Professional Documents

Culture Documents

Implementing Field Oriented Control of A Brushless DC Motor

Uploaded by

Phạm Văn TưởngOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Implementing Field Oriented Control of A Brushless DC Motor

Uploaded by

Phạm Văn TưởngCopyright:

Available Formats

Implementing field oriented control of a brushless DC motor

An electric motor is a machine that converts electrical energy into mechanical energy. Electric motors are extremely important to modern-day life and are used in many different applications ranging from vacuum cleaners, dishwashers, computer printers, fax machines, video cassette recorders, machine tools, printing presses, automobiles, subway systems, sewage treatment plants, and waterpumping stations.

Electric motors can be widely classified into 3 types: AC, DC, and universal. As the name suggests, an AC motor runs with AC power and a DC motor runs with DC power. Universal motors can run with both AC and DC power. Examples of AC motors are AC induction motors and squirrel cage motors. They are further classified as single-phase and multi-phase motors. Examples of DC motors include Brushed DC motors, Brushless DC motors (BLDC), and stepper motors.

Existing Motor Control/Driving Techniques: DC motor drive is fairly simple to implement when compared to an AC motor drive. DC motors can be driven directly by means of a voltagefrequency (V/F) relation; i.e., the higher the applied voltage, the higher the frequency or speed. This kind of drive is typically implemented in brushed DC motors.

For AC motor drives and some motor drives where the controller converts the applied DC into AC to drive the motor (like BLDC or PMSM), complex driving algorithms are employed to commutate the coils in a sequence to achieve desired directional rotation. The rate at which the windings are commutated is proportional to the speed with which the motor runs. A wide range of control algorithms are available: Trapezoidal control: Also known as 6-step control, this is the simplest algorithm. For each of the 6 commutation steps, a current path is formed between a pair of windings, leaving the third winding disconnected. This method generates high torque ripple, leading to vibration, noise, and poorer performance compared to other algorithms.

Sinusoidal control: Also known as voltage-over-frequency commutation, sinusoidal control overcomes many of the issues involved with trapezoidal control by supplying smoothly (sinusoidal) varying current to the 3 windings, thus reducing the torque ripple and offering a smooth rotation. However, these time-varying currents are controlled using basic PI regulators, which lead to poor performance at higher speeds.

Field Oriented Control (FOC): Also known as vector control, FOC provides better efficiency at higher speeds than sinusoidal control. It also guarantees optimized efficiency even during transient operation by perfectly maintaining the stator and rotor fluxes. FOC also gives better performance on dynamic load changes when compared to all other techniques.

What is Field Oriented Control? Field Oriented Control is one of the methods used in variable frequency drives or variable speed drives to control the torque (and thus the speed) of three-phase AC electric motors by controlling the current. With FOC, the torque and the flux can be controlled independently. FOC provides faster dynamic response than is required for applications like washing machines. There is no torque ripple and smoother, accurate motor control can be achieved at low and high speeds using FOC.

The torque of an induction motor is at a maximum when the stator and the rotor magnetic fields are orthogonal to each other. In FOC, the stator currents are measured and adjusted so that the angle between the rotor and stator flux is 90 degrees to achieve the maximum torque (as shown in the following figures)

FOC operates on the resultant vector of the three phase currents rather than controlling each phase independently. The control variables of an AC induction motor are made stationary (DC) using mathematical transformations. In a way, FOC tries to control an induction motor by imitating DC motor operation as it deals with stationary parameters.

There are two methods used in FOC. Using Direct FOC, the rotor flux angle is directly computed from flux estimations or measurements. With Indirect FOC, the rotor flux angle is indirectly computed from available speed and slip computations.

The steps involved in sensored FOC are as follows:

Step 1: Two of the three stator phase currents are measured and the third current is determined using Kirchoffs current relation,

Ia + Ib + Ic = 0

Where Ia, Ib, and Ic are phase currents.

Step 2: The three phase currents are converted into a 2-axis coordinate system from the 3-axis system of the stator, using a Clarke transformation,

Where Ia and are the stator currents transformed to the 2-axis coordinate system.

