Professional Documents

Culture Documents

Methane Cost Curve Report

Uploaded by

Colin GardetteCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Methane Cost Curve Report

Uploaded by

Colin GardetteCopyright:

Available Formats

EconomicAnalysisof

MethaneEmission

ReductionOpportunities

intheU.S.OnshoreOil

andNaturalGas

Industries

March2014

Preparedfor

EnvironmentalDefenseFund

257ParkAvenueSouth

NewYork,NY10010

Preparedby

ICFInternational

9300LeeHighway

Fairfax,VA22031

blank

page

EconomicAnalysisofMethaneEmissionReductionOpportunitiesintheU.S.OnshoreOilandNaturalGas

Industries

ICFInternational iii March2014

Contents

1. ExecutiveSummary....................................................................................................................11

2. Introduction...............................................................................................................................21

2.1. GoalsandApproachoftheStudy..............................................................................................21

2.2. OverviewofGasSectorMethaneEmissions.............................................................................22

2.3. ClimateChangeForcingEffectsofMethane.............................................................................25

2.4. CostEffectivenessofEmissionReductions...............................................................................26

3. ApproachandMethodology.......................................................................................................31

3.1. OverviewofMethodology.........................................................................................................31

3.2. Developmentofthe2011EmissionsBaseline...........................................................................32

3.3. Projectionto2018.....................................................................................................................34

3.4. IdentificationofTargetedEmissionSources.............................................................................36

3.5. SelectedMitigationTechnologies.............................................................................................39

3.6. SourceCategoriesNotAddressed...........................................................................................323

4. AnalyticalResults.......................................................................................................................41

4.1. DevelopmentofEmissionControlCostCurves.........................................................................41

4.2. EmissionReductionCostCurves................................................................................................42

4.3. CoBenefits..............................................................................................................................411

5. CaseStudies...............................................................................................................................51

5.1. WetSealCompressorDegassingforCentrifugalCompressors.................................................51

5.2. DrySealReplacement/Retrofit..................................................................................................52

5.3. WetSealDegassingCaptureSystems........................................................................................52

5.3.1. EconomicAnalysisofInstallingWetSealDegassingCaptureSystems........................53

5.4. LiquidsUnloading......................................................................................................................56

5.4.1. Background...................................................................................................................56

5.4.2. PlungerLifts..................................................................................................................57

5.4.3. AdditionalOptionsforRemovingorRemediatingLiquidsProblems...........................59

5.4.4. LiquidsIssuesinHorizontalWells...............................................................................512

6. Conclusions................................................................................................................................61

AppendixA.AdditionalSensitivities..................................................................................................A1

AppendixB.Developmentofthe2011EmissionsBaseline................................................................B1

AppendixC.EmissionProjectionto2018..........................................................................................C1

AppendixD.MethaneMitigationTechnologies.................................................................................D1

Figures

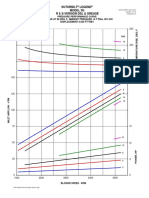

Figure11MarginalAbatementCostCurveforMethaneReductionsbySource...................................12

Figure21NaturalGasIndustryProcessesandExampleMethaneEmissionSources............................23

Figure31EmissionProjectionto2018(IncludingOffshore)..............................................................35

Figure32DistributionofEmissionsin2018...........................................................................................35

EconomicAnalysisofMethaneEmissionReductionOpportunitiesintheU.S.OnshoreOilandNaturalGas

Industries

ICFInternational iv March2014

Figure33EIAOilandGasRegions..........................................................................................................36

Figure342018ProjectedOnshoreEmissions........................................................................................38

Figure35ReciprocatingCompressorRodPacking...............................................................................313

Figure36WetSealCompressorSchematic..........................................................................................315

Figure37PlungerLiftSchematic..........................................................................................................317

Figure41ExampleMACCurve...............................................................................................................42

Figure42NationalAggregateMACCurveforBaselineTechnologyAssumptions................................43

Figure43DistributionofEmissionReductionPotential.........................................................................45

Figure44EmissionReductionbyIndustrySegment..............................................................................46

Figure45EmissionReductionsfortheGasProductionSegment.........................................................47

Figure46EmissionReductionsfortheOilProductionSegment............................................................48

Figure47EmissionReductionsfortheGatheringandBoostingSegment.............................................49

Figure48EmissionsReductionsfortheGasTransmissionSegment.....................................................49

Figure49NationalAggregateMACCurvewithBaselineTechnologyAssumptionand

EconomyWideValueRecognition.........................................................................................410

Figure410NationalAggregateMACCurvebyRegion.........................................................................411

Figure411CoBenefitReductionsofVOCsandHAPs.........................................................................412

Figure412VOCReductionCoBenefits................................................................................................412

Figure413HazardousAirPollutantCoBenefits..................................................................................413

Figure51DrySealsonaCentrifugalCompressor..................................................................................52

Figure52Wetsealdegassingrecoverysystemforcentrifugalcompressors(SourceU.S.

EPA)..........................................................................................................................................53

Figure53PlungerLiftSchematic............................................................................................................57

Figure54InstallationofVelocityTubingServingtoReductiontheCrossSectionAreaof

theProductionTubing............................................................................................................511

Figure55DifferentTypesofHorizontalWells......................................................................................513

Tables

Table31Summaryof2011MethaneEmissionsBaseline......................................................................33

Table32HighestEmittingOnshoreMethaneSourceCategoriesin2018.............................................37

Table33LDARHourlyCostCalculation................................................................................................310

Table34CostCalculationQuarterlyLDAR........................................................................................312

Table35AssumptionsforRodPackingReplacement..........................................................................314

Table36SummaryofMitigationMeasuresApplied............................................................................321

Table37SummaryofMitigationMeasureCharacteristics..................................................................322

Table41AnnualizedCostandReductionandInitialCapitalCost.........................................................44

Table42InitialCapitalCostbyIndustrySegment..................................................................................47

Table51DegassingRecoverySystemEstimatedInstallationandEquipmentCosts.............................54

Table52WetSealDegassingRecoverySystemCostsandSavingsforOneCompressor......................56

Table53WetSealDegassingRecoverySystemCostsandSavingsforFourCompressors

ataStation...............................................................................................................................56

Table54ReportedCapitalandOperatingCostRangesforInstallingPlungerLift

Systems....................................................................................................................................59

EconomicAnalysisofMethaneEmissionReductionOpportunitiesintheU.S.OnshoreOilandNaturalGas

Industries

ICFInternational v March2014

Acknowledgement

ICFreceivedandconsidereddataandcommentaryfromnumerousstakeholderorganizations,

includingoilandgasproducers,pipelines,equipmentvendors,serviceproviders,andatrade

organization.Noinformationinthisreportshouldbeattributedtoanysingleorganization,asall

dataisaggregatedfrommultiplesourcesandoftenusesaveragevalues.Furthermore,

acknowledgementofindustryparticipationdoesnotimplytheiragreementwiththestudy

conclusions,whichreflecttheprofessionaljudgmentofICF.

Wethankallofthestakeholderorganizationsforprovidinginputtothisstudy,andspecifically

acknowledgethefollowingentities:AnadarkoPetroleum,BGGroup,PioneerNaturalResources,

SouthwesternEnergy,andtheAmericanGasAssociation.

EconomicAnalysisofMethaneEmissionReductionOpportunitiesintheU.S.OnshoreOilandNaturalGas

Industries

ICFInternational vi March2014

AcronymsandAbbreviations

Acronym/Abbreviation StandsFor

AEO AnnualEnergyOutlook

BAMM BestAvailableMonitoringMethods

bbl Barrel

Bcf BillionCubicFeet

BTEX Benzene,Toluene,Ethylbenzene,andXylenes

CapEx CapitalExpenditures

CH

4

Methane

CO

2

CarbonDioxide

CO

2

e CarbonDioxideEquivalent

DI&M DirectedInspectionandMaintenance

EDF EnvironmentalDefenseFund

EIA U.S.EnergyInformationAdministration

EPA U.S.EnvironmentalProtectionAgency

ESD EmergencyShutdown

FERC FederalEnergyRegulatoryCommission

GDP GrossDomesticProduct

GGFR GlobalGasFlaringReduction

GHG GreenhouseGas

GHGRP GreenhouseGasReportingProgram

HAP HazardousAirPollutant

hp Horsepower

IR Infrared

LDAR LeakDetectionandRepair

LDCs LocalDistributionCompanies

LNG LiquefiedNaturalGas

MAC MarginalAbatementCost

Mcf ThousandCubicFeet

MMcf MillionCubicFeet

MMTCH

4

MillionMetricTonnesMethane

EconomicAnalysisofMethaneEmissionReductionOpportunitiesintheU.S.OnshoreOilandNaturalGas

Industries

ICFInternational vii March2014

Acronym/Abbreviation StandsFor

MMTCO

2

e MillionMetricTonnesCO

2

equivalent

NESHAP NationalEmissionStandardsforHazardousAirPollutants

NPV NetPresent Value

NSPS NewSourcePerformanceStandards promulgatedundertheFederalCleanAirAct

OpEx OperatingExpenditures

PRO PartnerReportedOpportunity

psig PoundsperSquareInch Gauge

RECs ReducedEmissionCompletions

scf StandardCubicFeet

scfd StandardCubicFeetperDay

scfh StandardCubicFeetperHour

scfm StandardCubicFeetperMinute

TEG TriethyleneGlycol

TSD TechnicalSupportDocument

USD U.S.Dollars

VOC VolatileOrganicCompound

VRU VaporRecoveryUnit

EconomicAnalysisofMethaneEmissionReductionOpportunitiesintheU.S.OnshoreOilandNaturalGas

Industries

ExecutiveSummary

ICFInternational 11 March2014

1. ExecutiveSummary

Methaneisanimportantclimatechangeforcinggreenhousegas(GHG)withashorttermimpactmany

timesgreaterthancarbondioxide.Methanecomprised9%ofU.S.greenhousegas(GHG)emissionsin

2011accordingtotheU.S.EPAInventoryofUSGreenhouseGasEmissionandSinks:19902011

1

,and

wouldcompriseasubstantiallyhigherportionbasedonashortertimescalemeasurement.Recent

researchalsosuggeststhatmitigationofshorttermclimateforcerssuchasmethaneisacritical

componentofacomprehensiveresponsetoclimatechange

2

.Emissionsfromtheoilandgasindustryare

amongthelargestanthropogenicsourcesofU.S.methaneemissions.Atthesametime,therearemany

waystoreduceemissionsoffugitiveandventedmethanefromtheoilandgasindustryand,becauseof

thevalueofthegasthatisconserved,someofthesemeasuresactuallysavemoneyorhavelimitednet

cost.

