Professional Documents

Culture Documents

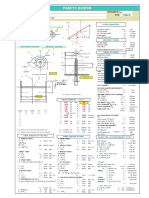

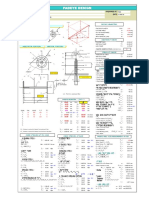

GG Honey Comb Cast Shape Add Plate

Uploaded by

Fian ArdiyanaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GG Honey Comb Cast Shape Add Plate

Uploaded by

Fian ArdiyanaCopyright:

Available Formats

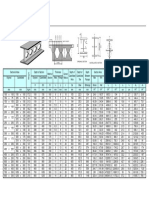

HONEY COMB

PT. GUNUNG GARUDA

(HONEY COMB + ADDING PLATES)

Ds

Dtee

mm

mm

mm

mm

mm

18.55

15.50

33.60

23.50

19.90

53.00

32.50

28.10

76.80

40.50

35.20

99.90

54.40

45.40

141.62

72.30

62.10

83.90

99.50

118.50

165.00

177.50

191.10

218.00

100

150

150

200

198

200

250

248

250

300

298

300

350

346

350

400

396

450

500

600

588

400

700

800

200

300

300

400

396

400

500

496

500

600

596

600

700

692

700

800

792

900

1000

1200

1176

800

1400

1600

100

75

150

100

99

200

125

124

250

150

149

300

175

174

350

200

199

200

200

200

300

400

300

300

6

5

7

5.5

4.5

8

6

5

9

6.5

5.5

10

7

6

12

8

7

9

10

11

12

13

13

14

8

7

10

8

7

12

9

8

14

9

8

15

11

9

19

13

11

14

16

17

20

21

24

26

10

8

11

11

11

13

12

12

16

13

13

18

14

14

20

16

16

18

20

22

28

22

28

28

50

75

75

100

99

100

125

124

125

150

149

150

175

173

175

200

198

225

250

300

294

200

350

400

156

231

231

306

303

306

381

378

381

456

453

456

531

525

531

606

600

681

756

906

888

606

1056

1206

22.0

34.5

34.5

47.0

46.5

47.0

59.5

59.0

59.5

72.0

71.5

72.0

84.5

83.5

84.5

97.0

96.0

109.5

122.0

147.0

144.0

97.0

172.0

197.0

184

286

280

384

382

376

482

480

472

582

580

570

678

674

662

774

770

872

968

1166

1136

758

1352

1548

t1

t2

DIMENSIONAL TOLERANCE

HEAD OFFICE & FACTORY

Jl. Imam Bonjol 4, Warung Bongkok,

Sukadanau, Cikarang Barat,

Bekasi 17520, West Java, INDONESIA

Sales Department

Phone DID : (62-21) 898 38 161 - 167

Phone Flexy :

(021) 7085 3164 - 165

(021) 7085 3169

Fax. : (62-21) 8910 - 7711,

(62-21) 8900-555 / 976 / 977

e-mail : pjl01@grdsteel.com

pjl02@grdsteel.com

Flange width (B)

(mm)

+ 3.0

Under 400

400 - 600

600& over

Depth of

cell form

hole (Ds)

(mm)

+ 4.0

+ 5.0

+ 6.0

+ 3.0

Depth (Dc)

(mm)

Dbflange Gross

cm 2

27.90

25.35

50.64

38.16

32.09

79.53

52.66

45.08

114.68

66.28

57.19

149.80

87.64

73.44

215.90

116.12

99.88

137.26

164.20

200.40

263.06

270.70

326.50

379.40

Net

Ix

Iy

ix

iy

Zx

Zy

cm 2

18.54

13.80

34.47

21.33

18.46

55.05

29.80

26.18

80.39

36.64

32.28

104.20

50.47

41.94

152.18

67.64

57.88

75.97

88.60

100.74

156.50

191.92

189.22

210.56

cm 4

1712

3022

7308

8216

6917

20867

18055

15523

47611

32198

27846

89361

60394

48949

177408

105531

88376

150151

216055

355610

519725

292713

898606

1317191

cm 4

cm

cm

cm 3

cm 3

134

49

563

134

114

1600

294

255

3650

508

442

6751

984

792

13602

1740

1450

1871

2141

2282

9023

22403

10805

11707

9.61 2.69 171.2

26.8

14.80 1.88 201.5

13.1

14.56 4.04 487.2

75.1

19.63 2.51 410.8

26.8

19.36 2.49 349.3

23.0

19.47 5.39 1043.4 160.0

24.61 3.14 722.2

47.0

24.35 3.12 625.9

41.1

24.34 6.74 1904.4 292.0

29.64 3.72 1073.3

67.7

29.37 3.70 934.4

59.3

29.28 8.05 2978.7 450.1

34.59 4.42 1725.5 112.5

34.16 4.35 1414.7

91.0

34.14 9.45 5068.8 777.3

39.50 5.07 2638.3 174.0

39.08 5.01 2231.7 145.7

44.46 4.96 3336.7 187.1

49.38 4.92 4321.1 214.1

59.41 4.76 5926.8 228.2

57.63 7.59 8838.9 601.5

39.05 10.80 7317.8 1120.2

68.91 7.56 12837.2 720.3

79.09 7.46 16464.9 780.5

MECHANICAL PROPERTIES

Yield Point

N / mm 2

Classification

Thickness (mm)

