Professional Documents

Culture Documents

Quality of Compressed Air

Uploaded by

Mouayed ZeadanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Quality of Compressed Air

Uploaded by

Mouayed ZeadanCopyright:

Available Formats

What Is Quality of Compressed Air, and Who Cares?

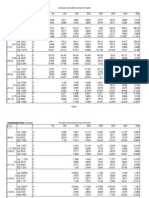

ISO 8573.1s quality classes of compressed air

Quality of compressed air is a broad term. One person may deem his compressed air quality as poor if he finds water at the end-use point. Another may tell you that her compressed air is high quality because she is able to maintain a dew point temperature at 40F or lower. As with any measurement, in order to be consistent, we must have a reference for comparison. In the world of compressed air, the most common reference is ISO 8573.1. ad:22097] The quality of compressed air is determined primarily by measuring three contaminants: solid particles as measured by their size or concentration, water vapor content as measured by pressure dew point temperature, and oil content as measured by concentration. The contamination level is influenced by the type of compressor, dryer, filtration, and other related components used. A higher quality of air in any of these categories usually equates to more expensive equipment. A more subjective qualification of compressed air divides air quality into one of four categories: power air, instrument air, process air or breathing air. Power air is typically used for applications such as power-tool operation, sand blasting, or pneumatic pumps. Water in the air is more of an annoyance than a major concern, as are oil and particles. Power air might equate to compressed air at ISO 8573.1 class 4 or 5, as seen in figure 1. Instrument air is a cleaner quality of compressed air used in more sensitive areas where particulates or water could cause significant quality issues in the

process. Powder coating and paint spraying are good examples of where contaminants affect product quality. This type of air may be dried to a higher standard and filtered for oil or particles. Instrument air might equate to compressed air at ISO 8573.1 class 3 or 4. Process air is used during actual production of a product likely to be ingested by a human or animal. For example food or drug production would require a higher quality of air because the product would come into contact with the compressed air at one or more points in the production line. Air may have to be completely oil free and with very few parts of water vapor. Process air might equate to compressed air at ISO 8573.1 class 1 or 2. Breathing air must be suitable for a human to safely breathe. This type of air must contain a certain amount of water vapor and be completely free of contaminants. Compressed air for diving or hospital use is common applications. Breathing air would fall into ISO 8573.1 class 1 for particles and oil, but would be class 4, 5, or 6 for humidity.

You might also like

- Crane Life Cycle and Crane Working Leve..Document3 pagesCrane Life Cycle and Crane Working Leve..Mouayed ZeadanNo ratings yet

- Appendix 2 - Technical SpecificationsDocument32 pagesAppendix 2 - Technical SpecificationsMouayed ZeadanNo ratings yet

- Construction of underground water tanksDocument36 pagesConstruction of underground water tanksMouayed ZeadanNo ratings yet

- Request For Proposals Dual Media Pressure Vessels FEBRUARY 14, 2020Document44 pagesRequest For Proposals Dual Media Pressure Vessels FEBRUARY 14, 2020Mouayed ZeadanNo ratings yet

- Ysf CL150 PDFDocument1 pageYsf CL150 PDFMouayed ZeadanNo ratings yet

- Appendix 2 - Technical SpecificationsDocument32 pagesAppendix 2 - Technical SpecificationsMouayed ZeadanNo ratings yet

- Pipe Laying MetodeDocument27 pagesPipe Laying MetodeMochamad SafarudinNo ratings yet

- Chemicals From Water Treatment and DistributionDocument6 pagesChemicals From Water Treatment and Distributiongad480No ratings yet

- Filtro Tipo y YSF-PN25-F1Document1 pageFiltro Tipo y YSF-PN25-F1eddy vilcaNo ratings yet

- Mechanical InstallDocument8 pagesMechanical InstallJuan Pedreno BernalNo ratings yet

- RFP 20-006 Equipment Installtion For Marine Repower Project FINAL1 PDFDocument52 pagesRFP 20-006 Equipment Installtion For Marine Repower Project FINAL1 PDFMouayed ZeadanNo ratings yet

- 682 E4 PADocument6 pages682 E4 PAGuiffridaNo ratings yet

- Inspection & Test Plan For Earthworks Excavation and Backfill For Underground FacilitiesDocument7 pagesInspection & Test Plan For Earthworks Excavation and Backfill For Underground FacilitiesMouayed ZeadanNo ratings yet

- Bills of Quantities For The Proposed Water TankDocument71 pagesBills of Quantities For The Proposed Water TankMouayed ZeadanNo ratings yet

- Spectrum Sensor PL Series Real Tech Inc.Document3 pagesSpectrum Sensor PL Series Real Tech Inc.Mouayed ZeadanNo ratings yet

- Process Analyzer: No Flow Point Analyzer Model P-840/P-840LTDocument5 pagesProcess Analyzer: No Flow Point Analyzer Model P-840/P-840LTMouayed ZeadanNo ratings yet

- Dow Water Management in Oil and Gas LenntechDocument12 pagesDow Water Management in Oil and Gas LenntechMouayed ZeadanNo ratings yet

- Environmental Measurement SolutionsDocument4 pagesEnvironmental Measurement SolutionsMouayed ZeadanNo ratings yet

- LT - Leaflet - Oil & Gas - Rev02Document6 pagesLT - Leaflet - Oil & Gas - Rev02Mouayed ZeadanNo ratings yet

- Y-Strainers - LenntechDocument2 pagesY-Strainers - LenntechMouayed ZeadanNo ratings yet

