Professional Documents

Culture Documents

CO2 High Pressure Systems

Uploaded by

NarineCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CO2 High Pressure Systems

Uploaded by

NarineCopyright:

Available Formats

CO2 High Pressure System

C O 2 Hi g h Pressure Fire E xting uishing System

Characteristics Suitable for extinguishing in closed spaces like engine rooms, auxiliary rooms, cargo holds, etc. Extinguish the fire within a short time and leave no residue after extinguishing: shut-down time after a fire will be reduced to a minimum Suitable for extinguishing fires in combustible liquids, gases and electrical equipment, and for extinguishing smouldering fires in wood, paper, textiles, etc. Installed as a total flooding central bank system inclusive a number of distributions Normally installed with pneumatic release, but can also be supplied with mechanical, electrical, and manual release

C K

Z

D 1 2 6

Z

K G P

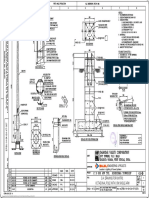

A. Cylinder battery B. Distribution valve C. Handle No. 1 D. Handle No 2 G. Control cylinder(s) (main and spare) H. Release box I. Pressure operated switch

K. Micro switches for start of alarm and stop for ventilation L. Control line No. 1 M. Control line No. 2 N. Bleeder valve O. Cylinder P. Pneumatic timer

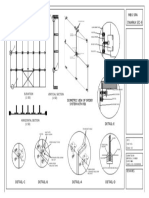

Danfoss Semco CO2 systems meet a number of international class requirements, including LRS, DNV, BV, PRS, CCS, ABS, GL, RMRS and NK, as well as national authorities. Construction. The Danfoss Semco CO2 system consists of one or more pressure cylinders containing the extinguishing agent CO2. The cylinders are connected via a common manifold. From the main manifold, the extinguishing agent is led through distribution valves to the protected spaces. The valve construction, cylinder size, and cylinder pressure, combined with the computer calculated pipe and nozzle dimensioning, ensures that the extinguishing agent is distributed in correct quantities and within the prescribed time. The release is activated pneumatically, electrically and/or mechanically. Danfoss Semco pressure-operated cylinder valves offer the possibility of connecting CO2 cylinders in groups operated pneumatically from one or more release cabinets equipped with CO2 gas cylinders. The release cabinets are equipped with pilot valves for use in opening cylinders and distribution valves by pipe connections. For pneumatic operation, the built-in actuator is used for each cylinder valve. These are connected to the other cylinder valves in the group via series-connected, flexible high-pressure hoses.

CO 2 Cylinders. The cylinders are delivered as 67.5-litre steel cylinders filled with 45 kg of CO2, or alter natively as 80-litre steel cylinders filled with 53.6 kg of CO2. To enable remote control and quick release, the cylinders are supplied with Danfoss Semco pressure operated quick opening valves, which also offer the possibil ity of manual operation. The valve construction secures against damaging overpressure in the cylinder, as the valve has a built-in bursting disc, activated at a nominal pressure of 190 bar. CO 2 Room. The cylinders are normally stored in a separate, well-ventilated and insulated room, where the temperature is kept between 0 and 40C. The room must have free access to open air. The room should have a minimum clear height of 2.4 m to provide adequate space for the mounting of manifolds and weighing beams for check weighing of the cylinders. Checking Equipment. The cylinders can be checked by a weighing device or liquid level measurement. Special Equipment. To reduce the installation time in CO2 rooms onboard ships, cylinder arrangements mounted in racks consisting of up to 100 pieces of 45/53.6 kg cylinders, complete with manifold and fixing equipment, can be supplied.

