Professional Documents

Culture Documents

Rodrigues Et Al

Uploaded by

Arini Tri KusumawatiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rodrigues Et Al

Uploaded by

Arini Tri KusumawatiCopyright:

Available Formats

African Journal of Microbiology Research Vol. 4 (3), pp. 210-213, 4 February, 2010 Available online http://www.academicjournals.

org/ajmr ISSN 1996-0808 2010 Academic Journals

Full Length Research Paper

Microbiological quality of yoghurt commercialized in Viosa, Minas Gerais, Brazil

L. A. Rodrigues1, M. B. T. Ortolani2 and L. A. Nero2*

1

Faculdade de Medicina Veterinria e Zootecnia, Universidade de So Paulo, So Paulo, SP, Brasil. 2 Departamento de Veterinria, Universidade Federal de Viosa, Viosa, MG, Brasil.

Accepted 17 December, 2009

Yoghurt consumption has been increasing since 1980 decade due to the search for healthy foods by consumers, including Brazil. In order to evaluate the quality of the yoghurt commercialized in Viosa, Minas Gerais, Brazil, 36 samples were collected from markets and analyzed for coliforms (total and thermotolerant) and lactic acid bacteria (LAB) enumeration and pH, considering different times for expiration. Coliforms were not detected at levels higher than 0.3 MPN/g, and only 7 (19.4%) samples 7 showed LAB counts lower than 10 CFU/g. However, the mean pH observed in these samples (4.4) was not significantly different when compared to samples with higher LAB counts, suggesting addition of weak starter cultures during the processing. In the samples with less than 15 days for expiration the LAB counts and pH values were 7.4 log CFU/g and 4.1, respectively, and they were lower when compared to samples with more than 16 days of commercial viability, but without significant differences. The obtained results indicate adequate quality of yoghurt commercialized in Viosa. Key words: Yoghurt, quality, coliforms, lactic acid bacteria, pH. INTRODUCTION The consumption of fermented milks by man dates from the beginning of civilization, once residues of these products were found in pottery fragments from Neolithic, Bronze and Iron Ages settlements in Britain (McKinley, 2005). It is accepted that the initial consumption of fermented or cultured milk products, such as yoghurt, butter and cheese, occurred around the time as they were recognized as effective means of prolonging the shelf-life of milk (Ross et al., 2002; Tamine and Robinson, 2007). One of the most traditional cultured milk is the yoghurt, which is a product of the lactic acid fermentation of milk by addition of a starter culture containing Streptococcus thermophilus and Lactobacillus delbrueckii subsp. bulgaricus (Steinkraus, 1997; Tamine and Robinson, 2007). This product is widely consumed worldwide, mainly in northern European countries, Balkans, MiddleEast and Indian sub-continents (Tamine, 2002). The main reasons pointed out for yoghurt consumption is the cultural and the increasing search for healthy foods (Kalantzopoulos, 1997; McKinley, 2005; lvarez-Len et al., 2006; Cueva and Aryana, 2008), and in Brazil, such consumption has been increasing since 1980s. The yoghurt production is quite simple, and the rising consumption of this product has led to the development of automated and sophisticated equipment for the Industrial processing. Despite the practicability, the current processing equipments must provide proper quality and safety (Salinas, 1986). The maintenance of these secure characteristics is essential even in the post-production steps, like storage, transport and commercialization. Microbiological parameters are generally used to verify these conditions, especially by coliforms and lactic acid bacteria (LAB) enumeration (Tamine and Robinson, 2007). At commercial points, yoghurts produced in Brazil 7 must contain at least 10 colony formers unit per gram (CFU/g) of LAB and less than 10 most probable number per gram (MPN/g) of thermotolerant coliforms for indicative samples (Brasil, 2000, 2001). Coliforms quantification allows the verification of raw milk quality and the efficiency of the processing, and LAB enumerating indicates the levels of added starter culture and its

*Corresponding author. E-mail: nero@ufv.br. Tel: 55 31 3899 1463. Fax: 55 31 3899 2317.

Rodrigues et al. 211

development during the storage and shelf-life. In addition, the measurement of acidity is also observed in order to evaluate the preservation of yoghurt status, varying from 0.6 to 1.5 g of lactic acid per 100 g of product, and the temperature of preservation in dairy industries and o markets must not be higher than 10 C (Brasil, 2000). The objective of this study was to evaluate the microbiological quality of yoghurts from different brands available in Viosa market, considering the levels of contamination by total and thermotolerant coliforms and counts of viable LAB in different shelf-life periods; pH values were also determined as another quality indicator.