Step 3: The components along the 2-axis of the stator currents are time varying in nature and to track them using traditional PIs is complex. Rather, the stationary reference is rotated based on the rotor position (which is determined with the help of sensors or from back EMF) to a rotary reference where the components along the axis remain constant and traditional PI controllers can be used to counter any error. This rotation is done using a Park transformation,

Where Id and Iq are the in-phase and quadrature phase stator currents from the rotor perspective.

Step 4: Once the vectors have become time invariant, we can compare the corresponding axis vectors with the reference and use a PI controller (see equation below) for each axis to determine the error correction signal. The Id reference controls the rotor magnetizing flux. The Iq reference controls the torque output of the motor.

Step 5: The corresponding outputs of the PI controllers are then passed through an inverse Park and Clarke transformation to convert them back to the 3-phase stator reference.

Step 6:

With the 3-phase reference signals generated, the PWM is modulated using Space Vector Modulation (SVM).

Why FOC? The scalar control or the six-step commutation process, which was traditionally used for controlling BLDC motors based on the hall sensor inputs (or also sensorless), has a dynamic response. It energizes a pair of windings only when the motor reaches the next position, and the commutation is moved to the next step. In the case of a sensored implementation, hall sensors are used to determine the rotor position and the motor is commutated accordingly. The advantage of scalar control is that it is very easy to implement. Some advanced scalar control methods use the back EMF generated from the motor to determine the rotor position. However, this kind of dynamic response is not suitable in applications where the load changes dynamically within a cycle. Only advanced algorithms such as FOC can handle these dynamic load changes.

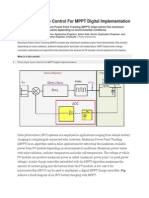

The following example shows how to implement an FOC control algorithm. For this example, the PSoC 3 from Cypress is used. The subsystem is split into several major modules:

The various modules of a Field Oriented Control control algorithm (as implemented using the PSoC 3 from Cypress).

1. Current reconstruction module A two-shunt method is used to reconstruct the currents. With this method, the current from two legs are measured and the third current is reconstructed using Kirchhoffs current law. The PWMs are designed to be center-aligned, and the two current samples are captured at the center of the PWM period, every FOC cycle. Once the samples are taken, the FOC begins the ADC conversion of these samples, and the currents are reconstructed.

1. Clarke and Park transformations

The reconstructed currents are then transformed to 2-phase stator reference and then to 2-phase rotor references using Clarke and Park transforms respectively. Once the transformations are completed, the current in the rotor reference is ready to be regulated for the desired speed and torque.

1. PI regulators

Generic PI controllers with adjustable gain and min-max saturation were implemented to regulate the 2-phase rotor reference current and the speed of the motor.

1. Inverse Park and Clarke transforms

The regulated output is then converted to the 3-phase reference (PWM duty cycle) again, to adjust the speed of the motor, by passing it through Inverse Park and Clarke transforms.

1. SVM (Space Vector Modulation)

The space vector modulation technique is used to generate a sine wave to be fed to the stator coils. Based on the 3-phase reference generated by the inverse Clarke transform, the SVM generates the PWM compare values, which are phase shifted 120 degrees.

Speed and Position sensing

First, the speed is measured by measuring the period between two rising or falling edges of one of the Hall sensor inputs. The period measured is nothing but one electrical period, which is the inverse of the electrical frequency or speed.

By accumulating this electrical speed value over every FOC cycle, the position T is computed. In this example, the FOC cycle is 200S. We use the relationship

The position T can also be calculated using the encoder inputs in place of hall sensor. Instead of accumulating speed, we get the position information directly.

With the kind of efficiency FOC brings enables, significant energy and dollar savings can be made by implementing this control technique to drive the motors which drive the world. And, with the flexibility, resources, and compact architecture provided SoCs such as the PSoC 3, the entire control algorithm inclusive of hardware (other than the driver board) can be implemented in a single chip.

About the Author Meenakshi Sundaram is an Applications Engineer at Cypress. He graduated from the College of Engineering Guindy, Chennai, India, with a major in Electronics and Communication engineering. Currently, he works on PSoC and related applications at Cypress.

