Professional Documents

Culture Documents

Banana Peel As Removal Agent For Sulfide From Sulfur Springs Water PDF

Uploaded by

Alexander DeckerOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Banana Peel As Removal Agent For Sulfide From Sulfur Springs Water PDF

Uploaded by

Alexander DeckerCopyright:

Available Formats

Civil and Environmental Research ISSN 2224-5790 (Paper) ISSN 2225-0514 (Online) Vol.3, No.

10, 2013

www.iiste.org

Banana Peel as Removal Agent for Sulfide from Sulfur Springs Water

Tahseen Zaidan Department of Chemistry, College of Science University of Anbar , Ramadi, Iraq Email: taz711@yahoo.com Emad Salah (Corresponding author) Department of Applied Geology, College of Science, University of Anbar , Ramadi, Iraq E-mail: ealheety@yahoo.com Mohammad Waheed Department of Chemistry, College of Science University of Anbar , Ramadi, Iraq Email:Medo_iraqi_1987@yahoo.com Abstract Banana peel which consider as fruit waste has been tested for the removal of total sulfide from spring water in Heet area, Iraq. The chemical composition of peels was investigated. The results show that the composition consists of Sodium ,Potassium, Calcium ,Manganese and Phosphate and concentrations of these contents were 18.2mg/g, 62mg/g,15.4mg/g ,48mg/g and 0.37 mg/g , respectively. The alkalinity of peels was 5.2 mg/g and the moisture content was 5.8 % . The treatment efficiency was studied as a function of the retention time and concentration of sulfide ion .The maximum sorption for sulfide was found to be 97% and it was nearly effective as activated carbon. As a result of the removal process , the concentrations of some common anions ,cations and heavy metals (Mg+2,Ca+2,Na+,So4-2,cl-Po4-2, Cr, Fe, Ni, Cu and Zn) decreased ,the concentrations of K+ and Mn increased . Increasing of concentrations of K+ and Mn is attributed to their high content in the banana peels. A slight increase in pH of the treated water (6.5 7.5). This study revealed that the treatment of water using the banana peel is most effective for removal of hydrogen sulfide from sulfur spring water. Keywords: Sulfide removal, banana peel, sorbent, peel mineral content ,sulfur, spring water 1. Introduction Hydrogen sulfide contents in the environment, generally, have been studied due to its high toxicity, effect on health, it was also a common cause of industrial injury such direct corrosion of metals and indirect corrosion of metals and concrete ( McCrty 1974). Many methods were tabulated for sulfide contamination control ,the common methods for sulfide removal are physiochemical processes, which involve direct aeration or adding of oxidizing agent ,precipitating agent, and masking agent (Alleala and Ahmed 1984). The removal efficiency of a lab-scale biofilter for eliminating hydrogen sulfide has been modeled. The results demonstrate that is possible to totally remove the hydrogen sulfide from the biogas ( Ibarra-Berstegi et al. 2007). Hydrogen sulfide was removed by means of chemical adsorption in an iron-chelated solution catalyzed by Fe/EDTA, which converts Hydrogen sulfide into elemental sulfur (Horikawa et al. 2004). New publication describes a successful treatment of Hydrogen sulfide by applying bio filtration to hot gas effluent at high temperatures ( 700 C ) using a microbial community obtained from a hot spring ( Datta et al. 2007).The solid ferrites sludge can be used to remove hydrogen sulfide from gas stream, each gram of ferrite was able to retain 0.274 gm H2S (Barrado et al. 2001), however these methods are associated several disadvantages. Sorption using plant waste material (if it is available) is impending alternative to chemical methods for ions removal from water system ( Meunier, et al. 2003; Pangnaneli, et al. 2003).These methods were reported in literature as low cost methods for water treatment. Removal of As(III) and As(V) from aqueous solutions by waste material and Crab shells ( Rahman et al. 2007; Hui Niue, et al. 2007), cupper (II) by fly ash ( Kpanday, et al. 1985), Lead(II) by sorption on peat (Ho and Mckay 1999; Ho et al. 2001), removal and recovery of Cadmium(II) by low coast adsorbent (Periasamy and Namasivayam 1984), removal of phenol by fly ash ( Hairbabu, et al. 1993) and Chlophenols by bituminous shale (Tutem, et al. 1998). Heavy Metals (Cu, Pb and Zn ) had been also removed from the aqueous Solution by activated Carbons prepared from Coconut Shell and Seed Shell of the Palm Tree that activated chemically by phosphoric acid (Gueu, et al. 2006). Memon et al. (2008) used banana peels for removal Cr(III) from industrial waste water. Ashraf et al. (2011) applied banana peels for removal heavy metals (Pb, Cu, Zn and Ni). Banana peels were used for extraction of copper and lead from river water and preconcentration of metal ions ( Castro et al. 2011). The banana peel based biosorbent was evaluated for adsorptive removal of CU(II) from water and its desorption capability ( Hossain et al. 2012a). Banana peels were used by Hossain et al. (2012b) as bioadsorbent for removal of copper from water. Most of the ground water sources in Heet city (Fig.1) are springs water of high sulfide concentration. The existence of Hydrogen sulfide in the ground water of Heet and surrounding areas is attributed to the oil field

