Professional Documents

Culture Documents

Workshop Exercise - Fans and Blowers

Uploaded by

aravoof84Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Workshop Exercise - Fans and Blowers

Uploaded by

aravoof84Copyright:

Available Formats

Workshop exercise Fans and Blowers

FANS AND BLOWERS

QUESTION

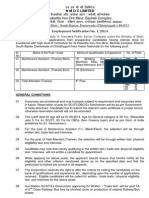

An induced draft industrial fan is used to draw air through a bag filter. The following information is given for this fan: � Flow rate is 90 m3/s at a static pressure of 80 mm water column (WC) � 65 mm WC is the static pressure across the bag filter � Motor power drawn is 120 kW � Motor efficiency is 86% � Impeller diameter is 70 mm � RPM is 1000 The company decided to replace the bag filter with an electrostatic precipitator (ESP). After installation of the ESP: � Static pressure across the ESP is 20 mm WC � Flow rate increased by 20% � The flow rate can be brought back to 90 m3/s by two options: (a) Impeller trimming and (b) Reduced pulley diameter to reduce the RPM Calculate the following: 1. Fan static efficiency before installation of the ESP 2. The new impeller diameter if the impeller is trimmed, that would result in a reduction in fan efficiency of 5% 3. The new RPM that would result in a fan efficiency of 60% 4. Which of the two options is more energy efficient

Energy Efficiency Guide for Industry in Asia www.energyefficiencyasia.org

UNEP

Workshop exercise Fans and Blowers

SOLUTION

1. Calculate the fan static efficiency before installation of the ESP Power input at fan shaft = power drawn by motor x motor efficiency = 120 x 0.86 = 103.2 kW Fan static efficiency = Flow x Pressure developed across fan 102 x Power required at fan shaft = 90 x 80 102 x 103.2 = 0.68 = 68 %

2. Calculate the new impeller diameter if the impeller is trimmed, that would result in a reduction in fan efficiency of 5% New fan static efficiency = 68% - 5% = 63% New static pressure across the fan = total static pressure static pressure across bag filter + static pressure across ESP = 80 65 + 20 = 35 mm WC New flow rate Q = original flow rate x increase = 90 m3/s x 1.2 = 108 m3/s Static pressure at a flow rate of 90 m3/s with ESP installed (H2) Q1 / Q2 = (H1/H2)2 Where Q = flow rate H = static pressure or head 108 / 90 = (35/H2)2 H2 = 32 mm Power required at the fan shaft Fan static efficiency = Flow x Pressure developed across fan 102 x Power required at fan shaft 0.63 = (90 x 32) / (102 x power developed at fan shaft) Power developed at fan shaft = 44.8 kW

Energy Efficiency Guide for Industry in Asia www.energyefficiencyasia.org

UNEP

Workshop exercise Fans and Blowers New impeller diameter (D2) (D1 / D2) = (kW1 / kW2) 1/ 3 D2 = (kW2 / kW1) 1/ 3 x D1 = 44.8 / 103.2) 1/ 3 x 70 = 53 mm

3. Calculate the new RPM that would result in a fan efficiency of 60% Power required at fan shaft Fan static efficiency = Flow x Pressure developed across fan 102 x Power required at fan shaft 0.60 = 90 x 32 / 102 x Power required at fan shaft Power required at fan shaft = (90 x 32) / (102 x 0.60) = 47 kW New RPM (N2) (N1 / N2) = (kW1 / kW2) 1/ 3 Where N = RPM KW = power N2 = (kW2 / KW1) 1/ 3 x N1 = (47/ 103.2) 1/ 3 x 1000 = 769 RPM 4. Determine which of the two options is more energy efficient Power required by impeller trimming = 44.8 kW Power required by reducing RPM = 47 kW Therefore impeller trimming is the more energy efficient option.

