Professional Documents

Culture Documents

Dye Penetration Test

Uploaded by

ezarul fitriCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dye Penetration Test

Uploaded by

ezarul fitriCopyright:

Available Formats

Dye Penetrant

L. Sollecchia

Corporate Communications May 4th, 2007

Aim

The aim of this activity is the research of suitable dye penetrant to be used to detect the cracks in Area Array Connections at the end of verification test made in accordance with the ECSS-Q-70-38. Indeed due to the configuration of connections a microsection will not allow the detection of size of the cracks. For these reasons the ECSS-Q-70-38 requires the use of dye penetrant testing, to identify the extension of the cracks at the end of verification testing. Based on the area of the cracks the assembly will be considered approved or not as per ECSS-Q-70-38 . Six tasks have been identified: � Task.1: Selection of Dye Penetrant on the market. � Task.2: Definition of Test Vehicles � Task.3: Definition of Pull-Out procedure. � Task.4: Thermal Cycles � Task.5: Dye Penetrant Test on Epoxy Test Vehicles. � Task.6: Dye Penetrant Test on Thermount 85 NT Test Vehicles & Electrical Test.

2

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

Task.1: Selection of Dye Penetrant

Selection of Dye Penetrant criteria applied are:

� The availability on the market: it has been found on the market 32 different dye penetrant from 6 manufacturer (Tab. 1).

� The application method: the Dye Penetrant may be applied to the test component by dipping, spraying, or brushing. For this application the preferred method is the dipping that assures the wettability of inner soldered join.

� Inspection Method: the inspection may be performed under ultraviolet or white light, depending upon the type of dye used, fluorescent or non-fluorescent (visible): the investigation takes in to account both type of penetrant.

� Solvent Type: the dye solution may be prepared mixing the dye pigment with solvent (like alcohols, acetone, toluene, etc.) or with water. So both classes of solution there are taken in to account.

3

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

Task.1: Selection of Dye Penetrant

Manufacturer

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 ITW Magnaflux ITW Magnaflux ITW Magnaflux Risk Reactor Risk Reactor Risk Reactor Risk Reactor Risk Reactor Risk Reactor Risk Reactor Risk Reactor Met. L.. Check. Met. L.. Check. Met. L.. Check. Met. L.. Check. Met. L.. Check. Met. L.. Check. Met. L.. Check. Met. L.. Check. Met. L.. Check. Met. L.. Check. Met. L.. Check. DYKEM SHERWIN SHERWIN SHERWIN SHERWIN SHERWIN SHERWIN SHERWIN SHERWIN ELITE

Product Name

MAGNAFLUX ZL-C2 MAGNAFLUX ZL-60S ARDROX 970 P25 DFSB-K87 DFSB-K43 DFSB-K61 DFSB-C7 DFSB-C0 DFPD-C2 DFDRY-C0 IFWB-C2 VP 30 FP 900 FP901.FP91B FP911 (BIO) FP902.FP92B (M) FBP912 (BIO) FP98A.FP99A. FP903 FBP913(BIO) FP 94 FP93A(M) FP97A(M) RED STEEL DP 51 HM 1 HM2D. HM220 (BIO) HM3A. HM406.HM412 HM440 (BIO) HM420C.HM430 HM604(BIO).HM607 (BIO HM704(BIO).HM707(BIO) K71 B 2

Base

SOLVENT SOLVENT SOLVENT SOLVENT SOLVENT SOLVENT SOLVENT SOLVENT SOLVENT WATER WATER SOLVENT/ WATER SOLVENT/WATER SOLVENT/WATER SOLVENT/WATER SOLVENT/WATER SOLVENT/WATER SOLVENT/WATER SOLVENT/WATER SOLVENT SOLVENT SOLVENT SOLVENT SOLVENT WATER WATER WATER WATER WATER WATER WATER WATER

Cleaner

TURCO METAL GLO 6 TURCO METAL GLO 6 TURCO METAL GLO 6 N.A. N.A. N.A. N.A. N.A. N.A. N.A. N.A. E59A E59A E59A E59A E59A E59A E59A E59A E59A E59A E59A N.A. DR 62 DR 62 DR 62 DR 62 DR 62 DR 62 DR 62 DR 62 ELITE 20

Remover

MAGNAFLUX SKC-S MAGNAFLUX SKC-S MAGNAFLUX SKC-S N.A. N.A. N.A. N.A. N.A. N.A. N.A. N.A. E59A E59A E59A E59A E59A E59A E59A E59A E57/E58D E57/E58D E57/E58D N.A. DR 62 DR 62 DR 62 DR 62 DR 62 DR 62 DR 62 DR 62 BC 1

Developer

MAGNAFLUX SKD-S2 MAGNAFLUX SKD-S2 MAGNAFLUX SKD-S2 N.A. N.A. N.A. N.A. N.A. N.A. N.A. N.A. E 70 E78B E78B E78B E78B E78B E78B E78B E76B/E78B E76B/E78B E76B/E78B N.A. DR 100 DR90G/ DR90G DR90G DR90G DR90G DR90G DR90G D 112A

4

Corporate Communications May 15th, 2007

Tab.1: Dyes Penetrant on the Market

All rights reserved 2007, Thales Alenia Space

Task.1: Selection of Dye Penetrant

� The employ easiness: often the dye penetrant technique needs of cleaner, remover and developer to be used. When the flaws or the cracks are not very deep, the use of remover may produce the cleaning of dye penetrated in the defects. The process is more complicate with 3 different step of dipping, and moreover these kind of dye are applicable where the flaw or the crack is visible, but in this case the cracks cannot directly inspected. For these reasons it takes in to account only the Dye Penetrants which dont need of any additional product.

Use of Cleaner, Remover and Developer

5

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

Task.1: Selection of Dye Penetrant

To all these dyes an unusual substance has been added, used basically like disinfectant, named Neomercurocromo and produced by Laboratorio Farmaceutico SIT, which contains a pigment EOSINA used in biology to mark the cells. The composition is (100 ml of product): � 2.0 g of Eosina � 30 g of active ingredients � 95% of ethylic alcohol � refined water

EOSINA (Tetrabromofluoresceina) C20H6Br4Na2O5 Neomercurocromo EOSINA

6

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

Task.1: Selection of Dye Penetrant

Manufacturer Risk Reactor Risk Reactor Risk Reactor Risk Reactor Risk Reactor Risk Reactor Risk Reactor Risk Reactor Dykem SIT

Product Name DFSB-K87 DFSB-K61 DFSB-K43 DFSB-C7 DFSB-C0 DFDRY-C0 DFPD-C2 IFWB-C2 Red Steel Eosina Selected Dye Penetrant

7

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

Task.1: Selection of Dye Penetrant

Solubility (g/ml) Dye Penetrant DFDRY-C0 1 g /100 ml

Solvent

Physical Aspect Powder

Inspection

Color

Safety

Water

UV Light

Blue brilghte

Irritant Flammable, Toxic Irritant

DFSB-C0

1 g / 100 ml

MEK

Powder

UV Light

Blue

DFSB-C7

0.5 gr /100 ml

MEK

Powder

UV Light

Red

Flammable, Toxic

DFSB-K43

1 g / 100 ml

Acetone

Powder

UVLight

Yellow

Flammable, Toxic

DFSB-K61

1 g /100 ml

MEK

Powder

UV Light

Violet

Flammable, Toxic

DFSB-K87

1 g / 100 ml

IPA

Powder

UV Light

Green - Yellow

Flammable, Toxic

DFPD-C2

1 g / 100 ml

Acetone

Powder

UV Light

Yellow

Flammable, Toxic Flammable, Toxic, Irritant Flammable

IFWB-C2

10 ml / 100 ml

Water

Liquid

UV Light

Yellow

EOSINA

N.A. (Ready to Use)

