Professional Documents

Culture Documents

A Machine Vision System For Real-Time Automated Gear Fatigue Pitting Detection

Uploaded by

Varthini RajaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Machine Vision System For Real-Time Automated Gear Fatigue Pitting Detection

Uploaded by

Varthini RajaCopyright:

Available Formats

A Machine Vision System for Real-time

Automated Gear Fatigue Pitting Detection

Zhang J ie

Mechatronics Center

Beijing Institute of

Technology Beijing, China

zhangjielovebit@126.com

Ma Shuyuan

Mechatronics Center

Beijing Institute of

Technology Beijing, China

Huang J ie

Mechatronics Center

Beijing Institute of

Technology Beijing, China

Long Zhenhai

Mechatronics Center

Beijing Institute of

Technology Beijing, China

AbstractThe machine vision system for the detection of the gear

pitting is an essential element for the mechanical fatigue test,

because the whole system effectively integrates internal

information of the fatigue test to classify the related data into

different sort automatically. Therefore, an industrial machine

vision for gear pitting detection is proposed in this paper, and an

image processing algorithm which mainly consists of image

segmentation algorithm and contour computation is presented.

Keywords-machine vision, gear pitting, fatigue, image

processing

I. INTRODUCTION

At present, most gear fatigue pitting detection and sorting

operations are done by human vision. The main shortage of

manual detect is low productivity, plenty of labors needed,

poor accuracy and none useful data gained in the process.

Nowadays industrial machine vision techniques, which have

found a great increasing application on mechanical defect

detection, have been increasingly crucial to keep the

mechanical systemgains in productivity [1]. The subject of

machine vision is treated with emphasis of fundamental tools

for image acquisition, processing and analysis.

The main task of the system is to inspect the amount and

area of gear pitting on the tooth face. Moreover, this system

provides a means of further classifying the pitting of gear in

accordance with its size and specific positions. The

experimental details, such as the test bench, working

environment and some results are described. The image

processing system to solve the problems, such as processing the

large amount of image information and increasing the precision

of detection is introduced in detail [2][3][4].

The machine vision systemis presented for gear pitting

detection in this paper based on real-time fatigue experiment.

The work is aimed at:

Building a machine vision model for gear pitting

detection to describe its properties using image processing and

hardware system.

Get the quantitative data through the gear fatigue test, in

order to optimize related design.

II. SYSTEM ARCHITECTURE

The proposed machine vision system consists of three

major components: gear contact fatigue test, image acquisition

system and image processing system. Image processing

system performs image segmentation, labeling and feature

extraction.

A. Experimental Environment

A tooth surface fatigue machine is used to get the gear

pitting. Enclosed structure is adopted towards the gear contact

fatigue test bench.

In order to simulate the actual working environment, the

test gear is working at a high speed under heavy load control.

And the related parameters of gears are shown in Tab.1.

TABLE I. RELATED PARAMETERS OF GEARS

Related Parameters of Gears

NO.

Parameter Name Parameter Value

1 Teeth number of the active gear Z1 26

2 Teeth number of the passive gear Z2 27

3 Module of gear m 6

4 Tooth width b 40

B. Image Acquisition System

The image acquisition system is used to capture the picture

of the tooth surface the working gear for further processing.

The main body of the system consists of the following parts:

CCD camera, image card and illumination device. A CCD

image sensor was clamped on a stand with lightning facilities.

The image sensor captures images and sends them to the

machine vision system.

Basler A602fc color camera together with the 1394 image

card installed in the computer forms the sensor-digitizer

combined with the computer. The LED lamps of 4 watt are

served as the illumination. Also the light level can be regulated

by adjusting the aperture of the microscope or adjusting the

number of the lighting LED lights. The image captured by the

camera is shown in Fig.1.

Sponsored by National Natural Science Foundation 50975030

Proceedings of 2012 International Conference on Mechanical Engineering and Material Science (MEMS 2012)

2012. The authors - Published by Atlantis Press 183

Figure 1. The original image captured by camera

C. Image Processing System

Image processing system is used to change the input image

to another image with the pitting characteristics required. In

this system, highlight the details of the image, by regulating the

signal-to-noise ratio and using image enhancement processing,

in order to make the details to be easily observed. The first

level image processing task includes noise removal, distortion

compensation etc. Segmentation and labeling, feature

extraction are generically classified as the intermediate level

processing [6].

Now, the software realized in this paper and the details of

the image processing algorithm is introduced shown in Fig.2.

