Professional Documents

Culture Documents

Fridge System, Awarness

Uploaded by

Ibrahima FallOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fridge System, Awarness

Uploaded by

Ibrahima FallCopyright:

Available Formats

Fridge System

2007

FRIDGE AND AIR CONDITIONING SYSTEMS

SMIP

SMIP

PDF created with pdfFactory trial version www.pdffactory.com

Fridge System

2007

Course content

I. II. Vapour-compression theoretical graphs Typical System

III. Components IV. Typical System of Air Conditioning Unit

SMIP

PDF created with pdfFactory trial version www.pdffactory.com

Fridge System

2007

FRIDGE SYSTEM

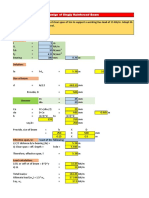

I. Vapour-compression theoretical graphs:

A) Absolute temperature - Entropy:

A-B, Isobaric He at absorp tion in th e e vaporator. B-C, Isentropic compression in the c ompressor (friction less a diabatic compression in ide al cycle ). C-D, Isobari c Heat removal in conde n ser. D-A, Constan t enth alpy exp ansion in expans ion v alve . Heat ener gy equivale nt of work done = Heat en ergy re jecte d- he at en ergy receive d. Coeffi ci ent of p erforman ce = heat ener gy rece ived/ Heat en ergy equiva lent of work done . Th e coeff icient o f performance for Freon is about 4 .7 It should be noted that under-cooling increases the heat rece ived by moving po int A to the left incr easing th e r efrigerant effect . B) p-h diagram (Mollier)

SMIP

PDF created with pdfFactory trial version www.pdffactory.com

Fridge System

2007

II.

Typi cal system

The system shown above and described below is typical of that fitte d on many ships other th an it is more common to have two low temperat ure rooms rather than one .

III. Components

Rooms: o Cold rooms / Meat Room -Low temperature room typica lly

working at -17 o C. o Veg/ handling room-typically working a t +4 o C.

Compressor: Ge neral ly it is of the sin gle sta ge, rec iprocat in g type. Larger systems have mult iple cyl in ders w ith an unloa ded system us in g SMIP 4

PDF created with pdfFactory trial version www.pdffactory.com

Fridge System

2007

the suction press ure as its signal . Refr iger ant is compressed in the compressor to a pressure depen de nt upon the temperat ure of the cooling wat er to the condenser , and to a l esser extent the vol ume of gas in the system. As the temp erature of th e c ooling w ater ris es so does the minimum temperat ure of the refr igerant liquid rise , a nd w ith it the corresponding saturat ion pressur e. o Compressor safety devi ces The compressor is protecte d by three s afe ty switches: The OP swit ch or Oil Di fferen tial Pr essure switch compares the measured l ubricat in g oil pressur e to the Suction (crankcas e) press ure. Should the different ia l pressur e fall bel ow a pre-set minimum (about 1.2 bars) then the compressor will trip a nd require a manua l reset to restart. The HP or High Pressure swit ch is fitted to the outl et of the compressor before the isolat ing v alv e. On over pressur isat ion (dep en dent on th e refriger ant, up to about 24 bars for R22) the sw itch will tr ip th e compressor an d a man ual res et is r equir ed b efore restart . The LP or Low Pressure switch when activate d ( at about 1 bar for R22) will trip the compressor an d req uire a manual res et before the compressor can be restart ed. Compressor control devi ces This normally takes the form of an LP cut out press ure switch w ith automatic r eset on press ure r ise. The cut out set point is just above the LP trip point say at about 1.4 bars. A n a djustable differe ntia l is set to about 1.4bar to give a c ut in pressur e of a round 2 .8 bars .