Alcohol Ethilic

Liquid

White Light

Red

RED STEEL

N.A (Ready to Use)

Various Solvent

Liquid

White Light

Red

Flammable, Irritant

Selected Dye Penetrant characteristics

8

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

Task.2: Definition of Test Vehicles

Area Array Connection Components It has been employed the Dimple Ball Grid Array (DBGA) in two different size: � DBGA 228 I/O : HTCC package with 228 area array perimetral contacts internally connected in daisy-chain, dimension 21 x 21 mm, pitch 1.27 mm, solder-ball 0.85 mm diameter, solder-ball composition 46Sn/46Pb/8Bi � DBGA 444 I/O : HTCC package with 444 area array perimetral contacts internally connected in daisy-chain, dimension 33 x 33 mm, pitch 1.27 mm, solder-ball 0.85 mm diameter, solder-ball composition 46Sn/46Pb/8Bi

DBGA 228 DBGA 444

9

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

Dimple Cross Section

Task.2: Definition of Test Vehicles

Printed Circuit Board It has been procured from Printca two different kind of PCB in term of base laminate (the layout is the same for the two version): � the first one PRT0912841 6 layers on Arlon Thermount 85 NT, with copper clad 1 oz/ft2 and final plating Tin/Lead refused, blind via 1-2 layers and plated thru holes 1-6 layer � the second one PRT0912842 6 layers on Epoxy, with copper clad oz/ft2 and final plating Tin/Lead refused, blind via 1-2 layers and plated thru holes 1-6 layer.

Footprint of DBGA228 Footprint of DBGA444 PCB 0912841 Thermount 85 NT

10

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

Task.2: Definition of Test Vehicles

It has been employed the PCB in Epoxy, in the preliminary trials of Dye Penetrant, to induce the cracks on soldered joint faster than the PCB in Thermount 85 NT, due to the increased CTE mismatch between the Epoxy (~16 ppm/C), instead of Thermount 85NT (~9 ppm/C), and the HTCC (~7 ppm/C) of package.

For each components it has been designed 8 couple of daisy-chain

T2 T1

T2 T1

T3 T4 T5 T6 T7 T8

T16 T15 T14 T13 T12 T11

T3 T4 T5 T6

T16 T15 T14 T13

T7

T12 T11

T9

T10

DBGA228 Daisy-Chain

T8

T9

T10

11

Corporate Communications May 15th, 2007

DBGA444 Daisy-Chain

All rights reserved 2007, Thales Alenia Space

Task.3: Definition of Pull-out Procedure

To inspect the component after the dye bath, the sample have to pulled-out. The scope is the total breaking of cracked soldered joints at the same point where the cracks, induced by thermal cycles, have to been generated. The main difficult of this procedure is that the pulling out may break the soldered joint not where the crack is generated, but may detach the PCB pad; in this case it results impossible to calculate the area of crack. This event could happen when the copper adhesion on the base laminate is lower than the force necessary to break the damaged soldered joint, this is the case of Thermount 85 NT.

After Enviromental Test

After Dye Bath

After Pull Out

Package Painted Area Solder Ball Crack Dye Unpainted Area

PCB

12

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

Task.3: Definition of Pull-out Procedure

To perform this test it has been employed INSTRON 1185 equipment with 1000 N Load Cell. The procedure consist in the fixing of PCB on the reference plane and by means of a metal cylinder (ked), which shall be engaged with the equipment traction wire, and glued on an aluminum sheet (the dimensions of this sheet shall be a little bit less of component package size, and thickness 1.5 2.0 mm). The aluminum sheet in turn shall be glued on the top of component package.

Assembly PCB-DBGA after Dye immersion

Steel foil

keg

Glue

13

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

Task.3: Definition of Pull-out Procedure

Two different PCB substrate employed on this activity have been required two different machine set-up: � for Epoxy Test Vehicles. � for the Thermount 85 NT Test Vehicles.

Analyzing the data sheet of the two base laminate in order to copper adhesion, the value of the peel strength after thermal stress for a copper thickness of 35 m for Epoxy is 1.4 N/mm whereas for the Thermount 85 NT is 0.8 N/mm. For the Epoxy laminate this value is 75% greater than the Thermount 85 NT laminate. For this reason the most critical situation is represented from the pulling-out of component on Thermount 85 NT substrate, and for this reason the first trial have been done on the easier situation represented from the Epoxy test vehicles. All the samples employed to the pull-out stat-up procedure have been previously submitted to the thermal cycles to replicate the real condition of test.

14

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

Task.3: Pull-out on Epoxy Test Vehicle

The components submitted the the preliminary pull-out test was DBGA 228 #1 and #2 from the Test Vehicle S/N 6 on Epoxy, and the DBGA 444 #1 from the same test vehicle. The first trial it has been done on DBGA 228 #1 with a traction velocity of 0.1 mm/min : the component has been pulled at 289.5 N but the inspection of soldered join shown that the profile of dimple was deformed from circular to elliptical .

So it has been increased the velocity up to 0.5 mm/min and it has been repeated the trial with the DBGA 228 #2 which has been pulled at 347.7 N. This result may appear strange but it is possible to explain it considering that the cracks percentage of DBGA 228 #2 was less than of #1. From the inspection it has been saw that the join profile are still circular and quite all the joints have been attached to the PCB (only 4 dimple in the inner position). After that, it has been performed a third trial on DBGA 444 which has been detached at 570.3 N with a circular profile for the dimples, and all the dimples attached to the PCB.

15

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

Task.3: Pull-out on Thermount85NT Test Vehicle

The component submitted to the first trial of pull-out test are � one DBGA 228 #1 from the Test Vehicle S/N 1 with a traction velocity of 0.5 mm/min � one DBGA 444 #1 from the Test Vehicle S/N 1 with a traction velocity of 0.5 mm/min. The results shown that an high number of joints still attached to the package, the Dog-bone pad was pulled-out from the PCB, with the impossibility to inspect the soldered join. Then with the second trial it has been modified the load-time profile of equipment in the following way: � DBGA 444 #2 from Polyimide-Thermount Test Vehicle S/N1 with a progressive load from 300 N to the final value with a step of 25 N and a steady-load time of 5 min. and rise traction velocity of 0.5 mm/min. � DBGA 228 #2 from Polyimide-Thermount Test Vehicle S/N1 with a progressive load from 150 N to the final value with a step of 25 N and a steady-load time of 5 min. and rise traction velocity of 0.5 mm/min. The results shown that the number of soldered joints still attached to the package, wasnt decreased significantly and so too many dimples was still not inspectionable; in addition the profiles of dimples under inspection have been shown a deformation of profile from circular to elliptical.

