Professional Documents

Culture Documents

En ASFA AU Koplik Atomic Spectrometry

Uploaded by

Rizka MaharanaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

En ASFA AU Koplik Atomic Spectrometry

Uploaded by

Rizka MaharanaCopyright:

Available Formats

Advanced strategies in food analysis

Atomic spectrometry Richard Koplk

Atomic spectrometry

Atomic absorption spectrometry (AAS)

Principle of the method absorption of resonance spectral line radiation by ground-state free atoms of the element.

lamp spectrum

isolated resonance line

flame

lamp monochromator detector

beam burner fuel + oxidant + sample aerosol

Applicability of AAS

determination of almost all metals, metalloids and some non-metals (B, Si, P) samples: solutions in diluted mineral acids (HNO3, H2SO4, HCl) resulting from the decomposition or hydrolysis of a solid sample diluted biological fluids (plasma, blood, urine, milk etc.) suspensions of solid samples (slurries) (solid powdered samples).

Techniques of AAS flame AAS (F AAS) intended for determination of higher concentrations (tenths to tens g/ml)

Advanced strategies in food analysis

Atomic spectrometry Richard Koplk

electrothermal AAS (ET AAS) or graphite furnace AAS (GF AAS) for determination of trace and ultratrace concentrations (tens pg/ml to tens ng/ml) vapour generation techniques (VG AAS) hydride generation AAS (HG AAS) trace conc. of As, Se, Sb, Te, Sn... cold vapour AAS (CV AAS) trace conc. of Hg.

Parts of conventional AA spectrometer

source of emission line of the element (e.g. hollow cathode lamp HCL) continuum radiation source D2 lamp atomizer (flame, graphite furnace or quartz tube) background corrector monochromator detector (e.g. photo-multiplier) control unit or computer.

Analytical features of AAS Sensitivity a slope of calibration line; sensitivity in F AAS is indirectly expressed as characteristicconcentration (i.e. such concentration g/ml of the element that gives the absorbance of 0.0044); characteristic mass pg is used to characterize analytical sensitivity in GF AAS. Detection limits in F AAS approx. 2 to 5 times lower than characteristic concentration. Working range approx. 2 to 3 orders of magnitude (a narrower range in GF AAS). Repeatability in F AAS under optimum conditions RSD 0.5-1.5 %; RSD in GF AAS ranges approx. from 1 to 5 %. Accuracy, trueness especially in GF AAS accuracy can be affected by the sample matrix (e.g via analyte transport, formation of thermally stable compounds, non-atomic absorption).

Measures to assure quality of analytical results in AAS

appropriate calibration

Advanced strategies in food analysis optimization of fuel-oxidant gas composition (in F AAS)

Atomic spectrometry Richard Koplk

optimization of all steps of the atomizer temperature programme (in GF AAS) selection of suitable matrix modifier for electrothermal atomization optimization of burner height (in F AAS) addition of suitable reagents (releasing or deionizing) to the samples in necessary cases (in F AAS).

Flame AAS

the liquid sample is aspirated into a nebulizer (4-7 ml/min) and the formed aerosol is introduced into flame, where aerosol desolvation, evaporation and analyte atomization occur a steady-state absorbance signal is measured

Flames air-acetylene flame (t 2000-2300C): for readily atomizable metals (alkali metals, Mg, Ca in the absence of interferents, Zn, Cu, Cd, Pb, Mn, Fe, casually Cr) nitrous oxide- acetylene flame (t 2800-3000 C): for hardly atomizable elements (Sr, Ba, V, Cr, Mo, Al, Si, B etc.); it is also applied for determination of other elements (Ca, Mg, Ni, Fe) in difficult matrices (those containing phosphates, silicates)

Factors influencing the sensitivity of F AAS analysis

selection of analytical line e.g. the most sensitive line for Cu detn. is 324.7 nm (characteristic conc. approx. 0.025 g/ml), while the least sensitive one is 244.2 nm (characteristic conc. 9 g/ml)

current of the lamp efficiency of sample aerosol formation (the nebulizer setting up, the viscosity and surface tension of the sample solution) length of atomization zone (the air-C2H2 burner has 10 cm slot, the N2O-C2H2 one only 5-6 cm slot) height of observation (given by vertical position of the burner)

Advanced strategies in food analysis atomization efficiency (effect of temperature).

