oxide or propylene oxide with alcohol, which are then esterified with acetic acid. The three major products are ethylene glycol monoethyl ether acetate (EEA), ethylene glycol monobutyl ether acetate (EBA), and propylene glycol monomethyl ether acetate (PMA, more commonly known as PGMEA in semiconductor manufacturing processes, where it is used as a resist solvent). This application consumes about 15% to 20% of worldwide acetic acid. Ether acetates, for example EEA, have been shown to be harmful to human reproduction. Acetic anhydride The product of the condensation of two molecules of acetic acid is acetic anhydride. The worldwide production of acetic anhydride is a major application, and uses approximately 25% to 30% of the global production of acetic acid. The main process involves dehydration of acetic acid to give ketene, which condenses with acetic acid to give the anhydride: CH3CO2H CH2=C=O + H2O

CH3CO2H + CH2=C=O (CH3CO)2O Acetic anhydride is an acetylation agent. As such, its major application is for cellulose acetate, a synthetic textile also used for photographic film. Acetic anhydride is also a reagent for the production of heroin and other compounds. Vinegar Vinegar is typically 4-18% acetic acid by mass. Vinegar is used directly as a condiment, and in the pickling of vegetables and other foods. Table vinegar tends to be more diluted (4% to 8% acetic acid), while commercial food pickling employs solutions that are more concentrated. The amount of acetic acid used as vinegar on a worldwide scale is not large, but is by far the oldest and best-known application. Use as solvent Glacial acetic acid is an excellent polar protic solvent, as noted above. It is frequently used as a solvent for recrystallization to purify organic compounds. Acetic acid is used as a solvent in the production of terephthalic acid (TPA), the raw material for polyethylene terephthalate (PET). In 2006, about 20% of acetic acid is used for TPA production. Acetic acid is often used as a solvent for reactions involving carbocations, such as Friedel-Crafts alkylation. For example, one stage in the commercial manufacture of synthetic camphor involves a Wagner-Meerwein rearrangement of camphene to isobornyl acetate; here acetic acid acts both as a solvent and as a nucleophile to trap the rearranged carbocation. Acetic acid is the solvent of choice when reducing an aryl nitrogroup to aniline using palladium-on-carbon. Glacial acetic acid is used in analytical chemistry for the estimation of weakly alkaline substances such as organic amides. Glacial acetic acid is a much weaker base than water, so the amide behaves as a strong base in this medium. It then can be titrated using a solution in glacial acetic acid of a very strong acid, such as perchloric acid. Niche applications Dilute solutions of acetic acids are also used as a stop bath during the development of photographic films, and in descaling agents to remove limescale from taps and kettles. In the clinical laboratory dilute acetic acid lyse red blood cells in order to facilitate microscopic examination. Acetic acid in the form of household vinegar is often used to clean indoor climbing holds of chalk (magnesium carbonate). The acidity is also used for treating the sting of the box jellyfish by disabling the stinging cells of the jellyfish, preventing serious injury or death if applied immediately, and for treating outer ear infections in people in preparations such as Vosol. In this manner, acetic acid is used as a spray-on preservative for livestock silage, to discourage bacterial and fungal growth. Acetic acid vapour is used for the fumigation of bee hives to control Nosema and other pests. Glacial acetic acid is also used as a wart and verruca remover. Organic or inorganic salts are produced from acetic acid, including: o Sodium acetate, used in the textile industry and as a food preservative (E262). o Copper(II) acetate, used as a pigment and a fungicide.