MATERIAL AND METHODS Sample collection and dilution Thirty-six yoghurt samples from different brands and shelf-lives, with either the addition of fruit pulp or not, were obtained in markets from Viosa, Minas Gerais, Brazil. All samples were kept under refrigeration condition during the transport to laboratory, when they were diluted serially in decimal scale using sterile NaCl 0.85% until 1:10,000,000. Microbiological analysis All microbiological analysis was conducted according to Wehr and Frank (2002) using culture media from Oxoid Ltda. (Basingstoke, England). Coliforms were quantified using the Multiple Tubes Technique (3 tubes per series) using undiluted and 1:10 and 1:100 diluted samples. The presumptive step was conducted with lauryl sulfate tryptose broth (35oC for 48 h) followed by the confirmation of total coliforms using brilliant green bile broth (35oC for 48 h). Thermotolerant coliforms were confirmed using Escherichia coli broth (44.5oC for 48 h) and tryptone broth (35oC for 48 h) followed by indol production detection. The levels of contamination by total and thermotolerant coliforms were obtained according to the combination of positive results in each dilution using a Table of Most Probable Number and the results were expressed as MNP/g. For LAB enumerating, the dilutions 1:1,000,000 and 10,000,000 were plated on de Man, Rogosa and Sharpe agar by pour plate technique with incubation in anaerobic conditions (Anaerobac, Probac do Brasil , So Paulo, S.P., Brazil) at 35oC for 48h. The obtained results were expressed in CFU/g. pH analyses The pH values of the yoghurts were measured at 20oC using a Bel W3B pH meter (Bel Engineering, Monza, Italy) after calibrating with fresh pH 4.0 and 6.86 standard buffers. Statistical analysis The obtained results were analyzed considering the official parameters established by Brazilian Agriculture and Health Departments (Brasil, 2000, 2001). In addition, the mean counts of microbiological parameters (converted in log10) and pH were calculated and compared by analysis of variance (ANOVA and Tukey, P < 0.05) considering the time for expiration (shelf-life) and levels of LAB. Associations between levels of contamination and shelf-life periods

were also made. All statistical analysis was processed in statistica 7.0 software (Stat Soft, Inc., Tulsa, OK, U.S.A.).

RESULTS AND DISCUSSION Only 7 samples showed microbiological parameters in disagreement with official standards (Brasil, 2000, 2001). 7 and all of these presenting LAB counts lower than 10 CFU/g (Table 1). All samples showed levels of coliforms (total and thermotolerants) lower than 0.3 MPN/g, indicating adequate heating treatment of milk and high hygienic standards of processing and packaging that precluded recontamination of the product. Coliforms detection or enumerating are often used as parameters for evaluating the yoghurt quality in different countries (Brasil, 2000, 2001; Con et al., 1996; Nogueira et al., 1998; Tamine and Robinson, 2007). The obtained results are similar when compared to other studies in Lebanon (Al-Kadamany et al., 2003), Turkey (Con et al., 1996) and Portugal (Nogueira et al., 1998). However, there have been instances where much higher counts of coliform group were found in yoghurt samples, with frequency varying from 35 to 80% (Con et al., 1996). Until this moment, there are no published studies focusing on coliforms enumerating or detection in Yoghurts produced and commercialized in Brazil, being impossible a broad comparison of the results obtained. In almost all dairy industries, heating the milk is the most widely used unit operation in the manufacture of o yoghurt. The heating treatment of milk at 85 - 90 C for 4 20 s to 30 min (high pasteurization) is usually applied in yoghurt production and it is sufficient to kill the majority, if not all, of the autochthonous microorganisms of raw milk (Con et al., 1996; Tamine, 2002; Olson and Aryana, 2007), including the coliforms. In Brazil this heating treatment is the preferred in yoghurt production once raw milk has notorious poor microbiological quality (Nero et al., 2004; Arcuri et al., 2006), being necessary suitable procedures to avoid any interference in the development of the added starter cultures. Low levels of LAB in fermented products can occur due to inappropriate conditions of storage leading to uncontrolled development of the starter cultures (Tamine, 2002; Tamine and Robinson, 2007), with consequent acid production. However, the mean pH values considering the levels of LAB counts were not significantly different when compared by Tukey (F = 0.16; df = 2; p = 0.85) (Figure 1), suggesting that small amounts of the starter cultures were inoculated in the samples with LAB counts lower 7 than 10 CFU/g. These findings were similar to the ones observed by Pereira et al. (2007) and Lin et al. (2006) studying viable LAB in yoghurts. The yoghurt shelf-life can also interfere in the quality of this product. Associated to this, when yoghurt is kept in inappropriate conditions the LAB from starter cultures tends to increase their development provoking high acidity

212

Afr. J.