Atomic spectrometry Richard Koplk

ionization of the analyte (ions formed from atoms by loss of electrons do not absorb the line radiation; temperature affects the rate of analyte ionization)

Some problems (difficulties) of F AAS application

1. partial ionization of some elements (alkali metals, alkali earth metals) in the flame and non-uniform deionizing effect of the matrix consequence: some loss of sensitivity, convex distortion of calibration curve, inaccurate results in the presence unknown amounts of other easily ionizable elements solution: addition of a compound of an easily ionizable element (CsCl or KCl) in a large excess (CsCl 1-5 mg/ml) 2. chemical interferences induced by the sample matrix resulting in the incomplete atomization of the analyte (e.g. that of Ca in the presence of Al, Ti, phosphates, silicates etc.) consequence: e.g. negative bias of the results of Ca determination in phosphoruscontaining samples (all biological materials) solution: addition of releasing agent (LaCl3, La conc. up to 10 mg/ml) to the samples and standards (in air-C2H2 flame) or measurement in hot N2O-C2H2 flame (addition deionizing agent is needed).

Advantages of F AAS

fast analysis (10-15 s per sample per element) very good precision (repeatability) no or moderate interferences that can be easily corrected easy automation of the measurement low cost

Advanced strategies in food analysis

Atomic spectrometry Richard Koplk

Electrothermal AAS

Synonyms: AAS with electrothermal atomization (ET AAS); the most common atomizer is a graphite tube; therefore the method is also known as graphite furnace AAS (GF AAS) the volume of a sample (10-50 l) is injected into the atomizer the sample is thermally treated and atomized (duration of measuring cycle is 1-3 min) absorbance of the element is measured during the atomization step (total absorbance peak and peak of the background signal is recorded) the method is by 2-3 orders of magnitude more sensitive than F AAS

Atomizer

is usually a graphite tube (diameter 3-4 mm, length 20-25 mm) with a sampling hole (injection port); the tube is electrically heated, cooled by water and rinsed by a flow of inert gas (Ar or N2); a graphite platform can be inserted into the tube.

Types of graphite tubes

made of porous graphite (normal tubes) or pyrolytically coated tubes (non-porous glassy surface) with or without a platform or a probe heated longitudinally or transversally

Steps of the measuring cycle in GF AAS

1. injection of the sample (and the modifier) on the wall or on the platform of the tube 2. drying evaporation of solvent at a temperature slightly above the boiling point (solutions in diluted HNO3 are dried at 120 C); the solution must not boil; duration of drying depends on the sample volume (1-2 s/l); inert gas flows through the tube

Advanced strategies in food analysis

Atomic spectrometry Richard Koplk

3. pyrolysis thermal decomposition at higher temperatures (300-1200 C) decomposition of sample matrix to gaseous products removed by the flow of inert gas e.g decomposition of nitrates: 2 M(NO3)2 2 MO + 4 NO2 + O2 other processes: reaction between the analyte and the modifier, between matrix components and the modifier duration of pyrolysis: tens seconds 4. atomization fast heating to high temperature (1400-2700 C) evaporation of the analyte, splitting molecules to atoms: MO M + O total absorbance and background signal are recorded (duration: 3-5 s) just before atomization the flow of inert gas is stopped two possibilities: atomization of the wall, or of the platform 5. cleaning heating to very high temperature (2400-2700 C) for approx. 3 s; inert gas flow removes all evaporated compounds off the atomizer 6. cooling of atomizer to laboratory temperature.

Matrix modifiers in GF AAS

Matrix modifiers are compounds added to the sample before injection or injected to the atomizer together with the sample. Modifiers affect the thermal processes taking place in the atomizer to minimize losses of analyte during pyrolysis and to enable more effective matrix components removal. Some modifiers change the sample matrix to evaporate the matrix components at lower temperature; other type of modifiers work as an analyte stabilizer. Modifiers types and examples

compounds (e.g. NH4NO3) converting a non-volatile matrix (NaCl) to a volatile compound: NaCl

b.p. 1418 C

NH4NO3

decomposes at 210 C

NaNO3

at 380 C

NH4Cl

sublimes at 345 C

decomposes

Advanced strategies in food analysis

Atomic spectrometry Richard Koplk

compounds converting an analyte halogenide (volatile species) to a less volatile salt (e.g. sulphate or phosphate) e.g. H2SO4 for detn. of Tl , NH4H2PO4 for most metals (Cd, Pb, Ni, Mn): MX2 + NH4H2PO4 M2P2O7 MO + P2O5 ; the analyte can be thermally stabilized also by the formation of intermetallic compound: e.g. compounds of platinum group metals (Pd, Ir) are applied for stabilization of volatile analytes (Pb, Cd) mixture of Pd(NO3)2+Mg(NO3)2 or Pd2+ salt + reducing agent (ascorbic acid); Ni2+ and Cu2+ salts are used to stabilize Se, As or Te

Non-specific absorption in AAS (absorption background)

is an attenuation of the analytical line radiation, which is not caused by absorption by free atoms of the element. If the non-specific absorption is not corrected it induces a positive bias. It is much more serious for GF AAS as compared to F AAS, especially in the region of 180350 nm.