Aluminium acetate and iron(II) acetateused as mordants for dyes. Palladium(II) acetate, used as a catalyst for organic coupling reactions such as the Heck reaction. o Silver acetate, used as a pesticide. Substituted acetic acids produced include: o Monochloroacetic acid (MCA), dichloroacetic acid (considered a by-product), and trichloroacetic acid. MCA is used in the manufacture of indigo dye. o Bromoacetic acid, which is esterified to produce the reagent ethyl bromoacetate. o Trifluoroacetic acid, which is a common reagent in organic synthesis. Amounts of acetic acid used in these other applications together (apart from TPA) account for another 510% of acetic acid use worldwide. These applications are, however, not expected to grow as much as TPA production. Diluted acetic acid is also used in physical therapy to break up nodules of scar tissue via iontophoresis. Safety Concentrated acetic acid is corrosive to skin and must, therefore, be handled with appropriate care, since it can cause skin burns, permanent eye damage, and irritation to the mucous membranes. These burns or blisters may not appear until hours after exposure. Latex gloves offer no protection, so specially resistant gloves, such as those made of nitrile rubber, are worn when handling the compound. Concentrated acetic acid can be ignited with difficulty in the laboratory. It becomes a flammable risk if the ambient temperature exceeds 39 C (102 F), and can form explosive mixtures with air above this temperature (explosive limits: 5.416%). The hazards of solutions of acetic acid depend on the concentration. The following table lists the EU classification of acetic acid solutions:

o o

Solutions at more than 25% acetic acid are handled in a fume hood because of the pungent, corrosive vapour. Dilute acetic acid, in the form of vinegar, is harmless. However, ingestion of stronger solutions is dangerous to human and animal life. It can cause severe damage to the digestive system, and a potentially lethal change in the acidity of the blood. Due to incompatibilities, it is recommended to keep acetic acid away from chromic acid, ethylene glycol, nitric acid, perchloric acid, permanganates, peroxides and hydroxyls. 2. Sodium bicarbonate

Sodium bicarbonate or sodium hydrogen carbonate is the chemical compound with the formula NaHCO3. Sodium bicarbonate is a white solid that is crystalline but often appears as a fine powder. It has a slightly salty, alkaline taste resembling that of washing soda (sodium carbonate). The natural mineral form is nahcolite. It is a component of the mineral natron and is found dissolved in many mineral springs. Since it has long been known and is widely used, the salt has many related names such as baking soda, bread soda, cooking soda, and bicarbonate of soda. In colloquial usage, its name is shortened to sodium bicarb, bicarb soda, or simply bicarb. The word saleratus, from Latin sal ratus meaning aerated salt, was widely used in the 19th century for both sodium bicarbonate and potassium bicarbonate. The term has now fallen out of common usage. History The ancient Egyptians used natural deposits of natron, a mixture consisting mostly of sodium carbonate decahydrate, and sodium bicarbonate. The natron was used as a cleansing agent like soap. In 1791, a French chemist, Nicolas Leblanc, produced sodium carbonate, also known as soda ash. In 1846, two New York bakers, John Dwight and Austin Church, established the first factory to develop baking soda from sodium carbonate and carbon dioxide. This compound, referred to as saleratus, is mentioned in the famous novel Captains Courageous by Rudyard Kipling as being used extensively in the 1800s in commercial fishing to prevent freshly-caught fish from spoiling. Production NaHCO3 is mainly prepared by the Solvay process, which is the reaction of sodium chloride, ammonia, and carbon dioxide in water. Calcium carbonate is used as the source of CO2 and the resultant calcium oxide is used to recover the ammonia from the ammonium chloride. It is produced on the scale of about 100,000 tonnes/year (as of 2001). NaHCO3 may be obtained by the reaction of carbon dioxide with an aqueous solution of sodium hydroxide. The initial reaction produces sodium carbonate: CO2 + 2 NaOH Na2CO3 + H2O Further addition of carbon dioxide produces sodium bicarbonate, which at sufficiently high concentration will precipitate out of solution: Na2CO3 + CO2 + H2O 2 NaHCO3