Microbiol. Res.

Table 1. Frequencies of yoghurt samples in agreement and disagreement with Brazilian standard microbiological parameters.

Agreement Disagreement Official standard

Thermotolerant coliforms n (%) 36 (100.0) 0 (0.0) * 10 MPN/g

Lactic Acid Bacteria n (%) 29 (80.6) 7 (19.4) 7 ** Higher than 10 CFU/g

Total n (%) 29 (80.6) 7 (19.4)

Brasil, 2001** Brasil, 2000.

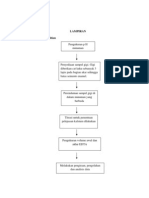

Figure 1. Mean values of pH considering different levels of lactic acid bacteria counts in yoghurt samples. Values with same letters did not differ significantly (Tukey, P < 0.05).

and consequently the killing of themselves (Tamine and Robinson, 2007). The mean values of pH and LAB counts considering different times for expiration of the samples are presented in Table 2, and no differences between these parameters were observed. Considering all samples, the mean of LAB counts was 7.9 log CFU/g and it was possible to observe a decrease in these counts in samples with less than 15 days to finish their viability (Table 2). The same behavior of LAB in yoghurt was observed by on et al. (1996) and Aryana and McGrew (2007), who described that the decrease in numbers of LAB may have occurred due to the accumulation of ambient lactic acid. During the storage, the added LAB starter culture is still able to develop and produce acids, causing, as a result, a decrease in pH. Although the pH is not an official parameter to verify the quality of yoghurt (Brasil, 2000, 2001), it can be measured in order to allow additional information. The pH of the samples varied from 3.59 to 5.24 (mean of 4.28),

slightly similar to the results obtained from Moreira et al. (1999). As for LAB, it can be observed that the pH tended to decrease in the samples with less than 15 days for expiration, confirming the continuous development of the LAB cultures with consequent acid production (Table 2). However, no significant differences between the pH of LAB means were observed, suggesting that this development occurred at expected speed. The same pH decrease was observed by Al-Kadamany et al. (2003) and Nogueira et al. (1998) during the storage of yoghurt o at 4 C. Conclusions According to the results of this study, it can be considered that the yoghurt commercialized in Vicosa presented adequate microbiological quality considering the low levels of contamination by coliforms microorganisms.

Rodrigues et al. 213

Table 2. Statistical parameters of pH and Lactic Acid Bacteria (LAB) in yoghurt samples, considering different times for expiration.

Days for expiration More than 31 16 to 30 Less than 15

*

Mean SD a 4.3 0.41 a 4.3 0.47 a 4.1 0.12

pH ** Min. 3.71 3.59 3.96

Max. 5.08 5.24 4.30

***

LAB (log CFU/g) Mean SD Min. Max. a 7.9 0.96 6.51 9.21 a 8.0 1.06 6.44 9.67 a 7.4 1.42 5.81 8.99

Values in each column with same letters did not differ significantly (Tukey, P < 0.05) Standard deviation, ** Minimum, *** Maximum

However, some samples with low counts of LAB were observed, suggesting inoculation of starter cultures in small amounts once no significant differences were observed in the pH and LAB mean values in different times for expiration. ACKNOWLEDGEMENTS The authors thank Patrcia H. Nero for reviewing grammar and spelling in this article. Also, to FAPEMIG, for supporting L. A. Nero (CVZ-PPM-00093-09).

