Professional Documents

Culture Documents

Low Outgassing Characteristics PDF

Uploaded by

rahul05singhaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Low Outgassing Characteristics PDF

Uploaded by

rahul05singhaCopyright:

Available Formats

Advanced Circuit Materials 100 S. Roosevelt Avenue Chandler, AZ 85226 Tel: 480-961-1382, Fax: 480-961-4533 www.rogerscorporation.

com

Advanced Circuit Materials

Properties

2.9.1

Low Outgassing Characteristics of Rogers Laminates Approved for Spacecraft Applications

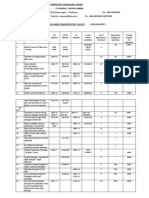

RT/duroid composites of PTFE with inorganic fiber filler and TMM temperature stable hydrocarbon composites, have outstanding resistance to outgassing, according to data compiled by NASA test procedure SP-R-0022A. Reinforced PTFE laminates and PTFE composites are thermally stable and have universal outgassing characteristics. Similarly, TMM temperature stable laminates are highly crosslinked hydrocarbons which do not evolve gases or by-products at elevated temperatures. Test data shown in the table (back page) were obtained on specimens etched free of copper foil. The test procedure2 consists of vacuum heating 100 to 300 mg specimens in a copper enclosure, with exit port at 125C for 24 hours with a chrome-plated collector maintained at 25C located 12.7 mm from the exit port. The Total Mass Loss (TML), Collected Volatile Condensable Materials (CVCM) and Water Vapor Recovered (WVR) are expressed as a % of the original specimen mass. In general, materials with TML over 1.0 or CVCM over 0.10 should be avoided in spacecraft applications. References:

1. William A. Campbell, Jr. and Richard S. Marriott of Goddard Space Flight Center, Greenbelt, MD, OUTGASSING DATA FOR SPACECRAFT MATERIALS, NASA Reference Publication 1124, August 1987. Note: The database of RP1124 is updated weekly and may be accessed or downloaded from the NASA website at http://epims.gsfc.nasa.gov/og/. 2. ANSI/ASTM E595-84 Standard Test Method for Total Mass Loss and Collected Volatile Condensable Materials from Outgassing in a Vacuum Environment, American Society for Testing and Materials, Annual Book of Standards.

The world runs better with Rogers.

Material Type

RT/duroid 5870 Laminates RT/duroid 5880 Laminates RT/duroid 6010 Laminates

RO4003C 3001 Bonding TMM10 TMM 3 RT/duroid 6002 High Frequency Film Temperature Temperature Laminates Circuit Stable Stable Materials Laminates Laminates Thermoset Polymer Composite

ULTRALAM 2000 Laminates

Composition

PTFE Glass-microfiber

PTFE Glass-microfiber

PTFE PTFE Glass-microfiber Glass-microfiber Ceramic filler Ceramic filler

Thermoset Thermoplastic Hydrocarbon Chlorofluroro- Cermic Woven Polymer Glass copolymer Composite

PTFE Woven

Nominal Dielectric Constant 2.33 2.20 10.2 2.94 3.27 ASTM 595-84 %TML %CVCM %WVR 0.05 0.00 0.04 0.03 0.00 0.02 0.03 0.00 0.02 0.02 0.01 0.01

9.20

2.28

3.38

2.40-2.60

0.04 0.00 0.03

0.06 0.00 0.04

0.13 0.01 0.02

0.06 0.00 0.02

0.03 0.02 0.02

CONTACT INFORMATION:

USA: Belgium: Japan: Taiwan: Korea: Singapore: Rogers Rogers Rogers Rogers Rogers Rogers Advanced Circuit Materials, ISO 9002 Certified Corporation - Gent Japan Inc. Taiwan Inc. Korea Inc. Technologies Singapore Inc. Tel: Tel: Tel: Tel: Tel: Tel: 480-961-1382 +32-9-2353611 81-3-5200-2700 886-2-86609056 82-31-716-6112 65-747-3521 Fax: Fax: Fax: Fax: Fax: Fax: 480-961-4533 +32-9-2353658 81-3-5200-0571 886-2-86609057 82-31-716-6208 65-747-7425

The information in this data sheet is intended to assist you in designing with Rogers' laminates. It is not intended to and does not create any warranties express or implied, including any warranty of merchantability or fitness for a particular application. The user should determine the suitability of Rogers' laminates for each application.