In order to compare the difference of edge detection among

the traditional algorithm and the improved algorithm presented

for the fatigue pitting detection, the options of several

algorithms are available. At the same time, three methods of

noise reduction are optional in the system, which are

threshold-value filter, average-filter and median filter

respectively, so as to adapt to different kinds of images. The

interface of the software system is shown in Fig.3 as follows.

Figure 2. Block diagramof machine vision

system

Figure 3. Interface of the Software System

III. GEAR PITTING PROCESSING ALGORITHM

A. Noise Reduction Algorithm

The image captured by CCD camera not only contains the

edge information needed, but also includes the noise

information of the experiment environment which will

influence the accuracy of feature extraction [7]. As a result,

noise reduction is especially essential before the edge detection.

Nowadays there are three main means to realize this function:

threshold-value filter, average-filter and median filter [8].

Noise reduction not only eliminates the noise of the image,

but also wakens part of the useful information. As a nonlinear

smooth filter based on sort statistical theory, it retains more

effective information and reduces the noise better as well. After

compare the different results of these three methods, as shown

in Fig.4, a 55 window median filter is chosen in the end.

a. average-filter

b. threshold-value filter

c. 55 window median filter

Figure 4. Different results of three noise filter

B. Edge Detection Algorithm

The contour of some designated area, as a basic

characteristic, is widely used in the recognition, segmentation

etc. Classic method based on gray of the gray grade of every

pixel and the method using the multi-scale characteristic of the

wavelet are commonly accepted. The main techniques are

Laplace, Sobel, Canny and LOG (Laplace of Gaussian)

algorithm etc [9]. Based on wavelet transform, Lipschitz

exponent feature of the noise and signal are commonly applied

as well [10]. With a view to the details of the objective image, a

new segmentation algorithm which is realized based on LOG

algorithmand Sobel algorithm is presented in this paper.

LOG, which is constituted of Gauss filter and Laplace edge

detective operator, is proposed by Marr and Hildreth [11]. The

output h(x, y) of LOG operator is generated by Convolution

computation:

2

( , ) [ ( , ) ( , )] h x y g x y f x y = V -

(1)

184

On the basis of convolution computation, there is:

2

( , ) [ ( , )] ( , ) h x y g x y f x y = V -

(2)

Where:

2 2

2

2 2 2

2

2

4

2

( , ) [ ]

x y

x y

g x y e

o

o

o

+

+

V =

(3)

On the basis of LOG algorithm, the Sobel algorithm is

incorporated with it. After LOG algorithm operation, the result

becomes more reliable by applying 33 square window

filtering of Sobel to the center point as shown in Fig.5. Two

thresholds are put into use, a looser one to keep more edge

information, and a strict one only to keep the edge information

which is continuous with the edge detected by the looser

threshold.

The original image is shown in Fig.1. After noise reduction

and edge detection, the processing results are shown as Fig.6.

Figure 5. Sobel Algorithm

Figure 6. Test result of different edge detection algorithm

C. Area Computation by Contour Tracing

After denoising and edge detection, it still cant

differentiate some edge information from noise. Therefore, the

continuous boundary for area computation should be

determined by taking out the separate points.

An improved eight-neighborhood contour tracing algorithm

is presented in this paper. Freeman chain code uses

0,1,2,3,4,5,6,7 to stand for the eight directions, the improved

algorithmsets point P(x, y) for the current point, the directions

of the pixels in the eight-neighborhood can be shown by the

direction code in Fig.7.

This algorithmselects the upper left corner as the start point

of the image, and scans the image fromleft to right and top to

bottom. Starting fromthe first black point, as shown in Fig.5,

the right direction of the point is defined as the initial search

direction; if the point is black, and then takes it as the boundary

point, otherwise revolve clockwise 45 degrees of the search

direction until finding the first black point. Then take this black

point as a new start one to cycle the above operation until the

last black point return to the original point. Finally the contour

of the area is gained for the further processing.

In this algorithm, 1,2,3 stand for the upward direction while

5,6,7 stand for the downward direction, and 3,4,5 stand for left

when 0,1,7 stand for right as well. It is easy to find the total

number of each direction equals to the one of the opposite

direction. Then, the equation of area computation is obtained as

follow:

(1,2,3) (3,4,5) Area x y sum sum = =

(4)

(1,2,3) (5,6,7) sum sum =

(5)

(3,4,5) (0,1,7) sum sum =

(6)

Finally, the pixels of each pitting region are calculated. The

concave and convex parts are offset to each other, so as to

ensure the accuracy of computation.