EnvironmentalDefenseFund(EDF)commissionedthiseconomicanalysisofmethaneemissionreduction

opportunitiesfromtheoilandnaturalgasindustriestoidentifythemostcosteffectiveapproachesto

reducethesemethaneemissions.Thestudyprojectstheestimatedgrowthofmethaneemissionsfrom

theseindustriesthrough2018asafuturedateatwhichnewemissionreductiontechnologiescouldbe

installed.Itthenidentifiesthelargestemittingsegmentsandestimatesthemagnitudeandcostof

potentialreductionsachievablethroughcurrentlyavailabletechnologies.Thekeyconclusionsofthe

studyinclude:

EmissionGrowthMethaneemissionsfromoilandgasactivitiesareprojectedtogrow4.5%from

2011to2018includingreductionsfromEPAregulationsadoptedin2012(knownasNewSource

PerformanceStandards(NSPS)SubpartOOOO).Alloftheprojectednetgrowthisfromtheoil

sector,largelyfromflaringandventingofassociatedgas.Growthfromnewnaturalgassourcesis

offsetbytheNSPSandothercontinuingemissionreductionactivities.Nearly90%oftheemissions

in2018comefromexistingsources(sourcesinexistencein2011).

80/20RuleforSources22oftheover100emissionsourcecategoriesaccountforover80%ofthe

2018emissions,primarilyatexistingfacilities.

AbatementMagnitudeandEconomicsA40%percentreductioninonshoremethaneemissionsis

projectedtobeachievablewithexistingtechnologiesandtechniquesatanettotalcostof

$0.66/Mcfofmethanereduced,orlessthan$0.01/Mcfofgasproduced,takingintoaccountsavings

thataccruedirectlytocompaniesimplementingmethanereductionmeasures(Figure11).Ifthefull

economicvalueofrecoverednaturalgasistakenintoaccount,includingsavingsthatdonotdirectly

accruetocompaniesimplementingmethanereductionmeasures,the40%reductionisachievable

1

Calculatedata100yearGWPof21seeSection2.3.

2

Shoemaker,J.et.al.,WhatRoleforShortLivedClimatePollutantsinMitigationPolicy?.ScienceVol34213December2013

EconomicAnalysisofMethaneEmissionReductionOpportunitiesintheU.S.OnshoreOilandNaturalGas

Industries

ExecutiveSummary

ICFInternational 12 March2014

whilesavingtheU.S.economyandconsumersover$100millionperyear.Thecostforsome

measuresandsegmentsoftheindustryismoreorlessthanthenettotal.Theinitialcapitalcostof

themeasuresisestimatedtobeapproximately$2.2billionwiththemajorityofthecostsintheoil

andgasproductionsegments.

Figure11MarginalAbatementCostCurveforMethaneReductionsbySource

AbatementOpportunitiesByvolume,thelargestopportunitiestargetleakdetectionandrepairof

fugitiveemissions(leaks)atfacilitiesandgascompressors,reducedventingofassociatedgas,and

replacementofhighemittingpneumaticdevices.

CoBenefitsReducingmethaneemissionswillalsoreduceatnoextracostconventional

pollutantsthatcanharmpublichealthandtheenvironment.Themethanereductionsprojected

herewouldalsoresultina44%reductioninvolatileorganiccompounds(VOCs)andhazardousair

pollutants(HAPs)associatedwithmethaneemissionsfromtheoilandgasindustry.

Thereareseveralcaveatstotheresults:

The2011EPAinventoryisthebeststartingpointforanalysis,butitisbasedonmanyassumptions

andsomeolderdatasources.Althoughtheinventoryisimprovingwithnewdata,itisdesignedto

beaplanningandreportingdocumentandisimperfect,especiallyatthedetailedlevel,fora

granularanalysisofthistype.

Emissionmitigationcostandperformancearehighlysitespecificandvariable.Thevaluesusedhere

areestimatedaveragevalues.

EconomicAnalysisofMethaneEmissionReductionOpportunitiesintheU.S.OnshoreOilandNaturalGas

Industries

ExecutiveSummary

ICFInternational 13 March2014

Theanalysispresentsareasonableestimateofpotentialcostandmagnitudeofreductionswithina

rangeofuncertainty.

EconomicAnalysisofMethaneEmissionReductionOpportunitiesintheU.S.OnshoreOilandNaturalGas

Industries

Introduction

ICFInternational 21 March2014

2. Introduction

Methaneemissionshaveanenhancedeffectonclimatechangebecausemethanehasaclimateforcing

effect25timesgreaterona100yearbasisthanthatofcarbondioxide,theprimarygreenhousegas

(GHG).Methanesimpactisalmostthreetimesgreaterona20yearbasisandthereisresearchthatmay

causebothfactorstobeincreased.(SeeSection2.3)Recentresearchalsosuggeststhatmitigationof

shorttermclimateforcerssuchasmethaneisacriticalcomponentofacomprehensiveresponseto

climatechange.

EmissionsfromtheoilandgasindustriesareamongthelargestanthropogenicsourcesofU.S.methane

emissionsaccordingtotheU.S.EPAInventoryofU.S.GreenhouseGasEmissions

3

,andrecentanalyses

indicatethattheEPAinventoryestimatesmayunderstatetotalmethaneemissionsfromthissource

category

4

.Atthesametime,therearemanywaystoreduceemissionsoffugitiveandventedmethane

fromtheoilandgasindustriesand,becauseofthevalueofthegasthatisconserved,someofthese

measuresactuallysavemoneyorhavelimitednetcost.

Companiesintheoilandgasindustrieshavemadesignificantvoluntaryreductionsinmethane

emissions.However,voluntaryadoptionofcontroltechniquesisuneven.TheU.S.hasestablished

emissionregulationsforconventionalpollutants(NSPSSubpartOOOOandoilandgasNESHAPS)that

willhavetheeffectofsignificantlyreducingmethaneemissionsfromcertainnewsourcesinsome

segmentsofthegasindustry.Somestatesalsohaveproposedorestablishedregulationsthatlimit

methaneemissionsfromtheoilandgasindustry.However,theseregulationsgenerallydonotapplyto

emissionsfromtheexistinginfrastructure,sothereisalargepopulationofuncontrolledsources.

Overall,methaneemissionsaresignificantandthereisasizeablepotentialforadditionalcosteffective

reductionopportunities.

2.1. GoalsandApproachoftheStudy

EnvironmentalDefenseFund(EDF)commissionedthiseconomicanalysisofmethaneemissionreduction

opportunitiesfromtheoilandnaturalgasindustry.ThisICFanalysisissolutionsorientedand

complementsEDFsongoingworkonmethaneemissionsintheoilandnaturalgassectors.The

approachtothestudywasto:

Defineabaselineofmethaneemissionsfromtheoilandgassectors.Thebaselinewasestablished

for2018asaconservativeestimateofapointwhennewmitigationtechnologiescouldhavebeen

installed.

3

U.S.EPA,InventoryofU.S.GreenhouseGasEmissionsAndSinks:19902011.April2013.

http://www.epa.gov/climatechange/ghgemissions/usinventoryreport.htmlBasedona100yearGWPof21seeSection2.3

4

Brandt,A.et.al.,MethaneLeaksfromNorthAmericanNaturalGasSystems.ScienceVOL34314February2014

EconomicAnalysisofMethaneEmissionReductionOpportunitiesintheU.S.OnshoreOilandNaturalGas

Industries

Introduction

ICFInternational 22 March2014

Reviewexistingliteratureandconductfurtheranalysistoidentifythelargestreduction

opportunitiesandvalidateandrefinecostbenefitestimatesofmitigationtechnologies.

Conductinterviewswithindustry,technologyinnovators,andequipmentvendorswithaspecific

focustoidentifyadditionalmitigationoptions.

Usethisinformationtodevelopmarginalabatementcost(MAC)curvesformethanereductionsin

theseindustries.

Documentandpresenttheresults.

Thefinaloutputsofthestudyinclude:

Theprojected2018emissionsbaseline.(Chapter3andAppendixC)

Inventoryofmethanemitigationtechnologies.(Chapters3and6andAppendixD)

Emissionsabatementcostcurvesacrossarangeofscenarios(Chapter4andAppendixA)

Indepthcasestudiesoftwospecificmethanemitigationoptions.(Chapter5)

Conclusions(Chapter6)

2.2. OverviewofGasSectorMethaneEmissions

Therearemanysourcesofmethaneemissionsacrosstheentireoilandgassupplychain.These

emissionsarecharacterizedaseither:

Fugitiveemissionsmethanethatleaksunintentionallyfromequipmentsuchasfromflanges,

valves,orotherequipment.

Ventedemissionsmethanethatisreleasedduetoequipmentdesignoroperationalprocedures,

suchasfrompneumaticdevicebleeds,blowdowns,incompletecombustion,orequipmentventing.

Althoughleaksissometimesusedtorefertoallmethaneemissionsfromtheoilandgasindustry,we

usethemorenarrowtechnicaldefinitionsinthisreport.