These commodities, technology or software are exported from the United States in accordance with the Export Administration regulations. Diversion contrary to U.S. law prohibited. RT/duroid and DUROID are licensed trademarks of Rogers Corporation. 1991-2002 Rogers Corporation, Printed in U.S.A. 1102-CC Publication #92

You might also like

- Guide To Insulation Product Specifications: ASTM Guides, Practices and Test MethodsDocument24 pagesGuide To Insulation Product Specifications: ASTM Guides, Practices and Test MethodszaheermechNo ratings yet

- Elastomer Properties GuideDocument5 pagesElastomer Properties GuidehadeNo ratings yet

- Astm D4000, 2004Document19 pagesAstm D4000, 2004aletapia100% (1)

- EPRI Sootblower PPDocument21 pagesEPRI Sootblower PPJackSparrow86No ratings yet

- High-Temperature Brazing in Controlled Atmospheres: The Pergamon Materials Engineering Practice SeriesFrom EverandHigh-Temperature Brazing in Controlled Atmospheres: The Pergamon Materials Engineering Practice SeriesNo ratings yet

- Project Standards and Specifications Piping Insulation Design Rev01Document10 pagesProject Standards and Specifications Piping Insulation Design Rev01hiyeonNo ratings yet

- Production of 1,5-Pentanediol From Biomass Via Furfural andDocument20 pagesProduction of 1,5-Pentanediol From Biomass Via Furfural andMihaela PatrascuNo ratings yet

- Catenary Sag-Tension Calculator (Even and Uneven)Document2 pagesCatenary Sag-Tension Calculator (Even and Uneven)mohsin160No ratings yet

- ARLON Substrate - Important PDFDocument16 pagesARLON Substrate - Important PDFrahul05singhaNo ratings yet

- MT Carbon Cancarb N990Document1 pageMT Carbon Cancarb N990Gaurav JainNo ratings yet

- EPRI Sootblower WDocument13 pagesEPRI Sootblower WSiva KumarNo ratings yet

- Different Types of PCB Base MaterialsDocument5 pagesDifferent Types of PCB Base Materialsmatrixworld20No ratings yet

- Tarecpir Project Spec Inst GuideDocument64 pagesTarecpir Project Spec Inst GuideFaizal YaacobNo ratings yet

- 3 LayerDocument4 pages3 LayerArya Raditya100% (1)

- Basic Info About Glaze FormulationsDocument3 pagesBasic Info About Glaze FormulationsThongMaVanNo ratings yet

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- High Frequency Laminates - Product Selector Guide and Standard Thicknesses and Tolerances Low Resolution PDFDocument12 pagesHigh Frequency Laminates - Product Selector Guide and Standard Thicknesses and Tolerances Low Resolution PDFrahul05singhaNo ratings yet

- High Frequency Laminates Product Selector Guide and Standard Thicknesses and Tolerances Low ResolutionDocument12 pagesHigh Frequency Laminates Product Selector Guide and Standard Thicknesses and Tolerances Low ResolutionPriyanka ChoudharyNo ratings yet

- Rogers Corp Product Selector GuideDocument3 pagesRogers Corp Product Selector GuideGeorgios SarrisNo ratings yet

- Ficha Tecnica Ultramid A4HDocument2 pagesFicha Tecnica Ultramid A4HSandip DesaiNo ratings yet

- RO3000 Laminate Data Sheet - RO3003, RO3006, RO3010Document4 pagesRO3000 Laminate Data Sheet - RO3003, RO3006, RO3010Juliano Rodrigues BrianezeNo ratings yet

- Reliability and Key Properties of RT Duroid 6002Document4 pagesReliability and Key Properties of RT Duroid 6002xdsesNo ratings yet