Figure 7. Freeman Chain Code

D. Pitting Classification

According to the size characteristics, pattern recognition

technology classifies the pitting into different categories:

micropitting and macropitting. Save each region as an

individual data, and sort them on the basis of the size, so as to

confirmthe specific circumstance of each pitting area. The

threshold which differentiates these two conditions can be

gained as appropriate.

Micropitting, which is grey or glitter in appearance by

naked eyes, occurs in the dedendum, addendum, or both but

seldom at the pitch line and is orienting against of tractive force.

It is small in size within the limits of 5-10um in length, with the

depth between 5-20um. On the contrary, macropitting occurs at

the pitch line with large size.

185

IV. RESULT

As shown in Fig.6, the new edge detection algorithm

improves the efficiency of region detection compared with the

traditional algorithm. The new algorithm not only overcomes

the LOG algorithm with a lot of noise in the image, but also

overcomes shortcomings of the Sobel algorithm which lose

amount of useful information. The new algorithm retains

information of macropitting and micropitting, which

demonstrate the details of pitting conditions.

Tab.2 shows the total count of pixels which stands for the

pitting condition. It shows that with larger the number, the

pitting shall be more serious. For the same image, the 55

median filter reduces more noise information than the other

two methods with a smaller whole number of pixels. At the

same time, the size of each pitting part is saved in PC as a

separate data so that they can be classified. As explained before,

the results also shows median filter can differential the useful

image information fromnoise more effectively. With the total

area of each surface in contact, the threshold for classification

shall be determined more accurate by its location and size.

TABLE II. EXPERIMENTAL RESULTS OF DIFFERENT FILTERS

Experimental results of different filters

Image

NO

Filter Area Value

1 threshold 28469

average 26913

median55 25317

2 threshold 11485

average 12844

median55 11686

3 threshold 30786

average 31879

median55 28806

4 threshold 24343

average 24178

median55 20652

5 threshold 57926

average 60199

median55 64604

V. CONCLUSION AND FURTHER STUDIES

In this work a novel machine vision systemfor gear fatigue

pitting detection is presented. It has shown that the machine

vision system in this paper is optimal in terms of efficiency and

accuracy, compared with the manual detect. As the

experimental results show, the algorithm presented a good

performance in preserving small regions and edge locations

when processing noisy images, as compared to the other

methods. Nevertheless, with the future development of real-

time image acquisition and algorithm optimization, the

machine vision system for real-time detection shall be

continually improved.

Actually this machine vision system not only needs to

recognize the image in the computer, but also shall process the

real-time image captured by the CCD camera, so as to get the

conclusion required. The system consists of complex image

processing and the process how the image is gained. Then in

the future this system should be extended to set a coordinate

systemused to change the pixel to actual area of each part of

pitting. At the same time, the algorithm shall be improved for

better effect of detection.

ACKNOWLEDGMENT

The authors would like to thank the Key Laboratory of

Fundamental Science for Advanced Machining for their

support of this work. Special thanks to National Natural

Science Foundation of China for their support under

grants 50975030.

REFERENCES

[1] ElMasry G, Wang N, Vigneault C, Qiao J , ElSayed A. Early Detection

of Apple Bruises on Different Background Colors using Hyperspectral

Imaging. LWT-Food Science and Technology, 2008, 41 (2): 337-345.

[2] J in H. Study on the Machine Vision Based on Virtual Instrumentation.

Computer Automated Measurement and Control, 2000, 8(1): 18-20.

[3] Hiroshi Sako, Recognition Strategies in Machine Vision Applications,

International Machine Vision and Image Processing Conference, 2007.

[4] Sadayuki Tsugawa, Vision-Based Vehicles in J apan: Machine Vision

Systems and Driving Control Systems, IEEE Transactions on Industrial

Electronics, 1994, 41(4):398-405.

[5] A Guide for Fatigue Testing and the Statistical Analysis of Fatigue

DataASTM STP9 1 A1964.

[6] Malik Abdul Waheed, Thornberg Benny, Meng Xiaozhou, Real-time

Machine Vision SystemUsing FPGA and Soft-core Processor, SPIE

Conference on Real-Time Image and Video Processing, 2012.

[7] Loupas T, McDicken W N, Allan P L. An Adaptive Weighted Median

Filter For Speckle Suppression In Medical Ultrasonic Images, IEEE

Transactions on Circuits and Systems, 1989, 36( 1) : 129- 135

[8] A. P. Richard, A new algorithm for image noise reduction using

mathematical morphology, IEEE Transaction on Image Processing, 1995,

4(5):554568.