Figure21illustratesthemajorsegmentsofthenaturalgasindustryandexamplesoftheprimary

sourcesofmethaneemissionsasgasisproduced,processed,anddeliveredtoconsumers.Naturalgasis

producedalongwithoilinmostoilwells(asassociatedgas)andalsoingaswellsthatdonotproduce

oil(asnonassociatedgas).Upuntilthepastfewyears,mostoftheU.S.naturalgassupplycamefrom

theGulfofMexicoandfromwesternandsouthwesternstates.Morerecently,midcontinentaland

northeasternshaleplayshavebeenagrowingsourceofoilandgassupply.

EconomicAnalysisofMethaneEmissionReductionOpportunitiesintheU.S.OnshoreOilandNaturalGas

Industries

Introduction

ICFInternational 23 March2014

Figure21NaturalGasIndustryProcessesandExampleMethaneEmissionSources

Sources:AmericanGasAssociation;EPANaturalGasSTARProgram

Rawgas(includingmethane)isventedatvariouspointsduringtheproductionprocess.Gascanbe

ventedwhenthewelliscompletedattheinitialphaseofproduction.Further,becausegaswellsare

ofteninremotelocationswithoutelectricity,thegaspressureisusedtocontrolandpoweravarietyof

controldevicesandonsiteequipment,suchaspumps.Thesepneumaticdevicestypicallyreleaseor

bleedsmallamountsofgasduringtheiroperation.Inbothoilandgasproduction,waterand

hydrocarbonliquidsareseparatedfromtheproductstreamatthewellhead.Theliquidsreleasegas,

whichmaybeventedfromtanksunlessitiscaptured.Waterisremovedfromgasstreambyglycol

dehydrators,whichventtheremovedmoistureandsomegastotheatmosphere.Insomecases,thegas

releasedbytheseprocessesandequipmentmaybeflaredratherthanvented,tomaintainsafetyandto

relieveoverpressuringwithindifferentpartsofthegasextractionanddeliverysystem.Flaringproduces

CO

2

,asignificantbutlesspotentGHGthanmethane,butnoflareis100%efficient,andsomemethaneis

emittedduringflaring.Inadditiontothevarioussourcesofventedemissions,themanycomponents

andcomplexnetworkofsmallgatheringlineshavethepotentialforfugitiveemissions.

Althoughsomegasispureenoughtobeusedasis,mostgasisfirsttransportedbypipelinefromthe

wellheadtoagasprocessingplant.Thegatheringsystemhaspneumaticdevicesandcompressorsthat

ventgasaswellaspotentialfugitiveemissions.Gasprocessingplantsremoveadditionalhydrocarbon

liquidssuchasethaneandbutaneaswellasgaseousimpuritiesfromtherawgas,includingCO

2

,inorder

forthegastobepipelinequalityandreadytobecompressedandtransported.Suchplantsareanother

sourceoffugitiveandventedemissions.

EconomicAnalysisofMethaneEmissionReductionOpportunitiesintheU.S.OnshoreOilandNaturalGas

Industries

Introduction

ICFInternational 24 March2014

Fromthegasprocessingplant,naturalgasistransported,generallyoverlongdistancesbyinterstate

pipelinetothecitygatehubandthentoconsumers.Thevastmajorityofthecompressorsthat

pressurizethepipelinetomovethegasarefueledbynaturalgas,althoughasmallshareispoweredby

electricity.CompressorsemitCO

2

andmethaneemissionsduringfuelcombustionandarealsoasource

offugitiveandventedmethaneemissionsthroughleaksincompressorseals,valves,andconnections

andthroughventingthatoccursduringoperationsandmaintenance.Compressorstationsconstitute

theprimarysourceofventedmethaneemissionsinnaturalgastransmission.

Somepowerplantsandlargeindustrialfacilitiesreceivegasdirectlyfromtransmissionpipelines,while

othersaswellasresidentialandcommercialconsumershavegasdeliveredthroughsmallerdistribution

pipelinesoperatedbylocalgasdistributioncompanies(LDCs).Distributionlinesdonottypicallyrequire

gascompression;however,somemethaneemissionsdooccurduetoleakagefromolderdistribution

linesandvalves,connections,andmeteringequipment.Thisisespeciallytrueforoldersystemsthat

havecastirondistributionmains.

Manyoftheemissionsourcesfromdomesticoilproductionaresimilartothoseingasproduction

completionemissions,pneumaticdevices,processingequipmentandengine/compressors.Crudeoil

containsnaturalgasandthegasisseparatedfromtheoilstreamatthewellheadandcanbecaptured

forsale,vented,orflared.Ventingorflaringismostcommoninregionsthatdonothavegasgathering

infrastructure.ThisisthecasecurrentlyinNorthDakota,whererapidgrowthinoilproductionhastaken

placeinaregionwithlittlegasgatheringinfrastructure.Whilenewgatheringlinesarebeingbuilt,

productionisstillaheadofthegatheringcapacity,resultingincontinuedflaring.

Oilistakenfromthewellheadinelectricpoweredpipelinesandmorerecentlybyrail,torefineriesfor

processing.Petroleumproductsarethentakentoconsumersbypipeline,truck,rail,orbarge.The

downstreammethaneemissionsinthepetroleumsectoraremuchsmallerthaninthegassectoras

mostofthemethanehasbeenremovedfromtheoilbythispoint.

Forthelast100years,domesticoilproductionhasbeenprimarilyintheSouthwest(Texas,Arkansas,

Oklahoma),theGulfofMexico,California,andAlaska.Domesticgasproductionhasbeenmostlyinthe

Southwest,GulfofMexico,andtheRockies.Morerecently,thefocusofnewnaturalgasandoil

developmenthasbeenintheextractionofgasfromshaleformations.Shaleisasedimentaryrock

composedofcompactedmud,clayandorganicmatter.Overtime,theorganicmaterialcanproduce

naturalgasand/orpetroleum,whichcanslowlymigrateintoformationswhereitcanberecoveredfrom

conventionaloilandgaswells.Theshalerockitselfisnotsufficientlypermeabletoallowthegastobe

economicallyrecoveredthroughconventionalwells;thatis,gaswillnotflowsufficientlyfreelythrough

theshaletoawellforproduction.

Gasandoilfromshaleformationsisrecoveredbyhydraulicallyfracturingtheshalerocktoreleasethe

hydrocarbons.Thisinvolvespumpingwaterandadditivesathighpressureintothewelltofracture

theshale,creatingsmallcracksthatallowthegasand/oroiltoflowout.Whenthewaterflowsback

EconomicAnalysisofMethaneEmissionReductionOpportunitiesintheU.S.OnshoreOilandNaturalGas

Industries

Introduction

ICFInternational 25 March2014

outofthewell,methaneisentrainedandmaybevented.Duetothehighglobalwarmingpotentialof

methane,thiscanbealargesourceofGHGs.Forthesereasons,theincreasedproductionofshalegasis

apotentialsourceofincreasedGHGemissions.

Federalregulationspromulgatedin2012requirethemajorityofnewhydraulicallyfracturedgaswellsto

captureorflaretheflowbackgas.Theseregulationsandotherfederalandstateregulationsalsorequire

controlofothermethaneemittingprocesses,thoughmanyapplyonlytonewsourcesandtothose

wellsthatprimarilyproducenaturalgasratherthanwellsthatprimarilyproduceoil,sothereremainsa

largepopulationofexistinguncontrolledsources.

Significantamountsofbothoilandgasareproducedfromoffshorefacilities.Whilethesefacilities

reportsignificantmethaneemissions,thereportsdonothavethedetailandspecificityoftherestofthe

methaneinventoryandthereforecannotbeincludedinthesamemethodologyappliedtotherestof

theinventoryforthisanalysis.Therefore,thisstudyfocusesonlyononshoreoilandgasindustry

operations.Additionalstudyofoffshoreemissionsandreductionopportunitieswouldbeauseful

followuptothisanalysis.

2.3. ClimateChangeForcingEffectsofMethane

Differentgreenhousegasespersistintheatmospherefordifferentlengthsoftimeandhavedifferent

warmingeffects,andthushavedifferenteffectsonclimatechange.Inordertocomparethem,the

scientificcommunityusesafactorcalledtheglobalwarmingpotential(GWP),whichrelateseachGHGs

effecttothatofCO

2

,whichisassignedaGWPof1.Thescienceandpolicycommunitieshavehistorically

lookedtotheIntergovernmentalPanelonClimateChange(IPCC)assessmentreportsasthe

authoritativebasisforGWPvalues.ThecurrentlyacceptedvaluesarefromtheIPCCFourthAssessment

report

5

(AR4).

CO

2

emissionsdeterminetheamountofclimatechangeoverthelongterm,duetotheirlonglifetimein

theatmosphere.BecausestabilizingclimatewillrequiredeepcutsinCO

2

emissions,GWPvaluesare

mostcommonlyexpressedona100yeartimehorizon.Ona100yearbasis,methaneisassignedaGWP

of25bytheAR4.Thismeansthatonetonofmethanehasthesameeffectas25tonsofCO

2

over100

years.The100yearGWPisthestandardvalueusedbytheEPAandotherfederal,state,and

internationalagenciestomeasureGHGemissions.(OneexceptionistheEPAGHGinventory,whichuses

a100GWPof21,asspecifiedbytheUnitedNationsFrameworkConventiononClimateChange(UNFCC)

inventoryprotocol.)

5

IPCC.ClimateChange2007:ThePhysicalScienceBasis.ContributionofWorkingGroupItotheFourthAssessmentReportof

theIntergovernmentalPanelonClimateChange.(CambridgeUniversityPressandNewYork,NY,Cambridge,UnitedKingdom,

2007).