- RO4000 Laminates Data SheetDocument4 pagesRO4000 Laminates Data SheetJavier De La VegaNo ratings yet

- Crestomer, Adhesivo Estructural de Alta ResistenciaDocument3 pagesCrestomer, Adhesivo Estructural de Alta ResistenciaTommy VargasNo ratings yet

- Ceramic Fiber BlanketDocument2 pagesCeramic Fiber BlanketYYo YudiNo ratings yet

- C 582 - 95 - Qzu4mi1sruqDocument8 pagesC 582 - 95 - Qzu4mi1sruqGovinda RajNo ratings yet

- RT Duroid 5870 5880 Data SheetDocument2 pagesRT Duroid 5870 5880 Data SheetAnonymous yz5MQGtNo ratings yet

- Full Intruction About Rogers Circuit Board MaterialDocument16 pagesFull Intruction About Rogers Circuit Board MaterialjackNo ratings yet

- D 4000 - 01 - RdqwmdatmdfbrteDocument18 pagesD 4000 - 01 - Rdqwmdatmdfbrtevongoctu2016No ratings yet

- MX 4926N M.CDocument4 pagesMX 4926N M.Csubham chakrabortyNo ratings yet

- RO3000 Pour Rogers 3006 PDFDocument4 pagesRO3000 Pour Rogers 3006 PDFTeddy112No ratings yet

- RO4500 Antenna Grade Laminates For High Volume ApplicationsDocument4 pagesRO4500 Antenna Grade Laminates For High Volume ApplicationsMeenakshi Sundaram KaruppiahNo ratings yet

- Fiber and TextileDocument43 pagesFiber and Textileinfo.akira.ictNo ratings yet

- Advanced Silicide Based Materials - MoSi2Document13 pagesAdvanced Silicide Based Materials - MoSi2chandravadiyaketanNo ratings yet

- Thermoplastic Composites - Best Practice GuideDocument49 pagesThermoplastic Composites - Best Practice GuidemanikandapriyaNo ratings yet

- StandardsDocument18 pagesStandardsvikramNo ratings yet

- RT Duroid 6006 6010 Laminate Data SheetDocument2 pagesRT Duroid 6006 6010 Laminate Data SheetdrhammoudaNo ratings yet

- Types of Insulation Used On Rotating Machines, Their Insulation Life, and Deterioration CausesDocument14 pagesTypes of Insulation Used On Rotating Machines, Their Insulation Life, and Deterioration CausessantoshkumarNo ratings yet

- Elastomric Insulation-C534-03 PDFDocument5 pagesElastomric Insulation-C534-03 PDFAmr KamelNo ratings yet

- Handbook PolymeDocument9 pagesHandbook PolymeTrùm Dầu Mỏ BkNo ratings yet

- Tarecpir Quick Guide Nov15 FINALDocument16 pagesTarecpir Quick Guide Nov15 FINALdvtrascaNo ratings yet

- Refractory Materials For Slagging GasifiersDocument24 pagesRefractory Materials For Slagging GasifiersMian GaoNo ratings yet

- FMC - Novolastic Subsea Thermal Insulation - LOW RESDocument3 pagesFMC - Novolastic Subsea Thermal Insulation - LOW RESalphading50% (2)

- TR-620 - Material Compatibility in Envirotemp FR3 Fluid (FinalKR)Document17 pagesTR-620 - Material Compatibility in Envirotemp FR3 Fluid (FinalKR)rodineicarraroNo ratings yet

- Photocatalytic Membrane of A Novel High Surface Area Tio Synthesized From Titanium Triisopropanolamine PrecursorDocument6 pagesPhotocatalytic Membrane of A Novel High Surface Area Tio Synthesized From Titanium Triisopropanolamine PrecursorNanuNo ratings yet

- A Review On Ceramic and Polymer Materials For Radome ApplicationsDocument4 pagesA Review On Ceramic and Polymer Materials For Radome Applicationsrajaram huptaNo ratings yet