C O 2 E xting uishing System: Rel e as e System

The Pressure Controlled Cylinder Valve. All Danfoss Semcos release systems are based on the unique pressure operated cylinder valve. This valve is used in all systems in which pressure cylinders (CO2 and N2) form a part. CO2 cylinders, with contents of up to 60 kg discharge, can be released within one minute. Valve housings and internal parts are made of brass or stainless steel, with tightening materials of neoprene or copper. The valve is constructed as a combined pressure operated quick opening valve with hand wheel for manual opening. The Danfoss Semco valve is designed with a unique function that enables the user to perform a real check of the valve function. By opening the control valve for releasing the cylinders while leaving the distribution valve closed, the manifold will be pressurised. It can then be proved that each valve is opened. By closing the control valve, the release piping system will be relieved and the cylinder valves will close. This function is required by some classes and authorities. Pneumatic Release System. Total flooding systems require groups of cylinders to be released simultaneously. For this purpose, pneumatically operated cylinder valves are used in conjunction with the pilot pressure from the master release box containing control cylinder(s) (CO2 or N2), two control valves, a pressure gauge, and one or two door switches. As an option, the system can be supplied with a pneumatic time delay device to delay the opening of the main valve. Emergency release from the CO2 room can be made by manually opening the cylinder valve and then operating the two local control valves.

Th e Danfoss Semco QA system is in accordance with EN ISO 9001: 2000 and is certifi ed by DNV. Our ongoing internal training programs make our employees naval architects, sales engineers, project managers, service engineers, etc. fully qualifi ed to handle our fi re fi ghting systems for the marine industry. An important element is the use of an approved computer program for hydraulic calculations, which secures a quick and precise system design.

www.danfoss-semco.com

For further information, please contact: CO2, Foam, dry Chemical Powder da n F O S S S E m C O a / S FirE PrOtECtiOn S ta m H O l m E n 1 1 1 2 6 5 0 H V i d O V r E , d E n m a r k t E l . : + 4 5 7 4 8 8 7 8 5 0 Fa X : + 4 5 7 4 8 8 7 8 5 1 f i r e p r o te c t i o n @ d a n fo s s - s e m c o. c om Water mist da n F O S S S E m C O a / S FirE PrOtECtiOn SVEndBOrgVEJ 253 5260 OdEnSE S, dEnmark t E l . : + 4 5 7 4 8 8 7 8 0 0 Fa X : + 4 5 7 4 8 8 7 8 0 1 s e m s a fe @ d a n fo s s - s e m c o. c om

Danfoss A/S , G1 Advertising 07.02

You might also like

- Ansul Bulk Low Pressure CO2 System PDFDocument4 pagesAnsul Bulk Low Pressure CO2 System PDFMohammed ZabiNo ratings yet

- Air Purger & Ammonia PurifierDocument22 pagesAir Purger & Ammonia PurifierJulius Wahyu AgungNo ratings yet

- 5-5 CO2 Low Pressure SystemDocument74 pages5-5 CO2 Low Pressure Systemhamzeh100% (1)

- Material Safety Data Sheet: Section 1. Chemical Product and Company IdentificationDocument6 pagesMaterial Safety Data Sheet: Section 1. Chemical Product and Company Identificationandy hamonanganNo ratings yet

- Reduce Compressor Damage with Proper Suction Accumulator SelectionDocument5 pagesReduce Compressor Damage with Proper Suction Accumulator Selectionpaplus50% (2)

- User'S Manual: InstructionsDocument46 pagesUser'S Manual: InstructionsNikola Markovski100% (1)

- Leading provider of foam fire protection solutionsDocument8 pagesLeading provider of foam fire protection solutionsi786zzyNo ratings yet

- FM200 Fire Suppression System: 1-1/2" BS 336 MaleDocument18 pagesFM200 Fire Suppression System: 1-1/2" BS 336 MaleSofiqNo ratings yet

- Dectron DSV Series CatalogDocument4 pagesDectron DSV Series Catalogbluemojo0% (2)

- SMARDT Catalogue TW ClassWaterCooled-En WebDocument7 pagesSMARDT Catalogue TW ClassWaterCooled-En WebBrunoWelterNo ratings yet

- Refrigerant Selection ConsiderationsDocument27 pagesRefrigerant Selection Considerationsme12m113No ratings yet

- Copeland Discus TechnicalDocument62 pagesCopeland Discus Technicalkhalil.g.semaan100% (2)

- Technical Papers: 34th Annual Meeting International Institute of Ammonia RefrigerationDocument40 pagesTechnical Papers: 34th Annual Meeting International Institute of Ammonia Refrigerationrohitkb09No ratings yet

