Professional Documents

Culture Documents

Instrumentation Data Sheets

Uploaded by

Chandresh YadavCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Instrumentation Data Sheets

Uploaded by

Chandresh YadavCopyright:

Available Formats

Sr. No.

Units I General & Process 1 Process Details Average flow Peak Factor Peak Flow Raw sewage BOD5 at 20 c Raw sewage TSS Treated sewage BOD Treated sewage TSS Total Head loss (m) in STP (from stilling chamber of STP to 2 Chlorine Contact Tank) 3 Total land area (hectare) proposed for STP II (a) 1 2 3 4 5 6 7 (b) 1 2 3 4 5 6 7 8 9 (d) (i) 1 2 3 4 5 6 Raw Sewage Pumping Station Receiving Chamber Design Peak Flow No of Units Detention Period Liquid Depth (m) Length (m) Width (m) Water Level (m) Coarse Screen Channels Design Peak Flow No. of Units (working + stand by) Clear Spacing Through bars Width of Channel (m) Length of Channel (m) Liquid Depth (m) Upstream Water Level (m) Downstream Water Level (m) Head Loss (mm) Wet Well Pump House Wet Well Pump House Design Peak Flow No of Units Detention Period Liquid Depth (m) Length (m) Width (m)

7 Water Level (m) (ii) Pump House Size (m*m) Height (m) Sewage Treatment Plant Stilling Chamber As required Number Retention Time Material of Construction Free Board, mm Top Steps in Chamber/Sump Bar Screens (fine) As required Number Type Average Flow Peak Factor Velocity at Peak Flow Manual Screen Bar Size (Manual) Bar Size (Mechanical) Clear Spacing (Mechanical) Material of Construction Size of channels Width,m (Manual) Length,m Liquid Depth (m) Free Board, mm Screen Manual Screen Clear Spacing (Manual) Material of Construction Velocity at Peak Flow Manual Screen Bar Size (Manual) Make Manual Mechanical Screen Clear Spacing (Manual) Material of Construction Velocity at Peak Flow Manual Screen Bar Size (Manual) Make Mechanical

Screen Conveyor to be Provide Mechanical Grit Separator As required Number Type Size of Grit Specific Gravity of Grit Retention Time (Peak flow) Material of Construction Size Free Board, mm Velocity Control Device SBR Basins with Biological selector zone As required System Proposed Design Flow Inlet BOD (mg/lit) Inlet SS (mg/lit) Outlet BOD (mg/lit) Outlet SS (mg/lit) Free Board, mm No of SBR Tanks (basin) Tank Material of Construction Hydrolic Retention time Details of Basins Length/breadth/ of each basin Side Water Depth (m) Volume of each basin MLSS (mg/lit) Oxygen Uptake Rate (OUR) Control Proved yes/No-nos PLC and SCADA provided Aeration System / Diffusers Type Material of Diffuser Dia and Length of each Diffuser Air Flow through each diffuser (Nm3/hr) Total nos of Diffuser Make Air Blowers Air Required (m3/hr) Type of AIR Blowers Make No of Blowers

Capacity of Blower (Nm3/hr) Head of Blower (kg/cm2) Blower RPM/ Aerator RPM Motor Rating (in kw) Decanting Mechanism Decanting Rate of Treated Sewage (m3/hr) Type Speed Decanting Capacity of each Decanter (MLD) No of Decanters per Basin (No) Operating hrs of each decanter hrs Motor Rating (in kw) No of decanters with VFD operation (No) Material of Construction Instrument for Air Measurement Type Nos Make Instrument Pressure indicator Type Nos of Pressure Make of Pressure Guage Disinfection As required Disinfectant Chlorine Dosage Required

Type Total Chlorine Required Chlorine shed and neutra pit size Material of Construction of chlorination shed and neutra pit Contact Tank Retention Time, min. Size- Chlorine Contact Tank As required Numbers Width / Diameter, m Length, m Liquid Depth, m Free Board, mm Tank Material of Construction Chlorine Contact Arrangement