- Machinable Materials High TDocument44 pagesMachinable Materials High TtonyjajaNo ratings yet

- Test Facilities Iit MadrasDocument18 pagesTest Facilities Iit MadrasM.Saravana Kumar..M.ENo ratings yet

- Scotchcast Resin Kits 92-NBB-1U and 92-NBB-2U Y-Branch Kit Series With Resin 1402FRDocument3 pagesScotchcast Resin Kits 92-NBB-1U and 92-NBB-2U Y-Branch Kit Series With Resin 1402FRflyingcowintheskyNo ratings yet

- Arc Insulations BrochureDocument5 pagesArc Insulations BrochureacompositesNo ratings yet

- Adhesive Fit For SpaceDocument10 pagesAdhesive Fit For SpaceChandrikaNo ratings yet

- Maeol Test CentreDocument5 pagesMaeol Test CentreSHYAM SUNDARNo ratings yet

- RO3035 Laminate Data Sheet PDFDocument2 pagesRO3035 Laminate Data Sheet PDFrahul05singhaNo ratings yet

- RT Duroid 6006 6010 Laminate Data SheetDocument2 pagesRT Duroid 6006 6010 Laminate Data SheetSaravanakumar SermarajaNo ratings yet

- Unique Features of The Rogers TMM 10i LaminateDocument4 pagesUnique Features of The Rogers TMM 10i LaminatejackNo ratings yet

- ASHU SHARMA'S PRESENTATION ON UPGRADED INSULATION SYSTEMSDocument125 pagesASHU SHARMA'S PRESENTATION ON UPGRADED INSULATION SYSTEMSpartha070No ratings yet

- 3mtm Viscoelastic Damping Polymers 112 130 PDFDocument9 pages3mtm Viscoelastic Damping Polymers 112 130 PDF1mmahoneyNo ratings yet

- Advanced Composite Materials in Typical Aerospace Applications-LibreDocument10 pagesAdvanced Composite Materials in Typical Aerospace Applications-LibrezaujahaminNo ratings yet

- Standard Geotextiles Iss 06 Group Product Data Sheet 1Document2 pagesStandard Geotextiles Iss 06 Group Product Data Sheet 1Naufal IhsanNo ratings yet

- MISE en OEUVRE Composites Thermoplastiques 2023 COURS 1 2 3Document45 pagesMISE en OEUVRE Composites Thermoplastiques 2023 COURS 1 2 3El gharbaoui AnasNo ratings yet

- SP-Q-1002.NGR-XXXX-006 - Pipe Coating Repair SystemDocument9 pagesSP-Q-1002.NGR-XXXX-006 - Pipe Coating Repair SystemSaravoot MetahNo ratings yet

- Where To Buy Rogers RT Duroid 5880 LaminateDocument5 pagesWhere To Buy Rogers RT Duroid 5880 LaminatejackNo ratings yet

- Silicone Rubber Cold Shrink Connector Insulators 8440 SeriesDocument4 pagesSilicone Rubber Cold Shrink Connector Insulators 8440 SerieshendrabudimanNo ratings yet

- Results:: Single Element Linear Tapered Antipodal Vivaldi AntennaDocument3 pagesResults:: Single Element Linear Tapered Antipodal Vivaldi Antennarahul05singhaNo ratings yet

- Device Attachment Methods and Wirebonding Notes For RT Duroid and RO4000 Series High Frequency Laminates PDFDocument8 pagesDevice Attachment Methods and Wirebonding Notes For RT Duroid and RO4000 Series High Frequency Laminates PDFrahul05singhaNo ratings yet

- Transient Signals in Computers: Ideal WorldDocument12 pagesTransient Signals in Computers: Ideal Worldrahul05singhaNo ratings yet

- RT-Duroid 5880 PropertiesDocument2 pagesRT-Duroid 5880 PropertiesJesus GarciaNo ratings yet

- Estimating Static Fields: Φ = Edz i ∝ r (spherical case), or ∝ ln r (cylindrical case) ∝ E r - - E r ∝Document9 pagesEstimating Static Fields: Φ = Edz i ∝ r (spherical case), or ∝ ln r (cylindrical case) ∝ E r - - E r ∝rahul05singhaNo ratings yet