- V Series BrochureDocument2 pagesV Series BrochureCesar Chu AcevedoNo ratings yet

- Refrigerant subcooling boosts cooling system efficiencyDocument2 pagesRefrigerant subcooling boosts cooling system efficiencySyarif SticksNo ratings yet

- Function of Oil Rectifier in A Refrigeration SystemDocument1 pageFunction of Oil Rectifier in A Refrigeration SystemmavericksailorNo ratings yet

- 275 Reflux 819 Fo mt103 e PDFDocument93 pages275 Reflux 819 Fo mt103 e PDFsilver lauNo ratings yet

- 70tpd liquid CO2 recovery proposalDocument36 pages70tpd liquid CO2 recovery proposalAriane Victoria DantesNo ratings yet

- Bock CO2 Compressor GBDocument68 pagesBock CO2 Compressor GBWilfrid DutruelNo ratings yet

- Tyco Sprinkler Catalog GPC 03-16Document100 pagesTyco Sprinkler Catalog GPC 03-16Dragana Miletic Dutina100% (1)

- Compressed Air Foam Outperforms Foam-Water SprinklersDocument34 pagesCompressed Air Foam Outperforms Foam-Water SprinklersDayanne MartinsNo ratings yet

- Ammonia Absorption Chiller 09Document13 pagesAmmonia Absorption Chiller 09AhmAd GhAziNo ratings yet

- PT Marcopolo Shipyard High Pressure CO2 Fire Extinguishing System Approval DrawingDocument105 pagesPT Marcopolo Shipyard High Pressure CO2 Fire Extinguishing System Approval DrawingGarry BernzNo ratings yet

- Helipad Foam Fire Protection ManualDocument12 pagesHelipad Foam Fire Protection ManualKhairil ShanklyNo ratings yet

- High Pressure CO2 Engineering Manual PDFDocument84 pagesHigh Pressure CO2 Engineering Manual PDFDatNo ratings yet

- 070.450-IOM XJF 2013-11 Rev 2022-03Document38 pages070.450-IOM XJF 2013-11 Rev 2022-03Mohamed HeshamNo ratings yet

- The World: A Brief Introduction To CO Refrigeration PossibilitiesDocument21 pagesThe World: A Brief Introduction To CO Refrigeration PossibilitiesCarlos YzaguirreNo ratings yet

- Water Mist Nozzle GW M5 PDFDocument6 pagesWater Mist Nozzle GW M5 PDFZulfi Andrie ZulkiarNo ratings yet

- CO2 Sensor RoomDocument8 pagesCO2 Sensor RoomTrần Khắc ĐộNo ratings yet

- FirePro Xtinguish V1.03Document99 pagesFirePro Xtinguish V1.03احمد الجزار2007100% (1)

- Chilled Water PipingDocument6 pagesChilled Water PipingunicornmepNo ratings yet

- OVUR-type Oil Separator: Installation, Operation and Maintenance ManualDocument8 pagesOVUR-type Oil Separator: Installation, Operation and Maintenance Manualmiguel callata0% (1)

- SM Dedicated Outdoor Air Unit DOASDocument204 pagesSM Dedicated Outdoor Air Unit DOASYudha P MNo ratings yet

- FTS004 Deep Fat FryersDocument3 pagesFTS004 Deep Fat FryersWissam JarmakNo ratings yet

- 2749 - Carrier 30 GH 095Document16 pages2749 - Carrier 30 GH 095Mohammad Amer100% (2)

- 800024-004 Diom Manual, Ihp Co2Document47 pages800024-004 Diom Manual, Ihp Co2rulo zamora mendez100% (1)

- Screw Compressor Packages Grasso SPduo Large SeriesDocument84 pagesScrew Compressor Packages Grasso SPduo Large SeriesManuel MartinezNo ratings yet

- Energy Efficiency On Chilled Water SystemDocument56 pagesEnergy Efficiency On Chilled Water Systembalraj100% (1)

- 07 Primary Secondary PumpingDocument63 pages07 Primary Secondary PumpingMMMOH200No ratings yet

- Honeywell CS10XE Evaporative Air Cooler English - Instructions - ManualDocument21 pagesHoneywell CS10XE Evaporative Air Cooler English - Instructions - Manualaljh71100% (2)