SMIP

PDF created with pdfFactory trial version www.pdffactory.com

Fridge System Oil Separator The purpos e of the oil separator, s ituate d on the compressor discharge line, is to return oil entra in ed in the gas, b ack to the compressor sump . The oil r eturn may be float controll ed as shown, electr ic solenoid controll ed on a t imer, or unco ntrolled with a small bore capillary t ube al lowin g cont in uous r eturn . With all of these methods a shut off valv e is fitt ed betwe en separator a nd compressor to allow for ma inten ance .

2007

The oil gas mix enters the separ ator where it is made to change direct ion , the heavier oil drop lets te nd to fall to the bottom. Condenser Genera lly a water cooled tube cooler. A safety valve an d ve nt are fitt ed. The p urpose of the ve nt is to ble ed off no n-conde nsable s uch as a ir which can enter the system when the suction pressure is allow ed to fall below atmospheric or can be containe d within the top up gas. Th e prese nce of noncondensabl e is ge neral ly indicate d by a compressor discharge pressur e consider ably above the s aturat ion pressur e of the refr igerant . The coolant flow to the conde nser is som etimes temperat ure re gul ated to prevent too low a temperature in the condenser which can affect pla nt effic iency due to the re duct ion in pressur e. Below the conde nser, or sometimes as a s eparate un it, is the reservo ir. Its purpose is to allow accur ate ga uge of the level of refr iger ant in the system. In addition to this it also al lows a spac e f or the refrigerant l iquid wh en the system is 'pumpe d down' . Th is refers to t he evacuat ion of the refr igerant gas to the condens er to al low mainte nance on the fridge system w ithout loss . For systems not fitted with a r eservoir , a sight glass is sometimes incorporate d on the s ide of the condenser . Care should be give n to ensur in g that th e l iquid level is not too high as th is re duc es th e surfac e ar ea of the cooling pipes avail able for con dens in g the liq uid an d can lea d to increas ed disch arge pressures . Sight Glass Often of the Bulls eye form. This al lows the operator to ensure that it is only liquid, and not a l iquid/ gas mix go ing to the expa nsion valv es. On some designs a water in dicator is incorporat e d, this is a coloure d rin g in contact with the l iquid, when water is detecte d it changes colo ur.

SMIP

PDF created with pdfFactory trial version www.pdffactory.com

Fridge System Filter Dr ier

2007

It can be either a compacted solid cartridge or bags of desicca nt. Th e main purpose of this un it is to remove the mois ture from the refr igerant . Moisture caus es two main problems. Firstly it can free ze to ic e in th e evaporator an d cause blocka ge. S econdly it can form acids by reaction w ith the Freon refrigerants . Th is acid attacks the copper in the l ines a nd depos its its in other parts of the system. Th is ca n become partic ular ly troublesome when it is de posit ed on the compresso r mechanical s eal f aces le adin g to damage an d le akage . Fine partic les wh ich coul d possibl e block the ex pans ion va lve are removed. Topp ing up the re frigeran t A fill in g conn ection is fitte d in w ay off th e filter dryer, either directly onto it or on the inlet lin e after the inlet sh ut off valve. This a llows addit iona l refrigerant to b e introduc ed into the syste m via the dryer el ement. The normal procedure is to shut or partially shut the in let to the filter . The compressor is now sucking from the system and deliver in g to the condenser wh ere the gas l iquefies. The f ilter dryer is on the o utlet from the condenser there fore with its in let valve s hut the liquid lev el begins to rise in the reservoir . As the on ly gas enter in g th e system is now comin g from the top up line, the compressor will te nd to reduce the suction s ide pr essure as it evacuat es the system into the con dens er. The in let va lve can be br iefly op ene d to allow more refrigerant into the system. Thermost at and Solenoid Valv e: These two elements form the ma in t emper ature control of the col d rooms. The Thermostat is set to the des ired temp erature a nd given a 3 to 4 degre e diff erent ial to prevent cycl ing. When the temperature in the room reaches the pre-set l evel the thermostat switch makes and the room solenoid is e nergise d allowin g gas to the refrigera nt l iquid to th e ex pans ion valv e. A manual override switch is fitt ed as w ell as a relay operat ed iso lating contact which shut th e sole noid when the defrost system is in use . System operation: Assume that the rooms are all warm and the compressor is runn ing w ith all the solenoid valves open sup plying ref riger ant to the respective ex pans ion valve an d ev aporator.