27

Civil and Environmental Research ISSN 2224-5790 (Paper) ISSN 2225-0514 (Online) Vol.3, No.10, 2013

www.iiste.org

water, where some brine water associated with petroleum, may contain several hundred mg/L of dissolved Hydrogen sulfide (Him 1970) , due to anaerobic oxidation reduction processes (Hussien and Gharbie 2010). The main aim of this research was to use banana peels as bioadsorbent for removal sulfide from springs water in Heet city, Iraq. 2. Material and Methods 2.1. Chemicals All chemicals used in the present study were of analytical grade and were purchased from Fluka, BDH. A stock standard solution of sulfide ion was prepared by dissolving appropriate amounts of sodium sulfide, sulfide antioxidant buffer was used too. 2.2. Sampling The coordinate of the ground water spring that represent the ground water in the area were determined with GPS (33 38 21.6) N and (042 48 53.5) E, (Figure .1). Water samples were collected in polyethylene washed with diluted Nitric acid and kept in cool place for testing. 2.3. Preparation of sorbent For Banana peel preparation, Slices of banana peels were cut into small pieces and were washed thoroughly with de-ionized water to remove physically adsorbed contamination, and then oven dried at 1000Cfor a period of 8 hours. The dried peels was ground and sieved through 4000 m sieve ( Memon, ea al. 2008) and kept in desiccators for further study. In one liter flask a suitable amount of the deride peel was conditioned by mixing with distilled water, then water decanted and the solution was transferred on small batches to a (18 cm) separation column. Another separation column was prepared using commercial activated carbon for comparison study. 2.4. Sorption behavior of water on banana peel separation column The sorption behavior of sulfide on the banana peel surface was investigated using sulfide standard solutions (5, 25, 50,100,250) mg/l .The standard solutions has been passed at flow rate 2 ml/ minutes on banana peel column and on an activated carbon column for comparison study, Table 1. The sorption of sulfide as function of time was investigated at room temperature using 50 gm adsorbent and 1000 ml adsorbate solution. The standard sulfide solution (250) mg/l was passed at flow rate 2 ml/ minutes through a column of banana peel and on an activated carbon column .The eluent was examined for sulfide concentration directly and after 15, 30, 60,120 minutes retention time. An analytical study has been investigated to check banana peels tendency for sulfide removal from fresh spring waters in Heet city. The study involves the interference effect of common anions and cations under the condition of study. Fresh Spring water sample was passed through the separation columns (banana peel column and activated carbon column) and the eluted water was collected and tested for pH, Ca, Mg, Na & K by flame photometric methods, Chloride ion with Fe (III) thiocyanate method at 455 nm, sulfate ion with Barium -sulfate turbidity method at 450 nm, sulfide at 660 nm, phosphate with Vanadomolymbdate method at 470 nm (Mendham 1989). Phoenix_986 Atomic absorption spectrophotometer (AAS) was used to determine the concentration of metals studied in Banana peel and spring water samples (Mn, Fe, Cr, Ni, Zn and Cu). The results compared with that of untreated water. 2.5.Chemical analysis Slices of the dried banana peels (700C for 72 hours) were crushed, and passed through mesh sieve 120 mesh sieve (125 m) and 0.5 gm was analyzed for chemical constituent following the procedure of kjeldahel digestion with H2SO4 ,HCLO4 , HNO3 (10:4:1), ( Jakson 1958). 3. Results and conclusion Generally different techniques have been used for hydrogen sulfide gas removal from spring waters. This study aims at finding new methods to treat the water of sulfur spring to get rid of the major polluting materials for public use. The treatment process depends on using banana's peels as low coast sorbent for sulfide from the spring water in Heet city. The spring water is rich with chloride, sulfide, sodium, calcium, tar and erupting stifling gases (Hussien and Gharbie 2010) The treatment process depends on using banana peels as low coast sorbent for sulfide. The chemical composition, phosphate, alkalinity and moisture content of the banana peels were investigated. The concentrations (mg/g) of sodium, Potassium, calcium, manganese, were found to be 18.2,62, 15.4 and 48 respectively. Phosphate concentration was 0.37 mg/g, the alkalinity was 5.2 mg/g and moisture content was 5.8 %. The banana peel has the highest content of Potassium and this agreed with literatures (Anhwange et al. 2009), Table 2. The concentration of hydrogen sulfide gas in the water samples of the spring exceeds the cutoff concentration ( Laboutka 1974). The existence of hydrogen sulfide in the ground water of the studied area (Heet) is attributed to