Elongation %

Tensile

Thickness (mm)

Strength

2

16 or Under Over 16 N / mm 5 or Under 5 to 16 Over 16

JIS G 3101 SS 400

245

235

400 - 510

21

17

WASTE LENGTH

Dtee

D add

mm mm

60

1.08 (Ds-Dadd)

t2

r

t1

B

ORIGINAL SECTION

Y

Dc

mm

Dbflange

mm

0.29 (Ds-Dadd)

Dc

mm

0.25 (Ds-Dadd)

100 X 100 200 x 100

150 X 75 300 x 75

150 X 150 300 x 150

400 x 100

200 X 100

396 x 99

200 X 200 400 x 200

500 x 125

250 X 125

496 x 124

250 X 250 500 x 250

600 x 150

300 X 150

596 x 149

300 X 300 600 x 300

700 x 175

350 X 175

692 x 174

350 X 350 700 x 350

800 x 200

400 X 200

792 x 199

450 X 200 900 x 200

500 X 200 1000 x 200

600 X 200 1200 x 200

588 X 300 1176 x 300

400 X 400 800 x 400

700 X 300 1400 x 300

800 X 300 1600 x 300

kg/m

0.25 (Ds-Dadd)

mm

0.29 (Ds-Dadd)

Castellated

mm

RADIUS OF MODULUS OF

GYRATION

SECTION

Ds

Original

MOMENT

OF INERTIA

0.54 (Ds-Dadd)

SECTIONAL INDEX

DEPTH DEPTH DEPTH DEPTH

WIDTH

OF

OF BETWEEN SECTION

OF THICKNESS CORNER OF

AREA

CASTEL- CASTELADDED

SECTION

RADIUS

PLATE LATED LATED FLANGES

Web Flange

Original Castellated

Min

HOLE

TEE

Max

DEPTH OF

SECTION

D_add

WEIGHT

METRIC SIZE

CASTELLATED SECTION

Y

21

iy

CHEMICAL COMPOSITION

GRADE

SS 400

WELDING

Chemical Composition (%)

C

-

Si

-

Mn

-

P

0.05 max

S

0.05 max

As per AWS

Welding material: E 6013

ix

Y

www.grdsteel.com

You might also like

- Tabel Baja StellaDocument1 pageTabel Baja StellaAlexander IgnatiusNo ratings yet

- Honeycomb TabelDocument2 pagesHoneycomb TabelYuki Gitara80% (5)

- PT GUNUNG RAJA PAKSI Steel Pipe SpecificationsDocument2 pagesPT GUNUNG RAJA PAKSI Steel Pipe SpecificationsDaniel Silva100% (1)

- Data Berat PlywoodDocument13 pagesData Berat PlywoodAndi RismayantiNo ratings yet

- TABEL BERAT BESI IWF DAN SIKU LDocument11 pagesTABEL BERAT BESI IWF DAN SIKU LIman Rahmatullah100% (3)

- (Cold Formed) : Steel Is Our BusinessDocument2 pages(Cold Formed) : Steel Is Our BusinessAndri MutiarNo ratings yet

- PT. GUNUNG GAHAPI BAHARA Steel Anchor Bolt SpecsDocument1 pagePT. GUNUNG GAHAPI BAHARA Steel Anchor Bolt SpecsAndri Mutiar0% (1)

- BOQ Konstruksi BajaDocument2 pagesBOQ Konstruksi BajaAndy YuliantoNo ratings yet

- Tabel Baja LengkapDocument29 pagesTabel Baja LengkapAlexander Ignatius50% (4)

- Anchor Bolt Specifications from PT Gunung Gahapi BaharaDocument6 pagesAnchor Bolt Specifications from PT Gunung Gahapi BaharamagiNo ratings yet

- Tabel Hollow SquareDocument2 pagesTabel Hollow SquarehendjoNo ratings yet

- Tabel Berat WiremeshDocument2 pagesTabel Berat WiremeshIndahWahyuni67% (3)

- Anchor BoltDocument2 pagesAnchor BoltYudi Herdiansah100% (2)