SMIP

PDF created with pdfFactory trial version www.pdffactory.com

Fridge System

2007

Should on e or two rooms be down to tem peratur e the soleno ids close th us reduc in g the volume of gas return in g to the compressor. The suct ion pr essur e drops an d the compressor unloa ds. If more rooms shut down then th e suct ion pressure will drop to cut out point and t he compressor will stop. When the rooms warm the solenoids op en a ga in, refr igerant p asses back to the compressor, the suction press ure rises and compressor starts. With more rooms openin g, the suct ion pr essure incr eases a nd the compressor loads up more cylinders . Thermost ati c ex pansion valv eThe pur pose of this valve is to eff icie ntly drop the pressure of the refr igerant. It achieves th is by pass ing the liquid thro ugh a var iabl e orif ice giv in g a constant enthalpy press ure drop . The refr igera nt at lower pressure has a correspon din g lower b oiling point (saturat ion allowin g temper ature ). heat to be Un der-cool ing absorbed in the the condenser increas es the effic ie ncy of the plant by more dur in g vapouris ation process. By this process of boilin g (vapor izat ion) and latent heat absorption i.e. chan ge of state, the refrigerant removes heat from the cold rooms. The e xpans ion process is controlle d by t he action of the bellows an d p ush p ins act ing o n the orif ice valve pl ate. The be llows is controlle d by a bulb which measur es the temperature of the gas at out let from t he evaporator. To e nsure no l iquid passes through to the compressor, the ex pansio n valve is set so that the gas at outlet from the evapor ator has 2 to 3 degrees of superheat . For larger systems where a sign ifica nt pressure drop e xists across the evaporator it is n ecessary to f it a ' B alance line '. This is a small bore t ube which fee ds the out let pressur e back to the thermostatic valv e 'motor' element . Therefore the meas ure d temp erature is directly relat ed to the superhe at temperat ure at out let pr essure .

Note Carefu l no te sh ou ld be taken th at sy st em t emp erature s are se t by th e room so lenoi d and not by th e expan sion va lve wh ich are genera lly fa ctor y se t an d do no t re quire a dju st men t.

Back pressure regul ator v alve This valve is fitt ed to the higher temper ature rooms, vegetable a nd flo ur (+5 o C) only an d not to the Meat a nd F ish rooms (-20 o C). SMIP 8

PDF created with pdfFactory trial version www.pdffactory.com

Fridge System They serve two ma in purposes :

2007

Firstly when all soleno id valves are ope ned they act as system ba lanc ing divert ers, they restrict the l iquid flow to the rooms which can be kept at the higher t emperatur e an d del iver the bulk t o the colder rooms. Secondly they serve to limit the pressur e drop across the exp ansion va lve by givin g a set min imum pressure in the evaporator coil. This in turn l imits the temperat ure of the refr igerant thereb y prevent ing del icate foo dstuffs such as vegetabl es from being damage d by havin g air at very low temperat ures blown over them. Ultimately they may also be set to provide a sa fety limit t o the room temperature by restr ict ing th e press ure to give a correspo nding minimum sat uration temperat ure of 0 o C. Oil recti fier In some installat ions there is a te nde ncy for oil to collect in the evaporator under speed certa in of con dit ions and such as low load when the movement agit ation of the evaporat in g refrigerant are ins uff icient to keep the o il movin g. To prevent loss of oil from the sump to the system, a n oil rectifier may be fitted. The oil heat is a utomatica lly exchan ger in ble d which from the evaporator to a liquid refr igerant mixe d with the oil is va porise d. The heat for vaporis in g the refrigerant is obta ine d by pass ing warm liquid Freon from the condenser , through the heat e xchanger. Vapo ur an d oil ar e passe d to the compressor where oil ret urns to th e sump whil e th e Freon p asses to the compressor suction . The r egulator is th ermostatical ly controlle d va lve wh ich op erates in the same way as the exp ansion valve o n the main system. It automat ically bleeds the o il from the evaporator so tha t the gas le aves the heat e xchan ger in a sup erheate d con dit ion.