Non-specific absorption is caused by

light scattering on solid particles of dry aerosol or particles of carbon resulting from the incomplete burning of acetylene in reducing flame; in GF AAS the non-volatile components of the sample matrix cause this effect in the step of atomization if they were not removed in the step of pyrolysis;

absorption of the radiation by molecules and molecular fragments it is manifested by broad absorption bands in the region of 200-400 nm (alkali halogenides) or fine structure rotational and vibrational transitions of radicals, molecules or molecular ions and fragments

Correction of absorption background

using continuum source of radiation i.e. D2 lamp (most effective up to 350 nm) or halogen bulb with tungsten filament (in the region of visible light) two signals are measured:

Advanced strategies in food analysis total absorption measured with line source (e.g. HCL) non-specific absorption measured with the continuum source using Zeeman effect

Atomic spectrometry Richard Koplk

based on splitting of en energy levels of the atom (spectral lines) in magnetic field

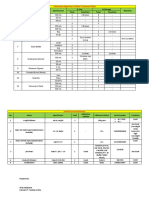

Temperature programme of the graphite tube atomizer

is chosen according to: physico-chemical properties of the analyte and its compounds contents of matrix components way of sample preparation type of atomizer (with or without a platform etc.) kind of matrix modifier

Optimization of temperature programme:

test of drying temperature and the duration of drying pyrolysis and atomization temperature plot analyte alone analyte + modifier analyte + matrix analyte + matrix + modifier optimum pyrolysis temperature is the maximum temperature, at which any losses of the analyte do not occur yet and maximum analyte absorbance and minimum background is achieved during atomization; optimum atomization temperature is minimum temperature , at which a complete and fast evaporation of the analyte is achieved and a reproducible signal (in terms of height and shape of the peak) is recorded.

Advanced strategies in food analysis

Atomic spectrometry Richard Koplk

Possible GF AAS applications

trace analysis and microanalysis (from very small samples) analysis of liquid samples even when organic matrix is present (beverages, milk, blood, plasma etc.) analysis of liquid samples with permanent inorganic matrix (urine, sea water etc.) rather difficult task analysis of powdered solids or suspensions of solid samples

Disadvantages of GF AAS a lot of interferences a thorough optimization of analysis conditions is necessary limited concentration working range (especially with Zeeman s instruments) slow analysis expensive equipment

Hydride generation AAS

HG AAS is applied namely for determination of trace amounts of As, Se (Te, Sb, Ge, Sn, Pb...) the gaseous hydride of the analyte (e.g. AsH3 or H2Se) is formed from the corresponding compound of the analyte (H3AsO3 or H2SeO3) by reducing reaction with NaBH4 (sodium borohydride); the reaction takes place in a hydride generator, gaseous products are delivered to the atomizer (usually a heated quartz tube) the technique is by 2-3 orders of magnitude more sensitive than F AAS as a consequence of analyte transfer into gaseous phase most of interferences are eliminated (namely those manifested on analytical lines of As and Se that are located in the region of wavelength 200 nm).

Advanced strategies in food analysis

Atomic spectrometry Richard Koplk

Conditions of the hydride-forming reaction the reaction takes place in an acidic solution the acidic solution (HCl or H2SO4) of a sample is mixed with an alkaline solution of sodium borohydride (0.5- 10 % NaBH4 in 0.1-1 M NaOH); the reaction of BH4 and H+ generates hydrogen atoms BH4 + H+ + 3 H2O H3BO3 + 8 H that reduce the analyte compounds into the form of hydride H3AsO3 + 6 H AsH3 + 3 H2O H2SeO3 + 6 H H2Se + 3 H2O it is advisable to assure that the analyte is present in one oxidation state only (As III or AsV, SbIII or SbV, SeIV or SeVI); as the lower valency is more advantageous the analyte compounds of the higher valency are mostly reduced before the hydride-forming reaction; heating of a sample with potassium iodide in acidic medium and with hydrochloric acid alone is used for reduction of AsV and SeVI, respectively: H3AsO4 + 2 I + 2 H+ H3AsO3 + I2 + H2O H2SeO4 + 2 Cl + 2 H+ H2SeO3 + Cl2 + H2O

Arrangement of the hydride-generation system hydride generator (reactor) gas-liquid separator atomizer or hydride generator (reactor) gas-liquid separator collector atomizer

Hydride generator

consists of a pump for a sample solution and reagents a reactor (a container or a capillary) a gas-liquid separator

10

Advanced strategies in food analysis Types of hydride generators

Atomic spectrometry Richard Koplk

1. continual generators the sample solution, the sodium borohydride solution (and diluted hydrochloric acid) are aspirated by the peristaltic pump; the flows are joined and mixed in a PTFE capillary; small bubbles of gaseous products (hydrogen + hydride) are formed; the flow of liquid and gas enters the gas-liquid separator and the gaseous phase is transferred with carrier gas (N2 or Ar containing traces of oxygen) to the atomizer, where the hydride is atomized and a steady-state absorbance is recorded 2. batch generators use a container (flask) as a reactor; to the sample dose in the reactor the borohydride reagent is injected and the gaseous products are delivered by the carrier gas flow to the atomizer; the peak of absorbance is recorded 3. flow injection generators a certain volume of the sample is injected into the flow of carrier liquid (HCl solution), the flow is mixed with the flow of the borohydride solution; after the reaction, gas separation and atomization an absorbance peak is recorded.