28

Civil and Environmental Research ISSN 2224-5790 (Paper) ISSN 2225-0514 (Online) Vol.3, No.10, 2013

www.iiste.org

the oil field water where some brine water associated with petroleum, may contain several hundred mg\l of dissolved hydrogen sulfide (Him 1970). The main source of hydrogen sulfide gas which has distinct smell and poisonous effect on man health, is reduction of sulfate by sulfate reducing bacteria according to the following reaction ( Zobell 1963). CaSO4 + CnH2n+2CaS + CO2 + 2H2O CaS + CO2+ 2H2O H2S + Ca(HCO3)2 3.1. Mechanism of sorption This study was conducted to assess the efficiency of sulfide elimination and its relation with the sulfide concentration and the time of contact. The sorption of sulfide as function of time was investigated at room temperature. A series of sulfide standard solution (5, 25, and 50,100,250) mg/l has been passed at flow rate 2 ml/ minutes on banana peel column and on activated carbon column for sulfide removal, Table 1. The results showed the high efficiency of banana peel column for sulfide sorption (94.4%-98.5%) at low sulfide concentration (5-25 mg/l) and (99.5% -99.8) at high sulfide concentration ( 100-250 mg/l). The study of sorption mechanism by panama peels indicates the similarity to activated carbon sorption mechanism. The recent literatures about the thermodynamics of sorption by banana peels shows that the positive value of H indicated the endothermic sorption process while the negative value of G indicated spontaneous nature ( Memon et al. 2008) and the energy value obtained from the isotherms indicated that the sorption of physical nature (Memon et al. 2008). The banana peels has large surface area (measured by BET method) about 13 m2 /g ( Memon et al., 2008). gives good evidence that there are large number of absorption site have the ability for removal of sulfide ion from aqueous solution at room temperature over a wide range of sulfide concentration (0-250 mg\l).The banana peels has approximately the same efficiency of sulfide sorption comparing with commercial activated carbon. A standard sulfide solution (250) mg/l was passed through a column of banana peel and the eluent was examined for sulfide concentration directly and after 15, 30, 60,120 minutes retention time. The sorption was very fast and the maximum sulfide removal 99.79% was achieved after 15 minutes retention time with very little increase in sorption at 2 hours (99.87%). The results showed that the removal process was affected by time of contact and the result was compared with activated carbon.(99.89% at 15 minutes and 99.95% after 2 hours, Table 3. 3.2. Multiple use of banana peel In order to check the reusability of Banana Peel as economical sorbent for sulfide , it has been subjected to several loading experiments. The eluent spring water was tested for sulfide concentration directly ,and after 1,2,3,4,5 liter volume of the spring water. The capacity of the sorbent was found to be constant with variation of 1-1.8% after 3 times of one liter volume of the spring water repeated use. 3.3. Interferences effect An analytical study has been investigated to check banana peels tendency for sulfide removal from fresh spring waters in Heet city. The study involves the interference effect of common anions and cations and heavy metals under the condition of study. Fresh Spring water sample was passed through the separation columns (banana peel column and activated carbon column) and the eluted water was collected and tested for, Ca, Mg, Na & K , Chloride ion , sulfate ion, sulfide, phosphate, in addition to heavy metals (Cr, Mn, Fe, Ni, Cu and Zn). The study has shown excellent results in spring water treatment and the treatment results has explored the suitability of banana peel for sulfide removal from water spring in the presence of different cations and anions in high concentration. Sulfide content of main sulfur spring in Heet was 236 mg/l before treatment, the treatment with banana peels helps in eliminating sulfide concentration to 0.58 mg/l with treatment efficiency of 99.7%, comparing with treatment efficiency of 99.87% by activated carbon, Figure 2. There was a noticeable decrease in the treated water content of the studied anion and cations. The efficiency of sulfate and chloride removal on banana peel was 70% and 40% compared to that of activated carbon 94% and 70.7 % , Figures. 3 and 4.The phosphate ion removal was undetectable (2.7%) as in the case of commercial activated carbon (60%), Figure 5. The efficiency of Na, Mg and Ca removal was 43%, 34% and 20%, respectively, by banana peels while it was 41% , 19% and 22% respectively. The treated water by the two methods has a concentration more than the standard limit of Na ( > 200 mg/l ), Mg (> 50 mg/l ) and Ca ( > 200mg/l)due to high content of the three elements in the untreated spring water , Figures 6,7and 8. The high concentration of potassium in the peels of banana (62 mg/g) has affected the potassium content in the treated water causing a concentration increase of potassium after the treatment with banana peels (345 to 852 mg/l ), Figure 9. There was a noticeable decrease in the concentration of the trace elements in the treated water below the standard limits where the treatment efficiency sometimes reaches 98% as in chrome (Figure 10) and iron 96% (Figure 12), copper 38.7% (Figure 14) and zinc 33. % (Figure 15).The efficiency of nickel removal was 60% but dont reach the standard limits (Ni > 0.2 mg/l) due to high Ni concentration in spring water, although it was more effective than commercial activated carbon, Figure 13. There was a noticeable increase in Manganese