- Perhitungan Kekuatan Curtain Wall Proyek Bandara Sultan Hasanuddin Makasar PDFDocument17 pagesPerhitungan Kekuatan Curtain Wall Proyek Bandara Sultan Hasanuddin Makasar PDFBoby PrimatamaNo ratings yet

- Tabel HoneycombDocument2 pagesTabel HoneycombAzwar HalimNo ratings yet

- Steel Weight PDFDocument4 pagesSteel Weight PDFmoorthymech1979No ratings yet

- H Beam ChartDocument4 pagesH Beam ChartKarthimeena MeenaNo ratings yet

- T Beam PDFDocument2 pagesT Beam PDFjabri kotaNo ratings yet

- DIN and Standard Parts Hex Head BoltsDocument1 pageDIN and Standard Parts Hex Head BoltsoscardgNo ratings yet

- Materials Standard Duty: STD: Steel 214M15/045M10 ALTERNATIVE: Brass, Tufnol or Delrin SpecialsDocument6 pagesMaterials Standard Duty: STD: Steel 214M15/045M10 ALTERNATIVE: Brass, Tufnol or Delrin Specials741852963aaaNo ratings yet

- Data Stock Gudang PertashopDocument24 pagesData Stock Gudang PertashopDhodho Agung S MachinNo ratings yet

- Columns Design - Code 2017Document9 pagesColumns Design - Code 2017Mohammed Nader GalalNo ratings yet

- Equal angle steel profiles data sheetDocument2 pagesEqual angle steel profiles data sheetGalih PutraNo ratings yet

- Hyundai-Lifeboat - GRP Pipe BrochureDocument9 pagesHyundai-Lifeboat - GRP Pipe Brochure유연호No ratings yet

- Rohm - Spindles and ChucksDocument12 pagesRohm - Spindles and ChucksGatyo GatevNo ratings yet

- Confinement Check d0Document15 pagesConfinement Check d0Srishti Project ConsultantsNo ratings yet

- Wide Flange ShapeDocument3 pagesWide Flange ShapeFindy Pradestra TyashadiNo ratings yet

- Astral Upvc Sch80 Pipes and Fittings PricelistDocument2 pagesAstral Upvc Sch80 Pipes and Fittings PricelistAkash Goyal78% (23)

- Columns Design - Code 2017Document9 pagesColumns Design - Code 2017foush bashaNo ratings yet

- Technical information on tensile strength, tightening torque and stainless steelDocument13 pagesTechnical information on tensile strength, tightening torque and stainless steelAngelo PereiraNo ratings yet

- Tevi Fitinguri PVC KGDocument5 pagesTevi Fitinguri PVC KGCatalin StefanNo ratings yet

- GIACOMELLO - Euro ProfileDocument8 pagesGIACOMELLO - Euro ProfileVantu-Voiculescu CristiNo ratings yet

- Serie 523 - ISO 15552Document69 pagesSerie 523 - ISO 15552NixiusNo ratings yet

- BYG Master Catalog en LRS Classicwearparts 01Document169 pagesBYG Master Catalog en LRS Classicwearparts 01Niten GuptaNo ratings yet

- Profile HDDocument1 pageProfile HDcorina dorofteiNo ratings yet

- Ctg. O-RingsDocument38 pagesCtg. O-RingsFelipe RamirezNo ratings yet

- Aluminium Prices PDFDocument13 pagesAluminium Prices PDFRachmatullaNo ratings yet

- Section 22 22Document41 pagesSection 22 22DEEPANKAR CHOUDHURYNo ratings yet

- Merchantbar SteeldataDocument3 pagesMerchantbar SteeldataDevnarayan MahatoNo ratings yet

- TestDocument8 pagesTestVeera ManiNo ratings yet

- Techson Brochure SEP NEWDocument15 pagesTechson Brochure SEP NEWKamal SharmaNo ratings yet

- Hjda 2009-2 R1 (Jar)Document2 pagesHjda 2009-2 R1 (Jar)Anonymous ciu3QEjuSNo ratings yet

- Informations Techniques: Caractéristiques DimensionnellesDocument8 pagesInformations Techniques: Caractéristiques Dimensionnellesanto90kNo ratings yet

- Tool MẫuDocument31 pagesTool MẫuPhước TânNo ratings yet

- Haitian Mars Tech SpecificationsDocument8 pagesHaitian Mars Tech Specificationsaakashlakhanpal9830100% (2)

- Price List Semi Seamless Elbow 17.2.23Document1 pagePrice List Semi Seamless Elbow 17.2.23Amol GoreNo ratings yet

- Material specifications and quantitiesDocument40 pagesMaterial specifications and quantitiesDEEPANKAR CHOUDHURYNo ratings yet