You might also like

- 00908a - Using The DsPIC30F For Vector Control of An ACIMDocument76 pages00908a - Using The DsPIC30F For Vector Control of An ACIMJandfor Tansfg ErrottNo ratings yet

- DavidDocument25 pagesDavidgtchsekharNo ratings yet

- Brushed DC Sensorless FeedbackDocument3 pagesBrushed DC Sensorless FeedbackHoon Miew JieNo ratings yet

- Chapter 1 Introduction A. Background: Full Speed, Torque Acceleration Deceleration. Power ConsumptionDocument13 pagesChapter 1 Introduction A. Background: Full Speed, Torque Acceleration Deceleration. Power ConsumptionfirmanNo ratings yet

- Ijaiem 2013 08 25 054Document11 pagesIjaiem 2013 08 25 054International Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Simplified Sensorless Control For BLDC Motor, Using DSP TechnologyDocument12 pagesSimplified Sensorless Control For BLDC Motor, Using DSP Technologymichael.schuhNo ratings yet

- DC Link Approach To Variable-Speed, Sensorless,: Induction Motor DriveDocument5 pagesDC Link Approach To Variable-Speed, Sensorless,: Induction Motor DrivesamirmansourNo ratings yet

- Scalar Speed Control of Induction MotorsDocument21 pagesScalar Speed Control of Induction MotorsRami100% (1)

- Chapter 2 NewDocument11 pagesChapter 2 NewKyaw SoeNo ratings yet

- Field Oriented Control Reduces Motor Size, Cost and Power Consumption in Industrial ApplicationsDocument6 pagesField Oriented Control Reduces Motor Size, Cost and Power Consumption in Industrial ApplicationsnikanikolinaNo ratings yet

- State of The Art of Induction Motor ControlDocument6 pagesState of The Art of Induction Motor Controldusan.papez9216No ratings yet

- Servomotor-synchro- AC Tachometers GuideDocument9 pagesServomotor-synchro- AC Tachometers GuideNarendra SinhaNo ratings yet

- Simplified Sensorless Control For BLDC MDocument12 pagesSimplified Sensorless Control For BLDC MAlg DimasNo ratings yet

- SPWM V/HZ InverterDocument51 pagesSPWM V/HZ InverterLabi BajracharyaNo ratings yet

- Closed Loop Speed Control of 3-Phase Induction MotorDocument27 pagesClosed Loop Speed Control of 3-Phase Induction MotorRajesh kumar yadavNo ratings yet

- Design and Implementation of The Extended Kalman Filter For The Speed and Rotor Position Estimation of Brushless DC MotorDocument9 pagesDesign and Implementation of The Extended Kalman Filter For The Speed and Rotor Position Estimation of Brushless DC MotorSoujanya VinnakotaNo ratings yet

- Electric Drive Q-Bank AnswersDocument22 pagesElectric Drive Q-Bank AnswersGoud SannyNo ratings yet

- Direct Torque Control (DTC) in Induction Motor: M.G.MorshadDocument12 pagesDirect Torque Control (DTC) in Induction Motor: M.G.MorshadAdil FarzandNo ratings yet

- Extended Kalman Filter Based Speed Sensorless PMSM Control with Load ReconstructionDocument16 pagesExtended Kalman Filter Based Speed Sensorless PMSM Control with Load ReconstructionSohibul HajahNo ratings yet

- Sensorless FOC of ACIDocument43 pagesSensorless FOC of ACIdimitaringNo ratings yet

- Direct Torque Control InductionDocument9 pagesDirect Torque Control InductiononafetsNo ratings yet

- Speed Control of Three Phase Induction Motor Using Arduino and V/F TechniqueDocument10 pagesSpeed Control of Three Phase Induction Motor Using Arduino and V/F TechniqueAnonymous oyUAtpKNo ratings yet

- Vsi Fed 3ph ImDocument13 pagesVsi Fed 3ph ImWisemin LinsNo ratings yet

- Permanent Magnet Synchronous Motor ControlDocument7 pagesPermanent Magnet Synchronous Motor ControlAmjad JatoiNo ratings yet

