Professional Documents

Culture Documents

Maintenance Management

Uploaded by

jewettwaterOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Maintenance Management

Uploaded by

jewettwaterCopyright:

Available Formats

MAINTENANCE MANAGEMENT

What is Maintenance? Repairs and general upkeep necessary for the efficient operation of physical plants, property, equipment, and vehicles. Types of Maintenance Corrective - Maintenance performed only when equipment fails Signs of this are: Not planning or scheduling works, Inability to budget adequately, Poor use of resources, and a High incidence of equipment and system failure. Also includes emergency maintenance Emergency - Maintenance performed under emergency conditions Normal Occur on a daily basis Example: Water Main Break Extraordinary Bad weather Example: Power Outage in a Rainstorm ****These are always be unpredictable**** Preventative - A systematic ongoing plan to inspect, monitor, and service - at scheduled and specific intervals equipment, motors, pumps, valves, vehicles, and so on to ensure efficient operations on such equipment and prolong its product life. Predictive - Maintenance establishing a baseline performance data, monitoring performance criteria over a period of time, and observing changes so that failures can be predicted and maintenance con be performed on a planned, scheduled basis. What types of maintenance are you currently doing? maintenance is: Corrective _______ Emergency Preventative _______ Predictive What % of your _______ _______

When talking about activities for Maintenance, Corrective & Emergency types are REACTIVE, whereas Preventative & Predictive are PROACTIVE. Proactive activities are what we need to strive for in a good maintenance management program. Question I have for you..Do you have a Preventative Maintenance program? If the answer is YEShow good is your program? If the answer is NO.then you should be moving towards one. You might ask, Why should we have a Preventative Maintenance program? Here are [5] reasons. To keep equipment operating efficiently. Customers depend on you to provide services with little or no interruptions. Saves money eventually it will. Good public relations tool shows customers and local government officials that you are responsible. Collecting accurate data to base O&M of the system helps to justify requests for financial resources necessary to support your operations.

Components of a good Preventative Management Program are: Planning and Scheduling Records management Spare Parts management Cost and Budget control Emergency repair procedures Training Program Accountability You might say, I am doing corrective and emergency maintenance right now. How can I or We move from a Reactive to a Proactive Maintenance program? List below are steps on how to do so. How to start and/or develop an effective PM program 1. Recognize that a change is needed in your maintenance program 2. Identify all items requiring maintenance 3. Identify maintenance for each item 4. Set the priority of each item to your operations 5. Identify resources needed to do the maintenance 6. Plan and schedule maintenance 7. What can we do right now? 8. Start the maintenance 9. Recordkeeping & accountability 10. Spare parts / Inventory management Lets take a closer look at each of these items. 1. Recognize that a change is needed in your maintenance program. 2. Identify ALL items requiring maintenance. This to include: pumps, valves, motors, piping, chlorinators, water tanks, chemical feed equipment, hoses, rotating equipment, filters, motor control centers, meter vaults, belts, filters, manholes, pump stations, metal surfaces, generators, fuel tanks, vehicles, trash containers, buildings, office equipment, etc Identify needed maintenance for each item. Identify needed maintenance lubrications, cleaning, oil changes, replacement of parts [filters, belts, etc.], checking levels and gauges, etc. Identify frequency of maintenance hourly, daily, weekly, monthly, quarterly, semi-annually, annually Information on equipment maintenance can be found by researching equipment manufactures O&M manuals if not available contact manufacture or look at liked equipment for ideas. Set the priority of each item to your operations - Rate importance of each item needing maintenance and set the priority to your main operations. Examples: Water service, garbage pickup etc. Vital - Necessary Major Minor

3.

4.

5. 6. 7. 8. 9. 10.