[9] Paulo F U Gotardo, Olga R P Bellon, Luciano Silva, Range Image

Segmentation By Surface Extraction Using An Improved Robust

Estimator, IEEE Computer Society Conference on Computer Vision and

Pattern Recognition, 2003.

[10] O Bellon, L Silva, New Improvements On Range Image Segmentation

By Edge Detection, IEEE Signal Processing Letters, 2002, 9(2):43-45.

[11] D.Marr, Vision- A Computational Investigation into the Human

Representation and Processing of Visual Information, Journal of

Mathematical Psychology, 1982, 27(1):107-110.

186

You might also like

- Research of Sorting Technology Based On Industrial Robot of Machine VisionDocument5 pagesResearch of Sorting Technology Based On Industrial Robot of Machine VisionMekaTronNo ratings yet

- Computer Aided Spur Gear Data Extraction Based On Image Processing TechniqueDocument12 pagesComputer Aided Spur Gear Data Extraction Based On Image Processing TechniqueAli AbbarNo ratings yet

- Identify Defects in Gears Using Digital Image Processing: Amandeep MaviDocument7 pagesIdentify Defects in Gears Using Digital Image Processing: Amandeep MaviIJERDNo ratings yet

- A Genetic Algorithm Based Approach For Segmentingand Identifying Defects in Glass BottlesDocument9 pagesA Genetic Algorithm Based Approach For Segmentingand Identifying Defects in Glass BottlesAJER JOURNALNo ratings yet

- 3.KRS036 Final SubmissionDocument6 pages3.KRS036 Final SubmissionAravind MikeNo ratings yet

- Toward Higher Automation and Flexibility in Commercial Digital Photogrammetric SystemDocument3 pagesToward Higher Automation and Flexibility in Commercial Digital Photogrammetric SystemKobalt von KriegerischbergNo ratings yet

- Zone Theory Applied To Boost Recognition Rate of HMM Based SystemDocument7 pagesZone Theory Applied To Boost Recognition Rate of HMM Based SystemInternational Association of Scientific Innovations and Research (IASIR)No ratings yet

- Automated Vision Inspection of Critical Steel Components Based On Signal Analysis Extracted Form ImagesDocument4 pagesAutomated Vision Inspection of Critical Steel Components Based On Signal Analysis Extracted Form ImagesMatteo LanciniNo ratings yet

- PDF/JCSSP 2012 528 532Document5 pagesPDF/JCSSP 2012 528 532mohitegaurv87No ratings yet

- Automated Test System With VisionDocument6 pagesAutomated Test System With VisionWan ShahmisufiNo ratings yet

- Real-time Tracking and Pose Estimation for Industrial Objects using Geometric FeaturesDocument6 pagesReal-time Tracking and Pose Estimation for Industrial Objects using Geometric FeaturesHaydee Tu Ya SabesNo ratings yet

- Jianbiao Ding, Yajun Zhang, Jian Zhuang and Ri Pan: A Method of Plastic Gear Inspection Based On Machine VisionDocument4 pagesJianbiao Ding, Yajun Zhang, Jian Zhuang and Ri Pan: A Method of Plastic Gear Inspection Based On Machine VisionHuseyin CakmakNo ratings yet

- Image Processing Applied To TrafficDocument13 pagesImage Processing Applied To TrafficDivya SreeNo ratings yet

- Real-Time Face Detection On A "Dual-Sensor" Smart Camera Using Smooth-Edges TechniqueDocument5 pagesReal-Time Face Detection On A "Dual-Sensor" Smart Camera Using Smooth-Edges TechniquehioioioioNo ratings yet

- 7.mech IJME Manipulator MihirDocument7 pages7.mech IJME Manipulator Mihiriaset123No ratings yet

- The Real Time Vechicle License Plate Identification System: P.Mohan Kumar, P.Kumaresan, Dr.S.A.K.JilaniDocument5 pagesThe Real Time Vechicle License Plate Identification System: P.Mohan Kumar, P.Kumaresan, Dr.S.A.K.JilaniIJERDNo ratings yet

- Image Contour Extraction Method Based On Computer TechnologyDocument5 pagesImage Contour Extraction Method Based On Computer TechnologyIbrahim IsleemNo ratings yet

- Recognition of 3D Compressed Images and Its Traffic Monitoring ApplicationsDocument5 pagesRecognition of 3D Compressed Images and Its Traffic Monitoring ApplicationsCristiane SantosNo ratings yet

