Professional Documents

Culture Documents

Calculation of PipeReinforcement ASMEB31.1

Uploaded by

jayaarnavOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Calculation of PipeReinforcement ASMEB31.1

Uploaded by

jayaarnavCopyright:

Available Formats

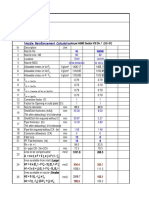

PRESSURE DESIGN STRAIGHT PIPE ( RUN PIPE)

STRAIGHT PIPE THICKNESS UNDER INTERNAL PRESSURE (tm) , mm.

18.11

1. Where

tm =[(PDo)/2(SE+PY)]+A

18.11

2. tm =(Pd+2SEA+2YPA)/2(SE+PY-P)

17.97

P Doh S E Y d A

Internal Design Gauge Pressure, N/mm2. Outside Diameter of Pipe, mm. Stress Value for Material, N/mm . Quality Factor For Longitudinal Weld Joints in Pipes. Coefficient for Materials. Inside Diameter of Pipe, mm. sum of mechanical, corrosion, erosion allowance,mm.

2

4.2 711.2 88.25 1 0.4 669.20 1.5

REINFORCEMENT OF WELDED BRANCH CONNECTIONS

h b Th Tb d1 d2 L4 Tb Th tr tmh tmb

subscript referring to run or header. subscript referring to branch. nominal thickness of run or header. nominal thickness of branch. effective length removed from pipe at branch, mm. "half width" of reinforcement zone, mm. height of reinforcement zone outside of run pipe, mm. branch pipe thickness, mm. run pipe thickness, mm. minimum thickness of reinforcing pad, mm. pressure design thickness of run pipe, mm. pressure design thickness of branch pipe, mm. smaller angle between axis of branch and run.

21 13 199.35 199.35 42.19 11.38 18.38 18.4 18.11 6.62 90

Dob Doh

outside diameter of branch pipe, mm. outside diameter of run pipe, mm.

219.10 711.20

1. d1 = [Dob - 2(T b - A)]/sin

199.35

2. d2= greater of d1 or (T b - A) + (T h - A) + d1/2 Therefore d2

126.43 199.35

3.

L4 = lesser of 2.5(T h - A), mm or 2.5(T b - A) + tr, mm.

42.19 43.09

REQUIRED REINFORCEMENT AREA

1. A7 = (tmh - A)d1(2 - sin), mm2

3310.72

AVAILABLE AREA

A1 + A2 + A3 + A4 + A5 >= A7

Where A1 A2 A3 A4 A5 Dr Sr ha hb Area resulting from excess thickness in the run pipe wall, mm2. Area resulting from excess thickness in the branch pipe wall, mm2. Area provided by deposited weld metal beyond the outside diameter of the run & branch, mm 2. Area provided by a reinforcing ring, pad or integral reinforcement, mm2. Area provided by a saddle on right angle connection, mm2. Outside diameter of reinforcement ring, mm. Stress value for reinforcement ring material, N/mm2. Height of the fillet weld between run pipe & reinforcement ring, mm. Height of the fillet weld between branch pipe & reinforcement ring, mm. 1930.16 324.00 88.25 3.00 3.00 53.31 401.51

1. A1 = (2d2 - d1)(Th - tmh) 2. A2 = 2L4(Tb - tmb)/sin 3. A5 = (Dr - Dob) tr

53.31 401.51 1930.16

A1 + A2

454.82

Additional reinforcement required A7 - ( A1 + A2 ) <= A3 + A4 + A5

YES 2855.90

1. Area of reinforcement ring, mm2. 2. Area of fillet weld, mm2.

1927.54 18.00

NOTES: 1. All values are rounded of upto two decimal places. 2. Some nomenclatures which are not present in the figure have been added for carrying out calculations. 3. Height and base of the fillet welds is assumed to be equal. 4. d2 in any case shall not be greater than Doh.

PRESSURE DESIGN STRAIGHT PIPE ( RUN PIPE)

STRAIGHT PIPE THICKNESS UNDER INTERNAL PRESSURE (tm) , mm.