16

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

Task.3: Pull-out on Thermount85NT Test Vehicle

To solve this problem it has been defined a multiple pull-out procedure, that is described briefly later on : � Step 1: the component is pulled-out with a traction velocity of 0.5 mm/min. � Step 2: shall be performed the inspection of dimples attached to the PCB side

Assembly PCB-DBGA after Dye immersion

Steel foil

keg

Glue

DBGA after 1 Pull-out

st

PCB with inspectionable joint st 1 Pull-out

17

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

Task.3: Pull-out on Thermount85NT Test Vehicle

�Step 3 :shall be prepared an aluminum base (1.5 2.0 mm of thickness and larger in dimension to the piece of PCB where the component was soldered), and with the aid of a certain number of Kapton adhesive ply (in this case the base kapton thickness is 50 um thickness per ply and it has been employed 4 ply to reach a final thickness of 200m) it is possible create a sort of stencil to deposit the glue on the aluminium plate with a controlled thickness. � Step 4: the component shall be placed with residual dimples on the aluminum plate with glue and shall be applied a soft pressure, on the top of component, to guarantee a good penetration of two parts. � Step 5: After the polymerization time, the sample it will able to be pulled-out again

Steel foil

Steel foil with Kapton (4 sheet of 50 m for total Thk= 200m)

Steel foil with Kapton and glue (Thk glue = ~200m)

DBGA package on glue for 2nd out

pull-

DBGA package

Steel foil and balls after 2nd pull-out

DBGA package (Final Visual Inspection)

Balls after 2nd pull-out (Final Visual Inspection)

18

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

Task.3: Pull-out on Thermount85NT Test Vehicle

Sample prepared to 1 pull-out

Package after 1 pull-out

PCB after 1 pull-out

Package prepared to 2 pull-out

PCB Alias after 2 pull-out

Package after 2 pull-out

19

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

Task.4: Thermal Cycles

All the Test Vehicles have been submitted to thermal cycles test, respecting the at least the ECSS-Q70-08 criteria about the temperature range, the dwell time and the temperature gradient, in order to induce the cracks on the DBGA soldered joint, and after that to submit the cracked samples to the dye penetrant test. It has been employed Epoxy PCB in addition to the Thermount 85 NT to accelerate the cracking processes in the soldered joint due to the higher Epoxy CTE (16 ppm/C) respect to Thermount 85 NT CTE (6-9 ppm/C). This doesnt influence the dyes penetrant performances because they have been examined on the cracks of soldered joint and not on the substrate.

The Test Vehicles have been assembled:

� Epoxy Test Vehicles with 2 DBGA228 and 2 DBGA444 each one

� Thermount85NT Test Vehicles with 4 DBGA228 and 4 DBGA444 each one

20

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

Task.4: Thermal Cycles

Thermal Cycles for Epoxy Test Vehicles

Temperature range -55C /+100C -55C /+125C -65C /+135C S/N 1 700 cycles 200 cycles N.A. S/N 2 700 cycles 200 cycles N.A. S/N 3 300 cycles 300 cycles 200 cycles S/N 4 200 cycles 200 cycles 200 cycles S/N 5 200 cycles 200 cycles 200 cycles S/N 6 200 cycles 200 cycles 200 cycles

Thermal Cycles for Thermount 85 NT Test Vehicles

Temperature range -55C /+100C -55C /+125C -65C /+135C S/N 1 500 cycles 200 cycles 200 cycles S/N 2 300 cycles 200 cycles 200 cycles S/N 3 300 cycles 200 cycles 200 cycles S/N 4 300 cycles 200 cycles 200 cycles

21

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

Task.5: Dye Penetrant Test on Epoxy Test Vehicles

On this task the Test Vehicles on Epoxy PCB have been submitted to the Dye penetrant test to have a first evaluation of dyes performances and, basing on that, to do a sub-selection of the most suitable ones . Summary of Dye Penetrant Test Procedure: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. Dye Penetrant Solution Preparation Samples Preparation Dye Bath Immersion Vacuum Drying of samples Pull-out of BGA Inspection to Microscope Inspection on UV Light or White Light Analysis of results Photo report

Manufacturer Risk Reactor Risk Reactor Risk Reactor Risk Reactor Risk Reactor Risk Reactor Risk Reactor Risk Reactor S.I.T. Dykem Dye Penetrant DFDRY-C0 DFSB-C0 DFSB-C7 DFSB-K43 DFSB-K61 DFSB-K87 DFPD-C2 IFWB-C2 EOSINA RED STEEL

Dye Penetrant under evaluation

22

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

Task.5: Dye Penetrant Test on Epoxy Test Vehicles

At the first, the Dye Penetrant Test has been performed on the DBGA 444 components from the Test Vehicle S/N1, S/N2, S/N3, S/N4, S/N5 , two components each Test Vehicles, and each component has been tested with one dye. The visual inspection has been focused on: � the visibility � the boundary of dyes traces to evaluate the definition � the penetration � the capability to be photographed � other aspects For this it has been focused the interest to the joints partially cracked to evaluate the behaviour of dyes. For all Samples the results of the visual inspection was the same: quite all the soldered joint on the external places on the components have been completely cracked, whereas moving versus the inner places the joints shown a minor damaged percentage. The inner joints in most cases didnt show crack or had cracks with a percentage less than 515%

23

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

Task.5: Dye Penetrant Test on Epoxy Test Vehicles

DFDRY-C0

The Dye Penetrant Test has been performed on DBGA 444 #1 from Test Vehicle S/N 1 All the joints have been inspected with the exception of 12 joints not pulled-out

� The profile of cracked joint is well defined � The penetration is good � Visibility good At this step the DFDRY-C0 has been considered suitable for crack detection

24

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

Task.5: Dye Penetrant Test on Epoxy Test Vehicles

DFSB-C0

The Dye Penetrant Test has been performed on DBGA 444 #1 from Test Vehicle S/N 2 All the joints have been inspected with the exception of 15 joints not pulled-out

� Low level of visibility � The profile of cracked joint isnt well defined � The penetration is good At this step the DFSB-C0 has been considered not suitable for crack detection

25

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

Task.5: Dye Penetrant Test on Epoxy Test Vehicles

DFSB-C7

The Dye Penetrant Test has been performed on DBGA 444 #2 from Test Vehicle S/N 2 All the joints have been inspected with the exception of 8 joints not pulled-out

� Not sufficient visible � The profile of cracked joint isnt well defined � Presence of isolated traces (caused by contamination) At this step the DFSB-C7 has been considered not suitable for crack detection

26

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

Task.5: Dye Penetrant Test on Epoxy Test Vehicles

DFSB-K43

The Dye Penetrant Test has been performed on DBGA 444 #1 from Test Vehicle S/N 3 All the joints have been inspected with the exception of 13 joints not pulled-out

� Sufficient visible � The profile of cracked joint quite well defined � The penetration is good � Presence of isolated traces (caused by contamination) � Dusty traces in some cases (probably cause of contamination)

27

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

At this step the DFSB-K43 has been considered not suitable for crack detection

Task.5: Dye Penetrant Test on Epoxy Test Vehicles

DFSB-K61

The Dye Penetrant Test has been performed on DBGA 444 #2 from Test Vehicle S/N 3 All the joints have been inspected with the exception of 21 joints not pulled-out

� The profile of cracked joint not defined � The penetration is poor � Dusty At this step the DFSB-K61 has been considered not suitable for crack detection

28

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

Task.5: Dye Penetrant Test on Epoxy Test Vehicles

DFSB-K87

The Dye Penetrant Test has been performed on DBGA 444 #1 from Test Vehicle S/N 5 All the joints have been inspected with the exception of 17 joints not pulled-out

� The profile of cracked joint sufficient defined � Traces not well marked � Almost dusty At this step the DFSB-K87 has been considered not suitable for crack detection