- RO3035 Laminate Data Sheet PDFDocument2 pagesRO3035 Laminate Data Sheet PDFrahul05singhaNo ratings yet

- TLC PDFDocument2 pagesTLC PDFrahul05singhaNo ratings yet

- Fabrication Guidelines RO4000 Series Laminates PDFDocument4 pagesFabrication Guidelines RO4000 Series Laminates PDFrahul05singhaNo ratings yet

- Properties Guide PDFDocument12 pagesProperties Guide PDFrahul05singhaNo ratings yet

- Properties Guide PDFDocument12 pagesProperties Guide PDFrahul05singhaNo ratings yet

- Copper Foils For High Frequency Circuit Materials PDFDocument8 pagesCopper Foils For High Frequency Circuit Materials PDFrahul05singhaNo ratings yet

- Temperature Rise Estimations in Rogers High Frequency Circuit Boards Carrying Direct or RF CurrentDocument2 pagesTemperature Rise Estimations in Rogers High Frequency Circuit Boards Carrying Direct or RF Currentrahul05singhaNo ratings yet

- High Frequency Laminates RT Duroid 5870 5880 Data SheetDocument2 pagesHigh Frequency Laminates RT Duroid 5870 5880 Data SheetbangntsuNo ratings yet

- ReadmeDocument3 pagesReadmerahul05singhaNo ratings yet

- RT Duroid 6006 6010 Laminate Data SheetDocument2 pagesRT Duroid 6006 6010 Laminate Data SheetAndrés Polochè ArangoNo ratings yet

- National Institute of Technology, Warangal Syllabus For Numerical ElectromagneticsDocument2 pagesNational Institute of Technology, Warangal Syllabus For Numerical Electromagneticsrahul05singhaNo ratings yet

- So Kindly Use Some Good System With RAM Memory Greater Than 8 GB (Better To Use 16 GB RAM)Document1 pageSo Kindly Use Some Good System With RAM Memory Greater Than 8 GB (Better To Use 16 GB RAM)rahul05singhaNo ratings yet

- Ideality Factor For PN Junction DiodeDocument5 pagesIdeality Factor For PN Junction Dioderahul05singhaNo ratings yet

- Application Form 2013 New PDFDocument2 pagesApplication Form 2013 New PDFrahul05singhaNo ratings yet