6.62

1. Where

tm =[(PDo)/2(SE+PY)]+A

6.62

2. tm =(Pd+2SEA+2YPA)/2(SE+PY-P)

6.30

P Dob S E Y d A

Internal Design Gauge Pressure, N/mm2. Outside Diameter of Pipe, mm. Stress Value for Material, N/mm . Quality Factor For Longitudinal Weld Joints in Pipes. Coefficient for Materials. Inside Diameter of Pipe, mm. sum of mechanical, corrosion, erosion allowance,mm.

2

4.2 219.1 88.25 1 0.4 193.10 1.5

You might also like

- Reinforcement CheckDocument2 pagesReinforcement Checkviv0102No ratings yet

- New - Reinforcement of NozzleDocument31 pagesNew - Reinforcement of NozzleChagar HarshpalNo ratings yet

- Shell Inputs: Use Asme Code Section-8 Division I (Ug-37)Document34 pagesShell Inputs: Use Asme Code Section-8 Division I (Ug-37)Bashu PoudelNo ratings yet

- Reinforcement CalculationDocument2 pagesReinforcement CalculationVekaymech100% (9)

- Calculation of PipeReinforcement ASMEB31 1Document4 pagesCalculation of PipeReinforcement ASMEB31 1threedlabsNo ratings yet

- Pipe Reinforcement Calculation (ASME-B31.3)Document3 pagesPipe Reinforcement Calculation (ASME-B31.3)jenshid100% (2)

- Calculation of Pipe Reinforcement ASME B31 3Document3 pagesCalculation of Pipe Reinforcement ASME B31 3Brant AkkanNo ratings yet

- Section VIII CalDocument21 pagesSection VIII CalRuben Samoel Barros RochaNo ratings yet

- Calculation Minimum Required Thickness For Bending Pipe r2Document11 pagesCalculation Minimum Required Thickness For Bending Pipe r2Exsan OthmanNo ratings yet

- Area Reinforcement CalculatorDocument5 pagesArea Reinforcement CalculatorAnonymous Iev5ggSR100% (1)

- Document Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking PlantDocument49 pagesDocument Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking Plantsusa2536No ratings yet

- ASME B31 8 Riser CalcDocument12 pagesASME B31 8 Riser CalcEmmanuel LawrenceNo ratings yet

- New - Reinforcement of NozzleDocument24 pagesNew - Reinforcement of NozzleVaniya GoelNo ratings yet

- Pipe Thickness Calculation For Straight Pipe Under Internal PressureDocument7 pagesPipe Thickness Calculation For Straight Pipe Under Internal PressureMakhdoom Ibad HashmiNo ratings yet

- Pd5500 Flange CalculationDocument6 pagesPd5500 Flange CalculationMakrand SakpalNo ratings yet

- Pipe Thickness Calculation PDFDocument1 pagePipe Thickness Calculation PDFHeny Martha67% (3)

- Pipe Wall Thickness Calculation (As Per Asme B31.3 Section 304.1.2)Document1 pagePipe Wall Thickness Calculation (As Per Asme B31.3 Section 304.1.2)farhadNo ratings yet

- Wall THK Calculation Asme b31.4Document5 pagesWall THK Calculation Asme b31.4Dwi Hermawan100% (2)

- PCC1 - Addendum - 31210130 (Feb 2013) - GM1-001-G0000-MS-7880-00003Document2 pagesPCC1 - Addendum - 31210130 (Feb 2013) - GM1-001-G0000-MS-7880-00003Abhay UpadhyayNo ratings yet

- PIPELINE WALL THICKNESS CALCULATIONSDocument24 pagesPIPELINE WALL THICKNESS CALCULATIONSMohsin RazaNo ratings yet

- #REF! #REF!: Ref: Procedure No. 3-4 Pg. No. 169, Pressure Vessel Design Manual by Dennis Moss, 4th EditionDocument31 pages#REF! #REF!: Ref: Procedure No. 3-4 Pg. No. 169, Pressure Vessel Design Manual by Dennis Moss, 4th EditionSivi NallamothuNo ratings yet

- Thickness Calculation ASME B31.3 (Revised) HP LOOP ELBOWDocument117 pagesThickness Calculation ASME B31.3 (Revised) HP LOOP ELBOWGohar ZamanNo ratings yet

- Design Calculation Anchor Flange ASME VIII Div 1 App 2Document3 pagesDesign Calculation Anchor Flange ASME VIII Div 1 App 2Septian FirdausNo ratings yet