EconomicAnalysisofMethaneEmissionReductionOpportunitiesintheU.S.OnshoreOilandNaturalGas

Industries

Introduction

ICFInternational 26 March2014

SomeGHGs,includingmethane,haveastrongerclimateforcingeffectthanCO

2

butashorterlifetimein

theatmosphere(12yearsformethane).Inordertoevaluatetheshorttermeffects,theGWPisalso

calculatedona20yearbasis.Ona20yearbasis,theAR4assignsmethaneaGWPof72.TheIPCCis

currentlypreparingaFifthAssessmentReport(AR5)

6

.Thefirstphaseofthatworkhasadoptedhigher

GWPvaluesduetoupdateddataonmethanesroleintheatmosphere.TheAR5valuesarea100year

GWPof28anda20yearGWPof84formethane.Insummary:

TheEPAGHGinventoryusesa100yearGWPof21.

Mostotherregulationsandinventories(includingtheEPAGreenhouseGasReportingruleasof

2013)usetheAR4100yearGWPof25.TheAR420yearGWPis72.

TheGWPsbeingputforthintheAR5are28for100yearsand84for20years.

ThisreportusestheAR4100yearGWPof25exceptwhereotherwisenoted.

2.4. CostEffectivenessofEmissionReductions

Itiscommonindiscussingemissionreductionstodescribecosteffectiveemissionreductions.

However,therearethreedifferentconceptsofcosteffectivenessthatmustbeunderstoodand

differentiated.

Thefirstconceptiscosteffectivenessforthecompanyimplementingthemeasure.Inthiscase,cost

effectivemeansthatthevalueofgasthatisrecoveredthroughamethanereductionmeasureexceeds

theincrementalcapitalandoperatingcostofthemeasuresufficientlytocreateapaybackorrateof

returnthatmeetsthecompanysinvestmentcriteria.Measuresthatmeetthesecriteriamightbe

describedashavingapositivenetpresentvalue(NPV),ashortpaybackperiod,oraninternalrateof

returnthatmeetsacertainthreshold.

Inorderforameasuretomeetthiscosteffectivenesscriterion,themeasuremustrecoverthemethane

emissionsandbeabletorecovertheirmonetaryvalue.Flaringofmethaneemissionsdoesnotmeetthis

criterion,forexample.Inaddition,thecompanymustbeabletomonetizethevalueoftherecovered

methane.Forexample,ifaproducerreducesmethanelosses,itwillhavemoregastosellandwill

receiveaneconomicbenefit.

Thesecondconceptiscosteffectivenessattheeconomywidescale.Insegmentsinwhichthecompany

ownsthegas,suchasoilandgasproduction,thecompanycanclearlymonetizethevalueofreduced

gaslosses.Thisisalsotrueinsomeothersectors.Mostmidstreamcompanies(gathering,processing,

6

IPCC.ClimateChange2013:ThePhysicalScienceBasis.ContributionofWorkingGroupItotheFifthAssessmentReportof

theIntergovernmentalPanelonClimateChange.(CambridgeUniversityPressandNewYork,NY,Cambridge,UnitedKingdom,

2013).

EconomicAnalysisofMethaneEmissionReductionOpportunitiesintheU.S.OnshoreOilandNaturalGas

Industries

Introduction

ICFInternational 27 March2014

storage)arepaidafixedfeeforgaslostandconsumedduringtheiroperations.Iftheycanreducetheir

lossesthentheywillbenefitdirectlyfromthereducedlosses.

Althoughtransmissionandlocaldistributioncompaniestypicallyhaveasimilarcoststructure,theyare

usuallyrequiredbyregulatorstoreturnthevalueofreducedlossestotheircustomers,sotheycannot

recoverthebenefitofreducedmethanelosses.Methanereductionsinthesesegmentsoftheindustry

willnothaveapositivereturntothecompanyorbecosteffectiveinthissense.Thatsaid,thevalueof

reducedlosseswillaccruetootherpartsoftheeconomy.IfapipelineorLDCreducesitslosses,the

benefitwilleventuallyflowthroughtothecustomersandtotheeconomyoverall.Reducedlosseswill

eventuallyflowthroughaslowerpricesforgasdeliveryanddeliveredcostofgastoconsumers.Thus,

evenwhentheentityimplementingareductioncannotdirectlybenefitfromreducedlosses,thereisa

broaderbenefitandthatfulleconomicbenefitcanbecalculatedandallocatedagainstthecostofthe

methanereduction,thesecondkindofcosteffectiveness.

Thelastconceptofcosteffectivenessisinthecontextofpollutioncontrolprograms.Inconventional

pollutioncontrolprogramsthecontroltechnologyrarelyresultsinacostreductiontothecompanythat

isrequiredtoimplementit.Thatis,thecostofcontrolisalmostalwayspositiveandthenetpresent

valueisnegativeandthereisnopaybackfortheinvestment.Nevertheless,theseprogramsincorporate

theconceptofcosteffectiveness,meaningthatthecostisacceptabletosocietyasameansofmeeting

publichealthandenvironmentalgoals.Thecosteffectivenessvariesfordifferentpollutantsand

differentregulatoryprograms.Forexample,$10,000/tonofVOCreducedmaybeconsideredcost

effectiveinsomeozonenonattainmentareaswhile$100/tonofSO

2

maybeconsideredcosteffective

foranacidrainreductionprogram.Inthiscontext,methanereductionscanbeconsideredcosteffective

eveniftheyhaveanetcosttothecompanyorsocietyoverall.Wheremethanereductionsdocreatea

netvaluetotheimplementingcompany,thecostofcontrolwillbenegative,i.e.,thecompanyis

reducingemissionsandsavingmoneyratherthanspendingmoney.

Inthisstudy,thevalueofrecoveredgasisincludedincalculatingthecosteffectivenessofmitigation

measureswherethegascanberecoveredandwhereitcanbemonetizedbythecompany.Therefore,

thesamemeasuremayhavedifferentcostsfordifferentsegments,e.g.,reducingcompressoremissions

willhavealowernetcostintheproductionsegmentthaninthetransmissionsegment.Thisreflectsthe

netcosttothecompanytoimplementthemeasure.However,wheregascanberecoveredthrougha

mitigationmeasure,itwillhavevaluetothebroadereconomy,evenifitisnotrecognizedbythe

companythatmustmaketheinvestment.Thereforewealsoshow,incertaincases,aneconomywide

costeffectivenessmeasure,whichrecognizesthevalueofallrecoveredgas,evenifitcannotbe

recognizeddirectlybytheaffectedcompany.Thesecasesareclearlylabeledassuch.Thecostof

control,whetherpositiveornegative,canbealsoevaluatedintheregulatorysenseandcomparedto

otheravailableemissionreductionoptions.Finally,thereareadditionalsocialandenvironmental

benefitsofmethanereductionsthatarenotcapturedinthesecalculations,includingthebroader

EconomicAnalysisofMethaneEmissionReductionOpportunitiesintheU.S.OnshoreOilandNaturalGas

Industries

Introduction

ICFInternational 28 March2014

economicvalueofreducedclimateriskandcobenefitreductionsofconventionalpollutantssuchas

groundlevelozoneandhazardousairpollutants.

EconomicAnalysisofMethaneEmissionReductionOpportunitiesintheU.S.OnshoreOilandNaturalGas

Industries

ApproachandMethodology

ICFInternational 31 March2014

3. ApproachandMethodology

3.1. OverviewofMethodology

Thissectionprovidesanoverviewofthemethodologyappliedforthisstudy.Themajorstepswere:

Establishthe2011BaselineforanalysistheanalysisstartedwiththemostrecentU.S.EPA

inventoryofmethaneemissionsintheEPAInventoryofU.S.GHGEmissionspublishedin2013with

datafor2011

7

.Thisinventorywasreviewedandrevisedtoaccountforadditional,morerecent

informationsuchasinformationfromtheEPAGHGReportingProgram

8

andtheUniversityof

Texas/EDFgasproductionmeasurementstudy

9

.ThesechangeswereappliedtodevelopanICF2011

Baseline,whichwasusedasthebasisforprojectingonshoremethaneemissionsto2018.

Projectemissionsto2018theanalysisofpotentialreductionswasbasedontheprojected2018

emissionlevel.Theyear2018waschosenasaconservativedatebywhichnewcontroltechnologies

couldhavebeeninstalled.TheinventorywasalsodisaggregatedfromthenationallevelintheEPA

inventorytothesevenregionsusedintheU.S.EIAsoilandgasdatatoprovideregionalreporting.

Identificationofmajorsourcesandkeymitigationoptionsthenextstepwastoidentifythe

largestemittingsourcesintheprojected2018inventoryandthemitigationoptionsthatwouldbe

mosteffectiveandcosteffectiveforthesesources.

Characterizationofemissionreductiontechnologiesakeypartofthestudywastoreviewand

updateinformationonthecostandperformanceoftheselectedmitigationtechnologies.

Informationwasgatheredfromequipmentmanufacturers,oilandgascompanies,andother

knowledgeableparties.

Developmentofthemarginalabatementcostcurvesthetechnologyinformationwasappliedto

theemissionsinventorytocalculatethepotentialemissionreductionandcost.Theresultswere

displayedinaseriesofmarginalabatementcostcurves.

Thekeystepsarediscussedfurtherinthefollowingsections.

7

U.S.EPA,InventoryofU.S.GreenhouseGasEmissionsAndSinks:19902011,

http://www.epa.gov/climatechange/ghgemissions/usinventoryreport.html

8

http://www.epa.gov/ghgreporting/

9

Allen,David,et.al.,MeasurementsofMethaneEmissionsatNaturalGasProductionSitesintheUnitedStates.

10.1073/pnas.1304880110

EconomicAnalysisofMethaneEmissionReductionOpportunitiesintheU.S.OnshoreOilandNaturalGas

Industries

ApproachandMethodology

ICFInternational 32 March2014

3.2. Developmentofthe2011EmissionsBaseline

Thedevelopmentofthe2011BaselinetakesasitsstartingpointtheU.S.EPAsInventoryofU.S.