- Ijcttjournal V1i2p9Document10 pagesIjcttjournal V1i2p9surendiran123No ratings yet

- The Techniques For Face Recognition With Support Vector MachinesDocument6 pagesThe Techniques For Face Recognition With Support Vector MachinesUdegbe AndreNo ratings yet

- A Simulation Tool For Evaluating Digital Camera Image QualityDocument8 pagesA Simulation Tool For Evaluating Digital Camera Image QualityTùng NguyễnNo ratings yet

- Image Processing in Road Traf C AnalysisDocument11 pagesImage Processing in Road Traf C AnalysisAshwiini Vigna BasuthkarNo ratings yet

- A Software Video Stabilization System For Automotive Oriented ApplicationsDocument6 pagesA Software Video Stabilization System For Automotive Oriented Applicationspavan kumar sharmaNo ratings yet

- Photogrammetric Techniques For Measurements in Woodworking IndustryDocument6 pagesPhotogrammetric Techniques For Measurements in Woodworking IndustryAsma AmalinaNo ratings yet

- Digital Image Processing 2 PresentationDocument18 pagesDigital Image Processing 2 PresentationNaveen KumarNo ratings yet

- Development of Automatic Welding and Inspecting System Using Machine Vision System For Nuts Welded On The Support HingeDocument7 pagesDevelopment of Automatic Welding and Inspecting System Using Machine Vision System For Nuts Welded On The Support HingetheijesNo ratings yet

- Vehicle Class Recognition Using 3D CG Models: Shirmila Mohottala, Masataka Kagesawa, Katsushi IkeuchiDocument10 pagesVehicle Class Recognition Using 3D CG Models: Shirmila Mohottala, Masataka Kagesawa, Katsushi IkeuchiRami RomeoNo ratings yet

- Camera Calibration Algorithm ImplementationDocument5 pagesCamera Calibration Algorithm ImplementationgeodesiikaNo ratings yet

- DEPTH MAPstereo-Pair VideoDocument7 pagesDEPTH MAPstereo-Pair VideoNk OsujiNo ratings yet

- Fuzzy Logic Based Image Edge Detection Algorithm in MATLABDocument5 pagesFuzzy Logic Based Image Edge Detection Algorithm in MATLABMuhammad Surya AndryanNo ratings yet

- Modern Mobile MappingDocument12 pagesModern Mobile Mappingn.ragavendiranNo ratings yet

- Automation in WCCM With Data Logger: IPASJ International Journal of Electronics & Communication (IIJEC)Document5 pagesAutomation in WCCM With Data Logger: IPASJ International Journal of Electronics & Communication (IIJEC)International Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Real Time Image Processing Applied To Traffic Queue DDocument12 pagesReal Time Image Processing Applied To Traffic Queue Dshajin2233No ratings yet

- Camera Calibration Technique Using Tsai'S Algorithm: Vol. 1 Issue 2 January 2011Document9 pagesCamera Calibration Technique Using Tsai'S Algorithm: Vol. 1 Issue 2 January 2011admin2146No ratings yet

- Design and Implementation of Fingerprint Recognition Process On FpgaDocument9 pagesDesign and Implementation of Fingerprint Recognition Process On FpgalambanaveenNo ratings yet

- Low Cost Motion CaptureDocument5 pagesLow Cost Motion CaptureioscherzoNo ratings yet

- Extraction of License-Plate Number of Over Speeding VehiclesDocument6 pagesExtraction of License-Plate Number of Over Speeding VehicleslambanaveenNo ratings yet

- A Smoothing Algorithm Based On Impulse Response For GPS Data ProcessingDocument2 pagesA Smoothing Algorithm Based On Impulse Response For GPS Data Processinga_kaeeNo ratings yet

- Real-Time Stereo Vision For Urban Traffic Scene UnderstandingDocument6 pagesReal-Time Stereo Vision For Urban Traffic Scene UnderstandingBasilNo ratings yet

- A High Efficient System For Traffic Mean Speed Estimation From MPEG Video (10.1109@AICI.2009.358)Document5 pagesA High Efficient System For Traffic Mean Speed Estimation From MPEG Video (10.1109@AICI.2009.358)YoungKimNo ratings yet

- Lane Detection and Tracking by Video SensorsDocument6 pagesLane Detection and Tracking by Video SensorsTriệu NguyễnNo ratings yet

- Design and Development of Automated 3D Visual Tracking SystemDocument8 pagesDesign and Development of Automated 3D Visual Tracking Systemvinay_2211No ratings yet

