Professional Documents

Culture Documents

Thin Custom Finials

Uploaded by

scaramagnaoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Thin Custom Finials

Uploaded by

scaramagnaoCopyright:

Available Formats

Thin Custom Finials

By

Joe Aliperti

A.K.A turbowagon

This tutorial was downloaded from http://www.penturners.org

The International Association of Penturners

A few people expressed interest in my method for turning thin finials to replace the stock finials for some of the popular pen kits like the Gentlemen's and Jr. Gentlemen's. This is not a new idea, and there are several articles in the library already on the topic, but I thought I would take some pictures and show my preferred method. This is a great mod that isn't too difficult and the end result is worth the extra effort. Do not attempt to follow these instructions unless you are capable of performing each step safely. Eye protection is a must. Start out by knocking out the stock finial from the pen kit. Here is an article in the library by JohnCrane that shows how to knock out the stock finial, and also shows his method for turning custom finials:

http://content.penturners.org/articles/2008/custom_finial.pdf

Measure the diameter of the finial you will be replacing. In this example, it is a finial for a full-sized Gentlemen's pen.

I begin by gluing a cutoff to the end of a hardwood dowel that is sized to fit in my collet chuck using Thick CA.

Bring up the tailstock with a scrap for support and begin to turn the cutoff with a skew until it is smooth and concentric with the axis of rotation. Do not turn down to the final diameter yet because the next step may result in skate marks which you will need to clean up.

Remove the tailstock and face the end with an arcing cut with the skew. This is a difficult cut and should be practiced on scrap first. When mastered, you can produce conical shavings and a glass smooth surface. If the skew skates across your work, don't worry... you should have enough meat left to clean them up. You may need to make a few cuts until you are happy with the shape of the profile.

Take the diameter down further, cleaning up any tear out or skate marks from the previous step. Keep checking with calipers until the end matches the diameter of the stock finial.

With a thin parting tool, begin to part a groove, leaving only the last 1 millimeter or so at full diameter. Do not part down all the way yet.

10

11

Double-check the diameter of the finial. In this case, it needs a little sanding. I will be using a CA finish, so the target diameter is about .002 short of the stock finial. Sand to at least 600 grit, remembering to sand with the lathe off as well with each grit.

12

13

14

Apply a CA finish using your favorite technique and polish it with micromesh. VERY IMPORTANT: be sure you are satisfied with the finish at this point. If not, redo it now, because you won't get another chance later.

15

16

Check the diameter of the stock tenon. Start to create a tenon on your own finial with a parting tool.

17

18

Once I create some clearance room, I like to take the final cuts with the toe of a small skew.

19

For a really good fit, you'll want to undercut the finial (again I use the toe of a small skew), to match the domed shape of the cap mortise. This might not apply for all pen styles.

20

Here's the finial after the tenon was checked to be the proper diameter.

21

If you're brave and skilled, you can now part the finial off with a thin parting tool or skew. I am neither brave nor skilled, so I use a hacksaw WITH THE LATHE OFF.

22

Here's the custom finial next to the stock one:

23

24

Test the fit in the cap and admire your work.

IMPORTANT: do not epoxy in place yet! Remove the finial before pressing the kit together. Only after everything is assembled, you should epoxy the finial in place. Otherwise, you risk marring your finial or finish during assembly. If possible, use a cutoff adjacent to the cap barrel for the finial and align the grain to match before gluing in place.

25

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Recipe - Ethiopian RecipesDocument15 pagesRecipe - Ethiopian Recipesscaramagnao100% (1)

- Dairy Science and Technology HandbookDocument1,383 pagesDairy Science and Technology Handbookscaramagnao96% (26)

- Build This Sturdy Large-Capacity Food Dehydrator by Charles 2001Document3 pagesBuild This Sturdy Large-Capacity Food Dehydrator by Charles 2001scaramagnaoNo ratings yet

- SolarSolarChimneyDehydrator Da FareDocument4 pagesSolarSolarChimneyDehydrator Da Farescaramagnao100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Lecture 4 ENGR 243 DynamicsDocument45 pagesLecture 4 ENGR 243 DynamicsRobby RebolledoNo ratings yet

- Huawei R4815N1 DatasheetDocument2 pagesHuawei R4815N1 DatasheetBysNo ratings yet