SMIP

PDF created with pdfFactory trial version www.pdffactory.com

Fridge System Defrost system

2007

Moisture fr eezes onto the evaporator eve ntual ly caus in g a restr iction an d reduc in g the eff iciency of th e p lant . This must be per iodical ly removed. For Veg an d Flo ur rooms, were not r estric ted to 0 o C minim um by the back pressure v alve , this is carr ie d out o nce p e r day. For the Meat an d Fish rooms this has to be carried out two or more times. Due to the low temperat ure in the rooms it is necessary to f it a dra in h ea ter. When on defrost the solenoid valve is shut and the fan is off. On some systems at end of defrost the solenoid val ve is opened momentarily before the fan is st arted. This a llows moistur e to be snap frozen onto the surfac e of the element , creatin g a rough incr ease d surf ace area and thereby incr easing the heat transfer rate .

Note Care sh ou ld be tak en after loading an y grea t quanti ty of s tore s e specia lly in to th e ve ge table rooms. Th e fre sh s tore s t end to sw eat and icing up of th e e vapora tor can bec ome rapid. Th e on ly solution is cons tant moni toring and d efros ting as soo n as nec es sary.

Effects of under and over ch arge The effects of overcharge are a f ull condenser/rec eiver gauge glass . System pressures are not affecte d unt il highly overcharged when a poss ibil ity of excessive HP pressur e exists . Underch arge caus es failure to mainta in col d room temperatures an d compressor cycling. Compressor cyclin g is caus ed by there being ins uff icient gas to ma inta in t he compressor loaded even with all room solenoids ope n. In extreme the compressor will c ut in an d o ut. Undercharge is detecte d by low levels in the condenser/rece iver gauge glass/ bubbles in l iquid s ight gl ass, compressor cycling and low s uction pressur es.

SMIP

10

PDF created with pdfFactory trial version www.pdffactory.com

Fridge System

2007

IV.

Typical System of Air Conditioning Unit

Table of relationship between saturation temperature and pressure [oC]

Bar R12 R22 R502 -0.5 -46 -51 -57 0 -30 -41 -46 1 -12 -24 -28 2 -1 -14 -19 4 17 0 -4 6 28 11 7 8 39 20 17 10 48 28 24 12 56 35 31 14 63 41 38 16 68 46 43 18 73 51 47 20 78 55 51

SMIP

11

PDF created with pdfFactory trial version www.pdffactory.com

You might also like

- Electric Motor Controls TutorialDocument24 pagesElectric Motor Controls Tutorialvijai daniel100% (4)

- History of Fuel InjectionDocument9 pagesHistory of Fuel InjectionrxhughesNo ratings yet

- Preparation For Startup Guide Line Solar Turbines CompressorDocument5 pagesPreparation For Startup Guide Line Solar Turbines CompressorIbrahima Fall0% (1)

- Temperature ControlDocument7 pagesTemperature ControlDina099No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Aws CatalogDocument43 pagesAws CatalogDesmond Chin100% (1)

- International Journal On Recent TechnoloDocument4 pagesInternational Journal On Recent TechnoloAdnan NajemNo ratings yet

- 4 Throttles' Vacuum From Toyota Corolla Levin AE101 4A-GE 20vDocument6 pages4 Throttles' Vacuum From Toyota Corolla Levin AE101 4A-GE 20vTobyNo ratings yet

- Ies 1997 - II ScanDocument21 pagesIes 1997 - II ScanK.v.SinghNo ratings yet

- Buku PDTO Rabiman FinalDocument134 pagesBuku PDTO Rabiman Finalilham romadhonaNo ratings yet