Commercial quantities of baking soda are also produced by a similar method: soda ash, mined in the form of the ore trona, is dissolved in water and treated with carbon dioxide. Sodium bicarbonate precipitates as a solid from this method: Na2CO3 + CO2 + H2O 2 NaHCO3 Mining Naturally occurring deposits of nahcolite (NaHCO3) are found in the Eocene-age (55.8 33.9 Ma) Green River Formation, Piceance Basin in Colorado. Nahcolite was deposited as beds during periods of high evaporation in the basin. It is commercially mined using in-situ leach techniques involving dissolution of the nahcolite by heated water that is pumped through the nahcolite beds and reconstituted through a natural cooling crystallization process. Chemistry Sodium bicarbonate is an amphoteric compound. Aqueous solutions are mildly alkaline due to the formation of carbonic acid and hydroxide ion: HCO3- + H2O H2CO3 + OH Sodium bicarbonate can be used as a wash to remove any acidic impurities from a "crude" liquid, producing a purer sample. Reaction of sodium bicarbonate and an acid produce a salt and carbonic acid, which readily decomposes to carbon dioxide and water: NaHCO3 + HCl NaCl + H2CO3 H2CO3 H2O + CO2(g) Sodium bicarbonate reacts with acetic acid (found in vinegar), producing sodium acetate, water, and carbon dioxide: NaHCO3 + CH3COOH CH3COONa + H2O + CO2(g) Sodium bicarbonate reacts with bases such as sodium hydroxide to form carbonates: NaHCO3 + NaOH Na2CO3 + H2O Sodium bicarbonate reacts with carboxyl groups in proteins to give a brisk effervescence from the formation of CO2. This reaction is used to test for the presence of carboxylic groups in protein. Thermal decomposition Above 70 C, sodium bicarbonate gradually decomposes into sodium carbonate, water and carbon dioxide. The conversion is fast at 200 C: 2 NaHCO3 Na2CO3 + H2O + CO2 Most bicarbonates undergo this dehydration reaction. Further heating converts the carbonate into the oxide (at ca. 1000 C) : Na2CO3 Na2O + CO2 These conversions are relevant to the use of NaHCO3 as a fire-suppression agent ("BC powder") in some dry powder fire extinguishers. Applications Cooking

Sodium bicarbonate, referred to as "baking soda" is primarily used in cooking (baking), as a leavening agent. It reacts with acidic components in batters, releasing carbon dioxide, which causes expansion of the batter and forms the characteristic texture and grain in pancakes, cakes, quick breads, soda bread, and other baked and fried foods. Acidic compounds that induce this reaction include phosphates, cream of tartar, lemon juice, yogurt, buttermilk, cocoa, vinegar, etc. Sodium bicarbonate can be substituted for baking powder provided sufficient acid reagent is also added to the recipe. Many forms of baking powder contain sodium bicarbonate combined with one or more acidic phosphates or cream of tartar. Sodium bicarbonate was sometimes used in cooking vegetables, to make them softer, although this has gone out of fashion, as most people now prefer firmer vegetables that contain more nutrients. However, it is still used in Asian cuisine to tenderise meats. Baking soda may react with acids in food, including Vitamin C (L-ascorbic acid). It is also used in breadings such as for fried foods to enhance crispness. Heat causes sodium bicarbonate to act as a raising agent by releasing carbon dioxide when used in baking. The carbon dioxide production starts at temperatures above 80 C. Since the reaction does not occur at room temperature, mixtures (cake batter, etc.) can be allowed to stand without rising until they are heated in the oven. Neutralization of acids and bases Many laboratories keep a bottle of sodium bicarbonate powder within easy reach, because sodium bicarbonate is amphoteric, reacting with acids and bases. Furthermore, as it is relatively innocuous in most situations, there is no harm in using excess sodium bicarbonate. Also, sodium bicarbonate powder may be used to smother a small fire, as heating of sodium bicarbonate releases carbon dioxide. A wide variety of applications follows from its neutralization properties, including reducing the spread of white phosphorus from incendiary bullets inside an afflicted soldier's wounds. Medical uses Sodium bicarbonate mixed with water can be used as an antacid to treat acid indigestion and heartburn. It is used as the medicinal ingredient in gripe water for infants. Sodium bicarbonate has been known to be used in first aid, in treating scalding, to prevent blistering and scarring with instructions to cover the scalded area with a liberal layer of sodium bicarbonate and water paste and seek medical assistance. This is due to the endothermic reaction that occurs between sodium bicarbonate and water and sodium bicarbonate's mild antiseptic properties. Intravenous sodium bicarbonate is an aqueous solution that is sometimes used for cases of acidosis, or when there are insufficient sodium or bicarbonate ions in the blood. In cases of respiratory acidosis, the infused bicarbonate ion drives the carbonic acid/bicarbonate buffer of plasma to the left and, thus, raises the pH. It is for this reason that sodium bicarbonate is used in medically supervised cardiopulmonary resuscitation. Infusion of bicarbonate is indicated only when the blood pH is markedly (<7.17.0) low.