- National Institute of Technology, Rourkela: Department of Electrical EngineeringDocument11 pagesNational Institute of Technology, Rourkela: Department of Electrical Engineeringvineeth kumarNo ratings yet

- Classical Control Methods for Power ConvertersDocument9 pagesClassical Control Methods for Power ConvertersEmmeth ArdienteNo ratings yet

- Implementing Embedded Speed Control For Brushless DC Motors Part 6Document7 pagesImplementing Embedded Speed Control For Brushless DC Motors Part 6charliesteven100% (1)

- Control system force-voltage analogyDocument18 pagesControl system force-voltage analogyAjeet Kumar shuklaNo ratings yet

- Rotor Flux Oriented Control of Induction MachinesDocument32 pagesRotor Flux Oriented Control of Induction MachinesGuru PrasadNo ratings yet

- 03 Listrik Statis 3Document11 pages03 Listrik Statis 3goodayNo ratings yet

- SFC OperationDocument10 pagesSFC OperationKelvin LiewNo ratings yet

- Induction Motor Control by Vector Control Method.: Miss. Bhagyashree Thool, Miss. Kalyani C. WakhareDocument6 pagesInduction Motor Control by Vector Control Method.: Miss. Bhagyashree Thool, Miss. Kalyani C. WakhareASumeethKumarNo ratings yet

- Position Control Performance Improvement of DTC-SVM For An Induction Motor: Application To Photovoltaic Panel PositionDocument14 pagesPosition Control Performance Improvement of DTC-SVM For An Induction Motor: Application To Photovoltaic Panel PositionأسامةبوعزيزNo ratings yet

- Speed Control of Three Phase Induction MotorDocument48 pagesSpeed Control of Three Phase Induction MotorChancy Dash100% (3)

- Simulation and Implementation of Current Control of Brushless DC Motor Based On A Common DC SignalDocument8 pagesSimulation and Implementation of Current Control of Brushless DC Motor Based On A Common DC SignalVally ZazaNo ratings yet

- Speed control of 3-phase IM using V/Hz for auto appsDocument6 pagesSpeed control of 3-phase IM using V/Hz for auto appsPrabhat KarnNo ratings yet

- A Variable-Speed, Sensorless, Induction Motor Drive Using DC Link MeasurementsDocument6 pagesA Variable-Speed, Sensorless, Induction Motor Drive Using DC Link Measurementsgowtam_raviNo ratings yet

- Permanent Magnet Synchronous Motor ControlDocument3 pagesPermanent Magnet Synchronous Motor ControlMarcin KowalskiNo ratings yet

- DC Motor Control Using Arduino: 1) IntroductionDocument10 pagesDC Motor Control Using Arduino: 1) IntroductionSoeAyeNo ratings yet

- Induction Motor.Document6 pagesInduction Motor.Kiran KumarNo ratings yet

- Current Control of Brushless DC Motor Based On A Common DC Signal For Space Operated VehicleDocument7 pagesCurrent Control of Brushless DC Motor Based On A Common DC Signal For Space Operated VehicleArif HassanNo ratings yet

- AVR194 Brushless DC Motor Control Using ATMega32M1Document16 pagesAVR194 Brushless DC Motor Control Using ATMega32M1u776287No ratings yet

- Project Synopsys1Document6 pagesProject Synopsys1jvnsr005No ratings yet

- Design and Implementation of IGBT Based Single Phase AC Drive Using PIC 18F452Document4 pagesDesign and Implementation of IGBT Based Single Phase AC Drive Using PIC 18F452lajosmol100% (1)

- Sensorbased Control of Three Phase Brushless DC Motor PDFDocument8 pagesSensorbased Control of Three Phase Brushless DC Motor PDFmike_helplineNo ratings yet

- New Sensor LessDocument10 pagesNew Sensor LessAbhishek AgarwalNo ratings yet

- 1405 6815 PDFDocument7 pages1405 6815 PDFPrashanthSamaNo ratings yet

- PROBLEM STATEMENT FOR TEMPERATURE CONTROL OF POLYHOUSESDocument36 pagesPROBLEM STATEMENT FOR TEMPERATURE CONTROL OF POLYHOUSESAbhishek SinghNo ratings yet