- Fahud Compressor Station Site Visit ReportDocument2 pagesFahud Compressor Station Site Visit ReportDeepak RajanNo ratings yet

- P&ID Symbols (Complete List & PDFDocument13 pagesP&ID Symbols (Complete List & PDFArjhay GironellaNo ratings yet

- Theory of Elasticity and Plasticity Lab Experiment No. 3 Study On AnisotropyDocument7 pagesTheory of Elasticity and Plasticity Lab Experiment No. 3 Study On AnisotropyVipul AgrawalNo ratings yet

- Climate Control PDFDocument80 pagesClimate Control PDFArivup PavalanNo ratings yet

- 1 KESSEL Backwater ProtectionDocument18 pages1 KESSEL Backwater ProtectionAhmed HakamNo ratings yet

- Airbus 21 A300 A310 Air ConditioningDocument146 pagesAirbus 21 A300 A310 Air ConditioningElijah Paul Merto100% (3)

- 4.2 Continuous Load Path: 4.3 Overall FormDocument10 pages4.2 Continuous Load Path: 4.3 Overall FormSirajMalikNo ratings yet

- Engine Controls Schematics (Delphi ECM - FX3)Document9 pagesEngine Controls Schematics (Delphi ECM - FX3)Data TécnicaNo ratings yet

- Dytran Reference ManualDocument866 pagesDytran Reference ManualDon100% (2)

- 01 - Ashrae - AerodynamicsDocument52 pages01 - Ashrae - AerodynamicsAnonymous A8HV1JiN2TNo ratings yet

- Structural Mechanics 2-Lesson 4-Buckling (Complete Note)Document27 pagesStructural Mechanics 2-Lesson 4-Buckling (Complete Note)Janith amarawickramaNo ratings yet

- Boll Duplex Type 2.04.5Document2 pagesBoll Duplex Type 2.04.5Phung Van HiepNo ratings yet

- PrimeProbe3+ PPS-PP3-044-2.0Document18 pagesPrimeProbe3+ PPS-PP3-044-2.0Kishan ChandrasekaraNo ratings yet

- Delphi Metri-Pack Series 150Document22 pagesDelphi Metri-Pack Series 150Jacky24No ratings yet

- Demolition Robot (Brokk 500) (Brochure) - 1Document2 pagesDemolition Robot (Brokk 500) (Brochure) - 1Julius GatchalianNo ratings yet

- Inv2 - 2021 - 11 - 23 00 - 56 - 24Document1 pageInv2 - 2021 - 11 - 23 00 - 56 - 24MayangNo ratings yet

- Systems: Chapter B-6Document22 pagesSystems: Chapter B-6stolehaNo ratings yet

- Modified Asphalt Binders: Need of Present PavementsDocument85 pagesModified Asphalt Binders: Need of Present PavementsPalika ChopraNo ratings yet

- Singly Reinforced Beam ExcelDocument3 pagesSingly Reinforced Beam ExcelVEERKUMAR100% (3)

- Determination of The Tensile Strength of An OCF Canister FoamDocument3 pagesDetermination of The Tensile Strength of An OCF Canister Foamemre sönmezNo ratings yet

- Toward A Consistent Design of Structural Concrete: Pci Journal May 1987Document10 pagesToward A Consistent Design of Structural Concrete: Pci Journal May 1987Hanif NugrohoNo ratings yet

- CraneDocument16 pagesCraneAdrian Franco MolinaNo ratings yet

- Investigation of building collapse in AbujaDocument15 pagesInvestigation of building collapse in AbujaEmeso OjoNo ratings yet

- Naza Ria Rover KV6 Engine Cam Marking Manual PDFDocument7 pagesNaza Ria Rover KV6 Engine Cam Marking Manual PDFAdrian PhillipsNo ratings yet

- Centrifugal Pump Lab ReportDocument16 pagesCentrifugal Pump Lab Reportapi-31051928380% (5)