GreenhouseGasEmissionsandSinks:19902011publishedin2013withdatafor2011

10

,specifically

theportiononmethanefromNaturalGasandPetroleumSystems.WhiletheEPAInventoryisthemost

comprehensivesourceforthistypeofinformation,itisdesignedtobeaplanningandreportingtool

ratherthanthebasisforthistypeofgranularanalysis.ThereforeICFdevelopedanew2011Baseline,

adaptingtheEPAstructuretotheneedsoftheanalysisandincorporatingmorerecentinformation.This

wasnotacompleteupdateoftheinventory,whichwasbeyondthescopeofthisproject,butanupdate

ofanysectionsforwhichneworbetterdatacouldbereadilyidentified.TheEPAInventory

11

estimates

436billioncubicfeet(Bcf)or8.4millionmetrictonnesofmethaneemissionsforthepetroleumand

naturalgassectorsincludingoffshoreproductionin2011.Thepetroleumandnaturalgassectorsare

thenfurtherdividedintothevarioussegmentsforthenaturalgassector(GasProduction,Gatheringand

Boosting,GasProcessing,GasTransmission,GasStorage,LNGImport/Export,andDistribution)andthe

petroleumsector(OilProduction,Transportation,andRefining).

TheEPAInventorybreaksoutmethaneemissionsforapproximately200sources,andcalculates

uncontrolledemissionsusingactivityfactors(e.g.,equipmentcounts)multipliedbyemissionfactors

(averageemissionsfromeachsource)toestimatethetotalemissions.Thetotaluncontrolledemissions

arereducedbyemissionreductionsreportedprimarilyfromtheEPAsvoluntaryNaturalGasSTAR

Program,plusadditionalreductionsfromothersources,suchasstateregulations.

Thedevelopmentofthe2011Baselinereliedonthe2011EPAInventoryanddatafromseveralpublically

availablereferences.ThemostcommonsourceofupdatedinformationwastheU.S.EPAsmandatory

GreenhouseGasReportingRule(GHGRP)subpartsC(combustionfromstationarysources)andW

(methaneemissionsfrompetroleumandnaturalgassystems).ICFalsousedinformationanddatafrom

theU.S.EnergyInformationAdministration(EIA),EPAs1996GRIstudyofmethaneemissions

12

,theEPA

ManualofEmissionFactorsAP42

13

,variousstateenergyandenvironmentaldepartments,andthe

EDF/UniversityofTexasmethanemeasurementstudy.Muchofthisinformationwasnotavailableatthe

timethatthe2011EPAinventorywasoriginallydeveloped.

Whilesomesourcecategoriesincreasedandsomedecreasedduetotheseadjustments,theoverall

effectwasanincreaseof2.4%inthenetestimatedmethaneemissionsfromtheoilandgassectorsto

10

U.S.EPA,InventoryofU.S.GreenhouseGasEmissionsAndSinks:19902011,

http://www.epa.gov/climatechange/ghgemissions/usinventoryreport.html

11

Whilethe2013editionoftheInventorywasthecurrentversionatthetimethestudywasinitiated,EPAhassincereleased

thedraftofthe2014edition.HoweverthisstudydoesnotaddressthatnewerversionoftheInventory.

12

http://epa.gov/gasstar/tools/related.htmlunderMethaneEmissionsfromtheNaturalGasIndustry

13

http://www.epa.gov/ttn/chief/ap42/index.html

EconomicAnalysisofMethaneEmissionReductionOpportunitiesintheU.S.OnshoreOilandNaturalGas

Industries

ApproachandMethodology

ICFInternational 33 March2014

446Bcf(8.6millionmetrictonnes)ofmethane.Theestimatedemissionsfromthenaturalgassector

were2%(10Bcf)lowerwhiletheemissionsfromtheoilsectorincreasedby26%(20Bcf)comparedto

theEPAinventory.Table31summarizestheemissionsinthe2011Baselinecomparedtothe2011EPA

Inventory.

ThechangesbyindustrysegmentareshowninTable31.

Table31Summaryof2011MethaneEmissionsBaseline

Segment

2011EPAInventory ICF2011Baseline

Change(%)

(Million

tonnesCH

4

)

(BcfCH

4

)

(Million

tonnesCH

4

)

(BcfCH

4

)

NaturalGas

GasProduction 2.2 113 2.0 103 9%

GatheringandBoosting 0.5 24 0.8 43 80%

GasProcessing 0.9 48 0.8 44 9%

GasTransmission 1.7 87 1.4 75 14%

GasStorage 0.3 17 0.3 15 11%

LNG 0.1 5 0.1 6 22%

GasDistribution 1.3 69 1.3 69 0%

Petroleum

OilProduction 1.4 72 1.8 92 27%

OilTransportation < 0.1 < 1 < 0.1 <1 1%

OilRefining < 0.1 1 < 0.1 1 0%

TotalNetGasEmissions 7.0 362 6.8 353 2%

TotalNetOilEmissions 1.4 73 1.8 93 26%

TotalEmissions 8.4 436 8.6 446 2.4%

ThelargestchangetothestructureoftheNaturalGassegmentinthe2011Baselinewasbreakingout

theGatheringandBoostingsegment.ThisisthesegmentbetweenonshoreProductionandeitherGas

ProcessingorGasTransmission.ThissegmentisincludedintheonshoreProductionsegmentoftheEPA

EconomicAnalysisofMethaneEmissionReductionOpportunitiesintheU.S.OnshoreOilandNaturalGas

Industries

ApproachandMethodology

ICFInternational 34 March2014

Inventorybasedonthe1996GRImeasurementstudyratherthanbeingfullybrokenoutasaseparate

segment.Inthisstudy,somesourcesweremovedfromProductiontotheGatheringandBoosting

segmentinordertoallowthemtobeanalyzedseparatelyforthissegment,andnewemissions

estimates,forsomesourcesunderrepresentedinthe2011EPAinventory,wereadded.Themajor

sourceadditionswerenewestimatesofcompressorandpneumaticdeviceemissions.Inaddition,

emissionsfromcondensatetanksweremovedfromtheProductionsegmenttotheGatheringand

Boostingsegment.

TheoverallnetchangetotheNaturalGassegmentoftheU.S.Inventoryisadecreaseof2%compared

totheEPAInventoryvalue.Thisistheneteffectofincreasedestimatesforwellheadfugitivesand

GatheringandBoosting(forcompressorsandpneumaticdevices)anddecreasesintheestimatesfor

wellcompletionandworkoveremissions(basedondataandfactorsfromSubpartW)andcompressor

exhaustemissions.ThesechangesarediscussedinAppendixB.

ThenetchangetothePetroleumsegmentofthe2011Baselineis26%higherthantheEPAInventory

value.Thebiggestcategoriescontributingtothisincreaseweretheinclusionofstrandedgasventing

fromoilwellsandupdatedestimatesofassociatedgasflaringestimates.Allofthesechangesare

discussedinmoredetailinAppendixB.

3.3. Projectionto2018

The2018forecastofnaturalgasandpetroleumsystemsmethaneemissionsstartswiththe2011

BaselinedescribedinSection3.2.Oneprimarydriverfortheprojectingthe2011emissionsto2018was

theU.S.EIAsAnnualEnergyOutlook2013and2014EarlyRelease.ICFalsoreliedupona2011studyfor

theINGAAFoundation

14

thatforecastrequirementsforselectedinfrastructureandequipmentforthe

naturalgasandpetroleumindustry.Inaddition,expectedemissionreductionsasaresultofNSPS

SubpartOOOOwereincorporatedintotheforecast.WithouttheNSPS,emissionsgrowfrom446Bcfin

2011to491Bcfin2018.WiththeNSPSadjustments,totalemissionsareprojectedtogrowby4.5%to

466Bcfthrough2018.Almostallofthisgrowthisfromtheoilsectorwhereasthenetemissionsforthe

gassectorarealmostunchanged(Figure31).Growthfromnewsourcesinthegassectorisoffsetby

NSPSreductions,andreductionsfromexistingsourcessuchascontinuingreplacementofcastiron

mainsandturnoverofhighemittingpneumaticdevices.Despitetheoverallgrowth,nearly90%ofthe

emissionsin2018comefromexistingsources(sourcesinplaceasof2011)asshowninFigure32.

14

NorthAmericanMidstreamInfrastructureThrough2035ASecureEnergyFuture,PreparedfortheINGAAFoundation,ICF

International,2011.

EconomicAnalysisofMethaneEmissionReductionOpportunitiesintheU.S.OnshoreOilandNaturalGas

Industries

ApproachandMethodology

ICFInternational 35 March2014

Figure31EmissionProjectionto2018(IncludingOffshore)

Figure32DistributionofEmissionsin2018

EconomicAnalysisofMethaneEmissionReductionOpportunitiesintheU.S.OnshoreOilandNaturalGas

Industries

ApproachandMethodology

ICFInternational 36 March2014

Theprojectionalsodisaggregatedthenationallevelemissionsestimateofthe2011inventorytoregions

usedbytheEIAtoreportoilandgasdata(Figure33).Thedetailsoftheanalysisarediscussedin

AppendixC.

Figure33EIAOilandGasRegions

3.4. IdentificationofTargetedEmissionSources

Table32summarizesthelargestemittingsourcecategoriesintheprojected2018emissionsfortheoil

andgassectorsbymajorsourcecategory.Duetothelackofspecificdataontheemissionsourcesfor

offshoreoilandgasproduction,thestudyfocusedononshoreproductionandoffshoreemissionsare

excludedfromthislist.Thetop22sourcecategoriesaccountfor80%ofthetotal2018onshoremethane

emissionsof404Bcfandtheremaining100+categoriesaccountfor1%orlessofthetotalemissions

each.Althoughthesesourcecategorieswerenotincludedinthisanalysisduetotheirsmallsize,there

aredemonstratedmethanereductiontechnologiesthatcanprovidecosteffectivereductionsformany

ofthem.