- JournalDocument1 pageJournalrahul05singhaNo ratings yet

- SFFFFFFFFFDocument1 pageSFFFFFFFFFrahul05singhaNo ratings yet

- SfsDocument1 pageSfsrahul05singhaNo ratings yet

- <!DOCTYPE HTML PUBLIC "-//W3C//DTD HTML 4.01 Transitional//EN" "http://www.w3.org/TR/html4/loose.dtd"> <HTML><HEAD><META HTTP-EQUIV="Content-Type" CONTENT="text/html; charset=iso-8859-1"> <TITLE>ERROR: The requested URL could not be retrieved</TITLE> <STYLE type="text/css"><!--BODY{background-color:#ffffff;font-family:verdana,sans-serif}PRE{font-family:sans-serif}--></STYLE> </HEAD><BODY> <H1>ERROR</H1> <H2>The requested URL could not be retrieved</H2> <HR noshade size="1px"> <P> While trying to process the request: <PRE> TEXT http://www.scribd.com/titlecleaner?title=bfjhbsdjbfsdbfsdhbfsdjabfasf.docx HTTP/1.1 Host: www.scribd.com Proxy-Connection: keep-alive Accept: */* Origin: http://www.scribd.com X-CSRF-Token: ab88e3555f8c557bb734ab1c47eddc7f5b48631f User-Agent: Mozilla/5.0 (Windows NT 6.1; WOW64) AppleWebKit/537.36 (KHTML, like Gecko) Chrome/28.0.1500.95 Safari/537.36 X-Requested-With: XMLHttpRequest Referer: http://www.scribd.com/upload-document?archive_doc=1018Document1 page<!DOCTYPE HTML PUBLIC "-//W3C//DTD HTML 4.01 Transitional//EN" "http://www.w3.org/TR/html4/loose.dtd"> <HTML><HEAD><META HTTP-EQUIV="Content-Type" CONTENT="text/html; charset=iso-8859-1"> <TITLE>ERROR: The requested URL could not be retrieved</TITLE> <STYLE type="text/css"><!--BODY{background-color:#ffffff;font-family:verdana,sans-serif}PRE{font-family:sans-serif}--></STYLE> </HEAD><BODY> <H1>ERROR</H1> <H2>The requested URL could not be retrieved</H2> <HR noshade size="1px"> <P> While trying to process the request: <PRE> TEXT http://www.scribd.com/titlecleaner?title=bfjhbsdjbfsdbfsdhbfsdjabfasf.docx HTTP/1.1 Host: www.scribd.com Proxy-Connection: keep-alive Accept: */* Origin: http://www.scribd.com X-CSRF-Token: ab88e3555f8c557bb734ab1c47eddc7f5b48631f User-Agent: Mozilla/5.0 (Windows NT 6.1; WOW64) AppleWebKit/537.36 (KHTML, like Gecko) Chrome/28.0.1500.95 Safari/537.36 X-Requested-With: XMLHttpRequest Referer: http://www.scribd.com/upload-document?archive_doc=1018rahul05singhaNo ratings yet

- Request Migration and Transfer Certificates from NIT AgartalaDocument2 pagesRequest Migration and Transfer Certificates from NIT Agartalarahul05singhaNo ratings yet

- <!DOCTYPE HTML PUBLIC "-//W3C//DTD HTML 4.01 Transitional//EN" "http://www.w3.org/TR/html4/loose.dtd"> <HTML><HEAD><META HTTP-EQUIV="Content-Type" CONTENT="text/html; charset=iso-8859-1"> <TITLE>ERROR: The requested URL could not be retrieved</TITLE> <STYLE type="text/css"><!--BODY{background-color:#ffffff;font-family:verdana,sans-serif}PRE{font-family:sans-serif}--></STYLE> </HEAD><BODY> <H1>ERROR</H1> <H2>The requested URL could not be retrieved</H2> <HR noshade size="1px"> <P> While trying to process the request: <PRE> TEXT http://www.scribd.com/titlecleaner?title=Version.txt HTTP/1.1 Host: www.scribd.com Proxy-Connection: keep-alive Accept: */* Origin: http://www.scribd.com X-CSRF-Token: 015180eec76aadd927ab9f397ad1400a9ff35156 User-Agent: Mozilla/5.0 (Windows NT 6.1; WOW64) AppleWebKit/537.36 (KHTML, like Gecko) Chrome/28.0.1500.72 Safari/537.36 X-Requested-With: XMLHttpRequest Referer: http://www.scribd.com/upload-document?archive_doc=46240511&metadata=%7B%Document1 page<!DOCTYPE HTML PUBLIC "-//W3C//DTD HTML 4.01 Transitional//EN" "http://www.w3.org/TR/html4/loose.dtd"> <HTML><HEAD><META HTTP-EQUIV="Content-Type" CONTENT="text/html; charset=iso-8859-1"> <TITLE>ERROR: The requested URL could not be retrieved</TITLE> <STYLE type="text/css"><!--BODY{background-color:#ffffff;font-family:verdana,sans-serif}PRE{font-family:sans-serif}--></STYLE> </HEAD><BODY> <H1>ERROR</H1> <H2>The requested URL could not be retrieved</H2> <HR noshade size="1px"> <P> While trying to process the request: <PRE> TEXT http://www.scribd.com/titlecleaner?title=Version.txt HTTP/1.1 Host: www.scribd.com Proxy-Connection: keep-alive Accept: */* Origin: http://www.scribd.com X-CSRF-Token: 015180eec76aadd927ab9f397ad1400a9ff35156 User-Agent: Mozilla/5.0 (Windows NT 6.1; WOW64) AppleWebKit/537.36 (KHTML, like Gecko) Chrome/28.0.1500.72 Safari/537.36 X-Requested-With: XMLHttpRequest Referer: http://www.scribd.com/upload-document?archive_doc=46240511&metadata=%7B%rahul05singhaNo ratings yet