29

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

Task.5: Dye Penetrant Test on Epoxy Test Vehicles

DFPD-C2

The Dye Penetrant Test has been performed on DBGA 444 #2 from Test Vehicle S/N 5 All the joints have been inspected

� The profile of cracked joint not defined � Dusty � Contamination At this step the DFPD-C2 has been considered not suitable for crack detection

30

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

Task.5: Dye Penetrant Test on Epoxy Test Vehicles

IFWB-C2

The Dye Penetrant Test has been performed on DBGA 444 #1 from Test Vehicle S/N 4 All the joints have been inspected with the exception of 15 joints not pulled-out

� The profile of cracked joint well defined � The penetration is good � Good visibility At this step the IFWB-C2 has been considered suitable for crack detection

31

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

Task.5: Dye Penetrant Test on Epoxy Test Vehicles

RED STEEL

The Dye Penetrant Test has been performed on DBGA 444 #2 from Test Vehicle S/N 4 All the joints have been inspected with the exception of 11 joints not pulled-out

� The profile of cracked joint well defined � The penetration is good � Good visibility in white light At this step the RED STEEL has been considered suitable for crack detection

32

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

Task.5: Dye Penetrant Test on Epoxy Test Vehicles

EOSINA

The Dye Penetrant Test has been performed on DBGA 444 #2 from Test Vehicle S/N 1 All the joints have been inspected with the exception of 8 joints not pulled-out

� The profile of cracked joint well defined � Excellent penetration � Good visibility in white light At this step the EOSINA has been considered suitable for crack detection

33

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

Task.5: Dye Penetrant Test on Epoxy Test Vehicles

At the end of this test run, it has been examined the results and performed a sub-selection of the most suitable dyes penetrant. Basing on the properties and on performances of each dye, it has been selected 4 dyes penetrant The other dyes have been considered not appropriate for this kind of test, because not definition of crack profile, dustiness and low penetration factor.

Manufacturer Risk Reactor Risk Reactor S.I.T. Dykem Dye Penetrant DFDRY-C0 IFWB-C2 EOSINA RED STEEL

Sub-selected Dye Penetrant

A second test run has been performed on the DBGA228 on Epoxy Test Vehicles to confirm the subselection. This time, in addition to the inspection of the PCB side, it has been taken in to account the inspection of package side too.

34

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

Task.5: Dye Penetrant Test on Epoxy Test Vehicles

DFDRY-C0

The Dye Penetrant Test has been performed on DBGA 228#1 from Test Vehicle S/N 3 (93% inspected) The Dye Penetrant Test has been performed on DBGA 228#2 from Test Vehicle S/N 2 (95% inspected)

PCB Side

Package Side

35

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

Task.5: Dye Penetrant Test on Epoxy Test Vehicles

DFDRY-C0

The results of the first run have been partially confirmed. The profile is nearly well defined, but during this second run a granular aspect has been detected, probably caused by a less concentration of dye bath, so in the next test it has been expected a review of dye bath concentration. The comparison between the inspections of cracks on PCB side and Package side didnt show differences.

36

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

Task.5: Dye Penetrant Test on Epoxy Test Vehicles

IFWB-C2

The Dye Penetrant Test has been performed on DBGA 228#1 from Test Vehicle S/N 4 (93% inspected) The Dye Penetrant Test has been performed on DBGA 228#2 from Test Vehicle S/N 4 (95% inspected)

PCB Side

Package Side

37

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

Task.5: Dye Penetrant Test on Epoxy Test Vehicles

IFWB-C2

The good behaviour of this dye has been confirmed from the results of the second test run. Each consideration done in the first test run in order to the profile definition or to other aspect has been verified. In addition the comparison between the inspections of cracks on PCB side and Package side didnt show differences .

38

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

Task.5: Dye Penetrant Test on Epoxy Test Vehicles

RED STEEL

The Dye Penetrant Test has been performed on DBGA 228#2 from Test Vehicle S/N 3 (91% inspected)

PCB Side

Package Side

39

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

Task.5: Dye Penetrant Test on Epoxy Test Vehicles

RED STEEL

The results of this test run confirmed the good properties of Red Steel in this kind of analysis. The comparison between the inspections of cracks on PCB side and Package side didnt show differences. In addition a pictures of whole component has been allowed from the possibility to work in white light. Some fine adjustment has been necessary in order to the drying procedure in the next step .

40

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

Task.5: Dye Penetrant Test on Epoxy Test Vehicles

EOSINA

The Dye Penetrant Test has been performed on DBGA 228#1 from Test Vehicle S/N 2 (89% inspected)

PCB Side

Package Side

41

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

Task.5: Dye Penetrant Test on Epoxy Test Vehicles

EOSINA

The results of this test run confirmed the suitability of Eosina for dye penetrant test. The comparison between the inspections of cracks on PCB side and Package side didnt show differences. Also in this case the possibility to work in white light has been allowed to take a pictures of whole component .

42

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

Task.6: Dye Penetrant Test on Thermount85NT

In this task it has been repeated the Dye Penetrant Test submitting to it the Test Vehicles on Thermount85NT. Basing on the observation of previous task, it has been performed some little adjustments to the Dye Penetrant Procedure. During the first part of this task, it has been reported the Dye Penetrant Test employing the multiple pull-out procedure to evaluate the feasibility of this procedure and to establish a final verdict for the dyes under analysis. At the end of this task some examples of analysis after Dye Penetrant Test have been described and a correlation has been done between these analysis and the electrical measurements on Test Vehicles performed before, during and at the end of thermal cycles. .

43

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

Task.6: Dye Penetrant Test on Thermount85NT

DFDRY-C0

The Dye Penetrant Test has been performed on DBGA 444#1 from Test Vehicle S/N 4. After the first Pull-Out, 245 soldered joints (55.2%) have been inspected and after the second Pull-Out 179 soldered joints (up to 95.5%) have been inspected, with 20 residual joints (4.5%) still attached to package.

Inspection after 1 Pull-Out

Inspection after 2 Pull-Out

44

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

Task.6: Dye Penetrant Test on Thermount85NT

IFWB-C2

The Dye Penetrant Test has been performed on DBGA 444#2 from Test Vehicle S/N 4. After the first Pull-Out 260 soldered joints (58.5%) have been inspected and after the second Pull-Out 175 soldered joints (up to 98.0%) have been inspected, with 9 residual joints (2.0%) still attached to package.

Inspection after 1 Pull-Out

Inspection after 2 Pull-Out

45

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

Task.6: Dye Penetrant Test on Thermount85NT

RED STEEL

The Dye Penetrant Test has been performed on DBGA 444#1 from Test Vehicle S/N 3. After the first Pull-Out 254 soldered joints (57.2%) have been inspected and after the second Pull-Out 188 soldered joints (up to 99.5%) have been inspected, with 2 residual joints (0.5%) still attached to package.

Inspection after 1 Pull-Out

Inspection after 2 Pull-Out

46

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

Task.6: Dye Penetrant Test on Thermount85NT

EOSINA

The Dye Penetrant Test has been performed on DBGA 444#2 from Test Vehicle S/N 3. After the first Pull-Out 271 soldered joints (61.0%) have been inspected and after the second Pull-Out 158 soldered joints (up to 96.6%) have been inspected, with 15 residual joints (3.4%) still attached to package .

