Professional Documents

Culture Documents

Minimum Requirement For Ayurvedic Manufacturing Unit

Uploaded by

Rudrani SarkarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Minimum Requirement For Ayurvedic Manufacturing Unit

Uploaded by

Rudrani SarkarCopyright:

Available Formats

LIST OF MACHINERY, EQUIPMENT AND MINIMUM MANUFACTURING PERMISES REQUIRED FOR THE MANUFACTURE OF VARIOUS CATEGORIES OF AYURVEDIC, SIDDHA

SYSTEM OF MEDICINES. S.No Category of Medicine Minimum manufacturing Machinery/ equipment recommend space required 1200 Square feet covered area with separatecabins partitions for each activity.If Unani medicines are manufactured in same Premises an additional Area of 400 sq. feet will be required. 100 Sq. feet Karel/mechnised/motorised,kharel, End runner/ Ball-Mill Sieves/Shifter 200 Sq.feet Grinder/ Disintegrator/ Manjan/Lepa Pulverisar/ Powder mixer/ sieves/shifted. 100 Sq.feet Ball Mill, Mass mixer powder mixer pill/vati cuttingmachine,stainless steel trays/ Containers for Storage. Driers/Mechanised chattee(for mixing guggul) where required. 100 Sq.feet Ball Mill, Mass Mixer/PowdermixerGranulator drier, Tablet compressing Machine and sugarCoating, foliching pay in case of sugar Coated tablets,mechanisedchattee (for mixing of guggulu) where required. 150 Sq.feet Bhatti, Karahi/ Stainless Steel Vessels/Patila Flask, Multani Matti/Plaster of Paris,Copper Rod,Earthen container, Gaj Put Bhatti, Muffle furnace(Electrically Operated) End/Edge Runner, Exhaust Fan, Wooden/S.S. Spatula 100 Sq.feet Earthen lamps for Collection of Kajal, Tipple Roller Mill, End Runner, Sieves, S.S.Patila,Filling/packing and manufacturing room should be provided with exhaust fan & ultra violet lamps 100 Sq.feet Air Conditioner, De humidifier, hygrometer,Thermo-meter, Capsule filling Machine and chemical balance. 100 Sq.feet Tube filling Pasai machine, Crimping Medicine/Ointment Mixer, End Runner /Mill (Where required), S.S. Storage Container S.S. Patila 100 Sq.feet Bhatti section fitted with Exhaust fan and should be fly proof, Iron Kadahi/ S.S. Patila and S.S. Storage container 150 Sq.feet Tinctum press, Kwath Manapaku exhaust fan fitted and fly proof, Bhatti section, Bottle washing Machine, filter press/Grav filter Liquid filling tank with tap/liquid filling machine, P.P. Copping Machine. 200 Sq.feet Same as mentioned above. Fermentation tanks containers and Distillation Plant where necessary, Filter Press 100 Sq.feet Same as mentioned above plus Distillation plant and Transfer pump 100 Sq.feet Maceration tank, Distillation plant, Liquid filling tank with tap/Gravity filter/ Filter press, Visual inspection box

1. 2. 3.

Anjana/Pisti Churna/Nasya Kwath Churn Pills/Vatti/Gutik a Matirai

4.

Tablets

5.

Kupi pakva/ Ksara/Parpati/ Lavana Bhasma Satva/ Sindura Karpu/Uppu/ Param Kajal

6.

7.

Capsules

8.

9.

10. Panak Syrup/Pravahi

11. Asava/Aristha

12. Sura 13. Ark Tinir

14. Tail/Ghrit Ney

100 Sq.feet

15. Aschyotan/ Netra Malham 100 Sq.feet Panir

Bhatti, Kadahi/S.S. Patila S.S. Storage Containers, Filtration equipment, filling tank with tap/Liquid filling machine. Hot air oven electrically heated with thermostatic control , cettle gas or electrically heated with suitable mixing arrangements collation mill or ointment mill, tube filling equipment, mixing and storage tanks of stainless steel or of other suitable material sintered glass funnel, seitz filter or filter candle, liquid filling equipment, autoclave.

16. Each manufacturing unit will have a separate area for Bhatti, furnaces, boilers, puta, etc. This will have proper ventilation, removal of smoke, prevention of flies, insects, dust etc. The furnace section could have tin roof.