REFERENCES Al-Kadamany E, Khattar M, Haddad T, Toufeili I (2003). Estimation of shelf-life of concentrated yogurt by monitoring selected microbiological and physicochemical changes during storage. LWT Food Sci. Technol. 36: 407-414. lvarez-Len EE, Romn-Vias B, Serra-Majem L (2006). Dairy products and health: a review of the epidemiological evidence. Brit. J. Nutr. 96: 94-99. Arcuri EF, Brito MAVP, Brito JRF, Pinto SM, ngelo FF, Souza GN (2006). Qualidade microbiolgica do leite refrigerado nas fazendas. Arq. Bras. Med. Vet. Zootec. 58: 440-446. Aryana KJ, McGrew P (2007). Quality attributes of yogurt with Lactobacillus casei and various prebiotics. LWT - Food Sci. Technol. 40: 1808-1814. Brasil. Ministrio da Agricultura, Pecuria e Abastecimento (2000). Resoluo n 5, de 13 de novembro de 2000. Oficializar os padres de identidade e qualidade de leites fermentados. Dirio Oficial da Unio, 27 Nov. Brasil. Ministrio da Sade, Agncia Nacional de Vigilncia Sanitria (2000). Resoluo RDC n 12, de 02 de janeiro de 2001. Aprova o regulamento tcnico sobre padres microbiolgicos para alimentos. Dirio Oficial da Unio, 10 Jan. 2001. on AH, akmaki A, a lar A, Gkalp HY (1996). Effects of different fruits and storage periods on microbiological qualities of fruit-flavored yogurt produced in Turkey. J. Food Prot. 59: 402-406. Cueva O, Aryana KJ (2008). Quality attributes of a heart healthy yogurt. LWT - Food Sci. Technol. 41:537-544. Kalantzopoulos G (1997). Fermented products with probiotic qualities. Anaerobe 3: 185-190. Lin WH, Hwang CF, Chen LW, Tsen HY (2006). Viable counts, characteristics evaluation for commercial lactic acid bacteria products. Food Microbiol. 23: 74-81. McKinley MC (2005). The nutrition and health benefits of yoghurt. Int. J. Dairy Technol. 58: 01-12.

Moreira SR, Schwan RF, Carvalho EP, Ferreira C (1999). Anlise microbiolgica e qumica de iogurtes comercializados em Lavras, MG. Cinc. Tecnol. Alim. 19: 147-152. Nero LA, Mattos MR, Beloti V, Barros MAF, Pontes Netto D, Nogueira Pinto JPA, Andrade NJ, Silva WP, Franco BDGM (2004). Hazards in non-pasteurized milk on retail sale in Brazil: prevalence of Salmonella spp., Listeria monocytogenes and chemical residues. Braz. J. Microbiol. 35: 211-215. Nogueira C, Albano H, Gibbs P, Teixeira P (1998). Microbiological quality of Portuguese yogurts. J. Ind. Microbiol. Biotechnol. 21: 19-21. Olson DW, Aryana KJ (2008). An excessively high Lactobacillus acidophilus inoculation level in yogurt lowers product quality during storage. LWT - Food Sci. Technol. 41: 911-918. Pereira MA, Almeida DM, Sauer E (2007). Avaliao da concentrao de bactrias lticas viveis em iogurtes com polpas de frutas. In: Santos Jnior G, Almeida DM (Eds) Srie em Cincia e Tecnologia de Alimentos: Desenvolvimento em Tecnologia de Alimentos. Ponta Grossa, UTFPR, pp. 7-13. Ross RP, Morgan S, Hill C (2002). Preservation and fermentation: past, present and future. Int. J. Food Microbiol. 92: 03-16. Salinas RJ (1986). Hygiene quality of commercial yoghurts. Alimentaria, 178: 27-30. Steinkraus KH (1997). Classification of fermented foods: worldwide review of household fermentation techniques. Food Control 8: 311317. Tamine AY (2002). Fermented milks: a historical food with modern applications - a review. Eur. J. Clin. Nutr. 56: 01-15. Tamine AY, Robinson RK (2007). Yoghurt: Science and Technology. 3rd ed. Cambridge, Woodhead Publishing Limited p. 808 Wehr HM, Frank JF (2004). Standard Methods for the Examination of Dairy Products. 17th ed. Washington, American Public Health Association. p. 570

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Notes On Electricity For Grade 6Document4 pagesNotes On Electricity For Grade 6Robert Hooke100% (1)

- Complete NEET Crash Course PDFDocument10 pagesComplete NEET Crash Course PDFsaksham modq50% (2)

- Key Design PDFDocument11 pagesKey Design PDFjohn139138No ratings yet

- Cylinder Design Standards WSNZDocument5 pagesCylinder Design Standards WSNZjamilNo ratings yet

- Tests For BricksDocument31 pagesTests For BricksTeddy0% (1)

- Antibacterial For Plastics PDFDocument24 pagesAntibacterial For Plastics PDFRiaNo ratings yet

- DSM Chemical Resistance TablesDocument32 pagesDSM Chemical Resistance TablesJacp2No ratings yet

- 053 7946am0801 366 372Document7 pages053 7946am0801 366 372Arini Tri KusumawatiNo ratings yet

- EmergenciesDocument5 pagesEmergenciesNimrat18No ratings yet

- MetLife Medical Emergencies 2007Document8 pagesMetLife Medical Emergencies 2007Atia Khalid100% (1)