- Lecture-16-Direct Torque Control PDFDocument33 pagesLecture-16-Direct Torque Control PDFKriban Govender100% (1)

- Motor Commutation - FOC vs. FECDocument5 pagesMotor Commutation - FOC vs. FECKhang Trần VỹNo ratings yet

- EKF Applied To BLDCDocument9 pagesEKF Applied To BLDCUma SathyadevanNo ratings yet

- CNC MCU Act Sys and MCU OrganisationDocument6 pagesCNC MCU Act Sys and MCU OrganisationsaitejaNo ratings yet

- Unit - V Synchronous Drives: 1 Variable Frequency ControlDocument22 pagesUnit - V Synchronous Drives: 1 Variable Frequency ControlHaripriya PalemNo ratings yet

- Atmel 2596 Sensor Based Control of Three Phase Brushless DC Motors Application Note Avr443Document9 pagesAtmel 2596 Sensor Based Control of Three Phase Brushless DC Motors Application Note Avr443Bogdan CosteaNo ratings yet

- Speed Control of Induction Motor Using FOCDocument5 pagesSpeed Control of Induction Motor Using FOCCharlotte ReynoldsNo ratings yet

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetFrom EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetNo ratings yet

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetFrom EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetRating: 2 out of 5 stars2/5 (1)

- Some Power Electronics Case Studies Using Matlab Simpowersystem BlocksetFrom EverandSome Power Electronics Case Studies Using Matlab Simpowersystem BlocksetNo ratings yet

- Simulation of Some Power System, Control System and Power Electronics Case Studies Using Matlab and PowerWorld SimulatorFrom EverandSimulation of Some Power System, Control System and Power Electronics Case Studies Using Matlab and PowerWorld SimulatorNo ratings yet

- Power Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlFrom EverandPower Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlRating: 5 out of 5 stars5/5 (1)

- Ect129 Uninterruptible Static Power Supplies and The Protection of PersonsDocument44 pagesEct129 Uninterruptible Static Power Supplies and The Protection of PersonsMarko VujicaNo ratings yet

- Uhc AwatersDocument60 pagesUhc Awaterskammu9713No ratings yet

- Ethernet IP Texas InstrumentsDocument6 pagesEthernet IP Texas InstrumentsFranzKafkaNo ratings yet

- Evaluation and DSP Based Implementation of PWM Approaches For SinDocument90 pagesEvaluation and DSP Based Implementation of PWM Approaches For SinPhạm Văn TưởngNo ratings yet

- Direct Duty Cycle Control For MPPT Digital ImplementationDocument5 pagesDirect Duty Cycle Control For MPPT Digital ImplementationPhạm Văn TưởngNo ratings yet

- All About HarmonicsDocument240 pagesAll About HarmonicsKhushal KharadeNo ratings yet

- Calculation of Short-Circuit CurrentsDocument35 pagesCalculation of Short-Circuit CurrentsdaodoquangNo ratings yet

- Control Intelligence Improves Renewable Energy EfficiencyDocument7 pagesControl Intelligence Improves Renewable Energy EfficiencyPhạm Văn TưởngNo ratings yet

- Disturbance Observers For Rigid Mechanical Systems - Equivalence, Stability, and DesignDocument10 pagesDisturbance Observers For Rigid Mechanical Systems - Equivalence, Stability, and DesignPhạm Văn TưởngNo ratings yet

- AN296110 Current Sensing For Renewable EnergyDocument4 pagesAN296110 Current Sensing For Renewable EnergyPhạm Văn TưởngNo ratings yet

- C Programming For Embedded System Applications PDFDocument54 pagesC Programming For Embedded System Applications PDFWendo David PesaNo ratings yet

- The Adventures of Huckleberry Finn by Mark TwainDocument289 pagesThe Adventures of Huckleberry Finn by Mark TwainBooks100% (5)