200 Sq.feet

You might also like

- Space and MachineryDocument3 pagesSpace and MachineryDrSurendra Chaudhary100% (2)

- Ayurveda Rasa Panchaka - 5 Qualities of SubstanceDocument9 pagesAyurveda Rasa Panchaka - 5 Qualities of SubstanceBuddhika NawagamuwaNo ratings yet

- Legal and Regulatory Status of Ayurveda PDFDocument130 pagesLegal and Regulatory Status of Ayurveda PDFSreedhar TirunagariNo ratings yet

- Siddha MedicineDocument4 pagesSiddha MedicineDoktormin106No ratings yet

- Understanding Ayurvedic Inhalers W.S.R. To Tamaka SwasaDocument15 pagesUnderstanding Ayurvedic Inhalers W.S.R. To Tamaka SwasaDrVikasNo ratings yet

- Ancient Traditional Technology For Preparing Bhasmas of Metals and Minerals With Special Reference To Preparation of Tamra Bhasma PDFDocument12 pagesAncient Traditional Technology For Preparing Bhasmas of Metals and Minerals With Special Reference To Preparation of Tamra Bhasma PDFWeare1_busyNo ratings yet

- Ayurvedic Treatment For Pancreatitis by Vaidya Balendu PrakashDocument41 pagesAyurvedic Treatment For Pancreatitis by Vaidya Balendu Prakashpadaav100% (1)

- Siddha Herbal FormulationsDocument70 pagesSiddha Herbal FormulationsLuven Balan100% (2)

- Making Herbarium GuideDocument7 pagesMaking Herbarium GuideFaisal HafizNo ratings yet

- Article Wjpps 1475213708Document29 pagesArticle Wjpps 1475213708Vaidya NurNo ratings yet

- 1 DR S N BelavadiDocument11 pages1 DR S N BelavadirakeshNo ratings yet

- Rasanjana For PrabahikiDocument7 pagesRasanjana For PrabahikiVaidya NurNo ratings yet

- Purificatory Processes of Sulphur Described in Medieval Indian Text AnandakandaDocument6 pagesPurificatory Processes of Sulphur Described in Medieval Indian Text AnandakandaKeith BoltonNo ratings yet

- An Ayurvedic Perspective of Bhallataka S PDFDocument16 pagesAn Ayurvedic Perspective of Bhallataka S PDFBhavana GangurdeNo ratings yet

- Of Andhra Region Written in Classical Telugu VersesDocument7 pagesOf Andhra Region Written in Classical Telugu VersessillypoloNo ratings yet

- Maharasa Varga: DR - Mahantesh B, Rudrapuri M.D. (Ayu), F.A.G.EDocument29 pagesMaharasa Varga: DR - Mahantesh B, Rudrapuri M.D. (Ayu), F.A.G.EPREM277272100% (2)

- Shlokartha Kriya Sharira 1Document113 pagesShlokartha Kriya Sharira 1Sukanta Sameer Sardesai50% (4)

- Ayurvedic Pharmaceutics and Insights OnDocument40 pagesAyurvedic Pharmaceutics and Insights OnBhavana GangurdeNo ratings yet

- Bhallataka Benefits for Cancer, Arthritis and Skin IssuesDocument21 pagesBhallataka Benefits for Cancer, Arthritis and Skin Issuesvs_akilanNo ratings yet

- Development of Rasasastra in Medieval PeriodDocument8 pagesDevelopment of Rasasastra in Medieval PeriodSundara Veer Raju MEDNo ratings yet

- A Single Armed Cinical Study To Evaluate Efficacy of Navana Nasya With Brihatkalyanaka Ghrita in Apabahuka W.S.R To Frozen ShoulderDocument8 pagesA Single Armed Cinical Study To Evaluate Efficacy of Navana Nasya With Brihatkalyanaka Ghrita in Apabahuka W.S.R To Frozen ShoulderEditor IJTSRDNo ratings yet

- KamathDocument166 pagesKamathCuriosityShopNo ratings yet

- Kenchappa Gambhari Compilation.Document76 pagesKenchappa Gambhari Compilation.Pavan PatilNo ratings yet

- Asava and ArishtaDocument7 pagesAsava and Arishtadrsa2No ratings yet

- The Siddha Pharmacopoeia of IndiaDocument224 pagesThe Siddha Pharmacopoeia of Indiaponsooriya100% (5)

- Bams SyllabusDocument22 pagesBams SyllabusPriyaNo ratings yet

- WUJASTYK - Perfect Medicine - Mercury in AyurvedaDocument26 pagesWUJASTYK - Perfect Medicine - Mercury in AyurvedaMarco PassavantiNo ratings yet