- AD 2000 Head Under Intenal PressureDocument3 pagesAD 2000 Head Under Intenal Pressuremechengg01No ratings yet

- Branch Reinforcement Pad Requirement CalculationDocument2 pagesBranch Reinforcement Pad Requirement CalculationAntoshal100% (4)

- Pipe Is Under Clamping ForceDocument7 pagesPipe Is Under Clamping Forcejosediaz141No ratings yet

- Pipe cap thickness and coupling rating calculationsDocument2 pagesPipe cap thickness and coupling rating calculationsmasaminathanNo ratings yet

- Reinforcement of Openings On Tori-Dish (Trial)Document23 pagesReinforcement of Openings On Tori-Dish (Trial)Sajal KulshresthaNo ratings yet

- Wall Thickness Calculation Verification under StressDocument1 pageWall Thickness Calculation Verification under StresshhgjdfNo ratings yet

- Blind flange design calculationDocument4 pagesBlind flange design calculationmukesh100% (2)

- NozzlePRO PDFDocument185 pagesNozzlePRO PDFIan CarrNo ratings yet

- Collar bolt sizing calculationDocument2 pagesCollar bolt sizing calculationMohammad Zahid50% (2)

- Wall Thickness Calculation ASME B31!8!2007Document1 pageWall Thickness Calculation ASME B31!8!2007shafeeqm3086No ratings yet

- UEPL THICKNESS CALCULATION FOR SBA AND SAC VESSELS ROSA TPPDocument8 pagesUEPL THICKNESS CALCULATION FOR SBA AND SAC VESSELS ROSA TPPmkchy12100% (1)

- AES Type Heat ExchangerDocument8 pagesAES Type Heat ExchangerSudhanshu67100% (1)

- ASME B31.3.4.8 Wall Thickness CalculatorDocument26 pagesASME B31.3.4.8 Wall Thickness Calculatoreko123No ratings yet

- ASME 31 - 8mDocument1 pageASME 31 - 8mMarcoAlbaNo ratings yet

- Calculation For Reinforced PadDocument4 pagesCalculation For Reinforced Padjsridhar_34750% (2)

- Piping Calculation Program For ASME B31 1 CodeDocument3 pagesPiping Calculation Program For ASME B31 1 CodeAMIT100% (2)

- Branch Reinforcement Calculation DetailsDocument17 pagesBranch Reinforcement Calculation DetailsVikash Tiwari100% (3)

- Hinge Calculation FormulasDocument2 pagesHinge Calculation FormulasamaNo ratings yet

- Wall THK Calculation Asme b31.4Document7 pagesWall THK Calculation Asme b31.4Luis Jose Duran100% (1)

- Steam tracing simulation determines Process Fluid TemperatureDocument74 pagesSteam tracing simulation determines Process Fluid TemperaturecybermineNo ratings yet

- Wall Thickness and MITERDocument1 pageWall Thickness and MITERnirgaNo ratings yet

- SADDLE SUPPORT DESIGNDocument6 pagesSADDLE SUPPORT DESIGNSISIR KR BARMAN0% (1)

- Pressure Drop Calculation - 6 Inch Permeate and Reject PumpDocument2 pagesPressure Drop Calculation - 6 Inch Permeate and Reject Pumpalmandhari33No ratings yet

- Nozzle Reinforcement Calculation Excel SheetDocument3 pagesNozzle Reinforcement Calculation Excel Sheetramesh punjabiNo ratings yet

- Imperial Piping Weight Load Calculation WorkbookDocument13 pagesImperial Piping Weight Load Calculation WorkbookKakoDa100% (1)

- Calculation of Pipe Reinforcement ASME B31.3Document9 pagesCalculation of Pipe Reinforcement ASME B31.3yhnsharma80% (5)

- Pressure Design Straight Pipe (Run Pipe)Document6 pagesPressure Design Straight Pipe (Run Pipe)gembirasekaliNo ratings yet

- Calculation of Pipe Reinforcement ASME B31 3Document4 pagesCalculation of Pipe Reinforcement ASME B31 3ArmandoZacariasAcosta0% (1)