29

Civil and Environmental Research ISSN 2224-5790 (Paper) ISSN 2225-0514 (Online) Vol.3, No.10, 2013

www.iiste.org

concentration when treated with banana peels column on contrast to that of activated carbon column, Figure 11. The increase in manganese concentration was due to the high content of Manganese (48 mg/g) in banana peel, Table 2. The treated water has a manganese concentration exceeds the standard limits ( Mn > 0.1 mg/l). The pH of the spring water before treatment was slightly acidic (pH =6.5). There was slight increase in the pH of the treated water with banana peel (6.5 to 7.5), Figure 16, due to carbonate content of the banana peel (5.2mg\g) ,Table 2. Regardless of this increase, the pH was within the specific limit (6.5-8.5), (WHO 2006). The previous studies employed the banana peels as biosorbent for removal heavy metals from water (eg. Ashraf et al. 2011; Castro et al. 2011; Hossain et al. 2012a ). This study was the first attempt to use banana peels for removal sulfide from water. 4. Conclusions From a results of this study , we conclude that the banana peels can be used as low cost ,fast ,and selective sorbent for sulfide at wide concentration range, in addition to its role in improvement of some physical and chemical properties of spring water. 5. References Alleala M , Ahmed S (1984) Collection and treatment of waste waters. Mosul publishing press, Mosul, Iraq. Anhwange BA, Ugye TJ, Nyiaatagher TD (2009) Chemical composition of Musa sapientum (Banana) peels. Electronic Journal of Environmental, Agricultural and Food Chemistry 8: 437-442. Ashraf MA, Wajid A, Mahmood K, Maah M., Yusoff I (2011) Low cost biosorbent banana peel (Musa sapientum) for the removal of heavy metals. Scientific Research and Essays 6: 4055 4064. Castro RS, Caetano L, Ferreria G, Padilha PM et al ( 2011) Banana peel applied to the solid phase extraction of copper and lead from river water: Preconcentration of metals ions with a fruit waste. Industrial & Engineering Chemistry Research 50: 3446 3451. Hossain MA, Ngo HH, Guo WS, Nguyen TV ( 2012a) Removal of copper from water by adsorption onto banana peel as bioadsorbant. Int. J . of GEOMATE 2: 227 234. Hossain MA, Ngo HH, Guo WS, Nguyen TV ( 2012b ) Biosorption of Cu(II) from water by banana peel based biosorbent: Experiments and models of adsorption and desorption. Journal of Water Sustainability 2: 87 104. Cobley L (1976) An introduction to the Botany of Tropical Crops. 2nd Ed., Longman. Gueu S, Yao B, Adouby K, Ado G (2006) Heavy Metals Removal in Aqueous Solution by Activated Carbons Prepared from Coconut Shell and Seed Shell of the Palm Tree. Journal of Applied Sciences 6 : 27892793 . Hairbabu E, Upathya YD, Upathya SN (1993) Removal of phenols from effluents by fly ash. Int. j. Environ. Stud. 43:169-176. Him JD (1970) Study and interpretation of the chemical characteristics of natural water.2ndedit.,GSWSpaper,1473. Ho YS, McKay G (1999) The sorption of lead(II) ions on peat. Water Res. 33: 578-584. Ho YS, Ng JC, McKay G (2001) Removal of lead(II) from effluent by absorption on peat using second order kinetics. Sep. Sci. Technol.36. Horikawa MS , Rossi F , Gimenes ML, Costa CM, et al (2004) Chemical absorption of H2S for biogas purification. Brazilian Journal of Chemical Engineering 21 : 415-422. Hussien BM, Gharbie MG (2010) Hydrogeochemical evaluation of the groundwater within Abu Jir fault zone , Hit Kubaisa region, central Iraq.Iraqi Bulletin of geology and Mining 6: 121-138. Indrani D, Roberta F, Shobha S, Grant A (2007) High-temperature biotrickling filtration of hydrogen sulfide. Applied Microbiology and Biotechnology 74 : 708-716 . Jackson ML (1958) Soil chemical analysis. Prentice hall, Inc. Englewood, cliffs, N.J. Laboutka M (1974) The hydrogeological tables and data (basic instruction No.3) Rep.No.3, GEOSURV, Baghdad, 40 pp. McCrty PL (1974) Anaerobic waste treatment fundamentals, part 3 Toxic material and their treatment. publ.UKS. Memon JR, Memon SQ, Bhanger MI, Khuhawar MY (2008) A green and economical sorbent for Cr(III) removal. Pak. J. Anal. Environ. Chem. 9: 20-25. Mendham G (1989) Vogel's text book of quantitative chemical analysis" 5th ed. John Willy and sons, Inc., New York. Meunier N, Laroulandle J, Blais JF, Tyagi RD ( 2003) Cocoa shells for heavy metals removal from acidic solutions. Bioresource. Technol. 90. Niu CH, Voleskyb B, Cleimanb D (2007) Biosorption of As(V) with acid- washed Crab shells. Water Res. 41: 2473-2478.