- B. List of Machinery, Equipment and Minimum Manufacturing Premises Required For The Manufacture of Various Categories of Unani System of MedicinesDocument3 pagesB. List of Machinery, Equipment and Minimum Manufacturing Premises Required For The Manufacture of Various Categories of Unani System of MedicineswasiuddinNo ratings yet

- Cant. Equipos Precio TotalDocument10 pagesCant. Equipos Precio TotalFernando JesúsNo ratings yet

- Laboratary EquipmentsDocument2 pagesLaboratary EquipmentsmsajidfccNo ratings yet

- Revised Offer To Al MArzouqDocument1 pageRevised Offer To Al MArzouqSanu PhilipNo ratings yet

- Data Umum SSH 2024Document376 pagesData Umum SSH 2024Ilham JuhardiNo ratings yet

- Shashikant Singh (Capsule Filling Machine)Document15 pagesShashikant Singh (Capsule Filling Machine)Shivang NamdevNo ratings yet

- Technical Equipment RamseyDocument2 pagesTechnical Equipment RamseythuNo ratings yet

- Typical Steam Consumption RatesDocument2 pagesTypical Steam Consumption RatesNiong DavidNo ratings yet

- Genaxy Price ListDocument196 pagesGenaxy Price ListDeepak Ranjan SahooNo ratings yet

- AAU ProfileDocument24 pagesAAU ProfilejumardinNo ratings yet

- Agri Gallery - View Videos & Photos of Farm ImplementsDocument5 pagesAgri Gallery - View Videos & Photos of Farm ImplementssunilbholNo ratings yet

- Quotation Pushpanjali Industries January 2024Document2 pagesQuotation Pushpanjali Industries January 2024saurabhdesh561No ratings yet

- Manual Capsule Filling Machine DimensionsDocument5 pagesManual Capsule Filling Machine Dimensionsamit chavanNo ratings yet

- Pacucoa LabDocument13 pagesPacucoa LabpremsyeolNo ratings yet

- YUV SCIENTIFIC INDUSTRIES Rate Products Am PDFDocument6 pagesYUV SCIENTIFIC INDUSTRIES Rate Products Am PDFAman DeepsinghNo ratings yet

- 2012 Iowa Farm Custom Rate Survey: Ag Decision MakerDocument2 pages2012 Iowa Farm Custom Rate Survey: Ag Decision MakerKyle WilkinsNo ratings yet

- MUSHROOM Apicol Final 280417Document9 pagesMUSHROOM Apicol Final 280417Debasishisabed PradhanNo ratings yet

- Bertuzzi Machinery For PassionFruitDocument4 pagesBertuzzi Machinery For PassionFruitPastillas DesodorantesNo ratings yet

- A Study On Shri Swami Atmanand Saraswati Ayurvedic Co-Operative Pharmacy Limited (ASFA)Document28 pagesA Study On Shri Swami Atmanand Saraswati Ayurvedic Co-Operative Pharmacy Limited (ASFA)Bhakti MehtaNo ratings yet

- For Mixer Agitators, Attachments and Accessories: Use and Applications HandbookDocument20 pagesFor Mixer Agitators, Attachments and Accessories: Use and Applications HandbookMahla Raj KumarNo ratings yet

- AsfaDocument28 pagesAsfaBhakti MehtaNo ratings yet

- Area StatementDocument13 pagesArea StatementLakshmi PillaiNo ratings yet

- Machines ManufacturerDocument6 pagesMachines ManufacturerArasan ArasanNo ratings yet

- Roundup WG Bula MonsantoDocument16 pagesRoundup WG Bula MonsantodandanyddNo ratings yet

- Equipment List Culinary ArtsDocument7 pagesEquipment List Culinary ArtsROHIT_80No ratings yet

- Source Machinery: REF: SOU/GEN/11-12/21 DATE: 12 December, 2011Document8 pagesSource Machinery: REF: SOU/GEN/11-12/21 DATE: 12 December, 2011Ravi k LavuNo ratings yet

- Restaurant Design: PHINMA - University of PangasinanDocument16 pagesRestaurant Design: PHINMA - University of Pangasinanbea mea gubatanNo ratings yet

- Eto SterilizerDocument2 pagesEto SterilizerHitesh B GandhiNo ratings yet

- Part-II Schedule MDocument13 pagesPart-II Schedule Mcollagelife2023No ratings yet

- Capsule Filling MachineDocument25 pagesCapsule Filling MachineKhairi Mustafa Salem100% (1)