It is used as well for treatment of hyperkalemia. Since sodium bicarbonate can cause alkalosis, it is sometimes used to treat aspirin overdoses. Aspirin requires an acidic environment for proper absorption, and the basic environment diminishes aspirin absorption in the case of an overdose. Sodium bicarbonate has also been used in the treatment of tricyclic antidepressant overdose. It can also be applied topically as a paste, with three parts baking soda to one part water, to relieve some kinds of insect bites and stings (as well as accompanying swelling). Adverse reactions to the administration of sodium bicarbonate can include metabolic alkalosis, edema due to sodium overload, congestive heart failure, hyperosmolar syndrome, hypervolemic hypernatremia, and hypertension due to increased sodium. In patients consuming a high-calcium or dairy-rich diet, calcium supplements, or calciumcontaining antacids such as calcium carbonate (e.g., Tums), the use of sodium bicarbonate can cause milk-alkali syndrome, which can result in metastatic calcification, kidney stones, and kidney failure. Sodium bicarbonate can be used to treat an allergic reaction to plants such as poison ivy -oak or -sumac to relieve some of the associated itching. Bicarbonate of soda can also be useful in removing splinters from the skin. Personal hygiene Toothpaste containing sodium bicarbonate has in several studies shown to have a better whitening and plaque removal effect than toothpastes without it. Sodium bicarbonate is also used as an ingredient in some mouthwashes. It works as a mechanical cleanser on the teeth and gums, neutralizes the production of acid in the mouth and also acts as an antiseptic to help prevent infections. Sodium bicarbonate in combination with other ingredients can be used to make a dry or wet deodorant. It may also be used as a shampoo. Sodium bicarbonate may be used as a buffering agent, combined with table salt, when creating a solution for nasal irrigation. Baking soda in sports Small amounts of sodium bicarbonate have been shown to be useful as a supplement for athletes in speed-based events, like middle distance running, lasting from about one to seven minutes. But overdose is a serious risk because sodium bicarbonate is slightly toxic and in particular gastrointestinal irritation is of concern. Additionally this practice causes a significant increase in dietary sodium. As a cleaning agent A paste from baking soda can be very effective when used in cleaning and scrubbing. For cleaning aluminium objects, the use of sodium bicarbonate is discouraged as it attacks the thin unreactive protective oxide layer of this otherwise very reactive metal. A solution in warm water will remove the tarnish from silver when the silver is in contact with a piece of aluminium foil. Baking soda is commonly added to washing machines as a replacement for softener and to remove odors from clothes. Sodium bicarbonate is also effective in removing heavy tea and coffee stains from cups when diluted with warm water.