30

Civil and Environmental Research ISSN 2224-5790 (Paper) ISSN 2225-0514 (Online) Vol.3, No.10, 2013

www.iiste.org

Pagnanelli F, Sara M, Veglio F, Luigi T (2003) Heavy metal removal by Olive pomace biosorbent characterization and equilibrium modeling. Chem. Eng. Sci. 58: 4709-4717. Panday K, Prasad G, Singh VN (1985) Cu(II) removal from aqueous solutions by flah. Water Res. 19 :869-873. Periasamy K, Namasivayam C (1984) Process development for removal and recovery of Cadmium(II) by low cost adsorbent: adsorption rates and equilibrium studies. Indus. Eng. Chem. Res. 33. Prieto BE, Lozano B, Arenas F J, et al (2001) Removal of H2S by metal ferrites produced in the purification of metal-bearing waste water, study of the reaction mechanism. Water, Air, and Soil Pollution 131: 367-381 . Rahman MS, Basu A, Islam MR ( 2008) The Removal of As(III) and As(V) from aqueous solution by waste materials. Bioresource technology 99: 2815-2823. Zobell G (1963) Organic Geochemistry. Longmans, London, P.392. W.H.O.( 2006) "Guidelines for Drinking Water Quality' ( electronic resources ): incorporating first addendum .Vol. 1 Recommendation. 3rd ed. Table 1. The sulfide concentration effect on the efficiency of banana peels in sulfide sorption comparing with activated carbon. Standard sulphide solution 5 (mg\l) 25(mg\l) 50(mg\l) 100(mg\l) 250(mg\l) treatment by banana peels 0.28 (mg\l) 0.37(mg\l) 0.39(mg\l) 0.47(mg\l) 0.52(mg\l) treatment by activated carbon 0.12 (mg\l) 0.19 (mg\l) 0.25 (mg\l) 0.30 (mg\l) 0.42 (mg\l)

Table 2. The chemical analysis of banana peels Test Concentration mg\g Na 18.2 K 62 Ca 15.4 Mn 48 PO4 0.37 Alkalinity 5.2 moisture 5.8% Table 3. The retention time effect on the efficiency of banana peels in sulfide sorption comparing with activated carbon using standard sulfide solution (250) mg/l. Time ( minutes) Direct elution 15 30 60 120 treatment by banana peels 0.54 (mg\l) 0.51 (mg\l) 0.48 (mg\l) 0.39 (mg\l) 0.31 (mg\l) treatment by activated carbon 0.32 (mg\l) 0.27 (mg\l) 0.21 (mg\l) 0.19 (mg\l) 0.11 (mg\l)

31

Civil and Environmental Research ISSN 2224-5790 (Paper) ISSN 2225-0514 0514 (Online) Vol.3, No.10, 2013

www.iiste.org

Figure 1. Location map of the study area.

250 200 150 100 50 0 active carbon banana peels

ppm

befor treatment after treatment

Figure 2. Total sulfide treatment by banana peels comparing with active carbon. 250 200 ppm 150 befor treatment 100 50 0 active carbon banana peels after treatment

Figure 3. Total sulfate treatment by banana peels comparing with active carbon.

32

Civil and Environmental Research ISSN 2224-5790 (Paper) ISSN 2225-0514 0514 (Online) Vol.3, No.10, 2013

www.iiste.org

400 300 ppm 200 100 0 active carbon banana peels befor treatment after treatment

Figure 4. Total chloride treatment by banana peels comparing with active carbon. 1.5 ppm 1 befor treatment 0.5 after treatment 0 active carbon banana peels

Figure 5. Total phosphate treatment by banana peels comparing with active carbon. 800 600 400 200 0 active banana carbon peels Figure 6. Total Magnesium treatment by banana peels comparing with active carbon. 500 400 300 200 100 0 active carbon banana peels

ppm

befor treatment after treatment

Ca ppm

befor treatment after treatment

Figure 7. Total calcium treatment by banana peels comparing with active carbon.

33

Civil and Environmental Research ISSN 2224-5790 (Paper) ISSN 2225-0514 0514 (Online) Vol.3, No.10, 2013

www.iiste.org

2500 2000 1500 1000 500 0 active carbon banana peels

Na ppm

befor treatment after treatment

Figure 8. Total sodium treatment by banana peels comparing with active carbon. 1000 800 K ppm 600 400 200 0 active carbon banana peels befor treatment after treatment

Figure 9. Total Potassium treatment by banana peels comparing with active carbon. 0.6 Cr ppm 0.4 befor treatment 0.2 after treatment 0 active carbon banana peels

Figure10. . Chromium treatment by banana peels comparing with active carbon. 7 6 5 4 3 2 1 0 active carbon banana peels

Mn ppm

befor treatment after treatment

Figure 11. Manganese treatment by banana peels comparing with active carbon.