- Ysf CL150 PDFDocument1 pageYsf CL150 PDFMouayed ZeadanNo ratings yet

- Filtro Tipo y YSF-PN25-F1Document1 pageFiltro Tipo y YSF-PN25-F1eddy vilcaNo ratings yet

- MEX Scheduler ReportDocument31 pagesMEX Scheduler ReportMouayed ZeadanNo ratings yet

- Filtro Tipo y YSF-PN25-F1Document1 pageFiltro Tipo y YSF-PN25-F1eddy vilcaNo ratings yet

- Filtro Tipo y YSF-PN25-F1Document1 pageFiltro Tipo y YSF-PN25-F1eddy vilcaNo ratings yet

- International Maintenance StandardsDocument13 pagesInternational Maintenance StandardsMouayed ZeadanNo ratings yet

- Ysf CL150 PDFDocument1 pageYsf CL150 PDFMouayed ZeadanNo ratings yet

- Ysf CL150 PDFDocument1 pageYsf CL150 PDFMouayed ZeadanNo ratings yet

- WeeklyDocument4 pagesWeeklyMouayed ZeadanNo ratings yet

- Maintenance Management Plan: Name of Project Contract #XXXXXDocument31 pagesMaintenance Management Plan: Name of Project Contract #XXXXXMouayed ZeadanNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Food Adulteration and Its Quick TestDocument17 pagesFood Adulteration and Its Quick TestZubair AbidNo ratings yet

- TDS Panax Blue-770 UK-SEUNG-ChemicalDocument1 pageTDS Panax Blue-770 UK-SEUNG-ChemicalJuanNo ratings yet

- Research and Experimentation For Clay Sedimentation in Aquatic EnvironmentDocument3 pagesResearch and Experimentation For Clay Sedimentation in Aquatic EnvironmentKOPSIDAS ODYSSEASNo ratings yet

- Big Bend Activity GuideDocument238 pagesBig Bend Activity GuideDanny GriffinNo ratings yet

- Gas AbsorptionDocument10 pagesGas AbsorptionReggie DueñasNo ratings yet

- Pressure VesselDocument6 pagesPressure VesselEshet ShumetNo ratings yet

- Astm D7678-11Document10 pagesAstm D7678-11Dwi PratiwiNo ratings yet

- Comissioning of de GreaserDocument14 pagesComissioning of de GreaserprabathnilanNo ratings yet

- Marichem C R LTDocument2 pagesMarichem C R LTVal VelasquezNo ratings yet

- Condensate Trapping Design Flaws - TraneDocument8 pagesCondensate Trapping Design Flaws - Tranesuat yilmazNo ratings yet

- Dianix Amber HLA CBBN25 (MSDS)Document6 pagesDianix Amber HLA CBBN25 (MSDS)zulendzraNo ratings yet

- Technical Bulletin: AudcoDocument12 pagesTechnical Bulletin: AudcoHrushikesh ReddyNo ratings yet

- Astm D1141 98 2021Document2 pagesAstm D1141 98 2021NettyNo ratings yet

- Ahlstrom-Munksjo Disruptor®filter Media For Water PurificationDocument6 pagesAhlstrom-Munksjo Disruptor®filter Media For Water PurificationmusNo ratings yet

- PENETRON Data SheetDocument2 pagesPENETRON Data SheetdinoNo ratings yet

- Klarol: Oil Cleaning SystemsDocument4 pagesKlarol: Oil Cleaning SystemsLord KrsnikNo ratings yet

- ESDD - Gosowong - 29 AugustDocument23 pagesESDD - Gosowong - 29 Augustzyy877rzzgNo ratings yet

- Dissolved Oxygen Fact SheetDocument1 pageDissolved Oxygen Fact SheetDr-Raju AhmedNo ratings yet

- GREASE MsdsDocument6 pagesGREASE Msdsazer AzerNo ratings yet

- Chapter 9 Applied MicrobiologyDocument73 pagesChapter 9 Applied MicrobiologyAsmamaw TesfawNo ratings yet

- Business Continuity Plan Template 24Document20 pagesBusiness Continuity Plan Template 24Paramita AstiNo ratings yet

- Tidal Datums ExplainedDocument22 pagesTidal Datums ExplainedUzairNo ratings yet

- Promoting Sustainable Urban and Peri-Urban Agriculture in Greater Accra, Ghana: Dzorwulu Case StudyDocument52 pagesPromoting Sustainable Urban and Peri-Urban Agriculture in Greater Accra, Ghana: Dzorwulu Case StudyThe Bartlett Development Planning Unit - UCL100% (1)

- Concrete Mix Design, Form Design, and Engineering: Pdhonline Course C291 (4 PDH)Document65 pagesConcrete Mix Design, Form Design, and Engineering: Pdhonline Course C291 (4 PDH)Mahsa Janati100% (1)

- Manual RKE2200B1-VW-G1 (EN) OrionDocument92 pagesManual RKE2200B1-VW-G1 (EN) Orionlanchon666No ratings yet

- 4167-GH2 Projects DownloadDocument54 pages4167-GH2 Projects DownloadFrancesco Giuseppe LadisaNo ratings yet

- Topic 9 Material Waste ManagementDocument57 pagesTopic 9 Material Waste ManagementNabilah NajwaNo ratings yet

- Nursery ManagementDocument59 pagesNursery Managementamol Akolkar ( amolpc86)50% (2)

- Superheated Steam: Compiled and Edited by Ejaz M ShahidDocument15 pagesSuperheated Steam: Compiled and Edited by Ejaz M Shahidhamzahassan14No ratings yet

- Banjir Bandang SentaniDocument4 pagesBanjir Bandang SentaniFadhilah Hayyu AuliaNo ratings yet