- Tutorial Digital Control Loop DesignDocument17 pagesTutorial Digital Control Loop DesignPhạm Văn TưởngNo ratings yet

- 309 An 09 Solar Panel PowerDocument3 pages309 An 09 Solar Panel PowerJoel Medina GuttiNo ratings yet

- Slaa 075Document19 pagesSlaa 075Manidhar ParvatamNo ratings yet

- Current-Transformer Phase-Shift Compensation and CalibrationDocument7 pagesCurrent-Transformer Phase-Shift Compensation and CalibrationrsrtnjNo ratings yet

- Study of A Non-Isolated Bidirectional DC - DC Converter: C.-C. Lin, L.-S. Yang, G.W. WuDocument8 pagesStudy of A Non-Isolated Bidirectional DC - DC Converter: C.-C. Lin, L.-S. Yang, G.W. WuPhạm Văn Tưởng100% (1)

- TW Exams Ielts How To Prepare Ielts TipsDocument2 pagesTW Exams Ielts How To Prepare Ielts TipsHoda ElhadaryNo ratings yet

- IEEE Transactions On Power Systems Volume 10 Issue 2 1995 (Doi 10.1109/59.387938) Larsen, E.V. Sanchez-Gasca, J.J. Chow, J.H. - Concepts For Design of FACTS Controllers To Damp Power SwingsDocument9 pagesIEEE Transactions On Power Systems Volume 10 Issue 2 1995 (Doi 10.1109/59.387938) Larsen, E.V. Sanchez-Gasca, J.J. Chow, J.H. - Concepts For Design of FACTS Controllers To Damp Power SwingsPhạm Văn TưởngNo ratings yet

- An Improved PV Battery Charger For Low Cost Low PowerDocument4 pagesAn Improved PV Battery Charger For Low Cost Low PowerPhạm Văn TưởngNo ratings yet

- Space Vector Modulation An IntroductionDocument10 pagesSpace Vector Modulation An IntroductionJohan LinderNo ratings yet

- A Novel Dynamic Var CompensatorDocument4 pagesA Novel Dynamic Var CompensatorPhạm Văn TưởngNo ratings yet

- Uninterruptible Power Supply Multiloop Control Employing Digital Predictive Voltage and Current RegulatorsDocument9 pagesUninterruptible Power Supply Multiloop Control Employing Digital Predictive Voltage and Current RegulatorsPhạm Văn TưởngNo ratings yet

- IEEE Transactions On Reliability Volume 43 Issue 1 1994 (Doi 10.1109/24.285133) Sallam, A.A. Desouky, M. Desouky, H. - Shunt Capacitor Effect On Electrical Distribution System ReliabilityDocument7 pagesIEEE Transactions On Reliability Volume 43 Issue 1 1994 (Doi 10.1109/24.285133) Sallam, A.A. Desouky, M. Desouky, H. - Shunt Capacitor Effect On Electrical Distribution System ReliabilityPhạm Văn TưởngNo ratings yet

- 1.A New Battery Model For Use With Battery Energy Storage Systems and Electric Vehicles Power SystemsDocument6 pages1.A New Battery Model For Use With Battery Energy Storage Systems and Electric Vehicles Power SystemschethanNo ratings yet

- Informatics in Control Automation and RoboticsDocument5 pagesInformatics in Control Automation and RoboticsPhạm Văn TưởngNo ratings yet

- NHSPE ReadingDocument5 pagesNHSPE ReadingMohamed HanafiNo ratings yet

- Phan Tich 1 Bai Task 2 by Ngoc BachDocument4 pagesPhan Tich 1 Bai Task 2 by Ngoc BachPhạm Văn Tưởng100% (1)

- (Matsui) Sensorless PM Brushless DC Motor DrivesDocument9 pages(Matsui) Sensorless PM Brushless DC Motor DrivesPhạm Văn TưởngNo ratings yet

- Inverters For Single-Phase Grid Connected Photovoltaic Systems - An OverviewDocument6 pagesInverters For Single-Phase Grid Connected Photovoltaic Systems - An OverviewPhạm Văn TưởngNo ratings yet