- Branch (1) Calculations: Pipe Branch Reinforcement Per ASME B31.1b - 2009 Power Piping CodeDocument2 pagesBranch (1) Calculations: Pipe Branch Reinforcement Per ASME B31.1b - 2009 Power Piping Codedeua2004No ratings yet

- PRESSURE DESIGN AND REINFORCEMENT OF STRAIGHT PIPES AND BRANCH CONNECTIONSDocument5 pagesPRESSURE DESIGN AND REINFORCEMENT OF STRAIGHT PIPES AND BRANCH CONNECTIONSUmar Aslam0% (1)

- Reinf S1Document2 pagesReinf S1tasingenieriaNo ratings yet

- Asme Viii Shell & Se HeadDocument5 pagesAsme Viii Shell & Se HeadSnr George RaczNo ratings yet

- Pipe Thickness & RF Pad Calculations As Per Asme b313Document3 pagesPipe Thickness & RF Pad Calculations As Per Asme b313Gaurav BhendeNo ratings yet

- Section VIII CalDocument19 pagesSection VIII CalPradeep Kothapalli100% (1)

- Calculation of Pipe Reinforcement Asme b31 3Document3 pagesCalculation of Pipe Reinforcement Asme b31 3KomedianTunggalNo ratings yet

- Equipment Design As Per Russian Norms - 20090218Document45 pagesEquipment Design As Per Russian Norms - 20090218vikasNo ratings yet

- Thickness Calculation of Pressure Vessel ShellDocument22 pagesThickness Calculation of Pressure Vessel ShellAkshat Jain88% (26)

- Everything You Need to Know About Titanium: Its Properties, Welding, and ApplicationsDocument19 pagesEverything You Need to Know About Titanium: Its Properties, Welding, and Applicationsjayaarnav100% (2)

- Open Book For API 653Document10 pagesOpen Book For API 653jayaarnavNo ratings yet

- Hydrotest Procedure As Per ASME B 31.1 (Power Piping)Document10 pagesHydrotest Procedure As Per ASME B 31.1 (Power Piping)jayaarnav100% (3)

- Mustapha FfsDocument21 pagesMustapha FfsjayaarnavNo ratings yet

- Api 575Document37 pagesApi 575Sakthi Pk100% (3)

- NORSOK Z-006 - PreservationDocument20 pagesNORSOK Z-006 - Preservationjoaocavti100% (4)

- En 473 Level 2 Preparatory Program Schedule For Oct 2013Document1 pageEn 473 Level 2 Preparatory Program Schedule For Oct 2013jayaarnavNo ratings yet

- Mechanical FitterDocument9 pagesMechanical Fitterjayaarnav0% (1)

- Steamfitter Pipefitter Practice ExamDocument9 pagesSteamfitter Pipefitter Practice ExamAbo Hasan Abade100% (2)

- Approximate RT Calculation For API 650 TankDocument2 pagesApproximate RT Calculation For API 650 Tankjayaarnav100% (6)

- Work Instruction On Tube ExpansionDocument40 pagesWork Instruction On Tube Expansionjayaarnav100% (1)

- RTDocument16 pagesRTjayaarnavNo ratings yet

- API 570 Question PDFDocument181 pagesAPI 570 Question PDFRamziAhmedNo ratings yet

- Cswip 3.2 Notes 1Document42 pagesCswip 3.2 Notes 1Sisira Chandrasoma100% (7)

- Inspection HandbookDocument126 pagesInspection Handbooksteffy18295% (21)

- Interesting PicturesDocument2 pagesInteresting PicturesjayaarnavNo ratings yet

- CWI SCWI Renewal PKG v1Document2 pagesCWI SCWI Renewal PKG v1jayaarnavNo ratings yet

- RTDocument8 pagesRTjayaarnav33% (3)

- CWI SCWI Renewal PKG v1Document2 pagesCWI SCWI Renewal PKG v1jayaarnavNo ratings yet

- 3 2Document3 pages3 2jayaarnav100% (1)

- 02 Heubach No 00181 ZPA RZ Epoxy Dispersion WDocument2 pages02 Heubach No 00181 ZPA RZ Epoxy Dispersion WnanoNo ratings yet