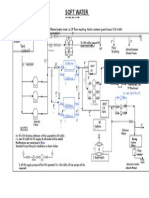

- Soft Water P & IdDocument1 pageSoft Water P & Idmfaisal68No ratings yet

- HPC LIST FLORICULTURE SEEDS FRUITS VEGETABLESDocument35 pagesHPC LIST FLORICULTURE SEEDS FRUITS VEGETABLESSatyanarayana PVVNo ratings yet

- Innovative Packtech Machines - CatalogueDocument8 pagesInnovative Packtech Machines - CatalogueDj Spark IndiaNo ratings yet

- Crtanje Lica I ProfilaDocument32 pagesCrtanje Lica I Profilaveljko1986No ratings yet

- Form-Guidelines For Ayurvedic ManufacturersDocument20 pagesForm-Guidelines For Ayurvedic ManufacturersRudrani SarkarNo ratings yet

- Positioning PDFDocument35 pagesPositioning PDFSk PrinceNo ratings yet

- 7 Day Candles LessonDocument4 pages7 Day Candles LessonRudrani Sarkar0% (1)

- Fascial ProportionsDocument3 pagesFascial ProportionsRudrani SarkarNo ratings yet

- Draw A FaceDocument6 pagesDraw A FaceRudrani SarkarNo ratings yet

- Use Case Templates - FunctreqDocument10 pagesUse Case Templates - Functreqshamp_a100% (3)

- Ganesha Spell To Break ObstaclesDocument3 pagesGanesha Spell To Break ObstaclesRudrani Sarkar100% (2)

- Color CorrenpondenceDocument1 pageColor CorrenpondenceRudrani SarkarNo ratings yet

- You Will Need The Following Items For This SpellDocument1 pageYou Will Need The Following Items For This SpellRudrani SarkarNo ratings yet

- History of WMDocument19 pagesHistory of WMRudrani SarkarNo ratings yet

- You Will Need The Following Items For This SpellDocument1 pageYou Will Need The Following Items For This SpellRudrani Sarkar100% (1)

- SccubusDocument3 pagesSccubusRudrani Sarkar100% (1)

- Hanging Gardens of Babylon: in Resorting To Aliens To Explain The Actions of Our Ancestors, We Sell Our Ancestors ShortDocument11 pagesHanging Gardens of Babylon: in Resorting To Aliens To Explain The Actions of Our Ancestors, We Sell Our Ancestors ShortRudrani SarkarNo ratings yet

- Spice - Gallery Photos in PDFDocument1 pageSpice - Gallery Photos in PDFkeval_kanakharaNo ratings yet

- Gratitude LuckDocument1 pageGratitude LuckRudrani SarkarNo ratings yet

- Casting Instructions For 'Healing A Family Member Spell: You Will Need The Following Items For This SpellDocument1 pageCasting Instructions For 'Healing A Family Member Spell: You Will Need The Following Items For This SpellRudrani SarkarNo ratings yet

- Casting Instructions For 'Hasten Recovery Spell': You Will Need The Following Items For This SpellDocument2 pagesCasting Instructions For 'Hasten Recovery Spell': You Will Need The Following Items For This SpellRudrani SarkarNo ratings yet

- Gratitude LuckDocument1 pageGratitude LuckRudrani SarkarNo ratings yet

- Open Your Third Eye in 3 Days and Awaken Psychic AbilitiesDocument2 pagesOpen Your Third Eye in 3 Days and Awaken Psychic AbilitiesRudrani Sarkar100% (2)

- Kabbala Secret WhyDocument3 pagesKabbala Secret WhyRudrani SarkarNo ratings yet

- You Will Need The Following Items For This SpellDocument1 pageYou Will Need The Following Items For This SpellRudrani SarkarNo ratings yet

- Self Healing Candle SpellDocument1 pageSelf Healing Candle SpellRudrani SarkarNo ratings yet

- You Will Need The Following Items For This SpellDocument1 pageYou Will Need The Following Items For This SpellRudrani SarkarNo ratings yet

- Camdle MagickDocument4 pagesCamdle MagickRudrani SarkarNo ratings yet

- Spell for Healing Pain with Crystal and Holy WaterDocument1 pageSpell for Healing Pain with Crystal and Holy WaterRudrani SarkarNo ratings yet

- The Order & Value of the English AlphabetDocument5 pagesThe Order & Value of the English AlphabetRudrani SarkarNo ratings yet