- Minutia Verification and Classification For Fingerprint MatchingDocument5 pagesMinutia Verification and Classification For Fingerprint MatchingSyed SamiullahNo ratings yet

- Gabor FilterDocument5 pagesGabor FilterInternational Journal of Computer and Communication System EngineeringNo ratings yet

- 097 Software PDFDocument12 pages097 Software PDFKobalt von KriegerischbergNo ratings yet

- Size Detection of Firebricks Based On Machine Vision TechnologyDocument4 pagesSize Detection of Firebricks Based On Machine Vision TechnologyMekaTronNo ratings yet

- Viola Jone's AlgorithmDocument25 pagesViola Jone's AlgorithmAkhil AhujaNo ratings yet

- Breast CancerDocument40 pagesBreast CancerVamsi ReddyNo ratings yet

- Ivs2006 2Document8 pagesIvs2006 2Ricardo RomeroNo ratings yet

- Vehicle License Plate Recognition Using Morphology and Neural NetworkDocument7 pagesVehicle License Plate Recognition Using Morphology and Neural NetworkJames MorenoNo ratings yet

- Brain Tumor Pattern Recognition Using Correlation FilterDocument5 pagesBrain Tumor Pattern Recognition Using Correlation FilteresatjournalsNo ratings yet

- Laser and camera techniques for tyre profile measurement and quality controlDocument7 pagesLaser and camera techniques for tyre profile measurement and quality controlHartwig SuhrNo ratings yet

- License Plate Automatic Recognition System Based On MATLAB-GUIDocument6 pagesLicense Plate Automatic Recognition System Based On MATLAB-GUIAlex TorresNo ratings yet

- Image Processing Technique For Ac Motor Speed ControlDocument6 pagesImage Processing Technique For Ac Motor Speed ControlUtkarsh VermaNo ratings yet

- G J E S R: Lobal Ournal of Ngineering Cience and EsearchesDocument6 pagesG J E S R: Lobal Ournal of Ngineering Cience and EsearcheshaianhlhpNo ratings yet

- Recognition of Number Plate in Car Parking System: ObjectiveDocument9 pagesRecognition of Number Plate in Car Parking System: ObjectiveVinod HandiNo ratings yet

- Intelligent Parking Space Detection System Based OnDocument4 pagesIntelligent Parking Space Detection System Based OnDidiek Ainul Yaqin100% (1)

- To Propose An Improvement in Zhang-Suen Algorithm For Image Thinning in Image ProcessingDocument8 pagesTo Propose An Improvement in Zhang-Suen Algorithm For Image Thinning in Image ProcessingIJSTENo ratings yet

- Development of An Image Enhancement Method and A GUIDocument8 pagesDevelopment of An Image Enhancement Method and A GUIDr-Dwipjoy SarkarNo ratings yet

- Design of Jigs, Fixtures and Press Tools UNIT 1: Jigs and FixtureDocument20 pagesDesign of Jigs, Fixtures and Press Tools UNIT 1: Jigs and FixtureVarthini RajaNo ratings yet

- Design of Jigs, Fixtures and Press Tools UNIT 1: Locating and Clamping PrinciplesDocument18 pagesDesign of Jigs, Fixtures and Press Tools UNIT 1: Locating and Clamping PrinciplesVarthini RajaNo ratings yet

- Renewable Energy: Salih N. Akour, Mohammed Al-Heymari, Talha Ahmed, Kamel Ali KhalilDocument9 pagesRenewable Energy: Salih N. Akour, Mohammed Al-Heymari, Talha Ahmed, Kamel Ali KhalilJuan ApzNo ratings yet

- Design of Jigs, Fixtures and Press Tools UNIT 1: Locating and Clamping PrinciplesDocument20 pagesDesign of Jigs, Fixtures and Press Tools UNIT 1: Locating and Clamping PrinciplesVarthini RajaNo ratings yet

- STRENGTH OF MATERIALS LAB MANUAL MECHANICAL ENGINEERINGDocument33 pagesSTRENGTH OF MATERIALS LAB MANUAL MECHANICAL ENGINEERINGDeanna ChapmanNo ratings yet

- Design of Jigs, Fixtures and Press Tools UNIT 1: Locating and Clamping PrinciplesDocument37 pagesDesign of Jigs, Fixtures and Press Tools UNIT 1: Locating and Clamping PrinciplesVarthini RajaNo ratings yet