During the Manhattan Project to develop the atomic bomb in the early 1940s, many scientists investigated the toxic properties of uranium. They found that uranium oxides stick very well to cotton cloth, but did not wash out with soap or laundry detergent. The uranium would wash out with a 2% solution of sodium bicarbonate (baking soda). Clothing can become contaminated with depleted uranium (DU) dust and normal laundering will not remove it. Those at risk of DU dust exposure should have their clothing washed with baking soda (about 6 ounces of baking soda in 2 gallons of water). As a biopesticide Sodium bicarbonate can be an effective way of controlling fungus growth, and in the United States is registered by the Environmental Protection Agency as a biopesticide. Cattle feed supplement Sodium bicarbonate is sold as a cattle feed supplement, in particular as a buffering agent for the rumen. Miscellaneous Sodium bicarbonate can be used to extinguish small grease or electrical fires by being thrown over the fire. However, it should not be applied to fires in deep fryers, as it may cause the grease to splatter. Sodium bicarbonate is used in BC dry chemical fire extinguishers as an alternative to the more corrosive ammonium phosphate in ABC extinguishers. The alkali nature of sodium bicarbonate makes it the only dry chemical agent, besides Purple-K, that was used in large-scale fire suppression systems installed in commercial kitchens. Because it can act as an alkali, the agent has a mild saponification effect on hot grease, which forms a smothering soapy foam. Dry chemicals have since fallen out of favor for kitchen fires, as they have no cooling effect compared to the extremely effective wet chemical agents specifically designed for such hazards. Sodium bicarbonate is used in a process for removing paint and corrosion called sodablasting; the process is particularly suitable for cleaning aluminium panels which can be distorted by other types of abrasive. It can be administered to pools, spas, and garden ponds to raise pH levels. It has weak disinfectant properties, and it may be an effective fungicide against some organisms. Since it acts as a neutralizing agent, it can be used to absorb odors that are caused by strong acid. Because baking soda will absorb musty smells, it has become a reliable method for used-book sellers when making books less malodorous.

C. Tools and materials 1) A volcano miniature 2) Acetic acid (CH3COOH) 3) Sodium bicarbonate (NaHCO3) 4) Mineral water 5) Liquid soap 6) Bottle

D. Procudure 1) Make a volcano miniature and make a hole in center of imitation mountain as a crater. 2) Pour the mineral water, liquid soap, and acetic acid in to crater of a volcano miniature. 3) Then pour the sodium bicarbonate in to crater of a volcano miniature 4) Observe it E. Conclution 1) A volcano miniature eruptions caused by the pressure that is on top of the mountain there is a reaction between acetic acid with sodium bicarbonate produce carbon dioxide. The more gas was produced, the pressure will also be greater, therefore increasing pressure spurred volcanic eruptions that gas and liquid magma (red vinegar solution) will explode together and out of the mountain. 2) The reaction between acetic acid and sodium bocarbonate produced CH3COONa and H2CO3, which easily broken down into carbon dioxide and water. NaHCO3 + CH3COOH CH3COONa + H2O + CO2 3) NaHCO3 is amphoteric that means alkaline compound can react either as an acid or a base, and rather easy to form salts. 4) NaHCO3 and CH3COOH react to produce CO2 that can be used to push the gas in this case is a volcanic eruption, by force press the gas produced. The greater the pressure of the gas produced the explosion of the volcano becomes greater.

Source : http://en.wikipedia.org/wiki/Acetic_acid http://en.wikipedia.org/wiki/Sodium_bicarbonate

http://www.adipedia.com/2011/04/larutan-kimia-cuka-asam-asetat.html http://earlfhamfa.wordpress.com/2009/03/21/letusan-gunung-berapi-volcanic-eruption/ http://riedwaen.wordpress.com/2007/12/27/letusan-gunung-api/

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Butter Cake (The Best!) PDFDocument3 pagesButter Cake (The Best!) PDFOblivionOmbre100% (1)

- Tarea 1 Tercer ParcialDocument4 pagesTarea 1 Tercer ParcialElder HernandezNo ratings yet

- Analysis of Market Scenario (Hot Tea Stall) of Ispahani TEA and Competitors in Dhaka CityDocument55 pagesAnalysis of Market Scenario (Hot Tea Stall) of Ispahani TEA and Competitors in Dhaka CityTurjo VlogsNo ratings yet