Energy Efficiency Guide for Industry in Asia www.energyefficiencyasia.org

UNEP

You might also like

- Southern Marine Engineering Desk Reference: Second Edition Volume IFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume INo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Calculate energy savings from fan and pump improvementsDocument11 pagesCalculate energy savings from fan and pump improvementstungau87No ratings yet

- γ γ × ∆ × × × × P 81 - 9 2 Cp A: Selected questionsDocument6 pagesγ γ × ∆ × × × × P 81 - 9 2 Cp A: Selected questionsHhaabbde SybaritzNo ratings yet

- Chapter Five Fans CharacteristicsDocument10 pagesChapter Five Fans CharacteristicsMohammed AbdoNo ratings yet

- Fluid Mechanics II (Chapter 5)Document10 pagesFluid Mechanics II (Chapter 5)Kaffel100% (1)

- Axial Fan Testing EquipmentsDocument8 pagesAxial Fan Testing EquipmentsVijay ShetNo ratings yet

- Transportasi Fluida (Compressible Fluid-Fan Blower)Document36 pagesTransportasi Fluida (Compressible Fluid-Fan Blower)Evia Salma ZauridaNo ratings yet

- Pressure Ake Int Absolute Stage Last of Pressure e Arg Disch AbsoluteDocument8 pagesPressure Ake Int Absolute Stage Last of Pressure e Arg Disch Absolutemasih tadayonNo ratings yet

- Fan LawsDocument8 pagesFan LawsKaijie LinNo ratings yet

- Air Compressor System Compressor Fundamentals: IntercoolingDocument56 pagesAir Compressor System Compressor Fundamentals: IntercoolingAmarendra Mani TiwariNo ratings yet

- @S V All FansDocument19 pages@S V All Fanshasanadel88No ratings yet

- Ojeda, Khen Mehko C. - Me 417-Bsme 4aDocument8 pagesOjeda, Khen Mehko C. - Me 417-Bsme 4akhinojidaNo ratings yet

- Introduction المقدمةDocument29 pagesIntroduction المقدمةziadNo ratings yet

- Fan & SystemDocument31 pagesFan & SystemAlberto FranciscoNo ratings yet

- BACK PRESSURE CALCULATION OF EXHAUST PIPELINEDocument12 pagesBACK PRESSURE CALCULATION OF EXHAUST PIPELINEmarjukiNo ratings yet

- 4 Performance of A Centrifugal FanDocument7 pages4 Performance of A Centrifugal Fanfinix33No ratings yet

- Blower Manual PDFDocument6 pagesBlower Manual PDFDatta DoifodeNo ratings yet

- Centrifugal Blower Test Rig PDFDocument7 pagesCentrifugal Blower Test Rig PDFGurmeet Mehma100% (2)

- Requirements of The Erp Directive On Hvac Systems. What You Need To KnowDocument9 pagesRequirements of The Erp Directive On Hvac Systems. What You Need To KnowchristianxlaNo ratings yet

- Fans and Blowers Part I ModuleDocument26 pagesFans and Blowers Part I ModuleCharlyn Flores67% (3)

- Calculate Leakage AmountDocument2 pagesCalculate Leakage AmountThivanka Nirushan Withanage100% (1)

- Paper-4 SetA Key Final 8may2009Document10 pagesPaper-4 SetA Key Final 8may2009SHAMSIK2002No ratings yet

- Ventialtion Calculation SampleDocument21 pagesVentialtion Calculation SampleNico EchavarriaNo ratings yet

- Lecture Notes 2.7.0Document18 pagesLecture Notes 2.7.0krsdz1500No ratings yet

- 6 Centrifugal BlowerDocument7 pages6 Centrifugal BlowerdhundterahoNo ratings yet

- UtilityDocument8 pagesUtilityAmit JainNo ratings yet

- 3.2 Design SystemDocument48 pages3.2 Design SystemMahmoud RababahNo ratings yet

- Industrial ElkonDocument8 pagesIndustrial ElkonsherryNo ratings yet

- Tutorial-1: Rel Rel HW Rel TWDocument3 pagesTutorial-1: Rel Rel HW Rel TWsaurabhNo ratings yet

- PressorsDocument8 pagesPressorsManoj MisraNo ratings yet

- How To Calculate A Id Fan Capacity and Sutable Motor in Kw'sDocument5 pagesHow To Calculate A Id Fan Capacity and Sutable Motor in Kw'shariprasadr519957% (7)