Atomizer for HG AAS is most often an externally heated quartz T-shaped tube positioned above the air-acetylene burner (heated by flame) or in a heating block (electrically heated to approx. 900 C) ; trace amount of oxygen is necessary for splitting of the hydride molecules into atoms.

Advantages of HG AAS low detection limits (0.1-0.3 ng/ml of As or Se using conventional systems) quite fast measurement (30-50 s per sample) most of interferences disappear when the analyte is transferred to a gaseous state

Disadvantages (problems) of HG AAS the specific chemical form of the analyte (certain valenncy) is required some ways of sample decomposition (e.g. procedures usin HNO3 only or HNO3 + H2O2 without H2SO4) are not suitable as oxidising agents mostly interfere with hydride generation high concentrations of Cu, Ni, platinum group metals and other transition metals cause serious interferences a large excess of the hydride-forming element makes determination of traces of the other one impossible (e.g. a lot of Se and traces of As or vice versa). 11

Advanced strategies in food analysis

Atomic spectrometry Richard Koplk

Atomic emission spectrometry

Principle of the method elements contained in a sample are atomized and partially ionized in a suitable excitation source; the atoms and the ions change their energy state to a higher level; when they return from the higher state to the lower or even the ground state they emit a spectrum consisting of characteristic spectral lines; the intensity of the spectral line is proportional to the element content.

Some excitation sources used for AES

flame spark discharge electric arc discharge plasma discharge direct current plasma (DCP) microwave induced plasma (MIP) inductively coupled plasma (ICP)

Flame photometry

Synonymous name: flame (atomic) emission spectrometry (F AES or FES)

Flames and burners

air-acetylene or nitrous oxide acetylene an aerosol of a sample is delivered to the burner the burner (in contrast with burners for AAS instruments) is a single vertical tube (but each flame AA spectrometer can operate in the emission mode)

12

Advanced strategies in food analysis

Atomic spectrometry Richard Koplk

Scheme of flame photometer

mirror

interference filter

detector

Applications of flame photometry: namely determination of alkali and alkali-earth metals. Advantages: wider dynamic range than that in F AAS, simple and cheap instruments. Disadvantages: the method is limited only to easily excited and easily ionized elements.

Inductively coupled plasma atomic emission spectrometry

Synonymous name: inductively coupled plasma optical emission spectrometry Abbreviations: ICP-AES, ICP-OES

an aerosol of the liquid sample is introduced into ICP, the elements are atomized and ionized at a very temperature (approx. 6000 K) and the intensities of emitted lines are measured

the method allows fast multi-element analysis (including all metals and some non-metals such as P, S)

detection limits are lower than those of flame AAS concentration working range is much wider than that in AAS; linear calibration within the range of 5 or more orders of magnitude are usually possible

needs a spectrometer of high quality and high spectral resolution (expensive instruments) quite high operating costs (large argon consumption)

13

Advanced strategies in food analysis

Atomic spectrometry Richard Koplk

ICP discharge

is created in the flow of excited argon at the outlet of plasma torch it is initialized by spark discharge and maintained by high-frequency energy from an induction coil (power input 1-1.8 kW) temperatue of the plasma discharge is 3500-10000 K

Inductively coupled plasma torch

induction coil

injector

The torch consists of three concentric quartz tubes (the injector tube is made of quartz or corundum or sapphire) positioned co-axially in an induction coil (made of copper). Argon flows through the individual tubes. Flows of argon: plasma (outer plasma): 12-20 l/min creates the discharge auxiliary (intermediate): 0-1 l/min stabilizes the discharge carrier (central): 0.5-1.5 l/min introduces the sample aerosol and creates an analytical channel

SiO2 tubes

auxiliary Ar plasma Ar

sample aerosol in carrier Ar

14

Advanced strategies in food analysis

Atomic spectrometry Richard Koplk

ICP spectrometer consists of a peristaltic pump for sample aspiration a nebulizer and a spray chamber a high-frequency generator operated at 27.12 or 40.68 MHz a torch a wavelength selector (monochromator or polychromator) a detector a control unit or a computer

The emitted lines can be viewed in radial direction (torch in a vertical position) or axial direction (torch in a horizontal position). Some instruments enable a dual view of the plasma.

