Professional Documents

Culture Documents

Flyer Zetacoat E PDF

Uploaded by

derimanaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flyer Zetacoat E PDF

Uploaded by

derimanaCopyright:

Available Formats

Properties

SurTec 609 ZetaCoat is a new generation of technology for pretreatment and conversion coating prior to painting is applied in spray and dip applications can be used for cold rolled steel (CRS) hot-dip galvanised steel (HDG) electrogalvanised steel (EG) aluminium (Al) SurTec 609 ZetaCoat provides high corrosion resistance excellent paint adhesion identiable visible conversion layer environmentally safe technology

SurTec 609 ZetaCoat The Visible Difference

Multi-metal: SurTec ZetaCoat on steel (left) and on HDG part (right) SurTec 609 ZetaCoat is a hazard-free non-phosphate conversion coating, based on patented trivalent chromium technology

Zn-ph

Quality 500-800 h ASTM B 117

ZetaCoat 100-500 h ASTM B 117 Fe-ph/Pass Fe-ph Costs

does not contain Hydroxyl hydroxylamine or hydroxyl ammonium sulphat is a simple, easy to control, user friendly process in compliance with international legislation and regulations such as RoHS, WEEE and ELV works at low temperature (25-35 C) no sludge build-up during production

Trivalent Chromium Based Conversion Coating Multi-Metal Pretreatment System for Paint and Powder Coating

Quality versus costs

Process Sequence

Corrosion Resistance

Further readings: www.SurTec.com

1. Cleaning SurTec 138: 1-3 %vol SurTec 086: 0.1-0.5 %vol (spray) SurTec 089: 0.1-0.5 %vol (dip) application time: 60-180 s temperature: 40-60 C pressure (spray): 1-1.5 bar 2. Rinse tap water 3. Rinse tap water/deionised water, max. 350 S/cm 4. Passivation SurTec 609 ZetaCoat: 3-5 %vol pH: 4-5 application time: 60-180 s temperature: 20-35 C pressure (spray): 0.8-1.2 bar 5. Rinse de-ionised/reverse-osmosis water

SurTec 609 ZetaCoat provides excellent corrosion resistance and paint adhesion on steel and aluminium substrates, hot dip galvanised steel and electrogalvanised steel.

Application Areas of S urTec Products: C orrosion Protection Aluminium Applications Passivation S tainless S teel Phosphating

600 h on HDG

600 h on EG

C leaning Electroplating C olouring Plating on Plastics Pickling Micro Technology

600 h on Al

600 h on CRS

Results after 600 hours salt spray test (DIN SS 50021) Test SurTec lab under corrosion (mm) cold rolled steel (CRS) hot dip galvanised (HDG) electrogalvanised (EG) aluminium (Al) 1 0-1 3-5 0 Test Independent lab under corrosion (mm) 0-1 0 4 0

Delacquering

SurTec International GmbH Stuckertstrae 18 D-64673 Zwingenberg Tel. 0(049)62 51-8 48 09-0 Fax 0(049)62 51-8 48 09-20 holding@SurTec.com www.SurTec.com

Steel surface treated with SurTec 609 ZetaCoat (left), untreated surface (right)

You might also like

- Formaldehyde by Ag OxideDocument12 pagesFormaldehyde by Ag OxideVinh Do ThanhNo ratings yet

- LegendDocument1 pageLegendderimanaNo ratings yet

- FORMALDEHYDE PROCESS SIMULATIONDocument19 pagesFORMALDEHYDE PROCESS SIMULATIONTan Yong ChaiNo ratings yet

- Duct DesignDocument46 pagesDuct DesignPushp Dutt100% (3)

- Paparan Kawasan Industri Indonesia (2012) EnglishDocument17 pagesPaparan Kawasan Industri Indonesia (2012) Englishyudhie_7No ratings yet

- Adn Enus PDFDocument93 pagesAdn Enus PDFderimanaNo ratings yet

- Aquence 866Document2 pagesAquence 866derimanaNo ratings yet

- Silver Catalyst FactsDocument4 pagesSilver Catalyst FactsderimanaNo ratings yet

- Quick-Connect Nozzle Systems: Experts in Spray TechnologyDocument20 pagesQuick-Connect Nozzle Systems: Experts in Spray TechnologyderimanaNo ratings yet

- Application Guide Powder Coatings On Hot-Dipped GalvanizedDocument4 pagesApplication Guide Powder Coatings On Hot-Dipped GalvanizedderimanaNo ratings yet

- Steam TablesDocument20 pagesSteam Tablesajitsamal456No ratings yet

- Domestic auto market and Exim by category Jan-Feb 2013Document1 pageDomestic auto market and Exim by category Jan-Feb 2013derimanaNo ratings yet

- Sizing Shell and Tube Heat ExchangerDocument17 pagesSizing Shell and Tube Heat ExchangerCallum Biggs100% (3)

- Domestic Auto Production by Category Jan-Feb 2013Document1 pageDomestic Auto Production by Category Jan-Feb 2013derimanaNo ratings yet

- Noxrust CatalogeeDocument8 pagesNoxrust CatalogeederimanaNo ratings yet

- Calculate Financial Indicators To Guide InvestmentsDocument7 pagesCalculate Financial Indicators To Guide InvestmentsderimanaNo ratings yet

- Noxrust CatalogeeDocument8 pagesNoxrust CatalogeederimanaNo ratings yet

- Exim TrioDocument8 pagesExim TrioderimanaNo ratings yet

- Chemprices 2012Document6 pagesChemprices 2012derimanaNo ratings yet

- Bycat Market Exim Jandec 2012 PDFDocument1 pageBycat Market Exim Jandec 2012 PDFderimanaNo ratings yet

