Professional Documents

Culture Documents

Vvsizing: Prepared By: Muhamad Nizar

Uploaded by

nizar ahmadOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vvsizing: Prepared By: Muhamad Nizar

Uploaded by

nizar ahmadCopyright:

Available Formats

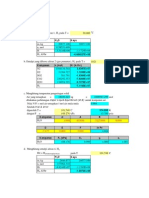

VVSizing

VVSizing is used to design Vertical Vessel Separator.

Vertical Vessel can be Flash Vapor Liquid Separator or Knock Out Drum

User inputs data in green cells

Output calculations are in gray cells

Red cells are recommended not to be changed because they are constants

References

Blackwell, W. Wayne, 1984, Chemical Process Design on A Programmable

Calculator, McGraw-Hill, United State of America.

Silla, Harry, 2003, Chemical Process Engineering – Design and Economics, Marcel

Dekker, Inc., New York, United State of America.

Prepared by: Muhamad Nizar

1. Design Data

WG = Gas rate = 11096.522 lb/jam

3

G = Gas density = 0.178 lb/ft

WL = Liquid rate = 7670.880 lb/jam

3

L = Liquid density = 49.678 lb/ft

2. Calculate Separation Factor (S)

S = 0.041

3. Calculate Velocity Factor (KV)

X = ln S = -3.185

B = -1.877

D = -0.815 DX = 2.594

E = -0.187 EX2 = -1.898

3

F = -0.015 FX = 0.469

4

G = -0.001 GX = -0.104

KV = 0.442

4. Calculate maximum gas velocity (Vmax)

Vmax = 7.374 ft/s = 2.248 m/s

5. Calculate volumetric gas flowrate (QV)

3 3

QV = 17.317 ft /s = 0.490 m /s

6. Calculate minimum area (AV)

2 2

AV = 2.348 ft = 0.218 m

7. Calculate column diameter (D) and height (H)

D = 1.730 ft = 0.527 m

using ratio of H/D = 3.000

H = 5.189 ft = 1.582 m

8. Calculate liquid volumetric flowrate (QL)

3 3

QL = 2.574 ft /min = 0.073 m /min

9. Calculate maximum liquid level in Column (LH)

T = liquid holding time in column, specified = 5.000 minutes

LH = 5.480 ft = 1.670 m

10. Calculate wall thickness (shell thickness, ts, and head thickness, th)

Operating pressure 1.000 atm 14.700 psi

Operating temperature 140.000 oF 60.000 C

a. Shell thickness (ts)

tc = allowable corrosion 0.125 inch

P = design pressure (psi) 39.700 psi

D = Vessel inside diameter 20.755 inch

Es = Weld efficiency for shell

0.800 <-- selected from Table 6.1 in sheet 'Design Data'

S = allowable stress

S is depended on selected material of construction and operating temperature

Table 6-37 from Perry's CEH is extensive source of S for various metal at various temperature

2

S = 20.000 kip/in 137.895 MPa = 20271 psi

Thus ,

αs = 0.001 inch

ts = 0.150 inch = 0.004 m

a. Head thickness (th)

Select type of head 1 <---- 1. For a torispherical head

2. For a 2:1 ellipsoidal head

Weld efficiency for head 0.800 <-- selected from Table 6.1 in sheet 'Design Data'

Then,

αh = 0.001 inch

th = 0.153 inch = 0.004 m

You might also like

- Heat Balannce:: Fluid AllocationDocument16 pagesHeat Balannce:: Fluid AllocationUsama AkramNo ratings yet

- Precast Driven Pile Section Analysis: Input DataDocument1 pagePrecast Driven Pile Section Analysis: Input DatacivixxNo ratings yet

- Barrel Type O.T1Document23 pagesBarrel Type O.T1gurumurthy38No ratings yet

- Design of Ungated Head RegulatorDocument5 pagesDesign of Ungated Head RegulatorAsha ChaudharyNo ratings yet

- Tank Design As Per IS803 and API650Document36 pagesTank Design As Per IS803 and API650Vikash Kumar Singh100% (1)