- Salads: 300 Salad Recipes For Rapid Weight Loss & Clean Eating (PDFDrive) PDFDocument1,092 pagesSalads: 300 Salad Recipes For Rapid Weight Loss & Clean Eating (PDFDrive) PDFDebora PanzarellaNo ratings yet

- ISO 9001 2015 AwarenessDocument23 pagesISO 9001 2015 AwarenessSeni Oke0% (1)

- Quantitative Methods For Economics and Business Lecture N. 5Document20 pagesQuantitative Methods For Economics and Business Lecture N. 5ghassen msakenNo ratings yet

- Global Geo Reviewer MidtermDocument29 pagesGlobal Geo Reviewer Midtermbusinesslangto5No ratings yet

- Dokumen - Pub - Bobs Refunding Ebook v3 PDFDocument65 pagesDokumen - Pub - Bobs Refunding Ebook v3 PDFJohn the First100% (3)

- Technology Management 1Document38 pagesTechnology Management 1Anu NileshNo ratings yet

- Career Essay 1Document2 pagesCareer Essay 1api-572592063No ratings yet

- LTE Networks Engineering Track Syllabus Overview - 23 - 24Document4 pagesLTE Networks Engineering Track Syllabus Overview - 23 - 24Mohamed SamiNo ratings yet

- Chapter 13 Exercises With AnswerDocument5 pagesChapter 13 Exercises With AnswerTabitha HowardNo ratings yet

- Digital MetersDocument47 pagesDigital MetersherovhungNo ratings yet

- Washing Machine: Service ManualDocument66 pagesWashing Machine: Service ManualFernando AlmeidaNo ratings yet

- Electives - ArchitDocument36 pagesElectives - Architkshitiz singhNo ratings yet

- E Flight Journal Aero Special 2018 Small PDFDocument44 pagesE Flight Journal Aero Special 2018 Small PDFMalburg100% (1)

- Report On GDP of Top 6 Countries.: Submitted To: Prof. Sunil MadanDocument5 pagesReport On GDP of Top 6 Countries.: Submitted To: Prof. Sunil MadanAbdullah JamalNo ratings yet

- Test Your Knowledge - Study Session 1Document4 pagesTest Your Knowledge - Study Session 1My KhanhNo ratings yet

- Hey Friends B TBDocument152 pagesHey Friends B TBTizianoCiro CarrizoNo ratings yet

- Organization and Management Module 3: Quarter 1 - Week 3Document15 pagesOrganization and Management Module 3: Quarter 1 - Week 3juvelyn luegoNo ratings yet

- Dialogue Au Restaurant, Clients Et ServeurDocument9 pagesDialogue Au Restaurant, Clients Et ServeurbanuNo ratings yet

- Ron Kangas - IoanDocument11 pagesRon Kangas - IoanBogdan SoptereanNo ratings yet

- Biological Beneficiation of Kaolin: A Review On Iron RemovalDocument8 pagesBiological Beneficiation of Kaolin: A Review On Iron RemovalValentin GnoumouNo ratings yet

- Methods of Recording Retruded Contact Position in Dentate PatientsDocument15 pagesMethods of Recording Retruded Contact Position in Dentate PatientsYossr MokhtarNo ratings yet

- TCL LD24D50 - Chassis MS09A-LA - (TKLE2413D) - Manual de Servicio PDFDocument41 pagesTCL LD24D50 - Chassis MS09A-LA - (TKLE2413D) - Manual de Servicio PDFFabian OrtuzarNo ratings yet

- DNA ReplicationDocument19 pagesDNA ReplicationLouis HilarioNo ratings yet

- DC 7 BrochureDocument4 pagesDC 7 Brochures_a_r_r_yNo ratings yet

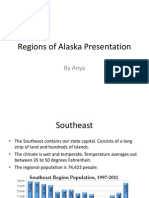

- Regions of Alaska PresentationDocument15 pagesRegions of Alaska Presentationapi-260890532No ratings yet

- Richardson Heidegger PDFDocument18 pagesRichardson Heidegger PDFweltfremdheitNo ratings yet

- Strucure Design and Multi - Objective Optimization of A Novel NPR Bumber SystemDocument19 pagesStrucure Design and Multi - Objective Optimization of A Novel NPR Bumber System施元No ratings yet

- Pivot TableDocument19 pagesPivot TablePrince AroraNo ratings yet