Inspection after 1 Pull-Out

Inspection after 2 Pull-Out

47

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

Task.6: Dye Penetrant Test on Thermount85NT

DFDRY-C0

The Dye Penetrant Test has been performed on DBGA 228#2 from Test Vehicle S/N 3. After the first Pull-Out 197 soldered joints (86.4%) have been inspected and after the second Pull-Out 31 soldered joints (up to 100%). 1& 2 Pull-Out Results

48

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

Task.6: Dye Penetrant Test on Thermount85NT

DFDRY-C0

Inspection after 1 Pull-Out

Inspection after 2 Pull-Out

49

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

Task.6: Dye Penetrant Test on Thermount85NT

IFWB-C2

The Dye Penetrant Test has been performed on DBGA 228#1 from Test Vehicle S/N 3. After the first Pull-Out 159 soldered joints (69.7%) have been inspected and after the second Pull-Out 69 soldered joints (up to 100%). 1& 2 Pull-Out Results

50

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

Task.6: Dye Penetrant Test on Thermount85NT

IFWB-C2

Inspection after 1 Pull-Out

Inspection after 2 Pull-Out

51

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

Task.6: Dye Penetrant Test on Thermount85NT

RED STEEL

The Dye Penetrant Test has been performed on DBGA 228#2 from Test Vehicle S/N 4. After the first Pull-Out 78 soldered joints (34.2%) have been inspected and after the second Pull-Out 143 soldered joints (up to 96.9%) have been inspected, with 7 residual joints (3.1%) still attached to package. 1& 2 Pull-Out Results

52

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

Task.6: Dye Penetrant Test on Thermount85NT

RED STEEL

Inspection after 1 Pull-Out

Inspection after 2 Pull-Out

53

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

Task.6: Dye Penetrant Test on Thermount85NT

EOSINA

The Dye Penetrant Test has been performed on DBGA 228#2 from Test Vehicle S/N 4. After the first Pull-Out 195 soldered joints (85.5%) have been inspected and after the second Pull-Out 143 soldered joints (up to 100%). 1& 2 Pull-Out Results

54

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

Task.6: Dye Penetrant Test on Thermount85NT

EOSINA

Inspection after 1 Pull-Out

Inspection after 2 Pull-Out

55

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

Task.6: Dye Penetrant Test on Thermount85NT

Comparison between the Dye Penetrant Test results and Electrical Measurement at Room Temperature

At the end of this task it has been performed an analysis of cracks extension by means Dye Penetrant Test, on a BGA444 and on a DBGA228 to demonstrate the feasibility of the annexed procedure, and to compare the results of Dye Penetrant Test with the electrical measurement at room temperature taken before, during and after the thermal cycles. The comparison has been performed on � DBGA444 submitted to Dye Pentrant Test with RED STEEL � DBGA228 submitted to Dye Pentrant Test with EOSINA

56

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

Task.6: Dye Penetrant Test on Thermount85NT

� Dye Penetrant Test on DBGA 444 on Themount85NT Test Vehicle

T2 T1

B B A A A A B B A A A A B A A A A A C A A A A A C A A A A A C B A A A A C B BB AB A A A A A A D B A A A A B B A A A A C B B B A A A A A A A A A A A A A A A A A A A B C CC B C A B AB AB AB A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A AB B B C D D D C B C C B C AB D AB C AB C BB C B BC ABC BB C AB C AB C AB C AB C B B C B B C BB C B BC B BC B B D BC D C D D C D D D D D

The Dye Penetrant Test has been performed on a DBGA444 with RED STEEL and some classes of crack percentage have been fixed, each one associated to a letter. These ranges arent very close but it is possible to calculate exactly the percentage of crack area and repeat a similar analysis with a great number of classes with more accurate intervals.

Code A B C D E F

Percentage of cracked area < 20 % 20 39 % 40 59 % 60 79 % 80 99 % 100 %

T7 T8 T3 T4 T5 T6

B B B BC B C BA C BA BB B A AA B BA BBA A BA A BA B BB C BA BA A BA A B BA BA A B A A F A A C A A C A A D A A D B B C C C

B B A A A A A A A A A A A A A A A A A A A B B

BB BA A A BA A A A A AA A A AA AA AA AA AA AA AA AA AA A A A A A A A A A A A A C A C D

B B A A A A

B A A A A A

B A A A A A

T16 T15 T14 T13

A A A A A C

A A A A A B

A A A A A B

A A A A B C

A A A A B C

A A A A A C

A A A A A C

A A A A A C

A A A A B D

A A A A A C

A A A A A C

A A A A B C

A A A A B C

T12 T11

Daisy-Chain 1 2 3 4 5 6 7 8 T1-T2 T3-T4 T5-T6 T7-T8 T9-T10 T11-T12 T13-T14 T15-T16

To 0.304 0.244 0.302 0.274 0.377 0.220 0.353 0.246

200 Cycles (-65C/+135C)

Contact Res ( ) ( R/Ro)% 0.3 0.4 0.3 0.7 0.3 1.4 0.3 0.4

PROGRESSIVE TYHERMAL CYCLES 100 Cycles 300 Cycles (-55C/+125C) (-55C/+100C)

Contact Res ( ) ( R/Ro)% 2.6 2.9 2.6 2.9 2.4 4.5 2.5 3.3 Contact Res ( ) ( R/Ro)% 3.9 4.1 3.3 4.4 3.4 5.9 3.7 4.9

100 Cycles (-55C/+125C)

Contact Res ( ) ( R/Ro)% 5.3 7.0 5.0 6.2 4.5 8.6 5.7 7.7

T9

T10

0.305 0.245 0.303 0.276 0.378 0.223 0.354 0.247

0.312 0.251 0.310 0.282 0.386 0.230 0.362 0.254

0.316 0.254 0.312 0.286 0.390 0.233 0.366 0.258

0.320 0.261 0.317 0.291 0.394 0.239 0.373 0.265

57

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

Task.6: Dye Penetrant Test on Thermount85NT

Dye Penetrant Test on DBGA 444 on Themount85NT Test Vehicle From the visual inspection and from electrical data, it has been observed: � In the T7-T8 daisy chain a fully open joint it has been detected, not revealed from electrical measurements. The T7-T8 Contact Resistance drift (+6.2%), even if there is an open joint, results less than the other Contact Resistance drift T3-T4 (+7.0%), T11-T12 (+8.6%), T15-T16 (+7.7%), which dont have any open joint. The corner daisy chain have a great Contact Resistance drift than the others.

So basing only on Electrical Measurement at room temperature, it could be possible to take erroneous conclusions, because one open joints has not been detected and it is impossible to know the cracked percentage of each joint.