- Design of Jigs, Fixtures and Press Tools UNIT 1: Locating and Clamping PrinciplesDocument18 pagesDesign of Jigs, Fixtures and Press Tools UNIT 1: Locating and Clamping PrinciplesVarthini RajaNo ratings yet

- Design of Jigs, Fixtures and Press Tools UNIT 1: Locating and Clamping PrinciplesDocument40 pagesDesign of Jigs, Fixtures and Press Tools UNIT 1: Locating and Clamping PrinciplesVarthini RajaNo ratings yet

- Design of Jigs, Fixtures and Press Tools UNIT 1: Jigs and FixtureDocument12 pagesDesign of Jigs, Fixtures and Press Tools UNIT 1: Jigs and FixtureVarthini RajaNo ratings yet

- Design of Jigs, Fixtures and Press Tools UNIT 1: Locating and Clamping PrinciplesDocument40 pagesDesign of Jigs, Fixtures and Press Tools UNIT 1: Locating and Clamping PrinciplesVarthini RajaNo ratings yet

- Design Jigs Fixtures Press Tools Unit 1 Jigs FixturesDocument14 pagesDesign Jigs Fixtures Press Tools Unit 1 Jigs FixturesVarthini RajaNo ratings yet

- FEM Lecture NotesDocument188 pagesFEM Lecture NotesHenry Martinez CarmonaNo ratings yet

- Design of Jigs, Fixtures and Press Tools UNIT 1: Jigs and FixtureDocument16 pagesDesign of Jigs, Fixtures and Press Tools UNIT 1: Jigs and FixtureVarthini RajaNo ratings yet

- Design of Jigs, Fixtures and Press Tools UNIT 1: Jigs and FixtureDocument11 pagesDesign of Jigs, Fixtures and Press Tools UNIT 1: Jigs and FixtureVarthini RajaNo ratings yet

- DESIGN OF JIGS, FIXTURES AND PRESS TOOLSDocument21 pagesDESIGN OF JIGS, FIXTURES AND PRESS TOOLSVarthini RajaNo ratings yet

- Design of Jigs, Fixtures and Press Tools UNIT 1: Jigs and FixtureDocument27 pagesDesign of Jigs, Fixtures and Press Tools UNIT 1: Jigs and FixtureVarthini RajaNo ratings yet

- Formability of Stamping Magnesium-Alloy AZ31 SheetsDocument5 pagesFormability of Stamping Magnesium-Alloy AZ31 SheetsVarthini RajaNo ratings yet

- Catia SurfaceDocument14 pagesCatia Surfaceapi-3799982100% (2)

- FEM in TwistDocument4 pagesFEM in TwistVarthini RajaNo ratings yet

- Artificial Neural Networks For BeginnersDocument8 pagesArtificial Neural Networks For BeginnersVarthini RajaNo ratings yet

- Seating Arrangement2Document9 pagesSeating Arrangement2Varthini RajaNo ratings yet

- Genetic AlgorithmDocument11 pagesGenetic AlgorithmVarthini RajaNo ratings yet

- Aluminium in AerospaceDocument2 pagesAluminium in AerospaceVarthini RajaNo ratings yet

- 2012 VisionSolutions Bro WebDocument24 pages2012 VisionSolutions Bro WebVarthini RajaNo ratings yet

- VK Jain - PDFV K JAIN Advanced Maching ProcessV K JAIN Advanced Maching ProcessDocument328 pagesVK Jain - PDFV K JAIN Advanced Maching ProcessV K JAIN Advanced Maching ProcessVarthini Raja60% (5)

- Role of Bottom-Up and Top-Down Role of Bottom-Up and Top-Down A.pdf Role of Bottom-Up and Top-Down A.pdf Role of Bottom-Up and Top-Down A.pdf ADocument2 pagesRole of Bottom-Up and Top-Down Role of Bottom-Up and Top-Down A.pdf Role of Bottom-Up and Top-Down A.pdf Role of Bottom-Up and Top-Down A.pdf AVarthini RajaNo ratings yet

- Niyama Criteria Niyama Criteria Niyama CriteriaDocument18 pagesNiyama Criteria Niyama Criteria Niyama CriteriaVarthini RajaNo ratings yet

- ZincDocument2 pagesZincVarthini RajaNo ratings yet

- Yale Romance Reading ListDocument9 pagesYale Romance Reading ListVarthini Raja100% (4)

- xg8000 - Series - Setup ManualDocument130 pagesxg8000 - Series - Setup ManualAbdou DENo ratings yet