Measurement of spectral line intensity

scanning of the line profile measurement at the top of the line

A subtraction of background signal in the proximity of the line is necessary.

Problems of ICP spectrometry

spectral interferences (spectral lines overlap, spectral background) non-spectral interferences e.g. a drop of analyte intensity caused by less efficient excitation and ionization of the analyte in the presence of excess of an easily ionisable element, such as K can be compensated using an internal standard element

15

You might also like

- An 44392 Analysis of Infant Formulae and Milk Powders Using The Thermo Scientific Icap 7400 Icp Oes DuoDocument6 pagesAn 44392 Analysis of Infant Formulae and Milk Powders Using The Thermo Scientific Icap 7400 Icp Oes DuoDewi WulandhariNo ratings yet

- Minerals in WaterDocument7 pagesMinerals in WaterK JNo ratings yet

- AAS vs ICP-OES Elemental Analysis TechniquesDocument8 pagesAAS vs ICP-OES Elemental Analysis TechniquesKim HiềnNo ratings yet

- Zeenit: Quality Is The DifferenceDocument16 pagesZeenit: Quality Is The DifferenceImad Aghila50% (2)

- TN43183 - E 11-13C-St2-HighDocument3 pagesTN43183 - E 11-13C-St2-HighYan RiveraNo ratings yet

- Atomic Spectroscopy Techniques Sample Introduction SourcesDocument35 pagesAtomic Spectroscopy Techniques Sample Introduction SourcesAndrés PacompíaNo ratings yet

- Atomic Spectroscopy: A Guide To Selecting The Appropriate Technique and SystemDocument17 pagesAtomic Spectroscopy: A Guide To Selecting The Appropriate Technique and SystemAnonymous gpNrjv0No ratings yet

- ICAP-7000 Detection LimitsDocument2 pagesICAP-7000 Detection LimitsKhalidNo ratings yet

- FAS 서비스 매뉴얼 3Document36 pagesFAS 서비스 매뉴얼 3ak_thimiriNo ratings yet

- Chapter 10 AesDocument14 pagesChapter 10 AesGowtham GanesanNo ratings yet

- History of JetDocument50 pagesHistory of JetMarko IstenicNo ratings yet

- Atomic Spectroscopy - A Guide To Selecting The Appropriate Technique and System PDFDocument16 pagesAtomic Spectroscopy - A Guide To Selecting The Appropriate Technique and System PDFAdamu OnakpaNo ratings yet

- Inductively Coupled Plasma SpectrosDocument1 pageInductively Coupled Plasma SpectrosBoonGen GeamNo ratings yet

- Seafast For Nexion IcpmsDocument2 pagesSeafast For Nexion Icpmsta quang khanhNo ratings yet

- Thermo Scientific Icap Q Icp-Ms: Gain More Performance, Experience More SimplicityDocument8 pagesThermo Scientific Icap Q Icp-Ms: Gain More Performance, Experience More SimplicityAnonymous UGpigqNo ratings yet

- New Product AAS IntroductionDocument63 pagesNew Product AAS IntroductionNguyễnHoàngDanhNo ratings yet

- AX309 Xilinx Spartan-6 Development Board Users ManualDocument38 pagesAX309 Xilinx Spartan-6 Development Board Users ManualjekNo ratings yet

- Icp-Ms Icap RQ CatalogDocument12 pagesIcp-Ms Icap RQ CatalogriskaNo ratings yet

- KK-CHP 3 (Aas)Document125 pagesKK-CHP 3 (Aas)ShafiqahFazyaziqahNo ratings yet

- Avio 200-500 ICP-OES ConsumablesDocument27 pagesAvio 200-500 ICP-OES ConsumablesNguyễnHoàngDanhNo ratings yet

- 5991 3719enDocument8 pages5991 3719enTrịnh Ngọc ĐứcNo ratings yet

- An 70048 Environmental Water Applications Notebook AN70048 EDocument134 pagesAn 70048 Environmental Water Applications Notebook AN70048 EKALLIOPINo ratings yet

- PreviewpdfDocument68 pagesPreviewpdfJoel Ccallo HuaquistoNo ratings yet

- Inductively Coupled Plasma - Optical Emission Spectroscopy: A ReviewDocument11 pagesInductively Coupled Plasma - Optical Emission Spectroscopy: A ReviewGenetics Mipa5No ratings yet

- Chromatography PDFDocument27 pagesChromatography PDFconstantinNo ratings yet

- De-62 Manual Software Equipo de AA ThermoDocument105 pagesDe-62 Manual Software Equipo de AA ThermoMelisa L CastrillonNo ratings yet