- Bycat Market Exim Jandec 2010 PDFDocument1 pageBycat Market Exim Jandec 2010 PDFderimanaNo ratings yet

- 4 Maret Jadwal SM Genap d4 TKPB PPL 12-13Document5 pages4 Maret Jadwal SM Genap d4 TKPB PPL 12-13abuahnfNo ratings yet

- Solid Waste To Energy PDFDocument30 pagesSolid Waste To Energy PDFderimana100% (1)

- Noxrust CatalogeeDocument8 pagesNoxrust CatalogeederimanaNo ratings yet

- 609e PDFDocument3 pages609e PDFderimanaNo ratings yet

- Material Safety Data Sheet: 1 Identification of SubstanceDocument5 pagesMaterial Safety Data Sheet: 1 Identification of SubstancederimanaNo ratings yet

- Manufacture Formaldehyde MethanolDocument51 pagesManufacture Formaldehyde MethanolArun Ebenezer63% (8)

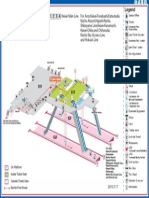

- Circuit Park Map: All Information in This Map Is Correct As of 12 September 2011 and Is Subject To ChangeDocument1 pageCircuit Park Map: All Information in This Map Is Correct As of 12 September 2011 and Is Subject To ChangeDeri PermanaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Celkon Mobiles - Wikipedia, The Free EncyclopediaDocument1 pageCelkon Mobiles - Wikipedia, The Free EncyclopediaJignesh ChaudharyNo ratings yet

- How To Model A Square Foundation On PlaxisDocument4 pagesHow To Model A Square Foundation On Plaxisomarrashad84No ratings yet

- Fundamental Rights of IndiaDocument6 pagesFundamental Rights of IndiaDhruv AsodariaNo ratings yet

- DRDO recruitment for scientists in remote areasDocument7 pagesDRDO recruitment for scientists in remote areasselva mechNo ratings yet

- Classification FIGODocument5 pagesClassification FIGOOlivier DOBANo ratings yet

- KLAXDocument95 pagesKLAXJorge Vega RodríguezNo ratings yet

- Case Study Biomaterials Selection For A Joint ReplacementDocument8 pagesCase Study Biomaterials Selection For A Joint ReplacementBjarne Van haegenbergNo ratings yet

- Jill Bush ResumeDocument3 pagesJill Bush ResumeAustinTalksNo ratings yet

- Robot ReportDocument49 pagesRobot ReportJiya MakwanaNo ratings yet

- Wattyl Killrust Brochure 2Document6 pagesWattyl Killrust Brochure 2Tech 84No ratings yet

- Statutory Construction - Legal MaximsDocument5 pagesStatutory Construction - Legal MaximsglendaNo ratings yet

- Fri Chiks Marketing Mix and Swot AnalysisDocument22 pagesFri Chiks Marketing Mix and Swot Analysisahsanparveen100% (1)

- Definition of Terms (Fire Code of The Philippines)Document9 pagesDefinition of Terms (Fire Code of The Philippines)broomer27No ratings yet

- Setting Up A Virtual Switch For A HyperDocument5 pagesSetting Up A Virtual Switch For A Hyperaleksandar71No ratings yet

- Completing Your Master's or PhD DegreeDocument2 pagesCompleting Your Master's or PhD DegreeChu ThứcNo ratings yet

- EchoSign V10 Installation GuideDocument34 pagesEchoSign V10 Installation GuidereupbertNo ratings yet

- Customer and Banker Relationship MCQDocument13 pagesCustomer and Banker Relationship MCQsn n100% (3)

- 12V 60Ah Lead Acid Battery Data SheetDocument4 pages12V 60Ah Lead Acid Battery Data SheetДима СелютинNo ratings yet

- Tkinter Cheat SheetDocument2 pagesTkinter Cheat Sheetphanina01No ratings yet

- Summary of Sales Report: Dranix Distributor IncDocument6 pagesSummary of Sales Report: Dranix Distributor Incshipmonk7No ratings yet

- AWS CWI Training Program PDFDocument22 pagesAWS CWI Training Program PDFDjamelNo ratings yet

- Proof of Stock OwnershipDocument5 pagesProof of Stock OwnershipSebastian GarciaNo ratings yet

- Behringer Europower-P0569 Hca2400 Sps1000 DPX Pmp-1280s 5000 SCHDocument15 pagesBehringer Europower-P0569 Hca2400 Sps1000 DPX Pmp-1280s 5000 SCHNorel Andrei100% (2)

- DMMEasyControl Software Guide - V1.4.3 (20211110)Document15 pagesDMMEasyControl Software Guide - V1.4.3 (20211110)Bruno FroesNo ratings yet

- ABB Connectivity PackagesDocument102 pagesABB Connectivity Packagestin_gabby4876100% (1)

- Model MRP: Samsung B7620Document19 pagesModel MRP: Samsung B7620Rajni MenonNo ratings yet

- Strategic Management Session XVIIDocument29 pagesStrategic Management Session XVIIharisankar sureshNo ratings yet

- Gastrointestinal Dysfunction in The CriticallyDocument17 pagesGastrointestinal Dysfunction in The Criticallysirenita33No ratings yet

- Masonry Bridge Assessment With Archie-M: Notes For A Masonry Bridge Masterclass Bill Harvey Associates LTD March 2011Document12 pagesMasonry Bridge Assessment With Archie-M: Notes For A Masonry Bridge Masterclass Bill Harvey Associates LTD March 2011Info Aviron LavalNo ratings yet

- Synopsis NDocument9 pagesSynopsis NAnonymous g7uPednINo ratings yet