- Rapid situational awareness for first respondersDocument13 pagesRapid situational awareness for first respondersSaeful AnwarNo ratings yet

- Research On Visual Navigation Algorithm of AGV Used in The Small Agile WarehouseDocument6 pagesResearch On Visual Navigation Algorithm of AGV Used in The Small Agile WarehouseLord VolragonNo ratings yet

- Lab ManualDocument28 pagesLab ManualWaleed AwanNo ratings yet

- Cognex Vidi Deep Technology: Challenges in Textile InspectionDocument9 pagesCognex Vidi Deep Technology: Challenges in Textile InspectionMard GeerNo ratings yet

- IPFM-Image Processing Fundamentals for Machine VisionDocument90 pagesIPFM-Image Processing Fundamentals for Machine Visionmoney_kandan2004No ratings yet

- Machine Vision and Metrology Workshop-10.Document2 pagesMachine Vision and Metrology Workshop-10.abhayNo ratings yet

- RoboticsDocument2 pagesRoboticsvasanthsatNo ratings yet

- ReportDocument13 pagesReportVon A. DamirezNo ratings yet

- Assembly MagazineDocument5 pagesAssembly MagazineShameem Abdul KadarNo ratings yet

- Dhanesh - N - Machine Vision SystemDocument23 pagesDhanesh - N - Machine Vision SystemAswin madhuNo ratings yet

- New Trends On Digitisation of Complex Engineering Drawings: Neural Computing and Applications June 2019Document19 pagesNew Trends On Digitisation of Complex Engineering Drawings: Neural Computing and Applications June 2019Mohammad ShreatehNo ratings yet

- XGX Provider enDocument63 pagesXGX Provider en54 amdNo ratings yet

- Machine Vision System Overview PDFDocument32 pagesMachine Vision System Overview PDFkfathi55No ratings yet

- Basics of Image Acquisition (2020) PDFDocument94 pagesBasics of Image Acquisition (2020) PDFWilson CheinNo ratings yet

- An Algorithm For Concrete Crack Extraction and IdentificationDocument26 pagesAn Algorithm For Concrete Crack Extraction and IdentificationSandhyaNo ratings yet

- Fruit Detection and Robotic Apple Harvesting SystemDocument14 pagesFruit Detection and Robotic Apple Harvesting SystemSindhu BhaskarNo ratings yet

- Teledyne Optech Co OverviewDocument60 pagesTeledyne Optech Co OverviewKunal SharmaNo ratings yet

- Datasheet-Pallet Scanning SystemDocument3 pagesDatasheet-Pallet Scanning SystemSergio Tarancón GabásNo ratings yet

- Auto Vision ManualDocument218 pagesAuto Vision ManualVernica Constantin AdrianNo ratings yet

- Prospects of Computer Vision Automated Grading and Sorting Systems in Agricultural and Food Products For Quality EvaluationDocument9 pagesProspects of Computer Vision Automated Grading and Sorting Systems in Agricultural and Food Products For Quality EvaluationshaheerNo ratings yet

- Vision-based sorting labDocument19 pagesVision-based sorting labMihail AvramovNo ratings yet

- BS en 16729-4-2018Document32 pagesBS en 16729-4-2018Tuan Thanh NghiemNo ratings yet

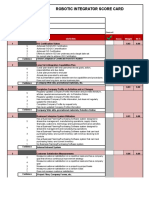

- Robotic Integrator Score Card: Item Rating Criteria Score Weight W+SDocument5 pagesRobotic Integrator Score Card: Item Rating Criteria Score Weight W+SdNo ratings yet

- Brochure VizsortDocument24 pagesBrochure VizsortNeeraj VohraNo ratings yet

- AutovisionmanualDocument224 pagesAutovisionmanualALEXNo ratings yet

- Computer Aided Quality Control: Unit-5Document14 pagesComputer Aided Quality Control: Unit-5kula shekar reddyNo ratings yet

- Image Processing Analysis and Machine Vision 4th Edition Sonka Solutions ManualDocument3 pagesImage Processing Analysis and Machine Vision 4th Edition Sonka Solutions ManualMariaHendricksafdry100% (12)

- A Review On Present Scenario of Tobacco Farming, Sorting, Grading and Balling by Patel 2019Document12 pagesA Review On Present Scenario of Tobacco Farming, Sorting, Grading and Balling by Patel 2019nunik eka dianaNo ratings yet

- History of Robotics DevelopmentDocument5 pagesHistory of Robotics DevelopmentpogisimpatikoNo ratings yet