- Universal Beam Dimension and Weight - BEAM - Metric PDFDocument5 pagesUniversal Beam Dimension and Weight - BEAM - Metric PDFAnonymous vmeAM32wNo ratings yet

- Splice Design - LRFDDocument22 pagesSplice Design - LRFDkalpanaadhiNo ratings yet

- Symbols Outer Ring: 1) DMP 2) DP DMP Bs B1s Bs IaDocument1 pageSymbols Outer Ring: 1) DMP 2) DP DMP Bs B1s Bs IaMiftakhu ZaimNo ratings yet

- 23Document30 pages23stringstrangeNo ratings yet

- Product Catalog PDFDocument38 pagesProduct Catalog PDFMbaye DiagneNo ratings yet

- Bolt Torque Requirements Chart for Flange GasketsDocument16 pagesBolt Torque Requirements Chart for Flange GasketsfrdnNo ratings yet

- 1 IwfDocument6 pages1 IwfBackup polinemaNo ratings yet

- Catalog: PT. Mitra Veterindo SelarasDocument19 pagesCatalog: PT. Mitra Veterindo SelarasMartha AnomNo ratings yet

- Conveyor Chain and SprocketsDocument5 pagesConveyor Chain and Sprocketsmartc35No ratings yet

- S L PP S: 3000 Socket Weld Pipe Fittings (Elbows, Tees & Crosses)Document9 pagesS L PP S: 3000 Socket Weld Pipe Fittings (Elbows, Tees & Crosses)Andres Fitria FarrelNo ratings yet

- Queen Cross: Cut From Hot Rolled Wide Flange ShapeDocument2 pagesQueen Cross: Cut From Hot Rolled Wide Flange ShapeNabilla ZaheraNo ratings yet

- Queen Cross PDFDocument2 pagesQueen Cross PDFjabri kotaNo ratings yet

- Padeye Design: Project: Prepared By: Client: Date: 14-May-20 CaseDocument7 pagesPadeye Design: Project: Prepared By: Client: Date: 14-May-20 CaseFian ArdiyanaNo ratings yet

- BS 6349-5 2016Document132 pagesBS 6349-5 2016Fian Ardiyana100% (15)

- Anode Calculation TemplateDocument1 pageAnode Calculation TemplateFian Ardiyana100% (1)

- GG Cell FormDocument56 pagesGG Cell FormFian ArdiyanaNo ratings yet

- En Load Combination For Marine StrcutureDocument1 pageEn Load Combination For Marine StrcutureFian ArdiyanaNo ratings yet

- Standard Profile Inertia CalculatorDocument17 pagesStandard Profile Inertia CalculatorFian Ardiyana100% (1)

- Anode CalculationDocument1 pageAnode CalculationFian ArdiyanaNo ratings yet

- Padeye Design: Project: Prepared By: Client: Date: 14-May-20 CaseDocument7 pagesPadeye Design: Project: Prepared By: Client: Date: 14-May-20 CaseFian ArdiyanaNo ratings yet

- Anchor Bolt DesignDocument6 pagesAnchor Bolt DesignFian ArdiyanaNo ratings yet

- Standard Profile Inertia CalculationDocument17 pagesStandard Profile Inertia CalculationFian ArdiyanaNo ratings yet

- 09 - King CrossDocument1 page09 - King CrossJoko TrisnantoNo ratings yet

- SWI PadeyeDocument11 pagesSWI PadeyeFian ArdiyanaNo ratings yet

- Green Pin Standard ShackleDocument1 pageGreen Pin Standard ShackleFian ArdiyanaNo ratings yet

- GG Queen CrossDocument1 pageGG Queen CrossFian ArdiyanaNo ratings yet

- GG T-BeamDocument1 pageGG T-BeamSurya DirmansyahNo ratings yet

- Hyundai LiftDocument21 pagesHyundai LiftFian Ardiyana100% (2)

- WF, Unp, Angle, Pipe Steel Profile CalculationDocument24 pagesWF, Unp, Angle, Pipe Steel Profile CalculationFian ArdiyanaNo ratings yet

- Biaxial Bending in ColumnsDocument14 pagesBiaxial Bending in Columnsnvnrev100% (1)

- Analysis Design Guidelines Precast CFRP GridDocument16 pagesAnalysis Design Guidelines Precast CFRP GridFian ArdiyanaNo ratings yet

- GG Honey Comb Cast ShapeDocument1 pageGG Honey Comb Cast ShapeFian ArdiyanaNo ratings yet

- Arch Dam DesignDocument240 pagesArch Dam Designtyukgomba100% (5)

- Sistem Slab (Kuliah I)Document9 pagesSistem Slab (Kuliah I)hafizh274No ratings yet

- Slope Deflection MethodDocument87 pagesSlope Deflection MethodFian ArdiyanaNo ratings yet