58

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

Task.6: Dye Penetrant Test on Thermount85NT

� Dye Penetrant Test on DBGA 228 on Themount85NT Test Vehicle A DBGA228 has been submitted to the Dye Penetrant Test with EOSINA and the photos of each daisy chain have been reported later on to compare them with the electrical measurement at room temperature

Daisy-ChainT1-T2

59

Corporate Communications May 15th, 2007

Daisy-ChainT3-T4

All rights reserved 2007, Thales Alenia Space

Task.6: Dye Penetrant Test on Thermount85NT

Dye Penetrant Test on DBGA 228 on Themount85NT Test Vehicle

Daisy-ChainT5-T6

60

Corporate Communications May 15th, 2007

Daisy-ChainT7-T8

All rights reserved 2007, Thales Alenia Space

Task.6: Dye Penetrant Test on Thermount85NT

Dye Penetrant Test on DBGA 228 on Themount85NT Test Vehicle

Daisy-ChainT11-T12 Daisy-ChainT9-T10

61

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

Task.6: Dye Penetrant Test on Thermount85NT

Dye Penetrant Test on DBGA 228 on Themount85NT Test Vehicle

Daisy-ChainT13-T14

Daisy-ChainT15-T16

62

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

Task.6: Dye Penetrant Test on Thermount85NT

Dye Penetrant Test on DBGA 228 on Themount85NT Test Vehicle

Daisy-Chain 1 2 3 4 5 6 7 8 T1-T2 T3-T4 T5-T6 T7-T8 T9-T10 T11-T12 T13-T14 T15-T16 To 0.133 0.189 0.135 0.177 0.131 0.173 0.136 0.186 200 Cycles

Contact Res ( ) ( R/Ro)% 0.0 0.0 0.0 0.6 0.8 0.6 -1.5 1.6

PROGRESSIVE TYHERMAL CYCLES 300 Cycles 100 Cycles

Contact Res ( ) ( R/Ro)% 4.5 4.8 2.2 4.0 2.3 3.5 1.5 6.5 Contact Res ( ) ( R/Ro)% 5.3 6.9 3.0 5.6 3.8 4.6 2.2 8.1

100 Cycles

Contact Res ( ) ( R/Ro)% 9.0 11.6 5.9 9.0 6.1 8.7 5.1 12.4

0.133 0.189 0.135 0.178 0.132 0.174 0.134 0.189

0.139 0.198 0.138 0.184 0.134 0.179 0.138 0.198

0.140 0.202 0.139 0.187 0.136 0.181 0.139 0.201

0.145 0.211 0.143 0.193 0.139 0.188 0.143 0.209

Electrical Measurements

63

Corporate Communications May 15th, 2007

Daisy-ChainT7-T8

Daisy-ChainT15-T16

All rights reserved 2007, Thales Alenia Space

Task.6: Dye Penetrant Test on Thermount85NT

Dye Penetrant Test on DBGA 228 on Themount85NT Test Vehicle From the visual inspection and from electrical data, it has been observed : � 3 open joints on T7-T8 and 6 open joints on T15-T16 have been detected, not revealed by electrical measurements at room temperature. The higher Contact Resistance drift results in T15-T16 (+12.4%), where 6 open joints have been detected, but the second higher Contact Resistance drift results in T3-T4 (+11.6%), where doesnt have any open joint, instead of T3-T8 (+9.0%), where 3 open joint have been detected. The corner daisy chain not ever have a Contact Resistance greater than others: in fact T1-T2 (+9.0%) has the same drift of T7-T8 and an higher drift of T11-T12 (+8.7%).

So, in this case too, basing only on Electrical Measurement at room temperature, it could be possible to take erroneous conclusions, because 9 open joints havent been detected and it is impossible to know the cracked percentage of each joint

64

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

Conclusion

Dye Penetrant At the end of this activity it is possible consider that: The UV inspection, even if more evocative, gives more problems � IFWB-C2: it is a good dye, suitable for detection of cracks on soldered joint. Moreover once dry, it doesnt produce any dust, and the inspection is quite easy. DFDRY-C0: it is a good dye but not like the previous one. In fact, even if this dye is able to detect the cracks on soldered join, in some cases the cracks profiles arent well defined, in other cases it produces dust which may contaminate not cracked area. In addition, when under UV light, this dye has the same spectral emission of the substances contained in the void of DBGA dimples, introducing the possibilities to occur an error during the crack area calculation. RED STEEL: it is a very suitable product to detect the solder join cracks, with an easiness of use and with the possibility to work on white light. EOSINA: like the previous one, it is a very suitable product to detect the solder join cracks, with an easiness of use and with the possibility to work on white light

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

�

65

Conclusion

Electrical Measurement at R.T. Comparison From the analysis on DBGA 444 and on DBGA 228 it is possible to consider that the Electrical Test at Room Temperature it isnt a suitable way for open joint detecting, whereas the Dye penetrant Test is able to detect them. Limits of this procedure Some consideration shall be done about the limits of annexed procedure, because it has been customized for DBGA components, but with some adjustment it will be applicable also for the other Area Array Components. Suggests Generally the Electrical Test, when applied in a correct way, is faster and less influenced by external factors, in other words is better. Basing on this and after the qualification activity, two Electrical Test are suggested for future studies: � By means of Event Detector, find the open connection DC measurement of Contact Resistance of Test Vehicles during a thermal cycle fixing a maximum percentage of variation around the measured central value. � By in the daisy-chain of Test Vehicles when submitted to a thermal cycle. product to detect the solder join cracks, with an easiness of use

66

Corporate Communications May 15th, 2007 All rights reserved 2007, Thales Alenia Space

You might also like

- Silverwing B Scan ReportDocument46 pagesSilverwing B Scan ReportpjhollowNo ratings yet

- Eddy Current White PaperDocument25 pagesEddy Current White PapervrapciudorianNo ratings yet

- Eddy Current ProbesDocument20 pagesEddy Current Probesedapo7950% (2)

- Product Technology: Steel Production and Casting MethodsDocument136 pagesProduct Technology: Steel Production and Casting MethodsTamilarasanNo ratings yet

- Prxnrnant Testtng: Buane & Ii T P O'NeillDocument6 pagesPrxnrnant Testtng: Buane & Ii T P O'NeillAzeem ShaikhNo ratings yet

- 9 Data Processing of Tofd FilesDocument6 pages9 Data Processing of Tofd FilesPuneet Vikram SinghNo ratings yet

- RT-Technique Sheet Items Level IIDocument3 pagesRT-Technique Sheet Items Level IISugianto TanNo ratings yet

- The Principles: HistoryDocument39 pagesThe Principles: HistoryLương Hồ VũNo ratings yet

- Set Theory Chapter 8 Concepts and ExamplesDocument40 pagesSet Theory Chapter 8 Concepts and Examplesshabbir626100% (1)

- High Temperature Ultrasonic ScanningDocument7 pagesHigh Temperature Ultrasonic ScanningscribdmustaphaNo ratings yet

- BPF-V-270 Test Separator-Cm-Pvir-Xxxxx-20Document32 pagesBPF-V-270 Test Separator-Cm-Pvir-Xxxxx-20Agung Prastyo WibowoNo ratings yet

- Tube Inspection InsertDocument2 pagesTube Inspection InsertManish SharmaNo ratings yet

- Course Material For ASNT LEVEL II in Liquid Penetrant Testing ISCODocument92 pagesCourse Material For ASNT LEVEL II in Liquid Penetrant Testing ISCOThulasi Ram100% (1)

- Soviet Union State Standards: Official PublicationDocument22 pagesSoviet Union State Standards: Official PublicationFreddyNo ratings yet

- Tube Inspection Intro PPT OutlineDocument9 pagesTube Inspection Intro PPT OutlinevibinkumarsNo ratings yet

- WE Inlastek 05A Visual ExaminationDocument30 pagesWE Inlastek 05A Visual Examinationhafidhrahadiyan2100% (1)

- Bevel and cap geometry dataDocument3 pagesBevel and cap geometry dataJ.CarrascoNo ratings yet

- Ultrasonic Testing - Wikipedia PDFDocument26 pagesUltrasonic Testing - Wikipedia PDFKarthicWaitingNo ratings yet