- Ricwil Catalog 10 Final PDFDocument32 pagesRicwil Catalog 10 Final PDFHermanuadi100% (2)

- York Cond Unit Piping GuidelinesDocument128 pagesYork Cond Unit Piping Guidelinesdokundot100% (1)

- SuperFan Whole House FanDocument3 pagesSuperFan Whole House FanOrganic MechanicNo ratings yet

- Uniflair Chiller Training ModuleDocument74 pagesUniflair Chiller Training ModuleGaniza Long100% (1)

- Refrigerant Recovery and Recycling Units: Supersedes: 50.40-OM1 Form 50.40-OM1Document44 pagesRefrigerant Recovery and Recycling Units: Supersedes: 50.40-OM1 Form 50.40-OM1James MurrayNo ratings yet

- Guidance On Venting of Gas Systems Issue 1 Publication 9th Nov 2010Document26 pagesGuidance On Venting of Gas Systems Issue 1 Publication 9th Nov 2010elikruNo ratings yet

- General Information About The Planning Manual Ventilation Technology For LaboratoriesDocument10 pagesGeneral Information About The Planning Manual Ventilation Technology For LaboratoriesRenato MendesNo ratings yet

- Pressure Relief Valves Protect Systems from OverpressureDocument3 pagesPressure Relief Valves Protect Systems from Overpressurepm2013No ratings yet

- GPDocument26 pagesGPceni_4No ratings yet

- CO2 Fire Extinguishing System Design and InstallationDocument28 pagesCO2 Fire Extinguishing System Design and InstallationChhomNo ratings yet

- Ansul R-102Document4 pagesAnsul R-102heliopintoNo ratings yet

- Cooling 2012 - RH - Ecat - 20120206Document456 pagesCooling 2012 - RH - Ecat - 20120206bryandown100% (1)

- Vortex Inhibitor VortibreakDocument1 pageVortex Inhibitor VortibreakNabil RamehNo ratings yet

- CO2 Handbook IIARDocument190 pagesCO2 Handbook IIAROnofreHalberNo ratings yet

- High and Low Pressure CO2 SystemDocument3 pagesHigh and Low Pressure CO2 SystemPawan kumarNo ratings yet

- Low Pressure CO2 SystemsDocument4 pagesLow Pressure CO2 SystemsNarineNo ratings yet

- Co2 Fixed Fire Fighting SystemDocument14 pagesCo2 Fixed Fire Fighting SystemHariprasath. A Marine 0012No ratings yet

- CO2 REQMT ClassDocument12 pagesCO2 REQMT ClassSumit RokadeNo ratings yet

- CO2 System: Total FloodingDocument49 pagesCO2 System: Total FloodingAkshay A KumarNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- PO CO2 SystemDocument2 pagesPO CO2 SystemCahya AuroraNo ratings yet

- Indonesia Production Planning Report SummaryDocument23 pagesIndonesia Production Planning Report SummaryCahya AuroraNo ratings yet

- Cv. Yatisa Marindo Utama: Penawaran HargaDocument3 pagesCv. Yatisa Marindo Utama: Penawaran HargaCahya AuroraNo ratings yet

- Co2 SystemDocument1 pageCo2 SystemCahya AuroraNo ratings yet

- Admin - Indonesia - JobsDBDocument1 pageAdmin - Indonesia - JobsDBCahya AuroraNo ratings yet

- Read Me1Document1 pageRead Me1Cahya AuroraNo ratings yet

- Condensate Recovery SystemsDocument14 pagesCondensate Recovery SystemsLuis Felipe Zuñiga100% (1)

- Sin1111500 13 3 25Document95 pagesSin1111500 13 3 25asyrafmuhddNo ratings yet

- Home Sitemap About Us Technical Data Privacy & Security Terms & Conditions Basket ContactDocument2 pagesHome Sitemap About Us Technical Data Privacy & Security Terms & Conditions Basket Contactninatena100% (1)

- Local Bye Laws - Bus TerminusDocument5 pagesLocal Bye Laws - Bus Terminusneeraj kumarNo ratings yet