Identify resources needed to do the maintenance Labor - Do you have experience people who can do the work? If no: Must train personnel to do the work Hire experience personnel to do the work Outsource the work - might look into to hiring professionals to maintain specific equipment such as chlorinators [have a service agreement] Tools Same situation as with labor [Rent] Materials Lubricants, seals, filters, belts, antifreeze, tires, etc. Money Budget funds Plan and schedule maintenance to be done. You might say, I cannot start with a total changeover of my maintenance system so..WHAT CAN WE DO RIGHT NOW? When does the maintenance need to be done? Also emergency procedures Who will do the work? Training needed? What equipment and tools are needed to perform the work? How much time is needed to complete each task? What can I do/change right now? Start the Maintenance. Recordkeeping & Accountability All work performed must be recorded and kept in a orderly permanent record on paper or on computer. Work performed must be checked on a regular basis by supervisory management all levels Key Word: ACCOUNTABILITY All levels of personnel will need to be involved in monitoring costs and should be consulted in the budgeting process of PM Training initial and on-going Spare Parts / Inventory Management Items you should keep sufficient amounts of: Lubricants, fluids, fuels Filters, hoses, belts, seals, gaskets . Replaceable items Tires Couplings, repair clamps Valves, pipe, fittings [elbows, tees, reducers] Electrical parts breakers, starters, fuses, contactors, heaters Chlorinator parts [washers, gaskets, o-rings] Repair kits Pump and motor parts maybe even an extra pump/motor Bearings and packing Critical nuts, bolts, screws, keys, connectors, etc. Properly store spare parts Store items in a secure, cool, & dry place Keep items out of direct sunlight [pvc pipe]

Monitor & watch for signs of damage & corrosion in spare parts Keep spare parts inventoried A least [2] responsible personnel should have access to the inventory of spare parts

Final Maintenance Notes In controlling corrosion, keep metal surfaces primed and painted with good oilbased coatings [primer and paints are not expensive]. Also control water draining from pumps, valves, and other sources. Finally provide proper ventilation. Safety is important. Personal safety gear should be provided and used eyewear, clothing, gloves, and headgear. Guards, shields, and covers on equipment should be in place. REMEMBER: Water and electricity do not mix. Beware of slippery floors and surfaces. Adhere to safety procedures with chemicals. All electrical equipment should be grounded. Take special caution when working with electrical and pneumatic equipment. ALWAYS shut-off electricity to rotating equipment while working on it In Final.....Components of a good Preventative Management Program are: Planning and Scheduling Records management Spare Parts management Cost and Budget control Emergency repair procedures Training Program Accountability

Jeffrey Jewett, is a Communal Enterprise Advisor working on the Serbian Local Government Reform Project [SLGRP] funded by USAID. The project provides training and technical assistance to local governments in Finance, Communal Enterprises, Citizens Participation, Information technology, Policy reform, and Association development.

You might also like

- Ancient Ruins of Tiwanacu and PumaPunku - World Mysteries BlogDocument42 pagesAncient Ruins of Tiwanacu and PumaPunku - World Mysteries BlogjewettwaterNo ratings yet

- Ancient History of Peru - Travel To EatDocument16 pagesAncient History of Peru - Travel To EatjewettwaterNo ratings yet

- 10 Reasons You Should Visit The Mysterious Tiwanaku Ruins in BoliviaDocument12 pages10 Reasons You Should Visit The Mysterious Tiwanaku Ruins in BoliviajewettwaterNo ratings yet

- Membrane Filtration Guidance Manual PDFDocument332 pagesMembrane Filtration Guidance Manual PDFchristianNo ratings yet

- CRSS Engineers - Operators Pocket Guide To Activated Sludge - Part II Process + TroubleshootDocument24 pagesCRSS Engineers - Operators Pocket Guide To Activated Sludge - Part II Process + TroubleshootjewettwaterNo ratings yet

- The Enigma of Tiwanaku and Puma Punku by Brien FoersterDocument146 pagesThe Enigma of Tiwanaku and Puma Punku by Brien Foersterjewettwater100% (2)

- TLC ConfinedSpace Book PDFDocument380 pagesTLC ConfinedSpace Book PDFjewettwaterNo ratings yet

- EPA - Membrane Filtration Guidance Manual 2006-2007Document20 pagesEPA - Membrane Filtration Guidance Manual 2006-2007jewettwaterNo ratings yet

- Ancient Ephesus and The New Testament - Mark DDocument22 pagesAncient Ephesus and The New Testament - Mark DjewettwaterNo ratings yet