Figure34showsthedistributionofsourcesgraphically.Fugitiveemissionsarethelargestemission

sourcecategoryoverall.Ventedemissionsfrompneumaticcontrollersandpumpsarealsosignificantas

isventedassociatedgasfromoilwellcompletionsandproduction.Ventingfromwetsealcentrifugal

compressorsisalsoalargesource.

EconomicAnalysisofMethaneEmissionReductionOpportunitiesintheU.S.OnshoreOilandNaturalGas

Industries

ApproachandMethodology

ICFInternational 37 March2014

Table32HighestEmittingOnshoreMethaneSourceCategoriesin2018

Source

2018

Emissions

(Bcf)

Percentof

Total

Cumulative

Bcf

Cumulative

%

ReciprocatingCompressorFugitives 53.8 13% 53.8 13%

HighBleedPneumaticDevices 28.7 7% 82.5 20%

LDCMetersandRegulators 28.7 7% 111.2 28%

CentrifugalCompressors(wetseals) 24.0 6% 135.3 33%

GasEngineExhaust 22.2 5% 157.5 39%

WellFugitives 20.8 5% 178.3 44%

ReciprocatingCompressorRodPacking 17.6 4% 195.9 48%

LiquidsUnloadingWellsw/PlungerLifts 13.2 3% 209.1 52%

IntermittentBleedPneumaticDevices 13.0 3% 222.1 55%

KimrayPumps 11.5 3% 233.6 58%

OilTanks 11.5 3% 245.1 61%

Flares 9.0 2% 254.1 63%

StrandedGasVentingfromOilWells 8.4 2% 262.5 65%

IntermittentBleedPneumaticDevicesDumpValves 7.7 2% 270.2 67%

OilWellCompletionswithFracturing 6.9 2% 277.1 69%

PipelineLeaks(All) 6.7 2% 283.8 70%

PipelineVenting(Transmission) 6.6 2% 290.4 72%

CentrifugalCompressors(dryseals) 6.4 2% 296.8 73%

MainsPlastic 6.3 2% 303.2 75%

MainsCastIron 6.3 2% 309.4 77%

TransmissionStationVenting 6.2 2% 315.7 78%

ChemicalInjectionPumps 5.9 1% 321.6 80%

Residential 5.6 1% 327.2 81%

GatheringandBoostingStations 5.6 1% 332.8 82%

EconomicAnalysisofMethaneEmissionReductionOpportunitiesintheU.S.OnshoreOilandNaturalGasIndustries

ApproachandMethodology

ICFInternational 38 March2014

Figure342018ProjectedOnshoreEmissions

EconomicAnalysisofMethaneEmissionReductionOpportunitiesintheU.S.OnshoreOilandNaturalGas

Industries

ApproachandMethodology

ICFInternational 39 March2014

3.5. SelectedMitigationTechnologies

Thefollowingsectionsdescribethemitigationmeasuresincludedinthisanalysistoaddressthehigh

emittingsourcecategories.Someofthemostsignificantmeasuresarediscussedingreaterdetailin

AppendixD.Muchofthecostandperformancedataforthetechnologiesisbasedoninformationfrom

theEPANaturalGasSTARprogram

15

buthasbeenupdatedandaugmentedwithinformationprovided

byindustryandequipmentvendorsourcesconsultedduringthisstudy.Thediscussionisorganized

accordingtotheemissionsourceandmitigationoption.

Thisanalysisattemptstodefinereasonableestimatesofaveragecostandperformancebasedonthe

availabledata.Thecostsandperformanceofanactualindividualprojectmaynotbedirectly

comparabletotheaveragesemployedinthisanalysisbecauseimplementationcostsandtechnology

effectivenessarehighlysitespecific.Costsforspecificactualfacilitiescouldbehigherorlowerthanthe

averagesusedinthisanalysis.

FugitiveEmissionsFugitiveemissionsaretheunplannedlossofmethanefrompipes,valves,flanges,

andothertypesofequipment.Fugitiveemissionsfromreciprocatingcompressors,compressorstations

(transmission,storage,andgathering),wells,andLDCmeteringandregulatorequipmentarethelargest

combinedemissioncategory,accountingforover120Bcf,or30%ofthehighlightedsources.

LeakDetectionandRepair(LDAR)isthegenerictermfortheprocessoflocatingandrepairingthese

fugitiveleaks.Thereareavarietyoftechniquesandtypesofequipmentthatcanbeusedtolocateand

quantifythesefugitiveemissions.ExtensiveworkhasbeendonebyEPAandotherstodocumentand

describethesetechniques,bothintheGasSTARreferencematerialsandinseveralregulatoryanalyses.

Thepotentialsizeandnatureofthesefugitiveemissionscanvarywidelybyindustrysegmentandeven

bysite.LDARprogramshavebeenanalyzedforseveralrecentregulatoryinitiatives,includingforthe

EPAsNSPSSubpartOOOO

16

andthecurrentproposedrevisionstotheColoradoAirQualityControl

CommissionRegulationNumber7(5CCR10019)

17

.ThisstudyusedboththeColoradoregulatory

analysisandtheEPATechnicalSupportDocument(TSD)

18

forNSPSSubpartOOOOasthebasisforcost

andreductioneffectivenesscalculations.

15

http://www.epa.gov/gasstar/

16

http://www.epa.gov/airquality/oilandgas/

17

http://www.colorado.gov/cs/Satellite/CDPHEAQCC/CBON/1251647985820

18

U.S.EPA,OilandNaturalGasSector:StandardsofPerformanceforCrudeOilandNaturalGasProduction,Transmission,and

Distribution.BackgroundSupplementalTechnicalSupportDocumentfortheFinalNewSourcePerformanceStandards.

http://www.epa.gov/airquality/oilandgas/pdfs/20120418tsd.pdf

EconomicAnalysisofMethaneEmissionReductionOpportunitiesintheU.S.OnshoreOilandNaturalGas

Industries

ApproachandMethodology

ICFInternational 310 March2014

Thekeyfactorsintheanalysisarehowmuchtimeittakesaninspectortosurveyeachfacility,howmany

inspectionsarerequiredeachyear,howmuchreductioncanbeachieved,andhowmuchtimeis

requiredforrepairs.ResearchcitedbybothColoradoandEPAindicatesthatmorefrequentinspections

resultingreaterreductions,summarizedasapproximately:

Annualinspection=40%reduction

Quarterlyinspection=60%reduction

Monthlyinspection=80%reduction

ICFadaptedtheColoradoanalysis,whichcalculatesthecapitalandlaborcosttofieldafulltime

inspector,includingallowancesfortravelandrecordkeeping(Table33).ICFaddedadditionaltimefor

training.Thecapitalcostincludesaninfraredcamera(whichisusedtolocatefugitiveemissions)atruck

andthecostofarecordkeepingsystem.Thecombinedhourlycostwasthebasisforthecost

estimates.

Table33LDARHourlyCostCalculation

Labor CapitalandInitialCosts

InspectionStaff $75,000 InfraredCamera $122,200

Supervision(@20%) $15,000 PhotoIonizationDector $5,000

Overhead(@10%) $7,500 Truck $22,000

Travel(@15%) $11,250 Recordkeepingsystem $14,500

Recordkeeping(@10%) $7,500 Total $163,700

Reporting(@10%) $7,500

Fringe(@30%) $22,500 TrainingHours 80

SubtotalCosts $146,250 TrainingDollars $6,223

Hours/yr 1880 AmortizedCapital +Training $44,825

HourlyLaborRate $77.79 AnnualLabor $146,250

AnnualTotal Cost $191,075

TotalCostasHourlyRate $101.64

Manyanalyseshaveusedfacilitycomponentcountsandhistoricaldataonthetimerequiredtoinspect

eachcomponenttoestimatefacilitysurveytimes.However,theuseoftheinfraredcameratechnology

EconomicAnalysisofMethaneEmissionReductionOpportunitiesintheU.S.OnshoreOilandNaturalGas

Industries

ApproachandMethodology

ICFInternational 311 March2014

allowsmuchshortersurveytimes

19

andtheEPAandColoradotimeestimateshavebeencriticizedastoo

long.Theestimatesherearebasedonexperiencewiththeinfraredcameraandareshorterthanthe

ColoradoandEPAestimatesthatbasedoncomponentcounts.

ICFthenadoptedthebaselineemissionvaluesforwells,gatheringandtransmissionstations,and

processingstationsfromtheEPAanalysis.EPAincludesthreewellpadsizeswithdifferentbaseline

emissions.TheEPAanalysisdidnotprovideestimatesofthedistributionofthethreesizesforexisting

facilitiessothemiddleestimatewasusedforthisanalysis.Usingthesmallerandlargerwellpad

emissionestimateswouldresultinhigherandloweremissionreductioncostsrespectively.

ForLDCs,theanalysisonlyincludeslargemeterandregulatorfacilities.Smallerfacilitieshadamuch

highercostduetothesmallbaselineemissions.TheLDCcostingwasdoneusingthesameoperatorand

capitalcostsasfortheupstreamandmidstreamfacilities.ThebaselineemissionfactorsforLDCswere

adaptedfromanEPAGasSTARdocument

20

whichfoundthatonaveragetwo100Mcf/yearleakswere

foundat50%ofthefacilitiesandtheleakswerereducedby50%throughtheprogram.

Table34summarizestheassumptionsfortheoverallLDARcalculation.Thisanalysisassumesquarterly

emissionsurveysforallfacilities.Thereductionisassumedtobe60%,whichisconsistentwithdata

presentedintheNSPSTSDandColoradoanalysis.Inadditiontothesurveys,theestimateincludesone

initialvisittoeachsitetoinventorytheequipment(equivalenthourstotwoinspectionvisitsforeach

sitewithcostaveragedoverfiveyears)andadditionalvisitsforrepairs.Gasprocessingplantsare

alreadysubjecttosomeLDARrequirementsforconventionalpollutants,whichresultincobenefit

methanereductions.Themiscellaneousfugitiveemissionsforgasprocessingwerebelowthesize

thresholdforthisanalysisbutthecostsdevelopedhereforgasprocessingareappliedtocompressorsin

thatsegment.