- TM 5-272 1944 Steel-Treadway Bridge M2Document74 pagesTM 5-272 1944 Steel-Treadway Bridge M2Advocate100% (1)

- Door Reinforcement DesignDocument1 pageDoor Reinforcement DesignP.MannaNo ratings yet

- Consol SivakuganDocument29 pagesConsol SivakuganJothi RamanathanNo ratings yet

- EXAMPLE OF MIX DESIGN .R.s.Document11 pagesEXAMPLE OF MIX DESIGN .R.s.Ramkiran TalariNo ratings yet

- Department Of Mechanical Engineering UNIT TEST - VDocument3 pagesDepartment Of Mechanical Engineering UNIT TEST - VsainathNo ratings yet

- Surkhet Rate 2072 073Document88 pagesSurkhet Rate 2072 073Mishal Limbu100% (1)

- Admixtures PresentationDocument34 pagesAdmixtures PresentationMudduKrishna shettyNo ratings yet

- Manufacturers and or Exporters of Aluminium Processing Industry in TurkeyDocument13 pagesManufacturers and or Exporters of Aluminium Processing Industry in Turkeytransfer.bauNo ratings yet

- General Overview On Site Drawings & TSSRDocument35 pagesGeneral Overview On Site Drawings & TSSRNazmul Hossain RakibNo ratings yet

- Mbs Spa: Isometric View of Spider System With RibDocument1 pageMbs Spa: Isometric View of Spider System With RibSuman Kumari100% (5)

- Hemp-Flax 2Document4 pagesHemp-Flax 2Gerson -No ratings yet

- Whessoe: Before Installation These Instructions Must Be Fully Read and UnderstoodDocument1 pageWhessoe: Before Installation These Instructions Must Be Fully Read and UnderstoodradanpetricaNo ratings yet

- Green Sand Testing for Strength and PermeabilityDocument3 pagesGreen Sand Testing for Strength and Permeabilityabubakaratan50% (2)

- Internship presentation on Mutual Builder Pvt. LtdDocument14 pagesInternship presentation on Mutual Builder Pvt. LtdSoo CealNo ratings yet

- Hardware Auto & MachineryDocument86 pagesHardware Auto & MachineryHenry ChanNo ratings yet

- Drop Forged Chain PDFDocument8 pagesDrop Forged Chain PDFluiNo ratings yet

- Cawi 2618Document2 pagesCawi 2618richardNo ratings yet

- SB Part Bill - 3 (GR Floor) of Protik Fine Ceramics Factory BuildingDocument10 pagesSB Part Bill - 3 (GR Floor) of Protik Fine Ceramics Factory BuildingShafiul AlamNo ratings yet

- Industry Career Guide: Ownership Dwellings and Real EstateDocument47 pagesIndustry Career Guide: Ownership Dwellings and Real EstatethanzeroNo ratings yet

- Construction Concrete Pre Pour Checklist Gdq5ygDocument1 pageConstruction Concrete Pre Pour Checklist Gdq5ygJay Mark ArbuesNo ratings yet

- Soil Permeability LectureDocument34 pagesSoil Permeability LectureSheikh AnikNo ratings yet

- (PDF) Design Standards - CONFERENCE BUILDINGS, EXHIBITION & RESEARCH BUILDINGS - Muath Humaid - Academia - Edu PDFDocument110 pages(PDF) Design Standards - CONFERENCE BUILDINGS, EXHIBITION & RESEARCH BUILDINGS - Muath Humaid - Academia - Edu PDFatchaya gopalsamyNo ratings yet

- Design Management Manual - Vol 2 - Design StandardsDocument87 pagesDesign Management Manual - Vol 2 - Design StandardsWissam JarmakNo ratings yet

- 2.5mm Two Core: Description Units DetailDocument2 pages2.5mm Two Core: Description Units DetailMuhammad Shabbir AwanNo ratings yet

- Timber Stone Estates Phase III PacketDocument7 pagesTimber Stone Estates Phase III Packetcarlosbedia9799No ratings yet

- Material Canvass FormDocument3 pagesMaterial Canvass FormMarie AriadneNo ratings yet