- FDA's Overview of The Guidance For Industry: Control of Nitrosamine Impurities in Human DrugsDocument57 pagesFDA's Overview of The Guidance For Industry: Control of Nitrosamine Impurities in Human DrugsPravin GaIkwadNo ratings yet

- Tandem MS For Drug AnalysisDocument93 pagesTandem MS For Drug AnalysisrostaminasabNo ratings yet

- GC 3 PDFDocument10 pagesGC 3 PDFs mvrht netNo ratings yet

- AA Troubleshooting and Maintenance GuideDocument12 pagesAA Troubleshooting and Maintenance Guiderichard008100% (1)

- ICP-MS Primer PDFDocument84 pagesICP-MS Primer PDFJohanna Rios GuerreroNo ratings yet

- ICP-OES 700 Sparepart CatalogueDocument4 pagesICP-OES 700 Sparepart CatalogueNirza FardhanaNo ratings yet

- Introduction To The HPLC Chemstation and AcquisitionDocument35 pagesIntroduction To The HPLC Chemstation and Acquisitionkir223No ratings yet

- AA700Usr PDFDocument194 pagesAA700Usr PDFvitoco1500No ratings yet

- Agilent 700 Series ICP-OESDocument52 pagesAgilent 700 Series ICP-OESRoger ManzanarezNo ratings yet

- En ASFA AU Koplík UV - VIS - SpectrometryDocument12 pagesEn ASFA AU Koplík UV - VIS - SpectrometryJedha YantiNo ratings yet

- Persiapan Sampel XRDDocument31 pagesPersiapan Sampel XRDCitra BuhatikaNo ratings yet

- Impurezas AgilentDocument32 pagesImpurezas AgilentArmando SaldañaNo ratings yet

- Introduction to Optical Emission Spectroscopy (OES) in <40 charsDocument30 pagesIntroduction to Optical Emission Spectroscopy (OES) in <40 charsKleverton JunioNo ratings yet

- 2.2.57. Inductively Coupled Plasma-Atomic Emission SpectrometryDocument3 pages2.2.57. Inductively Coupled Plasma-Atomic Emission SpectrometryPablo Parra100% (1)

- GC Column Guide: Choosing the Correct Type & DimensionDocument89 pagesGC Column Guide: Choosing the Correct Type & DimensionmcosicNo ratings yet

- Atomic Spectroscopy Basics: Fergus Keenan Thermo Fisher ScientificDocument25 pagesAtomic Spectroscopy Basics: Fergus Keenan Thermo Fisher Scientificzoom latihan100% (1)

- Clear Choice: TurbomatrixDocument10 pagesClear Choice: TurbomatrixSaleh HamadanyNo ratings yet

- Isotopic Dilution MethodDocument3 pagesIsotopic Dilution MethodZafar IqbalNo ratings yet

- ICP-MS Chapter 2 INTRODUCTIONDocument23 pagesICP-MS Chapter 2 INTRODUCTIONBayu Aji PrasetyoNo ratings yet

- Mass SpectrometryDocument30 pagesMass SpectrometryfatemaNo ratings yet

- Atomic Spectroscopy and Atomic Absorption SpectrosDocument80 pagesAtomic Spectroscopy and Atomic Absorption SpectrosMuhammad Mustafa IjazNo ratings yet

- Varioskan BrochureDocument4 pagesVarioskan BrochureSaurabh SaxenaNo ratings yet

- Atomic Spectroscopy 3Document36 pagesAtomic Spectroscopy 3Anonymous KzCCQoNo ratings yet

- Boron by ICP AESDocument10 pagesBoron by ICP AESNam Phạm Văn100% (1)

- GC-AAS Analysis of ElementsDocument9 pagesGC-AAS Analysis of ElementsSubhasish DashNo ratings yet

- Measuring PH CorrectlyDocument33 pagesMeasuring PH CorrectlyAnonymous Z7Lx7q0RzNo ratings yet

- Gas Chromatograph: Sujeewa S. PalayangodaDocument19 pagesGas Chromatograph: Sujeewa S. PalayangodaDian IpungNo ratings yet

- Detectors For GC.: Thermal Conductivity Detector (TCD) - The TCD Is Not As Sensitive As OtherDocument32 pagesDetectors For GC.: Thermal Conductivity Detector (TCD) - The TCD Is Not As Sensitive As OthermagicianchemistNo ratings yet

- Intro and Theory of XRF-Product Overview (Compatibility Mode)Document30 pagesIntro and Theory of XRF-Product Overview (Compatibility Mode)Yuli Yanti SundeNo ratings yet

- 2D NMRlatestDocument34 pages2D NMRlatestNandan ShindeNo ratings yet

- Thermal Analysis V2: Inorganic Materials and Physical ChemistryFrom EverandThermal Analysis V2: Inorganic Materials and Physical ChemistryRobert F. Jr. SchwenkerRating: 1 out of 5 stars1/5 (1)