Somerepairscanbemadeatthetimeofthesurvey,suchastighteningvalvepackingorflangesbut

otherswillrequireadditionalrepairtime.Thisanalysisassumesrepairtimeequivalenttothreesurvey

visitsforeachfacilityforrepairseachyear.Thecapitalcostoflargerrepairsisnotincludedonthe

assumptionthattheserepairswouldneedtobemadeanywayandtheLDARprogramissimplyalerting

theoperatortotheneed.ThetimeforrepairsisconsistentwiththelowendoftheColoradoanalysis

thatwasderivedbasedoncomponentcountsandleakrates.Thislowerrepairestimatetakesinto

accountthat:

Theseareaveragevaluesacrossfacilitiesnoteveryfacilitywillrequirerepairs.

19

Robinson,D,et.al.,RefineryEvaluationofOpticalImagingtoLocateFugitiveEmissions.JournaloftheAir&Waste

ManagementAssociation.Volume57June2007.

20

EPAGasSTARDirectedInspectionandMaintenanceatGateStationsandSurfaceFacilities.

http://epa.gov/gasstar/documents/ll_dimgatestat.pdf

EconomicAnalysisofMethaneEmissionReductionOpportunitiesintheU.S.OnshoreOilandNaturalGas

Industries

ApproachandMethodology

ICFInternational 312 March2014

Theseareaveragevaluesovertimenoteveryfacilitywillneedrepairseveryyearwhilebeing

monitoredonacontinuingbasis.

Someorallofcostofmajorrepairsisassumedtobepartofregularfacilitymaintenance.

Table34CostCalculationQuarterlyLDAR

WellPads Gathering Processing Transmission LDC

MethaneMcf/yr 440 1,676 2,448 4,671 150

%Reduction 60% 60% 60% 60% 60%

ReductionMcf 264 1,006 1,469 2,803 90

HourseachInspection 2.7 8 8 8 2

Frequency(peryear) 4 4 4 4 4

AnnualInspectionCost $1,084 $3,252 $3,252 $3,252

$813

InitialSetUp $108 $325 $325 $325

$81

RepairLaborCost $813 $2,439 $2,439 $2,439

$407

TotalCost/yr $2,006 $6,017 $6,017 $6,017

$1301

RecoveredGasValue* $1,340 $5,105 $7,455 $12,416

$399

NetCost $666 $912 $1,438 $6,399

$902

CostofReduction($/Mcfmethanereduced)

WithoutGasCredit $7.60 $5.98 $4.10 $2.15 $14.45

WithGasCredit $2.52 $0.91 $0.98 $2.28 $10.03

*Gasat$4/Mcf

Thevalueofreducedgaslossesiscreditedtotheprogramfortheupstreamsegments.Thesefinal

reductioncostvalueswereusedfortheanalysis.

ReciprocatingCompressorRodPackingReciprocatingcompressorsareusedinmostsegmentsofthe

naturalgasandoilindustry,thoughmuchlesscommonlyinlocalgasdistributionthaninother

segments.Rodpackingsystemsareusedtomaintainasealaroundthepistonrod,minimizingthe

leakageofhighpressuregasfromthecompressorcylinder,whilestillallowingtherodtomovefreely

(Figure35).However,somegasstillescapesthroughtherodpacking,andthisvolumeincreasesasthe

packingwearsoutovertime,potentiallytomanytimestheinitialleakrate.Thereisnostandard

optimumintervaltoreplacetherodpacking,buttheNSPSSubpartOOOOrequiresrodpackinginnew

EconomicAnalysisofMethaneEmissionReductionOpportunitiesintheU.S.OnshoreOilandNaturalGas

Industries

ApproachandMethodology

ICFInternational 313 March2014

reciprocatingcompressorsintheproductionandprocessingsectorstobereplacedevery26,000hours

ofoperation(approximatelyeverythreeyears).

Figure35ReciprocatingCompressorRodPacking

Industryreportsthattherodpackingforcompressorsatgasprocessingplantsandsometransmission

stationsisroutinelyreplacedatleastthatfrequentlyaspartofroutinemaintenance.However,itis

believedthatrodpackingintheproductionandgatheringandboostingsectorsisreplacedless

frequently.Thisisdue,inpart,toseveralfactors,includingtheremotelocationofthesecompressors,

thelackofabackupcompressorforuseduringcompressordowntime,andbecausemanyofthe

compressorsinthesesectorsareleasedratherthanowned.Thisanalysisassumesarequirementto

replacerodpackingforallreciprocatingcompressorsevery26,000hoursofoperation.

GasSTARdata

21

indicatethatrings(thecompressorpacking)costbetween$300and$600percylinder

and$1,000to$2,500percompressortoinstall.Industrysourcesforthisstudyputthecostat$5,000per

cylinder,whichwasadoptedforthisanalysis.TheTechnicalSupportDocument(TSD)forNSPSSubpart

OOOOprovidesadetailedanalysisofrodpackingreplacement.Theemissionsfromnewrodpackingare

estimatedintheTSDat11.5standardcubicfeetperhour(scfh).Baselineemissionsforrodpackingare

estimatedatapproximately57scfh,howevertheageofthepackingatthattimeisnotstated.Thereis

littledataontheemissionsfromrodpackingovertimebutreductionsforthismitigationoptioncome

fromreplacingtherodpackingatashorterintervalthancurrentlybeingpracticedatgivenfacility.

21

ReducingMethaneEmissionsFromCompressorRodPackingSystems

http://www.epa.gov/gasstar/documents/ll_rodpack.pdf

EconomicAnalysisofMethaneEmissionReductionOpportunitiesintheU.S.OnshoreOilandNaturalGas

Industries

ApproachandMethodology

ICFInternational 314 March2014

Forthisanalysisitwasassumedthatthefacilitycurrentlyreplacestherodpackingeveryfiveyearsand

thattheintervalisreducedtothreeyears(26,000hours).Itwasassumedthatthenewrodpacking

emits11.5scfhandtheemissionsincreaselinearlyto57scfhafterthreeyearsandincreaselinearly

thereafter.Comparingtheemissionsunderthisscenariofor15years,thethreeyearreplacement

schedulewouldemit35%lessthanthefiveyearreplacementschedule.Inaddition,thecostofrod

packingreplacementwouldbe66%greaterforthethreeyearreplacementschedulethanthefiveyear

schedule.Asnotedabove,itwasassumedthatrodpackingisalreadychangedonthisscheduleinmany

processingplantsandsometransmissionstations,sotheapplicabilitywasreducedto25%for

processingand70%fortransmission,storageandLNG.TheassumptionsaresummarizedinTable35.

Table35AssumptionsforRodPackingReplacement

CentrifugalCompressors(wetseals)Thesealsinacentrifugalcompressorperformasimilarfunction

totherodpackinginareciprocatingcompressorallowingtherotatingshafttomovefreelywithout

allowingexcessivehighpressuregastoescape(Figure36).Centrifugalcompressorswithwetsealsuse

circulatingoilasasealagainsttheescapeofhighpressuregas,andtheoilentrainssomeofthegasasit

circulatesthroughthecompressorseal.Thisgasmustbeseparatedfromtheoiltomaintainproper

operation(calleddegassingthesealoil),andthegasremovedfromthesealoilistypicallyventedto

theatmosphere.

22

Theseemissionscantotal30,000Mcf/yearormore.Whilewetsealscanbereplaced

bydrysealsthatdonotuseoilanddonotventsignificantamountsofgas,thisisanextremelyexpensive

process.Alowercostoptionistocaptureandusetheentrainedsealoilgasratherthanventingit.This

technologycurrentlyexistsatseveralcompressorstationsthathadsuchsystemsinstalledasoriginal

equipment,butithasnotbeenappliedcommerciallyasaretrofit.However,theequipmentneededfora

retrofitiscommerciallyavailable.Themeasuremodeledhereistoapplythistechnologyasaretrofit.

Thisisdescribedasoneofthecasestudiesinsection5.1wherethecapitalcostisestimatedat$33,700

fora99%reduction.Becausethistechnologyhasnotbeencommerciallydemonstratedasaretrofit,the

analysisassumedaconservativecostof$50,000and95%reduction,yieldingacosteffectivenessof

$4.87/Mcfwithcreditforrecoveredgasor$0.21/Mcfwithoutrecovery.Althoughthegascanbere

captured,itmaybedifficulttouseitproductively,asthisdependsonboththepressureofthecaptured

22

ReplacingWetSealswithDrySealsinCentrifugalCompressorshttp://www.epa.gov/gasstar/documents/ll_wetseals.pdf

CapitalCost

per

Compressor

Percent

Reduction

Mcf

Reduced/year

Lifetime

(years)

Costw/oGas

Credit

$6,000 35% 350 3 $6.89/Mcf

EconomicAnalysisofMethaneEmissionReductionOpportunitiesintheU.S.OnshoreOilandNaturalGas

Industries

ApproachandMethodology

ICFInternational 315 March2014

gasandwhetheraneedforthegasexists.Theapplicabilityisthereforediscountedby10%to25%

dependingontheindustrysegment.

Figure36WetSealCompressorSchematic

PneumaticDevicesPneumaticdevicesusethepressureofthenaturalgasstreamtooperatevarious

controlfunctions,suchasadjustingvalvestomaintainproperpressure,actuatingliquidleveland

temperaturecontrollers,etc.Somedevicesrequireacontinuoussmalldischargeofgasaspartofthe

controllerfunction.Thesetypesofdevicesaredesignatedaseitherlowbleeddevices(emitting<6

scf/hr)orhighbleeddevices(emitting6scf/hr,buttypicallymuchmoreoftenmorethan30scf/hr).

