Professional Documents

Culture Documents

10 - Offshore Deck Salvage System

Uploaded by

Ahmad Fikri0 ratings0% found this document useful (0 votes)

26 views2 pagesA new heavy lift system designed, built, and operated by Versabar was deployed in 2007. The Bottom Feeder was specifically developed for the lifting of structures as single units from the seabed. To date only six hurricane toppled platforms have been recovered in one piece, all by the Bottom feeder.

Original Description:

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentA new heavy lift system designed, built, and operated by Versabar was deployed in 2007. The Bottom Feeder was specifically developed for the lifting of structures as single units from the seabed. To date only six hurricane toppled platforms have been recovered in one piece, all by the Bottom feeder.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

26 views2 pages10 - Offshore Deck Salvage System

Uploaded by

Ahmad FikriA new heavy lift system designed, built, and operated by Versabar was deployed in 2007. The Bottom Feeder was specifically developed for the lifting of structures as single units from the seabed. To date only six hurricane toppled platforms have been recovered in one piece, all by the Bottom feeder.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

OFFSHORE DECK SALVAGE SYSTEM

2008 Nova Award Nomination 10

Versabar Bottom Feeder

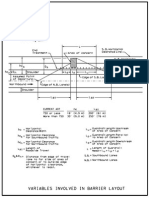

Deployed for the first time in June of 2007, a new heavy lift system designed, built, and operated by Versabar Inc. completed the task of retrieving six hurricane toppled platform topsides from the seabed. Each of the eight-leg topsides was retrieved as single lifts with peak lift weights of up to 1,600 tons. The decks were set onto cargo barges and scrapped onshore. This approach compared to small-piece removal, results in reduced personnel exposure offshore and is extremely cost-effective. Why it is innovative The pin-in-pin hinging of opposite ends of each of the two triangular trusses allows articulation of the barges in the X and Y directions. This feature prevents a quartering sea state from racking the lift system, effectively allowing the deployment and use of a gantry lift system in an offshore environment. The Bottom Feeder consists of two rigid space frame truss structures spanning from hinged supports on the centerlines of two regular deck transport barges, of 250ft x 72ft in size. The unique pattern of support hinges decouples the heave, pitch and roll motions of the support barges from the lift structures. The structural design of the system included for dynamic loads generated due to wave action that can be expected when lifting structures both under water and through the water surface allowing the system to remain completely stable under transit and lifting conditions. What has the Bottom Feeder changed - To date only six hurricane toppled platforms have been recovered in one piece, all by the Versabar Bottom Feeder. The Bottom Feeder answered the challenges of traditional salvage removal - safety of personnel and schedule. Traditional methods require cutting of the platform into smaller pieces, diver hook-up of lift equipment and single point lifts to the surface, all of which expose personnel to high levels of risk, in addition, prolonged periods of work with a large spread of marine assets. The Bottom Feeder was specifically developed for the lifting of structures as single units from the seabed in water depths of up to 400 feet and for a maximum safe lifting capacity of 4,000 short tons. Lifting is completed via the application of four independent lift blocks with a rated capacity of 1,000tons each. The use of four independent lift blocks with 45 feet by 80 feet spacing provides significant flexibility to efficiently distribute lift loads into the structure, accommodate structures that are significantly out of level at the time of lift, as well unknown lift weight and center of gravity location. The design of the system lift rigging allows diver less hook-up of the platform. Where and when did it originate In response to the large number of toppled platforms after hurricanes Katrina and Rita, marine assets where in short supply and Gulf of Mexico oil operators where searching for new technology to improve salvage. Due to Versabars vast experience with engineering offshore heavy lifts, an operator approached Versabar in the spring of 2006 with the challenge of platform recovery. Versabar engineered, built and operates the Bottom Feeder with its first platform recovery June 12th, 2007 with a total of four platform recoveries for that operator during the next 18 days. Two additional platform recoveries were completed for a second operator during the summer of 2007. Current campaign of work for 2008 includes multiple platform recoveries for several Gulf of Mexico operators.

The Power of Engineering Delivered www.vbar.com

Construction Innovation Forum 6494 Latcha Road, Walbridge, OH 43465 419-725-3108 Fax: 725-3079 E-mail: info@CIF.org www.CIF.org

OFFSHORE DECK SALVAGE SYSTEM

2008 Nova Award Nomination 10

Construction Innovation Forum 6494 Latcha Road, Walbridge, OH 43465 419-725-3108 Fax: 725-3079 E-mail: info@CIF.org www.CIF.org

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Managing operations service problemsDocument2 pagesManaging operations service problemsJoel Christian Mascariña0% (1)

- Guard RailDocument1 pageGuard RailAhmad FikriNo ratings yet

- Major Hydroelectric Plants in IndonesiaDocument7 pagesMajor Hydroelectric Plants in IndonesiaAhmad FikriNo ratings yet

- Standards For Testing Evaluating and Locating Roadside SafetyDocument60 pagesStandards For Testing Evaluating and Locating Roadside SafetyAhmad FikriNo ratings yet

- Numerical Analysis On Vehicle Collision To FPC Guard FenceDocument8 pagesNumerical Analysis On Vehicle Collision To FPC Guard FenceAhmad FikriNo ratings yet