- Tofd Development: TechniqueDocument32 pagesTofd Development: TechniqueLương Hồ VũNo ratings yet

- Product TechnologyDocument138 pagesProduct TechnologyRaja SekarNo ratings yet

- Penetrant TestingDocument36 pagesPenetrant Testingkumarmm1234100% (1)

- D-p5-Bv-pd-007 - Ect, Issue 01, Rev 00 - Eddy Current TestingDocument18 pagesD-p5-Bv-pd-007 - Ect, Issue 01, Rev 00 - Eddy Current TestingThinh NguyenNo ratings yet

- Twi Training & Certification (S.E. Asia) SDN - BHDDocument1 pageTwi Training & Certification (S.E. Asia) SDN - BHDjasminneeNo ratings yet

- Ut TwiDocument99 pagesUt TwiHao TranNo ratings yet

- L Ru WrittenDocument12 pagesL Ru Writtenmadhunikhil100% (1)

- Example Slide of User Functions: Time Guide The Slide Should Be Finished byDocument70 pagesExample Slide of User Functions: Time Guide The Slide Should Be Finished byHskumarReddy KarriNo ratings yet

- List of NDT & Inspection Approved Training Organisations: Part 1 Part 2 Part 3Document25 pagesList of NDT & Inspection Approved Training Organisations: Part 1 Part 2 Part 3PP043No ratings yet

- NDT Technician: Circumferential Scanning in Ultrasonic InspectionDocument12 pagesNDT Technician: Circumferential Scanning in Ultrasonic InspectionmaterialsNo ratings yet

- PT - Level 2 - S - 002 - Revised by RVMDocument4 pagesPT - Level 2 - S - 002 - Revised by RVMkingstonNo ratings yet

- Tube Probe Selection OlympusDocument12 pagesTube Probe Selection OlympusTechnical A-Star Testing & Inspection MalaysiaNo ratings yet

- TWI-2008-Reliability of Manually Applied Phased Array Ultrasonic Inspection For Detection and Sizing of Flaws PDFDocument60 pagesTWI-2008-Reliability of Manually Applied Phased Array Ultrasonic Inspection For Detection and Sizing of Flaws PDFRicardoSchayerSabinoNo ratings yet

- Purpose of Seminar: Phased Arrays: Codes and ApplicationsDocument6 pagesPurpose of Seminar: Phased Arrays: Codes and ApplicationsLương Hồ VũNo ratings yet

- Chapter 12.1 - Visual Testing VTDocument23 pagesChapter 12.1 - Visual Testing VTMauricio Marques100% (2)

- NDT Code Book Made Easy For AsmeDocument398 pagesNDT Code Book Made Easy For AsmeJosé Pablo Espinoza SolísNo ratings yet

- NDT AcceptanceDocument62 pagesNDT Acceptancebommakanti srinivasNo ratings yet

- C4 5 PDFDocument30 pagesC4 5 PDFLương Hồ VũNo ratings yet

- Isq-O&G Manual Ultrasonic Thickness & Corrosion Examination: ASNT Document UT-PTP7 Revision 2Document14 pagesIsq-O&G Manual Ultrasonic Thickness & Corrosion Examination: ASNT Document UT-PTP7 Revision 2muhammadazhanudinNo ratings yet

- Eddy Current Testing Parameters ExplainedDocument45 pagesEddy Current Testing Parameters ExplainedDhruv SahniNo ratings yet

- Casting Definitions and TerminologyDocument15 pagesCasting Definitions and TerminologyCharlie ChongNo ratings yet

- Digital: (4) : Aspects ofDocument30 pagesDigital: (4) : Aspects ofLương Hồ VũNo ratings yet

- D-p5-Bv-pd-018 - Ut, Issue 01, Rev 00 - Ultrasonic Testing (Asme Sec V)Document57 pagesD-p5-Bv-pd-018 - Ut, Issue 01, Rev 00 - Ultrasonic Testing (Asme Sec V)Thinh NguyenNo ratings yet

- MultiView 6.1 EN 201204Document12 pagesMultiView 6.1 EN 201204bian_barker100% (2)

- PAUT SS Blind Zone CoverageDocument3 pagesPAUT SS Blind Zone Coveragesnndhk0% (1)

- LPT Spe QB 2Document6 pagesLPT Spe QB 2Aruchamy SelvakumarNo ratings yet

- Eddy Current Tubing DentingDocument54 pagesEddy Current Tubing Dentingaldeanucu100% (3)

- Radiography TestingDocument1 pageRadiography TestingGulfnde Industrial ServicesNo ratings yet

- Radiography Part 1 - TWI PDFDocument7 pagesRadiography Part 1 - TWI PDFPahe DriveNo ratings yet

- ECT Inspection Technique: Setup and CalibrationDocument19 pagesECT Inspection Technique: Setup and CalibrationAbhishek DevarajNo ratings yet

- Lecture 3, Eddy Current NDEDocument49 pagesLecture 3, Eddy Current NDEMirza Safeer AhmadNo ratings yet

- NDT Methods GuideDocument12 pagesNDT Methods GuideSIVARAM PRASADNo ratings yet

- Advances in Tube Testing 2008Document39 pagesAdvances in Tube Testing 2008AhmedA.HassanNo ratings yet

- Weld Discontinuity Evaluation Guide-Bolje SkeniranoDocument19 pagesWeld Discontinuity Evaluation Guide-Bolje SkeniranoDinesh RadhakrishnanNo ratings yet

- UT III Mathematics: Metric/English Equivalents, Velocity Equivalents, Transducer Q, Focussed Immersion, Acoustic Impedance, Wavelength, Near Field, Beam Divergence, ReflectionDocument86 pagesUT III Mathematics: Metric/English Equivalents, Velocity Equivalents, Transducer Q, Focussed Immersion, Acoustic Impedance, Wavelength, Near Field, Beam Divergence, ReflectionDibyendu Bera100% (1)

- VP 31a Product Data Met L CheckDocument2 pagesVP 31a Product Data Met L CheckTopoilServNo ratings yet

- Lexan Thermoclear Technical ManualDocument26 pagesLexan Thermoclear Technical ManualPavo PerkovićNo ratings yet

- Corrosion Protection in Amine Treating Units PDFDocument12 pagesCorrosion Protection in Amine Treating Units PDFMubeenNo ratings yet

- Bolt Load Capacity TableDocument1 pageBolt Load Capacity Tableezarul fitri100% (2)

- Dead LoadsDocument3 pagesDead Loadsezarul fitriNo ratings yet

- Design of The Putrajaya Wetland ProjectDocument5 pagesDesign of The Putrajaya Wetland Projectezarul fitri100% (1)

- Reinforcement BarDocument1 pageReinforcement Barezarul fitriNo ratings yet

- Bolt Load Capacity TableDocument1 pageBolt Load Capacity Tableezarul fitri100% (2)

- Dead Loads ReferenceDocument6 pagesDead Loads Referenceezarul fitriNo ratings yet

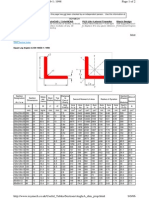

- Equal Angle Section TableDocument2 pagesEqual Angle Section Tableezarul fitri100% (1)

- Guidelines For Replacement of Bakau Piles For Common Did StructuresDocument5 pagesGuidelines For Replacement of Bakau Piles For Common Did Structuresezarul fitri100% (1)