- Tank Design As Per IS803 and API650Document36 pagesTank Design As Per IS803 and API650Vikk Suriya100% (1)

- Anion ExchengerDocument12 pagesAnion Exchengerdewi permatasari p.aNo ratings yet

- Asignación 2.costo de OperaciónDocument7 pagesAsignación 2.costo de OperaciónKike BayonaNo ratings yet

- Supported Cone Roof (CS) Add.4Document21 pagesSupported Cone Roof (CS) Add.4skhurramq100% (2)

- Process Equipment Design Exam QuestionsDocument2 pagesProcess Equipment Design Exam QuestionskhushbuNo ratings yet

- MIXER DESIGN FOR BIODIESEL AND TOCOPHEROL MIXTUREDocument13 pagesMIXER DESIGN FOR BIODIESEL AND TOCOPHEROL MIXTUREkurniawanNo ratings yet

- Ultimate Moment Capacity of Reinforced Concrete Section To EN 1992-2 - Clause 6.1Document5 pagesUltimate Moment Capacity of Reinforced Concrete Section To EN 1992-2 - Clause 6.1Randhir BharatNo ratings yet

- Radiator Fan Moterating CalculationDocument20 pagesRadiator Fan Moterating Calculationmyungkwan haNo ratings yet

- Line Sizing of The Main Production Header (A Gas / Liquid Two Phase Line)Document12 pagesLine Sizing of The Main Production Header (A Gas / Liquid Two Phase Line)Engr TheyjiNo ratings yet

- Steel Design 2Document19 pagesSteel Design 2John Pierce Gumapac67% (3)

- Base Plate Anchor Bolt DesignDocument8 pagesBase Plate Anchor Bolt DesignnoneofyourbusineesNo ratings yet

- Bottom Dome DesignDocument4 pagesBottom Dome DesignJayNo ratings yet

- Torsional Strength As Per 5100.5.2017: Beam DataDocument8 pagesTorsional Strength As Per 5100.5.2017: Beam DataSambhav PoddarNo ratings yet

- Rotary Dryer DesignDocument43 pagesRotary Dryer DesignsasitharNo ratings yet

- Design of Working PilesDocument36 pagesDesign of Working PilesSahil OzaNo ratings yet

- 12Document119 pages12Salihin FhooziNo ratings yet

- Design of Water Conductor (Alternate-I of WC Profile)Document14 pagesDesign of Water Conductor (Alternate-I of WC Profile)nira365No ratings yet

- Structural Analysis & DesignDocument8 pagesStructural Analysis & Designkurt paulo manaloNo ratings yet

- Ref Design Ice Plant Cold StorageDocument24 pagesRef Design Ice Plant Cold StorageTheodore VilaNo ratings yet

- Spek Pompa 1Document14 pagesSpek Pompa 1vennyNo ratings yet

- BASEPLT9Document5 pagesBASEPLT9Bunkun15No ratings yet

- Staircase DesignDocument4 pagesStaircase DesignDrafters EngineeringNo ratings yet

- Design of Axially Loaded Sloped Footing DataDocument11 pagesDesign of Axially Loaded Sloped Footing DataFatima tuz ZohraNo ratings yet

- Known Data: H Z 2 I R S GDocument6 pagesKnown Data: H Z 2 I R S GUjol PraNo ratings yet

- Strap Footing DesignDocument2 pagesStrap Footing DesignAbinash MandalNo ratings yet

- Asd VS LRFDDocument179 pagesAsd VS LRFDALONSO GOMEZNo ratings yet

- Design of Steel StructuresDocument179 pagesDesign of Steel StructuresneophymenNo ratings yet

- Combined FootingDocument117 pagesCombined FootingMashetty RahulNo ratings yet

- Calculo EjemploDocument52 pagesCalculo EjemplodmagnetoNo ratings yet

- Hydraulic and Structural Design of Super PassageDocument25 pagesHydraulic and Structural Design of Super PassageCPK100% (2)

- Culvert Design Using Staad As Per IrsDocument171 pagesCulvert Design Using Staad As Per IrsTanvir Shahrier MahmudNo ratings yet