- Report GCWDocument34 pagesReport GCWArchit HaldiaNo ratings yet

- Wolter Jetfan Broschuere English 2017 PDFDocument15 pagesWolter Jetfan Broschuere English 2017 PDFViệt Đặng XuânNo ratings yet

- (2012) A Greenhouse Gas Accounting Tool For Palm Products (RSPO - PalmGHG Beta Version 1)Document56 pages(2012) A Greenhouse Gas Accounting Tool For Palm Products (RSPO - PalmGHG Beta Version 1)anon_369860093No ratings yet

- Chapter 4 and 5Document51 pagesChapter 4 and 5Kyla Gabrielle TutoNo ratings yet

- New Australian Curriculum Senior Secondary ChemistryDocument44 pagesNew Australian Curriculum Senior Secondary Chemistryapi-252350138No ratings yet

- Cape Chemistry Unit Ii Module I Alkanes and Alkenes Worksheet and Revision GuideDocument5 pagesCape Chemistry Unit Ii Module I Alkanes and Alkenes Worksheet and Revision GuideDestinee SullivanNo ratings yet

- Ecosystem and Its ComponentsDocument19 pagesEcosystem and Its ComponentsSooraj KrishnanNo ratings yet

- 1 Auxilliary Equipment - US PricingDocument132 pages1 Auxilliary Equipment - US PricingOscar EspitiaNo ratings yet

- Low Temp Refrigeration Oil DataDocument1 pageLow Temp Refrigeration Oil DataGeorgiana DumitruNo ratings yet

- Chinese GMP 2010Document115 pagesChinese GMP 2010Atul SharmaNo ratings yet

- Distillation Lecture Note-2Document20 pagesDistillation Lecture Note-2BasseyNo ratings yet

- Warna Daun Padi LCCDocument12 pagesWarna Daun Padi LCCM Hisyam NasrullohNo ratings yet

- Test For Cations, Anions and Gases (QA) NotesDocument10 pagesTest For Cations, Anions and Gases (QA) Noteschong56100% (2)

- Kluebersynth GEM 4 N GB enDocument6 pagesKluebersynth GEM 4 N GB enIvan MarijanovićNo ratings yet

- Organic Chem. Lab. M6 ACTIVITY SHEET PCCH103L Santos Ronzel ANgelo M.Document3 pagesOrganic Chem. Lab. M6 ACTIVITY SHEET PCCH103L Santos Ronzel ANgelo M.Akira SantosNo ratings yet

- Computational Models For Drug Design and DelivDocument235 pagesComputational Models For Drug Design and DelivIbrahim Al SharabiNo ratings yet

- Yeom 2012Document10 pagesYeom 2012Deysi Suarez GomezNo ratings yet

- Vestamid L Polyamide 12 - EvonikDocument12 pagesVestamid L Polyamide 12 - EvonikHaryo Armono100% (1)

- Alkyl HalideDocument54 pagesAlkyl HalideNelvianaNo ratings yet

- Bio HGHDocument19 pagesBio HGHapi-240332064No ratings yet

- Lecture 4 - Reinforced Concrete - Bond, Development LengthDocument55 pagesLecture 4 - Reinforced Concrete - Bond, Development LengthChristopher PaladioNo ratings yet

- Stainless Steel 304 FlangesDocument6 pagesStainless Steel 304 FlangesiSteelindiaNo ratings yet

- Filter Elements, Parts for Compressors and EnginesDocument2 pagesFilter Elements, Parts for Compressors and Enginespgm900No ratings yet

- Ceilcote 242 Flakeline coating specification for concreteDocument2 pagesCeilcote 242 Flakeline coating specification for concretenoto.sugiartoNo ratings yet

- MotionDocument6 pagesMotionRobert willaimsNo ratings yet

- How buffers maintain pH levelsDocument4 pagesHow buffers maintain pH levelsManP13No ratings yet

- 5468-Tank Cleaning ChecklistDocument3 pages5468-Tank Cleaning ChecklistMaaloul FakherNo ratings yet

- Chem 31.1 Experiment 9 Synthesis of Organic CompoundsDocument68 pagesChem 31.1 Experiment 9 Synthesis of Organic Compoundshello87623100% (1)

- Magnaglo 14a Dry PowderDocument2 pagesMagnaglo 14a Dry Powdermlowe680No ratings yet