- Structure and Properties of Inorganic Solids: International Series of Monographs in Solid State PhysicsFrom EverandStructure and Properties of Inorganic Solids: International Series of Monographs in Solid State PhysicsNo ratings yet

- Laboratory Apparatus and Instrumentation ChemicalDocument2 pagesLaboratory Apparatus and Instrumentation ChemicalRizka MaharanaNo ratings yet

- Febuary Shift Schedule - 2016Document6 pagesFebuary Shift Schedule - 2016Rizka MaharanaNo ratings yet

- Water Treatment Shift Schedule September-19Document1 pageWater Treatment Shift Schedule September-19Rizka MaharanaNo ratings yet

- Daily Water Report 01.10.2018 To 31.10.2018Document64 pagesDaily Water Report 01.10.2018 To 31.10.2018Rizka MaharanaNo ratings yet

- WTP shift schedule for January 2016Document3 pagesWTP shift schedule for January 2016Rizka MaharanaNo ratings yet

- CV-Budi Santoso WORDDocument2 pagesCV-Budi Santoso WORDRizka MaharanaNo ratings yet

- Basic Resignation Letter TemplateDocument1 pageBasic Resignation Letter TemplateHaniyah NadhiraNo ratings yet

- Water Treatment Shift Schedule October-19Document2 pagesWater Treatment Shift Schedule October-19Rizka MaharanaNo ratings yet

- Water Treatment Plant - Schedule of February 2018Document3 pagesWater Treatment Plant - Schedule of February 2018Rizka MaharanaNo ratings yet

- Jadwal TrainingDocument14 pagesJadwal TrainingAnonymous xCSrahNo ratings yet

- Water Treatment Plant Daily Routine Schedule April-19Document1 pageWater Treatment Plant Daily Routine Schedule April-19Rizka MaharanaNo ratings yet

- Require Things For The Development WTPDocument1 pageRequire Things For The Development WTPRizka MaharanaNo ratings yet

- Condensor Performance Definition and SymptomsDocument9 pagesCondensor Performance Definition and SymptomsRizka MaharanaNo ratings yet

- Control Chart ExampleDocument9 pagesControl Chart ExampleRizka MaharanaNo ratings yet

- Water Treatment Plant Shift Schedule For June - 2016Document4 pagesWater Treatment Plant Shift Schedule For June - 2016Rizka MaharanaNo ratings yet

- Water Treatment Plant Shift Schedule For May - 2016Document4 pagesWater Treatment Plant Shift Schedule For May - 2016Rizka MaharanaNo ratings yet

- Laboratory Aparatus RequirementDocument3 pagesLaboratory Aparatus RequirementRizka MaharanaNo ratings yet

- Water Treatment Plant Shift Schedule For March - 2016Document3 pagesWater Treatment Plant Shift Schedule For March - 2016Rizka MaharanaNo ratings yet

- Operation DataDocument1 pageOperation DataRizka MaharanaNo ratings yet

- ChlorideDocument9 pagesChlorideRizka MaharanaNo ratings yet

- Safe Zones Sign For Pedestrian RouteDocument1 pageSafe Zones Sign For Pedestrian RouteRizka MaharanaNo ratings yet

- Water Treatment BasicsDocument5 pagesWater Treatment BasicsRizka MaharanaNo ratings yet

- Swro HP Pump Drg.Document1 pageSwro HP Pump Drg.Rizka MaharanaNo ratings yet

- Consumption Chemical Reagent in WTP LaboratoryDocument4 pagesConsumption Chemical Reagent in WTP LaboratoryRizka MaharanaNo ratings yet

- Hardness, Total Ultra Low Range - AP-67 - 1900Document3 pagesHardness, Total Ultra Low Range - AP-67 - 1900Rizka MaharanaNo ratings yet

- Basics of Ion ExchangeDocument4 pagesBasics of Ion ExchangeRizka MaharanaNo ratings yet

- Biuret in Urea Fertilizers: Effects and Safe ConcentrationsDocument2 pagesBiuret in Urea Fertilizers: Effects and Safe ConcentrationsRizka MaharanaNo ratings yet

- Myhack Guide - Myhack PDFDocument11 pagesMyhack Guide - Myhack PDFRizka MaharanaNo ratings yet

- Training Registration FormDocument1 pageTraining Registration FormRizka MaharanaNo ratings yet

- How To Install OS X Mountain Lion On Your PC With Iatkos PDFDocument16 pagesHow To Install OS X Mountain Lion On Your PC With Iatkos PDFRizka Maharana100% (1)

- SP11Document95 pagesSP11saopauloNo ratings yet

- Atomic Absorption Spectros PDFDocument9 pagesAtomic Absorption Spectros PDFAmelia RamdhaniNo ratings yet