34

Civil and Environmental Research ISSN 2224-5790 (Paper) ISSN 2225-0514 0514 (Online) Vol.3, No.10, 2013

www.iiste.org

0.3 ppm 0.2 befor treatment 0.1 after treatment 0 active carbon banana peels

Figure 12. Iron treatment by banana banana peels comparing with active carbon. 0.5 0.4 0.3 0.2 0.1 0 active carbon banana peels

ppm

befor treatment after treatment

Figure 13. - Nickel treatment by banana peels comparing with active carbon. 0.4 0.3 ppm 0.2 0.1 0 active carbon banana peels befor treatment after treatment

Figure 14. Cupper treatment by banana peels comparing with active carbon. 0.03 ppm 0.02 befor treatment 0.01 after treatment 0 active carbon banana peels

Figure 15. Zinc treatment by banana peels comparing with active carbon.

35

Civil and Environmental Research ISSN 2224-5790 (Paper) ISSN 2225-0514 0514 (Online) Vol.3, No.10, 2013

www.iiste.org

8 7.5 7 6.5 6 5.5 active carbon banana peels

befor treatment after treatment

Figure 16. pH change after treatment by banana peels comparing with active carbon.

36

This academic article was published by The International Institute for Science, Technology and Education (IISTE). The IISTE is a pioneer in the Open Access Publishing service based in the U.S. and Europe. The aim of the institute is Accelerating Global Knowledge Sharing. More information about the publisher can be found in the IISTEs homepage: http://www.iiste.org CALL FOR JOURNAL PAPERS The IISTE is currently hosting more than 30 peer-reviewed academic journals and collaborating with academic institutions around the world. Theres no deadline for submission. Prospective authors of IISTE journals can find the submission instruction on the following page: http://www.iiste.org/journals/ The IISTE editorial team promises to the review and publish all the qualified submissions in a fast manner. All the journals articles are available online to the readers all over the world without financial, legal, or technical barriers other than those inseparable from gaining access to the internet itself. Printed version of the journals is also available upon request of readers and authors. MORE RESOURCES Book publication information: http://www.iiste.org/book/ Recent conferences: http://www.iiste.org/conference/ IISTE Knowledge Sharing Partners EBSCO, Index Copernicus, Ulrich's Periodicals Directory, JournalTOCS, PKP Open Archives Harvester, Bielefeld Academic Search Engine, Elektronische Zeitschriftenbibliothek EZB, Open J-Gate, OCLC WorldCat, Universe Digtial Library , NewJour, Google Scholar

You might also like

- Asymptotic Properties of Bayes Factor in One - Way Repeated Measurements ModelDocument17 pagesAsymptotic Properties of Bayes Factor in One - Way Repeated Measurements ModelAlexander DeckerNo ratings yet

- Availability, Accessibility and Use of Information Resources and Services Among Information Seekers of Lafia Public Library in Nasarawa StateDocument13 pagesAvailability, Accessibility and Use of Information Resources and Services Among Information Seekers of Lafia Public Library in Nasarawa StateAlexander DeckerNo ratings yet

- Assessment of Housing Conditions For A Developing Urban Slum Using Geospatial AnalysisDocument17 pagesAssessment of Housing Conditions For A Developing Urban Slum Using Geospatial AnalysisAlexander DeckerNo ratings yet

- Barriers To Meeting The Primary Health Care Information NeedsDocument8 pagesBarriers To Meeting The Primary Health Care Information NeedsAlexander DeckerNo ratings yet

- Assessment of Knowledge, Attitude and Practices Concerning Food Safety Among Restaurant Workers in Putrajaya, MalaysiaDocument10 pagesAssessment of Knowledge, Attitude and Practices Concerning Food Safety Among Restaurant Workers in Putrajaya, MalaysiaAlexander DeckerNo ratings yet

- Assessment of The Skills Possessed by The Teachers of Metalwork in The Use of Computer Numerically Controlled Machine Tools in Technical Colleges in Oyo StateDocument8 pagesAssessment of The Skills Possessed by The Teachers of Metalwork in The Use of Computer Numerically Controlled Machine Tools in Technical Colleges in Oyo StateAlexander Decker100% (1)

- Assessment of Some Micronutrient (ZN and Cu) Status of Fadama Soils Under Cultivation in Bauchi, NigeriaDocument7 pagesAssessment of Some Micronutrient (ZN and Cu) Status of Fadama Soils Under Cultivation in Bauchi, NigeriaAlexander DeckerNo ratings yet

- Assessment of Relationships Between Students' Counselling NeedsDocument17 pagesAssessment of Relationships Between Students' Counselling NeedsAlexander DeckerNo ratings yet

- Assessment of The Practicum Training Program of B.S. Tourism in Selected UniversitiesDocument9 pagesAssessment of The Practicum Training Program of B.S. Tourism in Selected UniversitiesAlexander DeckerNo ratings yet