- Retaining Wall DesignDocument10 pagesRetaining Wall DesignklynchelleNo ratings yet

- Temporary Traffic ManagementDocument48 pagesTemporary Traffic Managementezarul fitriNo ratings yet

- Traffic Management Plan for Wanneroo Road WorksDocument41 pagesTraffic Management Plan for Wanneroo Road Worksezarul fitri67% (6)

- Temporary Traffic ManagementDocument48 pagesTemporary Traffic Managementezarul fitriNo ratings yet

- Concrete Reinforcement Spacing DataDocument1 pageConcrete Reinforcement Spacing Dataezarul fitriNo ratings yet

- Bolt Group DesignDocument4 pagesBolt Group Designezarul fitriNo ratings yet

- Guidelines For Public Safety & Health at Construction SitesDocument26 pagesGuidelines For Public Safety & Health at Construction SiteswkinsoiNo ratings yet

- Replace Bakau Piles with Timber or Concrete for Foundation StructuresDocument6 pagesReplace Bakau Piles with Timber or Concrete for Foundation Structuresezarul fitri100% (2)

- Specification For Pre-Fabricated Cold-Formed Steel Roof TrussesDocument24 pagesSpecification For Pre-Fabricated Cold-Formed Steel Roof Trussesezarul fitri100% (4)

- Design Calculation For Pile Length Using Meyerhoff FormulaeDocument1 pageDesign Calculation For Pile Length Using Meyerhoff Formulaeezarul fitri83% (6)

- Raft Foundation DesignDocument2 pagesRaft Foundation Designezarul fitri88% (25)

- Raft Foundation DesignDocument2 pagesRaft Foundation Designezarul fitri88% (25)

- Multiple RC Staircase DesignDocument3 pagesMultiple RC Staircase Designezarul fitri100% (1)

- Soil Investigation Standard BQ Without Rates in Semenanjung MalaysiaDocument11 pagesSoil Investigation Standard BQ Without Rates in Semenanjung Malaysiaezarul fitri75% (4)

- JKR - Conditions of ContractDocument56 pagesJKR - Conditions of Contractezarul fitri100% (4)

- Kod Piawaian Konkrit StrukturDocument5 pagesKod Piawaian Konkrit Strukturezarul fitriNo ratings yet

- Earth Retaining Wall DesignDocument30 pagesEarth Retaining Wall Designezarul fitri100% (7)

- Detention Pond Design Using MASMADocument72 pagesDetention Pond Design Using MASMAezarul fitri50% (2)

- Single RC Staircase DesignDocument4 pagesSingle RC Staircase Designezarul fitri100% (4)

- TransformerDocument14 pagesTransformerNegrea Cristian0% (3)

- Circuit Board Design: CATIA TrainingDocument56 pagesCircuit Board Design: CATIA TrainingCahyo ArdoyoNo ratings yet

- Pioneer X-hm10 X-hm20 SMDocument59 pagesPioneer X-hm10 X-hm20 SMmanuelomano0% (1)

- The "Three Fives" Discrete 555 Timer: DatasheetDocument8 pagesThe "Three Fives" Discrete 555 Timer: DatasheetAlex StanciuNo ratings yet

- Usb 3.0Document22 pagesUsb 3.0Avi Ramirez CervantesNo ratings yet

- OneTeslaTS User ManualDocument24 pagesOneTeslaTS User ManualBobbyNo ratings yet

- Led LCD TV: Service ManualDocument42 pagesLed LCD TV: Service ManualJm QuemadoNo ratings yet

- Lab 4 - Introduction To Printed Circuit Board (PCB) Drawing SoftwareDocument8 pagesLab 4 - Introduction To Printed Circuit Board (PCB) Drawing SoftwareArif AzmiNo ratings yet

- DX-S ManualDocument669 pagesDX-S Manualpericopepe100% (1)

- Machine CapabilityDocument41 pagesMachine Capabilityfrancisco.torres.carmonaNo ratings yet

- Introduction to Proteus PCB Design and Simulation SoftwareDocument14 pagesIntroduction to Proteus PCB Design and Simulation SoftwareGebBerhe100% (2)

- DC Motor Hybrid ICsDocument19 pagesDC Motor Hybrid ICsNaranbaatar Erdenesuren100% (2)

- Kenwood ts-430 AGC ModDocument23 pagesKenwood ts-430 AGC Modmrkris100% (1)

- Soldering and BrazingDocument25 pagesSoldering and BrazingSumma ThanNo ratings yet

- The Handyman's Guide To Homebrew Construction Practices From Copper To ManhattanDocument11 pagesThe Handyman's Guide To Homebrew Construction Practices From Copper To ManhattanJanIgnatius100% (4)

- CANON DR-4010C Service Manual PDFDocument142 pagesCANON DR-4010C Service Manual PDFdougdude37100% (1)

- Abbreviations and Acronyms Electronics DictionaryDocument104 pagesAbbreviations and Acronyms Electronics DictionaryJean Paul Muvara Kabiligi100% (1)

- Dual N-Channel Enhancement Mode Mosfet: DSS DS (ON) D ADocument6 pagesDual N-Channel Enhancement Mode Mosfet: DSS DS (ON) D AErkanNo ratings yet

- Maquet Servo-S Ventilator - Service Manual PDFDocument94 pagesMaquet Servo-S Ventilator - Service Manual PDFVinicius Belchior da SilvaNo ratings yet

- Milinda Pro - Make New Proteus Device With Its PCB Package. (Here For 7 Segment Display) )Document11 pagesMilinda Pro - Make New Proteus Device With Its PCB Package. (Here For 7 Segment Display) )Mehmet KibarNo ratings yet

- 10 Watt PLL New Version Assembly InstructionsDocument11 pages10 Watt PLL New Version Assembly InstructionsStephen Dunifer100% (8)

- Small Signal Mosfet 115 Mamps, 60 Volts: N-Channel Sot-23Document5 pagesSmall Signal Mosfet 115 Mamps, 60 Volts: N-Channel Sot-23zigmund zigmundNo ratings yet

- CSS Terminating and Connerting Electrical Wiring and Electronic CircuitsDocument19 pagesCSS Terminating and Connerting Electrical Wiring and Electronic CircuitsRalfh Pescadero De GuzmanNo ratings yet

- EL600 Single Rudder Redundancy Setup v1.11Document30 pagesEL600 Single Rudder Redundancy Setup v1.11RomanNo ratings yet

- Switching Investigations On A Sic Mosfet in A To-247 PackageDocument8 pagesSwitching Investigations On A Sic Mosfet in A To-247 PackageWesley de PaulaNo ratings yet

- Amstrad PC1640 PC-MD PC-CD PC-ECD Service Manual 300dpi AgujereadoDocument76 pagesAmstrad PC1640 PC-MD PC-CD PC-ECD Service Manual 300dpi AgujereadoShalon Melo100% (1)

- Philips BDP 2985 Service ManualDocument41 pagesPhilips BDP 2985 Service ManualEnya Andrea Ribba HernandezNo ratings yet

- Pioneer MVH-S21BT - S215BT - S219BT CRT6291Document26 pagesPioneer MVH-S21BT - S215BT - S219BT CRT6291corelc89% (9)

- Pengenalan SolidWorks Flow Simulasi Webinar PDFDocument61 pagesPengenalan SolidWorks Flow Simulasi Webinar PDFMuhamad Eko FebriansyahNo ratings yet