- Ceramics International 2017 PDFDocument8 pagesCeramics International 2017 PDFjulieta_aferreiraNo ratings yet

- CHM306 April 2019Document3 pagesCHM306 April 2019LouisNo ratings yet

- Lab #1: Absorption Spectra of Conjugated Dyes: E E E EDocument5 pagesLab #1: Absorption Spectra of Conjugated Dyes: E E E EIreneVeladoNo ratings yet

- Finding the Optimal Wavelengths for Coleus LeavesDocument8 pagesFinding the Optimal Wavelengths for Coleus LeavesMalak KamalNo ratings yet

- CHM260 Lab Report SubmissionDocument38 pagesCHM260 Lab Report Submissionasta yuno100% (1)

- Absorption SpectrosDocument10 pagesAbsorption SpectroselviapereiraNo ratings yet

- Week 5.analytical ChemistryDocument43 pagesWeek 5.analytical ChemistryChi NguyenNo ratings yet

- Analyses of Fat Oil and Grease in Wastewater or Receiving WaterDocument26 pagesAnalyses of Fat Oil and Grease in Wastewater or Receiving WaterFlorin Sorin Bolboaca100% (1)

- Comparative Analysis of Smokeless Gunpowders by Fourier Transform Infrared and Raman SpectrosDocument8 pagesComparative Analysis of Smokeless Gunpowders by Fourier Transform Infrared and Raman SpectrosmrenaultNo ratings yet

- Uv Visiblespectroscopyppt 170925144657Document58 pagesUv Visiblespectroscopyppt 170925144657meenu sruthi priyaNo ratings yet

- ChT-Additional-Questions-from-Sanfoundry-keyclean 3Document25 pagesChT-Additional-Questions-from-Sanfoundry-keyclean 3Reinalyn AnyayahanNo ratings yet

- IB Questionbank Chemistry 1Document19 pagesIB Questionbank Chemistry 1zarna nirmal rawalNo ratings yet

- Unimolecular Photochemistry of AnthraceneDocument28 pagesUnimolecular Photochemistry of Anthracenechama_gozNo ratings yet

- Encyclopedia of Astrobiology - ADocument136 pagesEncyclopedia of Astrobiology - ALogan NorrellNo ratings yet

- Lab Report Beer S LawDocument16 pagesLab Report Beer S LawRhema Mohabul100% (2)

- Stack Emission and Automobile Emission.Document29 pagesStack Emission and Automobile Emission.Kumar GauravNo ratings yet

- The Photophysical Properties of 2-Naphthol: An Undergraduate Physical Chemistry ExperimentDocument3 pagesThe Photophysical Properties of 2-Naphthol: An Undergraduate Physical Chemistry ExperimentJuan Diego CarrilloNo ratings yet

- Potassium Determination in Bananas by Atomic AbsorptionDocument9 pagesPotassium Determination in Bananas by Atomic AbsorptionŞerban VeronicaNo ratings yet

- G9.Synthesis of Nickel Oxide Nanoparticles Using Nickel AcetateDocument4 pagesG9.Synthesis of Nickel Oxide Nanoparticles Using Nickel AcetateGlendy ZamarNo ratings yet

- Spectroscopic Methods - LibretextsDocument106 pagesSpectroscopic Methods - Libretextsmacky 2No ratings yet

- Quiz 1: IR Spectroscopy (Chapter 2) Name: Fatin Wahida Binti Hashim Student ID: 2017680232 Group: A4AS1205 - 10Document5 pagesQuiz 1: IR Spectroscopy (Chapter 2) Name: Fatin Wahida Binti Hashim Student ID: 2017680232 Group: A4AS1205 - 10fatin hashimNo ratings yet

- Spectro Photo Me TryDocument4 pagesSpectro Photo Me TryRajsuryan SinghNo ratings yet

- MPharm - Pharmaceutics SyllabusDocument21 pagesMPharm - Pharmaceutics Syllabussreeramraghu0% (1)

- Fluorescence SpectrosDocument10 pagesFluorescence SpectrosChamith HerathNo ratings yet

- 12-Lab12 - F - AASDocument9 pages12-Lab12 - F - AASHoang ThaoNo ratings yet

- BE184P Exercise 1.1a SpectrophotometryDocument9 pagesBE184P Exercise 1.1a SpectrophotometryDen CelestraNo ratings yet

- Spectral Properties of Chalcones II: Begüm Evranos AKSÖZ, Rahmiye ERTANDocument12 pagesSpectral Properties of Chalcones II: Begüm Evranos AKSÖZ, Rahmiye ERTANGanesamoorthy ThirunarayananNo ratings yet

- Lecture 1 - Basics in UV SpectrosDocument54 pagesLecture 1 - Basics in UV SpectrosEmmanuella OffiongNo ratings yet