- Availability and Use of Instructional Materials and FacilitiesDocument8 pagesAvailability and Use of Instructional Materials and FacilitiesAlexander DeckerNo ratings yet

- Attitude of Muslim Female Students Towards Entrepreneurship - A Study On University Students in BangladeshDocument12 pagesAttitude of Muslim Female Students Towards Entrepreneurship - A Study On University Students in BangladeshAlexander DeckerNo ratings yet

- Assessment of Teachers' and Principals' Opinion On Causes of LowDocument15 pagesAssessment of Teachers' and Principals' Opinion On Causes of LowAlexander DeckerNo ratings yet

- Assessment of Productive and Reproductive Performances of CrossDocument5 pagesAssessment of Productive and Reproductive Performances of CrossAlexander DeckerNo ratings yet

- Assessment of Survivors' Perceptions of Crises and Retrenchments in The Nigeria Banking SectorDocument12 pagesAssessment of Survivors' Perceptions of Crises and Retrenchments in The Nigeria Banking SectorAlexander DeckerNo ratings yet

- Application of The Diagnostic Capability of SERVQUAL Model To An Estimation of Service Quality Gaps in Nigeria GSM IndustryDocument14 pagesApplication of The Diagnostic Capability of SERVQUAL Model To An Estimation of Service Quality Gaps in Nigeria GSM IndustryAlexander DeckerNo ratings yet

- Assessing The Effect of Liquidity On Profitability of Commercial Banks in KenyaDocument10 pagesAssessing The Effect of Liquidity On Profitability of Commercial Banks in KenyaAlexander DeckerNo ratings yet

- Applying Multiple Streams Theoretical Framework To College Matriculation Policy Reform For Children of Migrant Workers in ChinaDocument13 pagesApplying Multiple Streams Theoretical Framework To College Matriculation Policy Reform For Children of Migrant Workers in ChinaAlexander DeckerNo ratings yet

- Are Graduates From The Public Authority For Applied Education and Training in Kuwaiti Meeting Industrial RequirementsDocument10 pagesAre Graduates From The Public Authority For Applied Education and Training in Kuwaiti Meeting Industrial RequirementsAlexander DeckerNo ratings yet

- Antibiotic Resistance and Molecular CharacterizationDocument12 pagesAntibiotic Resistance and Molecular CharacterizationAlexander DeckerNo ratings yet

- Assessment in Primary School Mathematics Classrooms in NigeriaDocument8 pagesAssessment in Primary School Mathematics Classrooms in NigeriaAlexander DeckerNo ratings yet

- Assessment For The Improvement of Teaching and Learning of Christian Religious Knowledge in Secondary Schools in Awgu Education Zone, Enugu State, NigeriaDocument11 pagesAssessment For The Improvement of Teaching and Learning of Christian Religious Knowledge in Secondary Schools in Awgu Education Zone, Enugu State, NigeriaAlexander DeckerNo ratings yet

- Assessment of Factors Responsible For Organizational PoliticsDocument7 pagesAssessment of Factors Responsible For Organizational PoliticsAlexander DeckerNo ratings yet

- An Investigation of The Impact of Emotional Intelligence On Job Performance Through The Mediating Effect of Organizational Commitment-An Empirical Study of Banking Sector of PakistanDocument10 pagesAn Investigation of The Impact of Emotional Intelligence On Job Performance Through The Mediating Effect of Organizational Commitment-An Empirical Study of Banking Sector of PakistanAlexander DeckerNo ratings yet

- Application of Panel Data To The Effect of Five (5) World Development Indicators (WDI) On GDP Per Capita of Twenty (20) African Union (AU) Countries (1981-2011)Document10 pagesApplication of Panel Data To The Effect of Five (5) World Development Indicators (WDI) On GDP Per Capita of Twenty (20) African Union (AU) Countries (1981-2011)Alexander DeckerNo ratings yet

- An Overview of The Environmental Policies To Ensure SafeDocument9 pagesAn Overview of The Environmental Policies To Ensure SafeAlexander DeckerNo ratings yet

- Antioxidant Properties of Phenolic Extracts of African Mistletoes (Loranthus Begwensis L.) From Kolanut and Breadfruit TreesDocument8 pagesAntioxidant Properties of Phenolic Extracts of African Mistletoes (Loranthus Begwensis L.) From Kolanut and Breadfruit TreesAlexander DeckerNo ratings yet

- Analysis The Performance of Life Insurance in Private InsuranceDocument10 pagesAnalysis The Performance of Life Insurance in Private InsuranceAlexander DeckerNo ratings yet

- Analysis of Teachers Motivation On The Overall Performance ofDocument16 pagesAnalysis of Teachers Motivation On The Overall Performance ofAlexander DeckerNo ratings yet

- Analyzing The Economic Consequences of An Epidemic Outbreak-Experience From The 2014 Ebola Outbreak in West AfricaDocument9 pagesAnalyzing The Economic Consequences of An Epidemic Outbreak-Experience From The 2014 Ebola Outbreak in West AfricaAlexander DeckerNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Welder Qp3Document12 pagesWelder Qp3Lekshmanan PadmanabhanNo ratings yet