- Mechanical Power Department 4 Year Turbo-Machinery II Centrifugal CompressorDocument5 pagesMechanical Power Department 4 Year Turbo-Machinery II Centrifugal Compressorاحمد تاشهاويNo ratings yet

- Hydro TurbinesDocument17 pagesHydro TurbinesSavesh Tripathi100% (1)

- Ventilation Calculation For Generators RoomDocument3 pagesVentilation Calculation For Generators RoomRashid Ahmed Siddiqui100% (1)

- Fans BlowersDocument23 pagesFans BlowersPhilip Anthony MasilangNo ratings yet

- Industrial Fans: Delivery ProgramDocument42 pagesIndustrial Fans: Delivery ProgramKvvPrasadNo ratings yet

- B1. Fan Laws and Fan Control - RobinsonDocument74 pagesB1. Fan Laws and Fan Control - RobinsonNelly Isabel Narvaez PachecoNo ratings yet

- Thermal and hydraulic machines lectureDocument2 pagesThermal and hydraulic machines lectureMohamad MousaNo ratings yet

- Pelton TurbineDocument13 pagesPelton TurbineHitarth ShahNo ratings yet

- Energy Audit Methodology: Fans, Pumps and CompressorDocument39 pagesEnergy Audit Methodology: Fans, Pumps and CompressorRhen Jhing LopezNo ratings yet

- Air Compressor ProblemsDocument9 pagesAir Compressor ProblemsChristian Diano100% (4)

- Assessment of CompresorsDocument14 pagesAssessment of CompresorsranveerNo ratings yet

- Lecture 11 PDFDocument11 pagesLecture 11 PDFpsunmoorthyNo ratings yet

- Term End Exam - Nov 2014 TurbomachinesDocument4 pagesTerm End Exam - Nov 2014 TurbomachinesyashvantNo ratings yet

- Mechanical VentilationDocument81 pagesMechanical VentilationYusuf MislamNo ratings yet

- Fans and Blowers ProblemsDocument8 pagesFans and Blowers ProblemsJULIAN DOMINIC SOLEDADNo ratings yet

- Energy ConservationDocument27 pagesEnergy ConservationJAY PARIKHNo ratings yet

- EXP 7 To Determine The Volumetric Efficiency of A Four Stroke Petrol Engine at Variable LoadDocument2 pagesEXP 7 To Determine The Volumetric Efficiency of A Four Stroke Petrol Engine at Variable Load70130046No ratings yet

- BeeDocument20 pagesBeeAnudeep ChittluriNo ratings yet

- Normal and Oblique Shocks ExplainedDocument40 pagesNormal and Oblique Shocks Explainedguna sekaranNo ratings yet

- Air CompressorDocument31 pagesAir CompressorEr Bali Pandhare33% (3)

- CFM Calculation For Exhaust FanDocument2 pagesCFM Calculation For Exhaust FanSAKDA MAPRADITKUL100% (8)

- 110 Waveform Generator Projects for the Home ConstructorFrom Everand110 Waveform Generator Projects for the Home ConstructorRating: 4 out of 5 stars4/5 (1)

- Power Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlFrom EverandPower Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlRating: 5 out of 5 stars5/5 (1)

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideFrom EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideRating: 4 out of 5 stars4/5 (8)

- M1 DataDocument306 pagesM1 DataShukla SuyashNo ratings yet

- GeomorphologyDocument207 pagesGeomorphologymkprabhu100% (1)

- Address Research Group F 2021-07-09Document6 pagesAddress Research Group F 2021-07-09Shukla SuyashNo ratings yet

- Prasad Setty WorkbookDocument22 pagesPrasad Setty WorkbookShukla SuyashNo ratings yet

- Major Sites of Indus Valley CivilizationDocument1 pageMajor Sites of Indus Valley CivilizationShukla SuyashNo ratings yet

- SC Strikes Down NJAC - Logic and ImplicationsDocument4 pagesSC Strikes Down NJAC - Logic and ImplicationsShukla SuyashNo ratings yet