Chlorine Tonners Booster Pumps- Gas Chlorination As required Numbers Type Capacity Head Material of Construction Make of Pump Instruments- Pressure Indicator Type No of Pressure Guage Make of Pressure Guage Sludge Sump As required Dry Sludge Quantity Specific Gravity of Sludge Solid consistency in Sludge Volume of Sludge Retention Time, hours Size-Sump Quantity Length, m Width, m Liquid Depth, m Free Depth, m Tank Material of Construction Mixing in Sump Type Mixing Requirment, m3/hr/m3 Liquid Depth, m Air Grid Material of Construction Sludge sum Air Blowers Type of air blower Make No of working blowers No of stand by blowers Capacity of blowers (Nm3/hr) Head of Blower (kg/cm2) Motor Rating (in kw) Return Sludge Pump

As required Numbers Type Capacity Head Material of Construction Solid Size Motor Rating (in kw) Make of Pump Surplus Activated Sludge Pump As required Numbers Type Capacity Head Material of Construction Solid Size Motor Rating (in kw) Make of Pump Centrifuge Feed Pumps Pumps As required Numbers Type Capacity Head Material of Construction Make of Pump Instruments- Pressure Indicator Type No of Pressure Guage Make of Pressure Guage Sludge Dewatering Equipment Type As required Total Sludge (Dry basis) Working hrs/day Nos. Sludge Consistency Sludge Volume Solids Loading Dewatered Sludge Consistency Dewatered Sludge Quantity

Centrate Quantity Material of Construction Make Dewatering Polyelectrolyte Dosing System As required Quantityb of Polymer Chemical Solution % Volume of Chemical Solution Service time, hrs No of Tank Numbers Length, m Width, m Liquid Depth, m Free Depth, m Tank Material of Construction A Mixer- Dewatering Polyelectrolyte Dosing Tank As required Numbers Type Capacity Material of Construction Make of Mixer B Dewatering Polyelectrolyte Dosing Tank As required Numbers Type Capacity Material of Construction Make of Pump Raw Sewage Submersible Pumps As required Numbers Type Capacity Material of Construction Casing Impeller Shaft

Bearing Solid Size Motor Rating (in kw) Make of Pump Diesel Generating Set As required Numbers Capacity Type Make of Alternator Make of Engine Type of Supply

Details to be furnished by the bidder

As proposed by Bidder

As proposed by Bidder

As proposed by Bidder

As proposed by Bidder

Bidder to Specify Bidder to Specify Bidder to Specify Bidder to Specify

Bidder to Specify Bidder to Specify

Bidder to Specify Bidder to Specify Bidder to Specify Bidder to Specify Bidder to Specify Bidder to Specify Bidder to Specify Bidder to Specify Bidder to Specify Bidder to Specify Bidder to Specify Bidder to Specify

Bidder to Specify

As proposed by Bidder free chlorine Bidder to Specify in mg/lit to achive total Coliform count as required Gas chlorination-chlorination with safety equipment like canister mask, gloves, goggles, safety shower, emergency repair kit ect.

As proposed by Bidder 1

As proposed by Bidder Bidder to Specify (W+S) Bidder to Specify Bidder to Specify

As proposed by Bidder

As proposed by Bidder Bidder to Specify (W+S) Bidder to Specify Bidder to Specify Bidder to Specify

As proposed by Bidder Bidder to Specify (W+S) Bidder to Specify Bidder to Specify Bidder to Specify

As proposed by Bidder Bidder to Specify (W+S) Bidder to Specify Bidder to Specify Bidder to Specify

Solid Bowl Centrifuge As proposed by Bidder

As proposed by Bidder

As proposed by Bidder Bidder to Specify (W+S)

As proposed by Bidder

As proposed by Bidder

As proposed by Bidder

Chemical Dosing Chlorine Dosing for Coliform Removal to meet as per design Chemical Proposed to be Used

Dose Point At the inlet of Chlorine contact Tank At the Inlet of Centrifuge *-Bidder to Specify Sheds & Buildings Room for Blowers Building for Administration & Laboratory MCC Panel Room with Toilet Sludge Pump and Pump House Centrifuge Shed MCC Panel room/ L.t. room/ H.T. room

Dose in mg/l

Purity, %

Gas Chlorine Dewatering Polyelectrolyte

Bidder to Specify

Min. 200 m2 Bidder to Specify Bidder to Specify Bidder to Specify

Note: As space available for Treatment plant and sewage pumping station is limited, some of the units mentioned above m

Quantity in kg/d

Chemical Solution Required per annum

me of the units mentioned above may be accommodateed in double story building.