- Caffeinated Youth Regulation of Energy Drinks in QuestionDocument2 pagesCaffeinated Youth Regulation of Energy Drinks in QuestionArini Tri KusumawatiNo ratings yet

- 053 7946am0801 366 372Document7 pages053 7946am0801 366 372Arini Tri KusumawatiNo ratings yet

- Fin 2309Document9 pagesFin 2309Arini Tri KusumawatiNo ratings yet

- Lampiran Skema Alur Penelitian: Universitas Sumatera UtaraDocument14 pagesLampiran Skema Alur Penelitian: Universitas Sumatera UtaraArini Tri KusumawatiNo ratings yet

- MCQ CH 2 ElectrochemistryDocument2 pagesMCQ CH 2 ElectrochemistryGaurav SonarNo ratings yet

- Structure and Bonding (Chapter 3) Exam Questions: 141 Minutes 141 MarksDocument34 pagesStructure and Bonding (Chapter 3) Exam Questions: 141 Minutes 141 Marksrejymol100% (1)

- Spider Fitting Curtain Wall EngineeringDocument14 pagesSpider Fitting Curtain Wall EngineeringpotpotvolksNo ratings yet

- 11th Chemistry Full Book MCQs SQsDocument2 pages11th Chemistry Full Book MCQs SQsSalman AhmedNo ratings yet

- Sasolwax SP30 TDSDocument2 pagesSasolwax SP30 TDSLaboratorio Inkctech0% (1)

- Unit 3 Exam-SolutionsDocument8 pagesUnit 3 Exam-SolutionsbrunosipodNo ratings yet

- Lesson Plan: LP-LP Rev. No: 0 Date: 27-12-2012 Page 1 of 5 VIDocument6 pagesLesson Plan: LP-LP Rev. No: 0 Date: 27-12-2012 Page 1 of 5 VIDhileepan KumarasamyNo ratings yet

- Science Wet Lab PDFDocument4 pagesScience Wet Lab PDFMalachi MillerNo ratings yet

- INSPECTION of Galvanize Product PDFDocument24 pagesINSPECTION of Galvanize Product PDFNasikhatul AmanahNo ratings yet

- Lab - Properties of Carboxylic AcidsDocument2 pagesLab - Properties of Carboxylic Acidsapi-209270909No ratings yet

- UV Vis Spectroscopy Reveals Electronic TransitionsDocument4 pagesUV Vis Spectroscopy Reveals Electronic Transitionsurwah naveed100% (1)

- Mass Transfer Aka Sir AssignmentDocument4 pagesMass Transfer Aka Sir Assignmentওয়াসিমNo ratings yet

- PRODUCT INFORMATIONDocument2 pagesPRODUCT INFORMATIONAdriana GonçalvesNo ratings yet

- Non Chip FormingDocument33 pagesNon Chip FormingNur AmirahNo ratings yet

- Problemario 1 formulas químicasDocument11 pagesProblemario 1 formulas químicasmata viejitosNo ratings yet

- Is 2190.2010 Selection, Installation & Maintenance of Portable Fire ExtinguishersDocument26 pagesIs 2190.2010 Selection, Installation & Maintenance of Portable Fire ExtinguishersShivakumara ArehalliNo ratings yet

- Welcome To This Course Physics 1Document31 pagesWelcome To This Course Physics 1andrewsiby63No ratings yet

- F2 = 30 kNm)2/4) 70 × 109 N/m2Document11 pagesF2 = 30 kNm)2/4) 70 × 109 N/m2Don ValentinoNo ratings yet

- Determination of Specific Gravity or Relative Density of Substances (Formal Report)Document3 pagesDetermination of Specific Gravity or Relative Density of Substances (Formal Report)Zac AshtonNo ratings yet

- Kinetic Friction Experiment Finds Surface Material Affects CoefficientDocument8 pagesKinetic Friction Experiment Finds Surface Material Affects Coefficientkate anne del castroNo ratings yet

- LAB 14 - One-Dimensional Consolidation - Oedometer - Level 0 - 2ndDocument6 pagesLAB 14 - One-Dimensional Consolidation - Oedometer - Level 0 - 2ndAmirah ShafeeraNo ratings yet

- Forensic ChemistryDocument53 pagesForensic ChemistryJoana-MariNo ratings yet

- 4.122 MSC Chem Phy Sem III and IVDocument32 pages4.122 MSC Chem Phy Sem III and IVAsma MerchantNo ratings yet