- Un Drained Shear StrengthDocument18 pagesUn Drained Shear StrengthLogan PatrickNo ratings yet

- Simulacion Aero Enfriador PDFDocument40 pagesSimulacion Aero Enfriador PDFNicandroGonzalesNo ratings yet

- Perancangan Alat CekDocument19 pagesPerancangan Alat CekLilyNo ratings yet

- Aluminium Cladding DesignDocument2 pagesAluminium Cladding DesigntkofaiNo ratings yet

- Design Spread Footing for Fertilizer Storage BuildingDocument6 pagesDesign Spread Footing for Fertilizer Storage BuildingReab SimanthNo ratings yet

- Spek HopperDocument10 pagesSpek HopperzulmijarNo ratings yet

- LIFTING-LUG DESIGN CALCULATIONDocument5 pagesLIFTING-LUG DESIGN CALCULATIONAnisa Rifqi0% (1)

- 3WH-36-1.00 MM DesignDocument4 pages3WH-36-1.00 MM DesignmohanNo ratings yet

- Pipe Support2of 5Document1 pagePipe Support2of 5Anonymous fLgaidVBhz100% (1)

- Concret oDocument4 pagesConcret onelan dresNo ratings yet

- Steel Structure Design Example-3Document7 pagesSteel Structure Design Example-3Mesfin Derbew100% (1)

- Distillation Column - Stripping SectionDocument8 pagesDistillation Column - Stripping SectionKvspavan KumarNo ratings yet

- SADDLE STRESS ANALYSISDocument19 pagesSADDLE STRESS ANALYSISSiva baalanNo ratings yet

- Design of Steel Truss MembersDocument6 pagesDesign of Steel Truss MembersSaim WaqarNo ratings yet

- Desing of 200 Cubic Metre Reinforced Rectangular Clear Water Storage Tank For Rumphi Tank Geometry and DimensionsDocument23 pagesDesing of 200 Cubic Metre Reinforced Rectangular Clear Water Storage Tank For Rumphi Tank Geometry and DimensionsWjz WjzNo ratings yet

- Tup Manila Ice Plant and Cold Storage DesignDocument29 pagesTup Manila Ice Plant and Cold Storage DesignmyravganacNo ratings yet

- 3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesFrom Everand3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesNo ratings yet

- Hyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationFrom EverandHyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationNo ratings yet

- Analytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportFrom EverandAnalytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportNo ratings yet

- Environmental Consultant CVDocument3 pagesEnvironmental Consultant CVnizar ahmadNo ratings yet

- Muhamad Nizar - CVDocument12 pagesMuhamad Nizar - CVnizar ahmadNo ratings yet

- Implementation Report SMTMLK3 Berbasis KomputerDocument13 pagesImplementation Report SMTMLK3 Berbasis Komputernizar ahmadNo ratings yet

- Sounds of EquipmentsDocument3 pagesSounds of Equipmentsnizar ahmadNo ratings yet

- EFs For MiningDocument5 pagesEFs For Miningnizar ahmadNo ratings yet

- Biodiesel KineticsDocument4 pagesBiodiesel Kineticsnizar ahmad0% (1)

- Muhamad Nizar ProfileDocument13 pagesMuhamad Nizar Profilenizar ahmadNo ratings yet

- Sheet 'H+ Estimation' of Biomass HydrolysisDocument1 pageSheet 'H+ Estimation' of Biomass Hydrolysisnizar ahmadNo ratings yet

- Sheet 'Intro' of Biomass HydrolysisDocument1 pageSheet 'Intro' of Biomass Hydrolysisnizar ahmadNo ratings yet

- Sheet 'Main Calculations' of Biomass HydrolysisDocument2 pagesSheet 'Main Calculations' of Biomass Hydrolysisnizar ahmadNo ratings yet

- Heat Balance of Rotary DryerDocument2 pagesHeat Balance of Rotary Dryernizar ahmadNo ratings yet

- Design of Rotary DryerDocument2 pagesDesign of Rotary Dryernizar ahmad57% (7)

- VW Passat B5 Exhaust System 1,8 Aug AwmDocument14 pagesVW Passat B5 Exhaust System 1,8 Aug AwmNPNo ratings yet