- Thermodynamics and Kinetic Stability of Coordination ComplexesDocument27 pagesThermodynamics and Kinetic Stability of Coordination ComplexesMONIRUZZAMAN MONIR100% (1)

- Training Oilfield Production Chemicals 20 - 23 J - 220614 - 111151Document3 pagesTraining Oilfield Production Chemicals 20 - 23 J - 220614 - 111151Lusia PratiwiNo ratings yet

- Aa - List-Definition-Chemistry-protected PDFDocument10 pagesAa - List-Definition-Chemistry-protected PDFFahad Hameed AhmadNo ratings yet

- Packaging N Labelling of Packaged Drinking WaterDocument10 pagesPackaging N Labelling of Packaged Drinking WaterISHFAQ ASHRAFNo ratings yet

- Natural Gums and Its Pharmaceutical ApplicationDocument10 pagesNatural Gums and Its Pharmaceutical Applicationhosam alosNo ratings yet

- Organic Chemistry Question and AnswerDocument53 pagesOrganic Chemistry Question and Answergoi_pin100% (1)

- Introduction To BiopharmaceuticsDocument106 pagesIntroduction To BiopharmaceuticsHely Patel100% (1)

- Group 4 Biological Membranes RevisedDocument20 pagesGroup 4 Biological Membranes RevisedDjanelle Mei San MiguelNo ratings yet

- European Patent Application C07F 7/08: Method For Preparation of Organohydrogen PolysiloxanesDocument5 pagesEuropean Patent Application C07F 7/08: Method For Preparation of Organohydrogen Polysiloxanesswaroop_exlncNo ratings yet

- PolarityDocument22 pagesPolarityEvangelene Esquillo SanaNo ratings yet

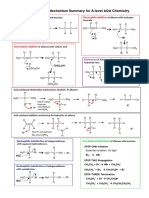

- Aqa Mechanisms A Level SummaryDocument5 pagesAqa Mechanisms A Level SummaryRS JNo ratings yet

- Gen Chem 3Document15 pagesGen Chem 3Marco SarmientoNo ratings yet

- IP 3. Protocol - Chemical Principles II LaboratoryDocument9 pagesIP 3. Protocol - Chemical Principles II LaboratoryJavier PratdesabaNo ratings yet

- Factors Affecting Enzymes ActivityDocument11 pagesFactors Affecting Enzymes ActivityZubair AslamNo ratings yet

- Ikatan Kovalen Polar Dan Asam Basa - Kimor 2Document29 pagesIkatan Kovalen Polar Dan Asam Basa - Kimor 2akbar_rozaaqNo ratings yet

- Model Answer Key For Grade 11Document5 pagesModel Answer Key For Grade 11Rohit Sur100% (1)

- Chloride: Silver Nitrate Method Method 8207 10 To 10,000 MG/L As CL Digital TitratorDocument6 pagesChloride: Silver Nitrate Method Method 8207 10 To 10,000 MG/L As CL Digital TitratorAlbertoNo ratings yet

- Questions - Homework - 10th - Science - 2021-11-21T08 - 31Document6 pagesQuestions - Homework - 10th - Science - 2021-11-21T08 - 31Nisha SinghNo ratings yet

- Cross Index MaterialDocument4 pagesCross Index MaterialioancNo ratings yet

- The Periodic Table Its Story and Its SignificanceDocument3 pagesThe Periodic Table Its Story and Its SignificanceJason Vinluan CarinanNo ratings yet

- TheSouthernWarPoetryoftheCivilWar 10134200Document195 pagesTheSouthernWarPoetryoftheCivilWar 10134200Isaiah ThomasNo ratings yet

- US4450090Document6 pagesUS4450090Abdulrahman HamdanNo ratings yet

- Research 2 Mind Map Draft Q1Document1 pageResearch 2 Mind Map Draft Q1Danielle CastilloNo ratings yet

- Journal of CO2 Utilization: 2 Ikhlas Ghiat, Tareq Al-AnsariDocument14 pagesJournal of CO2 Utilization: 2 Ikhlas Ghiat, Tareq Al-AnsariMuhammad Imran KhanNo ratings yet

- Mil DTL 81706BDocument20 pagesMil DTL 81706BwcwtnuiNo ratings yet

- 06chapters13 15Document19 pages06chapters13 15Achmad Arifudin HidayatullohNo ratings yet

- Lower and Higher Heating Values of Gas Liquid and Solid FuelsDocument2 pagesLower and Higher Heating Values of Gas Liquid and Solid FuelsElwathig BakhietNo ratings yet

- Ammonia Production ProcessDocument44 pagesAmmonia Production Processche_abdo89% (9)

- Fosroc Nitocote EPS Protective CoatingDocument4 pagesFosroc Nitocote EPS Protective CoatingmangjitNo ratings yet