1 Safety Equipment Air Breathing Apparatus Instant Action Resuscitator Safety Cloths Gas Fronted Cabinet Emergency Shower with Eye Wash Fountain Emergency Repair kit for Tonner Residual Chlorine Test kit 2 Others Trunnions/Roller Support Suspended Weigh Scale Lifting Beam for toner 3 Leak Absorption System 3.1 Half Hood Make Size MOC Quantity (Nos.) 3.2 Caustic Solution Tank Make Size MOC Quantity (Nos.) 3.3 Caustic Solution Pump Make Type Capacity Head (m) MOC Casing Impeller Shaft Drive Details: Make Type Rating 3.4 Air Blower Make Type Capacity Head (m) MOC Quantity (Nos.) Casing Impeller Shaft Drive Details:

Details to be Furnished by the bidder

Make Type Rating 3.5 Diffuser Make Size/Rating MOC Rating Quantity (Nos.) 3.6 Caustic Solutin Piping 3.6.1 Ball Valve Size MOC End Connection Quantity (Nos.) 3.6.2 Non Return Valve Size MOC End Connection Quantity (Nos.) 3.6.3 Y-strainer Size MOC End Connection Quantity (Nos.) 3.6.4 Pressure Gauge Make Range Type End Connection Quantity (Nos.)

Piping & Valve Schedual The bidder to fill in the following pipeline schedual-without the pipeline schedual the bid shall be considered as non Pipe & Fittings From

To

Valves Application

Type/Code

shall be considered as non-responsive. Use additional sheets if required.

Type/Code

Material of Construction

Remarks

Material of Construction

Remarks

Instrumentation Schedual DATA SHEETS FOR INSTRUMENTATION Sl. No. A 1 a b c d e f g h i j k l m n 2 a b 3 a b c 4 a b c d 5 a b c 6 a b c d e f 7 a b DESCRIPTION PRESSURE GAUGE GENERAL Tag No. Quantity Service Type Range Pressure (Nor./Max.) kg/cm2g Temprature (Nor./Max.) OC Case Material Bezel Gasket Zero Adjustment Window Material Accuracy Below Out Protection Over Range Protection DIAL Size Color ELEMENT Sensor Sensor Material Movement Material CONNECTION Gauge end connection Connection Location Process Connection Rating Connection ACESSORIES Snubber/Syphon Snubber/Syphon conn. Snubber/Syphon material DIAPHRAGM SEAL Primary Element Primary Element Material Other Wetted Part Upper Body Material Lower Body Material Seal Fluid REMARKS Enclosure Protection Mounting VALVE

c d B 1 a b c d e 2 a b c d e f g h i j k l m n 3 a b c d e f 4 a C 1 2 3

4 5 6 7 8 9 10 11

Area Classification Ambient Temp. LEVEL SWITCH GENERAL Tag no. Quantity Service Measuring Range Mounting ENLOSURE PROTECTION Enclosure Protection Enclosure Protection Material Conn. Size Flange Material Flange Rating Power Supply Switch Relay type Qty Contact Rating Cable Entry Single/Double Time Delay On & Off Fail Safe Setting Prob/Electrode material Ref. Electrode Material DESIGN DATA Fluid Pressure (Nor./Max.) kg/cm2g Temprature (Nor./Max.) OC SP. Gravity Probe Length Ref. Electrode Material SERVICE CONDITION Ambient Temp. LEVEL TRANSMITTER Type Type for Prob (MOC) Extention pipe Length: MOC: Measuring Cell linearity DIAPHRAGM SEAL Measuring Range Accuracy Automatic Temperature Compensation Output signal Voltage Protection Housing MOC