- Historical Waterworks in TurkeyDocument19 pagesHistorical Waterworks in TurkeyjewettwaterNo ratings yet

- Sanitation and Water Management in AncieDocument42 pagesSanitation and Water Management in AnciejewettwaterNo ratings yet

- Drainage and Sewerage Systems at AncientDocument47 pagesDrainage and Sewerage Systems at AncientjewettwaterNo ratings yet

- Water Quality Considerations For AquacultureDocument8 pagesWater Quality Considerations For AquaculturejewettwaterNo ratings yet

- Boiler Start Up ProceduresDocument8 pagesBoiler Start Up ProceduresamasrurNo ratings yet

- CRSS Engineers - Operators Pocket Guide To Activated Sludge - Part I The BasicsDocument22 pagesCRSS Engineers - Operators Pocket Guide To Activated Sludge - Part I The BasicsjewettwaterNo ratings yet

- Water Treatment Glossary of Terms From ESP Water ProductsDocument24 pagesWater Treatment Glossary of Terms From ESP Water ProductsjewettwaterNo ratings yet

- Review of DWSD Practices and PoliciesDocument16 pagesReview of DWSD Practices and PoliciesjewettwaterNo ratings yet

- Basic Guide To Boiler Water TreatmentDocument8 pagesBasic Guide To Boiler Water TreatmentjewettwaterNo ratings yet

- Potassium PermanganateDocument15 pagesPotassium Permanganatejewettwater100% (1)

- The Corrosion ProtectionDocument28 pagesThe Corrosion Protectionjewettwater100% (1)

- SBWCD - Meter Testing, Repair, ReplacementDocument3 pagesSBWCD - Meter Testing, Repair, ReplacementjewettwaterNo ratings yet

- Aquacare - Boiler Water TreatmentDocument14 pagesAquacare - Boiler Water TreatmentjewettwaterNo ratings yet

- AED Design Requirements - Water Tanks and System Distribution - Sep09 PDFDocument23 pagesAED Design Requirements - Water Tanks and System Distribution - Sep09 PDFAvonodOiratulcNo ratings yet

- Basic Guide To Boiler Water TreatmentDocument8 pagesBasic Guide To Boiler Water TreatmentjewettwaterNo ratings yet

- Sanitary Sewer and Septic SystemsDocument44 pagesSanitary Sewer and Septic SystemsMuhammad EhtshamNo ratings yet

- Wind Catchers - , The Cooling Systems in Traditional Iranian Architecture - CDocument7 pagesWind Catchers - , The Cooling Systems in Traditional Iranian Architecture - CjewettwaterNo ratings yet

- AED Design Requirements - Well Pumps and Well Design - Nov09Document44 pagesAED Design Requirements - Well Pumps and Well Design - Nov09Pangit BertNo ratings yet

- Hydro Heaven - HYDROPONICS 101 Hydroponic Gardens Are Not New by Any Means.Document5 pagesHydro Heaven - HYDROPONICS 101 Hydroponic Gardens Are Not New by Any Means.jewettwaterNo ratings yet

- Jerusalem - Water Systems of Biblical TimesDocument4 pagesJerusalem - Water Systems of Biblical TimesjewettwaterNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Fire Alarm System DBRDocument19 pagesFire Alarm System DBRKirty VardhanNo ratings yet

- DENISON HYDRAULICS axial piston pump goldcup series service informationDocument65 pagesDENISON HYDRAULICS axial piston pump goldcup series service informationDanilo Perez HenaoNo ratings yet

- FlowTek S20Document2 pagesFlowTek S20Gabriel Andrés Barcha AnguloNo ratings yet

- Manual de Densitometro InglesDocument91 pagesManual de Densitometro Inglesprincipito12No ratings yet

- Control Valve Exit Noise and Its Use To Determine Minimum Acceptable Valve SizeDocument16 pagesControl Valve Exit Noise and Its Use To Determine Minimum Acceptable Valve SizeamrandconanNo ratings yet