- Emotional ImprovementDocument2 pagesEmotional ImprovementRudrani SarkarNo ratings yet

- Candle HealingDocument1 pageCandle HealingRudrani SarkarNo ratings yet

- Indus Valley Civilization: Cradle of the Bronze AgeDocument18 pagesIndus Valley Civilization: Cradle of the Bronze Ageayandasmts100% (2)

- An Introduction To The Brahma SutrasDocument11 pagesAn Introduction To The Brahma Sutrasraj100% (2)

- Yoga Project Class 12 CbseDocument25 pagesYoga Project Class 12 CbseAYUSH NARWAL76% (85)

- Abhirami Ammai Pathikam - IIDocument7 pagesAbhirami Ammai Pathikam - IIPuducode Rama Iyer RamachanderNo ratings yet

- Padmasambhava Personal Deity YogaDocument12 pagesPadmasambhava Personal Deity YogaCéline Bosschaert100% (1)

- MNAPC V 11 I1 (v10 I3 63) P 16 30Document16 pagesMNAPC V 11 I1 (v10 I3 63) P 16 30PREM277272No ratings yet

- Adventure Comics and Youth Cultures in IndiaDocument33 pagesAdventure Comics and Youth Cultures in IndiaANUSHKA DAYALNo ratings yet

- KalyanDocument1 pageKalyanaNo ratings yet

- Lord Krishna Enters Mathura CityDocument41 pagesLord Krishna Enters Mathura CityDāmodar DasNo ratings yet

- Anicca Vata Sankhara (Bhikkhu Bodhi 2005)Document5 pagesAnicca Vata Sankhara (Bhikkhu Bodhi 2005)OmSilence2651100% (1)

- Names and Phone Numbers of 198 BBMP Corporators 2010Document9 pagesNames and Phone Numbers of 198 BBMP Corporators 2010Citizen Matters83% (6)

- Is 1848 2007 PDFDocument12 pagesIs 1848 2007 PDFSyed MuzakkirNo ratings yet

- Tamil MorphologyDocument1 pageTamil MorphologyamrikesaNo ratings yet

- Sexual Life in Ancient IndiaDocument297 pagesSexual Life in Ancient IndiaVeeramani Mani100% (1)

- Rig Veda Magic SquaresDocument44 pagesRig Veda Magic SquaresRaalito RaalitoNo ratings yet

- Government of Kerala General Administration (Political) DepartmentDocument3 pagesGovernment of Kerala General Administration (Political) DepartmentPrathviraj MeenaNo ratings yet

- Interior Design SchoolsDocument3 pagesInterior Design Schoolsanuj2201No ratings yet

- Oh My GodDocument6 pagesOh My GodanuragaryanNo ratings yet

- Is 2720 29 1975Document14 pagesIs 2720 29 1975biswashree10No ratings yet

- JapaDocument5 pagesJapadacian19666192No ratings yet

- Introduction to Kundalini Yoga CourseDocument113 pagesIntroduction to Kundalini Yoga CourseMike YonkersNo ratings yet

- Nakshatra Mantra: Cord and Back. Moola Mantra Om Sat Chit Ananda Parabrahma PurushothamaDocument22 pagesNakshatra Mantra: Cord and Back. Moola Mantra Om Sat Chit Ananda Parabrahma PurushothamaMeet JiNo ratings yet

- 498A IPC Criminal Complaint Cannot Continue After Settlement Between Parties in Marital Disputes SCDocument5 pages498A IPC Criminal Complaint Cannot Continue After Settlement Between Parties in Marital Disputes SCSuraj Kumar100% (1)

- How To Interpret Employment Through Horary Astrology - Astrology & HoroscopeDocument6 pagesHow To Interpret Employment Through Horary Astrology - Astrology & HoroscopeDeepak MishraNo ratings yet

- HUFDocument9 pagesHUFSmriti SharmaNo ratings yet

- Rakshabandhan ScriptDocument16 pagesRakshabandhan ScriptJaydeepNo ratings yet

- Prativedan EnglishDocument8 pagesPrativedan EnglishArya VeerNo ratings yet

- Kalakshetra Case StudyDocument17 pagesKalakshetra Case StudyYogesh67% (6)

- 2010 ComputerDocument3 pages2010 ComputerShishir Das K RNo ratings yet

- Ajaran Kesusilaan Dalam Satua Bali: Men Tiwas Teken Men SugihDocument7 pagesAjaran Kesusilaan Dalam Satua Bali: Men Tiwas Teken Men Sugihputusuta04No ratings yet