a b c d e f g h i a b c d e a b

12 Make DO ANALYSER 1 Minimum Measuring range DO Temperature 2 Accuracy DO Temperature 3 Reaction Time 4 Temperature Tolerance 5 Protection Class 6 Resolution of Data 7 Probe Type 8 Zero point calibration required/not required 9 Make Transmitter 10 Display Type 11 Air Compensation (yes/no) 12 Separate Output for Temperature (yes/no) 13 Output Type 14 Housing MOC 15 Voltage Protection Immersion Armature and Support 16 Depth of immersion (yes/No) 17 Support Type 18 Float Type ULTRASONIC FLOW METER GENERAL Tag no. Quantity Meter Size Accuracy 2 DESIGN DATA Fluid Pressure (Nor./Max.) kg/cm2g Temprature (Nor./Max.) OC Flow Rate (Nor/Max) m3/hr Velocity m/sec Range m3/hr SP. Gravity Viscosity CP Min. Conductivity S/cm 3 MATERIAL Body Tube Electrode Liner Grounding Ring 4 FLOW TRANSMITTER Output Isolated Local Display Indicator

c d e f g a b c d e

Power Supply Cable Entry Location Cable (in case of Remote) Mounting 5 REMARK Area Classification Enclosure Protection Liner Heating System Ambient Temp. Relative Humidity

You might also like

- Store Deta Elect 10.8Document2 pagesStore Deta Elect 10.8Chandresh YadavNo ratings yet

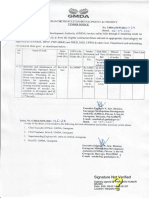

- Signature Not Verified: Digitally Signed by PARVEEN KUMAR Bajwa Date: 2021.09.02 14:18:35 IST Location: Haryana-HRDocument1 pageSignature Not Verified: Digitally Signed by PARVEEN KUMAR Bajwa Date: 2021.09.02 14:18:35 IST Location: Haryana-HRChandresh YadavNo ratings yet

- CP Fittings Inventory ReportDocument16 pagesCP Fittings Inventory ReportChandresh YadavNo ratings yet

- Store Deta Elect 10.8Document2 pagesStore Deta Elect 10.8Chandresh YadavNo ratings yet

- Tendernotice 1Document1 pageTendernotice 1Chandresh YadavNo ratings yet

- 21 Candlestick Patterns Every Trader Should KnowDocument83 pages21 Candlestick Patterns Every Trader Should KnowAlex Dela RosaNo ratings yet

- Schedule of Rates - RUIDP - 2017Document575 pagesSchedule of Rates - RUIDP - 2017nimm196267% (3)

- SBR ManualDocument27 pagesSBR ManualbjhamnaniNo ratings yet

- 13-Annexure 2a - Experience Certificate For Large Diameter Sewer LineDocument2 pages13-Annexure 2a - Experience Certificate For Large Diameter Sewer LineChandresh YadavNo ratings yet

- SBR ManualDocument27 pagesSBR ManualbjhamnaniNo ratings yet

- Technical Analysis: PDF Generated At: Wed, 02 Feb 2011 16:50:34 UTCDocument183 pagesTechnical Analysis: PDF Generated At: Wed, 02 Feb 2011 16:50:34 UTCb87208582100% (12)

- SBR ManualDocument27 pagesSBR ManualbjhamnaniNo ratings yet

- Enquiry StatusDocument2 pagesEnquiry StatusChandresh YadavNo ratings yet

- ExperienceDocument9 pagesExperienceChandresh YadavNo ratings yet

- ExperienceDocument9 pagesExperienceChandresh YadavNo ratings yet

- Sonipat Data SheetsDocument35 pagesSonipat Data SheetsChandresh YadavNo ratings yet

- Payment ReceiptDocument2 pagesPayment ReceiptChandresh YadavNo ratings yet

- Technical Schedule - Power, Chemicals & UtilitiesDocument12 pagesTechnical Schedule - Power, Chemicals & UtilitiesChandresh YadavNo ratings yet

- Wastewater Treatment MethodsDocument8 pagesWastewater Treatment MethodszzzamrNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Small Double Oor House Plan With 3 Bedroom and Stunning ExteriorDocument3 pagesSmall Double Oor House Plan With 3 Bedroom and Stunning Exteriorsaneesh81No ratings yet

- 4 - Water Storage Tank Safety StandardsDocument35 pages4 - Water Storage Tank Safety StandardsWidiyanto WidiyantiNo ratings yet

- A-811-Flooring Layout Overall Ground Floor PlanDocument1 pageA-811-Flooring Layout Overall Ground Floor PlanEmmanuel InfanteNo ratings yet