- Whirlpool FL 5105-A (ET)Document15 pagesWhirlpool FL 5105-A (ET)alfa00redNo ratings yet

- Tesco 250 EMI 400 Top DriveDocument12 pagesTesco 250 EMI 400 Top DriveBrandon Nowlin100% (1)

- ZYC180B-B Hydraulic Static Pile Driver Instruction ManualDocument42 pagesZYC180B-B Hydraulic Static Pile Driver Instruction ManualAdam LimNo ratings yet

- Series CRV Brass Product Literature 1Document2 pagesSeries CRV Brass Product Literature 1enghassanain6486No ratings yet

- Donaldson Self-Cleaning Filter System For Turbo M Achinery: 6 Golden Rules To Maintain The Highest Performance of YourDocument33 pagesDonaldson Self-Cleaning Filter System For Turbo M Achinery: 6 Golden Rules To Maintain The Highest Performance of YourKamal ArabNo ratings yet

- CVS Control ValveDocument24 pagesCVS Control ValvehdrNo ratings yet

- Cylinder Valve CatalogDocument48 pagesCylinder Valve CatalogbkprodhNo ratings yet

- ETS 608, Engineering Technical Spec, Pipework, Pipework - General RequirementsDocument6 pagesETS 608, Engineering Technical Spec, Pipework, Pipework - General RequirementsElmokadem EinsteinNo ratings yet

- 999 T4F CSM CTR233-03 05-16-17 PDFDocument298 pages999 T4F CSM CTR233-03 05-16-17 PDFJohn Locke100% (1)

- Fire Pump TheoryDocument41 pagesFire Pump Theorywinowo18No ratings yet

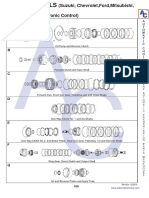

- (Suzuki, Chevrolet, Ford, Mitsubishi, Nissan) 4 Speed RWD (Electronic Control)Document4 pages(Suzuki, Chevrolet, Ford, Mitsubishi, Nissan) 4 Speed RWD (Electronic Control)Nachum IndurskyNo ratings yet

- Resol FlowSol B Installation ManualDocument8 pagesResol FlowSol B Installation ManualDan JungNo ratings yet

- Paint Equipment Standards: Sociedad Minera Cerro Verde S.A.ADocument26 pagesPaint Equipment Standards: Sociedad Minera Cerro Verde S.A.AEl_memitoNo ratings yet

- Water Distribution System InstallationDocument46 pagesWater Distribution System InstallationMohamedOmar83No ratings yet

- Leser API SeriesDocument68 pagesLeser API SeriespetroloritoNo ratings yet

- Hydro Power Plant Basic Terms, Types and Components: Prasad VejendlaDocument63 pagesHydro Power Plant Basic Terms, Types and Components: Prasad VejendlamimahmoudNo ratings yet

- Osmonics E2/Ez2 Series: Water Purification MachinesDocument25 pagesOsmonics E2/Ez2 Series: Water Purification MachinesLai Kok ChauNo ratings yet

- Iso 12149Document22 pagesIso 12149klasNo ratings yet

- Primus Dryer T13 - ManualDocument68 pagesPrimus Dryer T13 - ManualNadiah TnrmNo ratings yet

- TOP FLO Centrifugal Pump CatalogDocument30 pagesTOP FLO Centrifugal Pump CatalogGraziella CathleenNo ratings yet

- Re92076 2005-03Document32 pagesRe92076 2005-03Şenol MemişNo ratings yet

- Slickline Services Schlumberger Pressure Control EquipmentDocument62 pagesSlickline Services Schlumberger Pressure Control EquipmentHusseen HusseenNo ratings yet

- Elliott, Uniflex ROG Design Manual - Rev D PDFDocument43 pagesElliott, Uniflex ROG Design Manual - Rev D PDFdhlinva3205No ratings yet

- Stone Stomper Compactor ManualDocument98 pagesStone Stomper Compactor Manualgroomerz6612No ratings yet

- Modular Type Air Filters Series AFDocument14 pagesModular Type Air Filters Series AFAndika Arihta PasaribuNo ratings yet