- CanningDocument17 pagesCanningSakshi SargarNo ratings yet

- HSK Flashcards 4 2Document60 pagesHSK Flashcards 4 2flavinia14No ratings yet

- November 5, 2014Document16 pagesNovember 5, 2014Maple Lake MessengerNo ratings yet

- Case Study of Wal MartDocument10 pagesCase Study of Wal MartAudreyNo ratings yet

- JCI Vizag Super V Issue IIDocument4 pagesJCI Vizag Super V Issue IIvenkatavinayNo ratings yet

- The Wolf and The Seven Little Goats: ScriptDocument2 pagesThe Wolf and The Seven Little Goats: ScriptTata VeViNo ratings yet

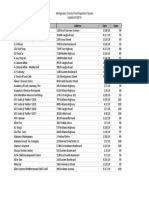

- Establishment Address Date Score: Montgomery County Food Inspection Scores Updated 5/28/19Document34 pagesEstablishment Address Date Score: Montgomery County Food Inspection Scores Updated 5/28/19GerardNo ratings yet

- Macdoland's: Ayoub Missori Zakariae El OuadiDocument9 pagesMacdoland's: Ayoub Missori Zakariae El OuadiAyoub MissoriNo ratings yet

- 61 Lateral Thinking Puzzles: Family-Friendly Logic PuzzlesDocument44 pages61 Lateral Thinking Puzzles: Family-Friendly Logic PuzzlesArbiel BorisaNo ratings yet

- Some of The Cebuano Words Recorded by Pigafetta in 1521Document3 pagesSome of The Cebuano Words Recorded by Pigafetta in 1521นีล ไบรอันNo ratings yet

- Developing Healthy Muffins With Pumpkin FillingDocument10 pagesDeveloping Healthy Muffins With Pumpkin FillingMN MNNo ratings yet

- Philippine Barangay CertificationDocument2 pagesPhilippine Barangay CertificationMelody Frac Zapatero75% (4)

- Tongue TwistersDocument3 pagesTongue Twisterscynthiaochoa_gNo ratings yet

- Jesus Is Arrested and CrucifiedDocument22 pagesJesus Is Arrested and CrucifiedNelly Theresia SianiparNo ratings yet

- Home Budget CalculatorDocument4 pagesHome Budget CalculatoraliasgarNo ratings yet

- The Storage of Tropical Agricultural Products: Agrodok 31Document84 pagesThe Storage of Tropical Agricultural Products: Agrodok 31Seyha L. AgriFoodNo ratings yet

- DR Shaukat (Plant Pathology)Document5 pagesDR Shaukat (Plant Pathology)Tanveer100% (1)

- Active or PassiveDocument2 pagesActive or PassivepaaaulinasNo ratings yet

- Name Age Sex Occupation Systemic DiseaseDocument10 pagesName Age Sex Occupation Systemic DiseaseRebin AliNo ratings yet

- 3.4.1 How To Make SomethingDocument6 pages3.4.1 How To Make SomethingStefmi Dhila WandaNo ratings yet

- A. Peter B. Peter's Hobby C. Peter's FamilyDocument14 pagesA. Peter B. Peter's Hobby C. Peter's Familyyoez scapeNo ratings yet

- Clasa A 8-ADocument2 pagesClasa A 8-ADBCooperNo ratings yet

- CV Shabrina AnwarDocument2 pagesCV Shabrina AnwarShabrina AnwarNo ratings yet

- ReferenceSheet MBRPGDocument56 pagesReferenceSheet MBRPGarancaNo ratings yet

- Community NuitritionDocument12 pagesCommunity Nuitritionmariet abrahamNo ratings yet

- Eating Well For 12-18 Year Olds: Practical GuideDocument90 pagesEating Well For 12-18 Year Olds: Practical GuideMiha MargineanNo ratings yet

- 3 Tengku Khairil AhsyarDocument8 pages3 Tengku Khairil AhsyarsuksesbesarNo ratings yet