- Development of A Powder Metallurgical Self Cooling Forging Die With Inner CavitiesDocument9 pagesDevelopment of A Powder Metallurgical Self Cooling Forging Die With Inner CavitiesJasbir S RyaitNo ratings yet

- Reciprocating Compressor ImprovementsDocument13 pagesReciprocating Compressor ImprovementsSANJANA SINGHNo ratings yet

- Automotive Tapered Roller and Ball Bearing Price ListDocument8 pagesAutomotive Tapered Roller and Ball Bearing Price ListAvijitSinharoyNo ratings yet

- (2a) Laminate & Reinforcement Mat'lDocument31 pages(2a) Laminate & Reinforcement Mat'laudheaykNo ratings yet

- SY335C8I2K液压挖掘机零部件图册Document370 pagesSY335C8I2K液压挖掘机零部件图册Edgar Martinez Carmona100% (5)

- PN 2300Document95 pagesPN 2300cresjohn100% (1)

- 4060 Feeder Manual PDFDocument87 pages4060 Feeder Manual PDFAle Maria100% (1)

- Installation QualificationDocument17 pagesInstallation Qualificationtrinath16198067% (6)

- Oaj Issue2 Kazan FinalDocument9 pagesOaj Issue2 Kazan FinalfcordNo ratings yet

- Reflection Paper: Plant DesignDocument3 pagesReflection Paper: Plant DesignroxetteNo ratings yet

- Kerpen 10px1 5 Is-Os En50288-7Document3 pagesKerpen 10px1 5 Is-Os En50288-7Rijo RajanNo ratings yet

- DIWA List of Approved Oils-Oil Change Interval Up To 120000 and 180000 KMDocument9 pagesDIWA List of Approved Oils-Oil Change Interval Up To 120000 and 180000 KMfugegaNo ratings yet

- LG 15.0-inch LCD Monitor Service ManualDocument37 pagesLG 15.0-inch LCD Monitor Service ManualRobert GreenNo ratings yet

- IPG Or-01 - PTC Train Infrastructure Electrical Safety RulesDocument50 pagesIPG Or-01 - PTC Train Infrastructure Electrical Safety Rules4493464No ratings yet

- Poster Arduino TrainingDocument1 pagePoster Arduino TrainingSebastien PaulNo ratings yet

- 11B Engine MechanicalDocument17 pages11B Engine Mechanicalcrysttina100% (1)

- Saudi Aramco RiggerDocument11 pagesSaudi Aramco RiggerShabbir Hussain85% (13)

- Hot Runner Athena RMB Rmbd15Document28 pagesHot Runner Athena RMB Rmbd15CesarNo ratings yet

- Manual: Flammable Gas SensorDocument7 pagesManual: Flammable Gas SensorWerliock MorlorumNo ratings yet

- Scania Press - TrademarkDocument2 pagesScania Press - TrademarkAnonymous zPUXs8aONo ratings yet

- Piping Specification ChecklistDocument6 pagesPiping Specification ChecklistBinodh DanielNo ratings yet

- 05 at (A750)Document14 pages05 at (A750)Carlos MachadoNo ratings yet

- General purpose 6X36WS + IWRC steel wire rope specificationsDocument1 pageGeneral purpose 6X36WS + IWRC steel wire rope specificationsloretoNo ratings yet

- Categorisation of DefectsDocument231 pagesCategorisation of DefectsSimon CooperNo ratings yet

- Flow of Fluids: Answers SheetDocument2 pagesFlow of Fluids: Answers SheetJohn P. BandoquilloNo ratings yet

- N E W S L E T T E R: Electronic Staging of Composite Propellant Rocket MotorsDocument8 pagesN E W S L E T T E R: Electronic Staging of Composite Propellant Rocket Motorsdrforbin666No ratings yet

- Y-Series Brushless Servo Motor: Installation InstructionsDocument16 pagesY-Series Brushless Servo Motor: Installation InstructionsrafaelNo ratings yet

- Install and operate your portable AC safelyDocument8 pagesInstall and operate your portable AC safelyPete PompesNo ratings yet