- 2720 (Part-20) PDFDocument5 pages2720 (Part-20) PDFSoundar PachiappanNo ratings yet

- HyperLite Data SheetDocument2 pagesHyperLite Data Sheetbiomedical_com_brNo ratings yet

- Aluminum Alloys For AerospaceDocument2 pagesAluminum Alloys For AerospaceNicholas Featherston100% (1)

- MAT224 User Guide-Aug25-2020Document32 pagesMAT224 User Guide-Aug25-2020YJ WangNo ratings yet

- Act-70ga (Xla-60) TDSDocument1 pageAct-70ga (Xla-60) TDSFairmont Ind Quality DivisionNo ratings yet

- June 2001 Practice DiplomaDocument42 pagesJune 2001 Practice DiplomaElaine LauNo ratings yet

- Purification of Wastewater by Metal Oxide NanoparticlesDocument12 pagesPurification of Wastewater by Metal Oxide NanoparticlesEditor IJTSRDNo ratings yet

- Hojas Msds 2011 Aceite RidgidDocument7 pagesHojas Msds 2011 Aceite RidgidPer CYNo ratings yet

- Nozzle Liners and Dip PipesDocument6 pagesNozzle Liners and Dip PipesHedi Ben MohamedNo ratings yet

- Allen: Final Jee-Main Examination - February, 2021Document7 pagesAllen: Final Jee-Main Examination - February, 2021Anu GraphicsNo ratings yet

- California Bearing RatioDocument5 pagesCalifornia Bearing RatioAbhishek Sharma67% (6)

- Answers & Solutions: For For For For ForDocument22 pagesAnswers & Solutions: For For For For ForYashNo ratings yet

- Lesson Plan ME-220 Engineering MaterialsDocument2 pagesLesson Plan ME-220 Engineering MaterialsHajiasifAliNo ratings yet

- Dalian Hivolt Power System Co. Glass Insulator Test ReportDocument5 pagesDalian Hivolt Power System Co. Glass Insulator Test ReportdiegoyyNo ratings yet

- Datasheet For Carbon Steel A333 Grade 6Document10 pagesDatasheet For Carbon Steel A333 Grade 6Aneesh JoseNo ratings yet

- D and F BlockDocument15 pagesD and F Blockthinkiit100% (1)

- Ion Exchange ProcessDocument10 pagesIon Exchange Process056 Jatin GavelNo ratings yet

- Chapter2 Di Pa TaposDocument13 pagesChapter2 Di Pa TaposDianne VillanuevaNo ratings yet

- Design For Production of PropyleneDocument168 pagesDesign For Production of PropyleneEmiliano Rohwein100% (1)

- Ferodo Motorcycle Catalogue FrenosDocument752 pagesFerodo Motorcycle Catalogue Frenospedro9494No ratings yet

- M&MSDocument2 pagesM&MSASIST MechNo ratings yet

- Gambian Petroleum Products StandardsDocument33 pagesGambian Petroleum Products StandardsSerge KohemunNo ratings yet

- Asignment - Chapter 1 PDFDocument3 pagesAsignment - Chapter 1 PDFDo Cong Minh100% (1)

- SoapsDocument7 pagesSoapsLucita P. CatarajaNo ratings yet

- 05 - Boat Building MaterialsDocument8 pages05 - Boat Building MaterialsPhong TuanNo ratings yet

- RM Pattern UK 208printDocument36 pagesRM Pattern UK 208printMarcelo Alberto AiresNo ratings yet

- Use of SBEDS For Blast Resistant Design in Accordance With UFC 3 340 02Document38 pagesUse of SBEDS For Blast Resistant Design in Accordance With UFC 3 340 02wokeoooNo ratings yet