- Windows and Window Treatments PowerPointDocument39 pagesWindows and Window Treatments PowerPointVashishta VashuNo ratings yet

- REAC Compilation Bulletin SummaryDocument39 pagesREAC Compilation Bulletin Summarymsr510No ratings yet

- Affordable Row Housing Project for EWS in RampurDocument41 pagesAffordable Row Housing Project for EWS in RampurJasim QamarNo ratings yet

- HPP INTERNATIONAL Floor Finishing Works SWAN Office Park BucharestDocument3 pagesHPP INTERNATIONAL Floor Finishing Works SWAN Office Park BucharestIbrahim SahinNo ratings yet

- No 1 Meridian PlazaDocument5 pagesNo 1 Meridian Plazaapi-267200582No ratings yet

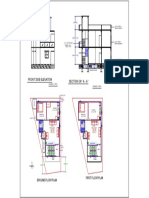

- Section On ' A - A ' Front Side Elevation: First Floor Plan Ground Floor PlanDocument1 pageSection On ' A - A ' Front Side Elevation: First Floor Plan Ground Floor PlanHusen GhoriNo ratings yet

- Daylighting Design StrategiesDocument11 pagesDaylighting Design StrategiesdasaNo ratings yet

- Hoesch Additive FloorDocument16 pagesHoesch Additive FloorbakkakraljNo ratings yet

- SECTION 06 10 00 Rough CarpentryDocument18 pagesSECTION 06 10 00 Rough CarpentryNerinel CoronadoNo ratings yet

- Boq FurnishingDocument3 pagesBoq FurnishingDevanshu GurudeoNo ratings yet

- Occupied-Unoccupied Mode ControlDocument3 pagesOccupied-Unoccupied Mode ControlLuisPadillaNo ratings yet

- Method Statement For Installation of RO Skids Pressure Vessels and Connecting Pipes R1Document8 pagesMethod Statement For Installation of RO Skids Pressure Vessels and Connecting Pipes R1abimanyubawonoNo ratings yet

- First Five Year Housing Plan of SingaporeDocument2 pagesFirst Five Year Housing Plan of SingaporeUdisha SinhaNo ratings yet

- Carga de Viento ASCE-7-05Document4 pagesCarga de Viento ASCE-7-05Anonymous aUl184No ratings yet

- Edited Map of Waterdeep Up CloseDocument1 pageEdited Map of Waterdeep Up CloseJamesRuthNo ratings yet

- Golden Opulence - Affordable Lifestyle Apartments at Poonamallee, ChennaiDocument32 pagesGolden Opulence - Affordable Lifestyle Apartments at Poonamallee, ChennaiGolden Homes Private LimitedNo ratings yet

- Precast in New Zealand: National Precast Concrete Association AustraliaDocument6 pagesPrecast in New Zealand: National Precast Concrete Association AustraliajimmydomingojrNo ratings yet

- QCS 2014 Electrical Works GuideDocument310 pagesQCS 2014 Electrical Works GuideVishnu M S100% (1)

- 2-01201-N-T-019 R05 Diseño de TuberiasDocument55 pages2-01201-N-T-019 R05 Diseño de TuberiasnarufredNo ratings yet

- Water Softeners Residential ProFloSXT Downflow Upflow Valve Softeners US ManualDocument16 pagesWater Softeners Residential ProFloSXT Downflow Upflow Valve Softeners US ManualPromagEnviro.comNo ratings yet

- House Painting 1000211256Document25 pagesHouse Painting 1000211256adiseif100% (1)

- Public Library GuidelinesDocument5 pagesPublic Library Guidelinesljubicica_No ratings yet

- Fms RailwayDocument34 pagesFms RailwayRohayah Che Amat100% (2)

- Local Intern. Case StudyDocument5 pagesLocal Intern. Case Studyjerome espirituNo ratings yet

- Mounting and Project Planning - Mounting Instructions V4 I400001GBDocument36 pagesMounting and Project Planning - Mounting Instructions V4 I400001GBFulki Kautsar SNo ratings yet

- Soakaway Sizing CalculationDocument5 pagesSoakaway Sizing CalculationMohammad Twaha JaumbocusNo ratings yet