- Master File of School Emails Across USADocument4,126 pagesMaster File of School Emails Across USAShukla Suyash75% (4)

- upGrad ed-tech startupDocument1 pageupGrad ed-tech startupShukla SuyashNo ratings yet

- CCPL Strategy Deputy Manager JobDocument3 pagesCCPL Strategy Deputy Manager JobShukla SuyashNo ratings yet

- Public-Administration Previous Paper 1998Document2 pagesPublic-Administration Previous Paper 1998pratyoNo ratings yet

- Survey Primary Teachers Attitudes Towards STEM EducationDocument27 pagesSurvey Primary Teachers Attitudes Towards STEM EducationShukla SuyashNo ratings yet

- PUB AD (9 A) - Chapter - 9 - Importance of HRD, Recruitment, Training PDFDocument8 pagesPUB AD (9 A) - Chapter - 9 - Importance of HRD, Recruitment, Training PDFShukla SuyashNo ratings yet

- Rebel WBBL match scheduleDocument201 pagesRebel WBBL match scheduleShukla SuyashNo ratings yet

- Address Research Group F 2021-07-09Document6 pagesAddress Research Group F 2021-07-09Shukla SuyashNo ratings yet

- 8 Sapru PDFDocument19 pages8 Sapru PDFShukla SuyashNo ratings yet

- What Is PolicyDocument24 pagesWhat Is Policydedon1234No ratings yet

- References and Further Reading on Governance and Public-Private PartnershipsDocument2 pagesReferences and Further Reading on Governance and Public-Private PartnershipsShukla SuyashNo ratings yet

- 4e1adcf3-0ec0-4c57-9d5e-0ca5c0a80121Document117 pages4e1adcf3-0ec0-4c57-9d5e-0ca5c0a80121Shukla SuyashNo ratings yet

- What Is Vibration ?: Imperfections in The Machine: Design Assembly Manufacture Operation Installation MaintenanceDocument2 pagesWhat Is Vibration ?: Imperfections in The Machine: Design Assembly Manufacture Operation Installation MaintenanceShukla SuyashNo ratings yet

- 09 Administrative Law PDFDocument21 pages09 Administrative Law PDFShukla SuyashNo ratings yet

- Jindal Steel & Power Limited: P.B.No.86.Barbil-Joda Highway, Barbil-758035 (Orissa)Document1 pageJindal Steel & Power Limited: P.B.No.86.Barbil-Joda Highway, Barbil-758035 (Orissa)Shukla SuyashNo ratings yet

- OptPubAdm7 - Personnel AdministrationDocument28 pagesOptPubAdm7 - Personnel AdministrationShukla SuyashNo ratings yet

- 5837 LM PAD P01 M20 Behavioural Approach LMDocument2 pages5837 LM PAD P01 M20 Behavioural Approach LMShukla SuyashNo ratings yet

- Low Heat Input SMAW Welding ElectrodesDocument62 pagesLow Heat Input SMAW Welding ElectrodesShukla SuyashNo ratings yet

- Postman Mail Guard and MTS Examination PUBLIC NOTICEDocument1 pagePostman Mail Guard and MTS Examination PUBLIC NOTICEShukla SuyashNo ratings yet

- Result of Postman and MTS Examination Held On 3rd Aug 2014 in Keonjhar DivisionDocument1 pageResult of Postman and MTS Examination Held On 3rd Aug 2014 in Keonjhar DivisionShukla SuyashNo ratings yet

- OTE Outotec Pallet Cars For Sintering and PelletizDocument4 pagesOTE Outotec Pallet Cars For Sintering and PelletizShukla SuyashNo ratings yet

- Service Manual: Parts ListDocument6 pagesService Manual: Parts ListShukla SuyashNo ratings yet

- FA-MA (Trainee) English Adv FinalDocument6 pagesFA-MA (Trainee) English Adv FinalUmesh PatelNo ratings yet

- Valve II Valve II Valve II: Dome Dome DomeDocument2 pagesValve II Valve II Valve II: Dome Dome DomeShukla SuyashNo ratings yet