- 04 - Tunnel Roof Casting MachinesDocument2 pages04 - Tunnel Roof Casting MachinesAhmad FikriNo ratings yet

- Rasio Besi - Beton PCUDocument6 pagesRasio Besi - Beton PCUAhmad FikriNo ratings yet

- 1940 El Centro Earthquake Acceleration Time HistoryDocument14 pages1940 El Centro Earthquake Acceleration Time HistoryAhmad FikriNo ratings yet

- General Comparisson As D VSL RFDDocument107 pagesGeneral Comparisson As D VSL RFDReza PrasetyoNo ratings yet

- SINGGAR MULIA ENGINEERING HORIZONTAL 2-PHASE SEPARATORDocument3 pagesSINGGAR MULIA ENGINEERING HORIZONTAL 2-PHASE SEPARATORElias EliasNo ratings yet

- Lead Magnet 43 Foolproof Strategies To Get More Leads, Win A Ton of New Customers and Double Your Profits in Record Time... (RDocument189 pagesLead Magnet 43 Foolproof Strategies To Get More Leads, Win A Ton of New Customers and Double Your Profits in Record Time... (RluizdasilvaazevedoNo ratings yet

- Factors Affecting Employee Turnover and Job Satisfaction A Case Study of Amari Hotels and Resorts Boondarig Ronra and Assoc. Prof. Manat ChaisawatDocument26 pagesFactors Affecting Employee Turnover and Job Satisfaction A Case Study of Amari Hotels and Resorts Boondarig Ronra and Assoc. Prof. Manat ChaisawathumeragillNo ratings yet

- VB 2Document11 pagesVB 2Sudhir IkkeNo ratings yet

- Career Guidance Activity Sheet For Grade IiDocument5 pagesCareer Guidance Activity Sheet For Grade IiJayson Escoto100% (1)

- 59 - 1006 - CTP-Final - 20200718 PDFDocument11 pages59 - 1006 - CTP-Final - 20200718 PDFshubh.icai0090No ratings yet

- Green Solvents For Chemistry - William M NelsonDocument401 pagesGreen Solvents For Chemistry - William M NelsonPhuong Tran100% (4)

- 01 NumberSystemsDocument49 pages01 NumberSystemsSasankNo ratings yet

- Iqvia PDFDocument1 pageIqvia PDFSaksham DabasNo ratings yet

- Successful Organizational Change FactorsDocument13 pagesSuccessful Organizational Change FactorsKenneth WhitfieldNo ratings yet

- Rust Experimental v2017 DevBlog 179 x64 #KnightsTableDocument2 pagesRust Experimental v2017 DevBlog 179 x64 #KnightsTableIngrutinNo ratings yet

- The Non Technical Part: Sample Interview Questions For Network EngineersDocument5 pagesThe Non Technical Part: Sample Interview Questions For Network EngineersblablaNo ratings yet

- Fluke - Dry Well CalibratorDocument24 pagesFluke - Dry Well CalibratorEdy WijayaNo ratings yet

- Micro Controller AbstractDocument6 pagesMicro Controller AbstractryacetNo ratings yet

- Ridge Regression: A Concise GuideDocument132 pagesRidge Regression: A Concise GuideprinceNo ratings yet

- Hindustan Coca ColaDocument63 pagesHindustan Coca ColaAksMastNo ratings yet

- Bolsas Transfer FKDocument7 pagesBolsas Transfer FKBelèn Caridad Nelly Pajuelo YaipènNo ratings yet

- Exp19 Excel Ch08 HOEAssessment Robert's Flooring InstructionsDocument1 pageExp19 Excel Ch08 HOEAssessment Robert's Flooring InstructionsMuhammad ArslanNo ratings yet

- Domestic Water Consumption in ChennaiDocument18 pagesDomestic Water Consumption in Chennaimaaz0% (1)

- Concept, Types, Characteristics and ClassificationsDocument6 pagesConcept, Types, Characteristics and ClassificationsCJ FaNo ratings yet

- FilesDocument12 pagesFilesRajesh TuticorinNo ratings yet

- The Earthing of Zenner BarrierDocument4 pagesThe Earthing of Zenner BarrierFatholla SalehiNo ratings yet

- Determining Total Impulse and Specific Impulse From Static Test DataDocument4 pagesDetermining Total Impulse and Specific Impulse From Static Test Datajai_selvaNo ratings yet

- AP Statistics - 2014-2015 Semester 1 Test 3Document4 pagesAP Statistics - 2014-2015 Semester 1 Test 3Camden BickelNo ratings yet

- Letter of Recommendation For Nicolas Hallett From Big Ten Network's Casey Peterson.Document1 pageLetter of Recommendation For Nicolas Hallett From Big Ten Network's Casey Peterson.Nic HallettNo ratings yet

- Personal InsuranceDocument11 pagesPersonal InsuranceSumit Kumar SharmaNo ratings yet

- Maintenance: ASU-600 SeriesDocument54 pagesMaintenance: ASU-600 SeriesMichael Maluenda Castillo100% (2)

- Admission Checklist (Pre-) Master September 2021Document7 pagesAdmission Checklist (Pre-) Master September 2021Máté HirschNo ratings yet

- Coa - Ofx-8040a (H078K5G018)Document2 pagesCoa - Ofx-8040a (H078K5G018)Jaleel AhmedNo ratings yet