Inadditiontothesetwocategories,thereareintermittentbleeddevicesthataredesignedtodischarge

gasonlywhentheyareactuating.Thesetypesofpneumaticdevicescanhaveemissionsanywhere

betweenhighandlowbleedcontrollers.Onecommondeviceisanintermittentlevelcontroldevice

(dumpvalve)thatemitsgasonlywhenactuatedandtypicallyhasemissionssimilartolowbleed

controllers.

TheEPAGHGReportingProgramSubpartWprovidesinformationonpneumaticcontrollersthatcanbe

usedtoestimatethedistributionofthesedevicesineachsegment.ThisanalysisisdiscussedinAppendix

Band,forexample,yieldsadistributionof10%highbleed,50%intermittentbleed,and40%lowbleed

devicesfortheProductionsegment.Furtheranalysiswasperformedtoestimatethedistributionof

higheremittingintermittentdevicesvsloweremittingdumpvalves,alsodiscussedinAppendixB.For

theProductionsegment,itwasestimatedthat75%oftheintermittentbleeddevicesareloweremitting

dumpvalves.

Thetwomitigationoptionsconsideredinthestudyare:

Replacehighbleedcontrollerswithlowbleedcontrollers.

EconomicAnalysisofMethaneEmissionReductionOpportunitiesintheU.S.OnshoreOilandNaturalGas

Industries

ApproachandMethodology

ICFInternational 316 March2014

Replacehighemittingintermittentcontrollers(notdumpvalves)withlowbleedcontrollers.

Somecomponentsrequirehighbleedcontrollersforoperationalreasons,primarilyforfastactingvalves

associatedwithcompressors,sothemeasurewasappliedtoonly60%oftheinventoryofhighbleed

controllersintransmission,storage,andLNG,80%inprocessingand90%ofthehighbleedcontrollersin

othersegments.AlthoughtherearelowercostestimatesfromGasSTARandvendors,thismeasure

assumedacostof$3,000perreplacementbasedonindustrycomments.Bothoptionsyieldagreater

than90%reduction.Thisyieldsareductioncostof$3.08/Mcfofmethaneforreplacementofhighbleed

pneumaticsand$0.58/Mcfofmethaneforreplacementofintermittentbleedpneumatics,includinga

creditforrecoveredgas,whereapplicable.

ChemicalInjectionPumpsThesearesmallpumpsusedtoinjectvariouschemicals,mostcommonly

methanol,intogaswellstopreventwellfreezeupduringcoldweather.Theyaretypicallydrivenbygas

pressureandventgaswhentheyoperate.Thesuggestedmitigationmeasureistoreplacethegasdriven

pumpswithelectricpumpsdrivenbysolarenergy.(Wellpadsandmanygathering/boostingstations

typicallydonothaveelectricity.)ThistechnologyhasbeendemonstratedbyGasSTARPartnersand

industryrespondentsindicatedthatitisgainingbroaderacceptance.Replacementresultsinelimination

ofthemethaneemissions,andthegasdrivenpumpcouldbeleftinplaceasabackup.Thecostofthe

measurewasestimatedat$5,000perpump,yieldinganannualreductionof180Mcf/yearandacost

effectivenessof$0.22/Mcfofmethanereducedwiththerecoveredgascredit.Localconditionsor

operationalconsiderationsmaylimittheapplicabilitysothemeasureisappliedto80%oftheinventory.

OilandCondensateTankswithoutControlDevicesCrudeoilandliquidcondensateproductionat

wellsandgatheringfacilitiesisstoredinfixedrooffieldtanksanddissolvedgasintheliquidsisreleased

andcollectsinthetankspaceabovetheliquid.Ultimately,thisgasisoftenventedtotheatmosphere.

Vaporrecoveryunits(VRUs)collectandcompressthisgas,whichcanthenberedirectedtoasalesline,

usedonsiteforfuel,orflared.BasedonGasSTARandindustrydata,thecapitalcostofthismeasureis

assumedtobe$100,000withanoperatingcost(electricity)of$7,500peryearandareductionof13,410

Mcfperyear.Thisyieldsareductioncostof$0.51/Mcfifthegasisrecoveredforsaleor$4.57/Mcfifit

isflared.SomefacilitiesalreadyhaveVRUsandtheymaynotbeeffectivewheretheliquidvolumeis

smallorthemethanecontentislow.AlsoVRUsrequireelectricity,whichisnotavailableatallsites.For

thesereasons,themeasureisappliedto50%oftheremainingoiland25%oftheremainingcondensate

tankemissioninventory.

KimrayPumpsKimraypumpsaregaspoweredpumpsusedtocirculateglycolingasdehydrators.They

arelargerthanthechemicalinjectionpumpsandventlargeramountsofgas.Inthefacilitiesthathave

electricity,thesecouldbereplacedbyelectricmotordrivenpumps.Thereplacementcostisestimated

at$10,000perpumpbasedonvendorandGasSTARdata.Unlikethesolarpumps,thesepumpswill

requiregridelectricity,estimatedtocost$2,000peryear.Basedona5,000Mcfemissionreduction,the

costeffectivenessis$4.17/Mcfofmethanewithcreditforgasrecoveredanditisappliedto50%ofthe

inventory.

EconomicAnalysisofMethaneEmissionReductionOpportunitiesintheU.S.OnshoreOilandNaturalGas

Industries

ApproachandMethodology

ICFInternational 317 March2014

LiquidsUnloadingLiquidsunloadingistheprocessofremovingliquidsfromthebottomofgaswells

whentheaccumulationisimpedingthegasproduction.Theliquidsmustberemovedinordertoallow

effectiveproductionfromthewell.Historicallythishasbeenpracticedonolder,verticalwellswhose

pressurehasdeclined.

Whilethereareavarietyofmethodsofremovingthisliquid,onemethodisbyventingorblowingthe

welltotheatmosphere,usingthepressurizedgasinthereservoirtoliftandblowtheliquidsoutofthe

well.Thefrequencyanddurationofliquidsunloadingdependsonthewellandreservoirconditions,

however,ventingisnotaveryeffectivemethodofremovingtheliquids.Further,sincethewellisvented

totheatmosphere,itresultsinlargemethaneemissionsandlossesofgas.Therearemultiplemethods

ofremovingliquidswithoutventing,butinstandardpractice,theprimarygoalofliquidsunloadingisto

improvewellperformance,notreduceemissions.Thechoiceofmethodisnormallyafunctionofthe

costversusthevalueofimprovedwellperformance.Thistopicisfurtherdiscussedinsection5.4.

Figure37PlungerLiftSchematic

Plungerliftsaredevicesthatfitintothewellboreandusethe

gaspressuretobringliquidstothesurfacemoreefficiently

whilecontrollingandlimitingtheamountofventing(Figure

37).Ifthereissufficientreservoirpressure,thegascanbe

directedtothesaleslinewithnoventing.Ifthereisinsufficient

pressuretodirectthegastothesaleslineandthegasmustbe

vented,theemissionscanstillbereducedby90%comparedto

uncontrolledventing.Plungerliftsarearelativelylowcost

optionandcanbeimplementedinarelativelysimplemanual

controlmethodormorecomplexautomatedinstallations.That

said,thetechnologydoeshavelimitations.Thewellmusthave

sufficientpressuretooperatetheplungerandolderwellsmay

requirecleanoutsorworkoverstoallowtheplungerto

operate.Further,notallwelltypescanuseaplungerliftfor

liquidsremoval.

GasSTARestimatesforplungerliftinstallationrangefrom$2,500to$10,000

23

butindustrycommenters

onthisstudycitedcostsintherangeof$15,000andpointedoutthatwelltreatmentsandcleanouts

mayberequiredbeforeplungerliftscanbeinstalled.Thisanalysisassumesacostof$20,000,including

theallowancethatsomewellsmayneedcleanoutsorotherwork.GasSTARPartnersreportreductions

ofventingemissionsof90%forplungerliftsthatdonotgotothesalesline.Inaddition,theyreportthat

liquidsunloadingcanincreaseproductionbyanywherefrom3to300thousandcubicfeetperday

23

InstallingPlungerLiftSystemsInGasWellshttp://epa.gov/gasstar/documents/ll_plungerlift.pdf

EconomicAnalysisofMethaneEmissionReductionOpportunitiesintheU.S.OnshoreOilandNaturalGas

Industries

ApproachandMethodology

ICFInternational 318 March2014

(Mcf/day).Theincreasedproductivityofthewellistheprimarygoalofliquidsunloadingandthehigher

gasproductioncanpayforthecostofplungerliftsmanytimesover.However,thesubsequentincrease

inwellproductivityisdifficulttopredictandisnotincludedinthisanalysis.Withoutcreditforthe

productivityincrease,thecosteffectivenessbreakevenpointisatabout1,200Mcf/yearofventing,

estimatedhereasareductioncostof$0.05/Mcfreduced.

Ifthewelldoesnothavesufficientpressureorcannotsupportaplungerlift,thereareavarietyof

mechanicalpumpingtechnologiesthatcanbeemployedtoremoveliquids.However,thesearemuch

moreexpensiveandwhiletheymayhaveapositivepaybackforincreasingwellproduction,theymost

oftendonotpurelyforthemethaneemissionreduction.Moreover,themethanereductionvalueonly

appliesifthewellwouldotherwisebevented.Asthewellpressuredeclines,ventingbecomesa

diminishinglyeffectiveoption.Inaddition,itisnotclearhoweffectiveventingwillbeatremovingliquids

fromlonghorizontalwellsthatarenowbeingdrilled.Itmaybethatventingforliquidsremovalwill

continuetobeprimarilyfocusedonolder,verticalwells.

TheGHGReportingProgramSubpartWprovidesdataonwellsthatareventingforliquidsunloading

withandwithoutplungerlifts.Thedatafor2012showover53,000wellsventinganaverageof167Mcf

peryearwithoutplungerliftsandover74,000wellswithplungerliftsventinganaverageof277Mcfper

year.Wellsthatuseplungerliftsandsendthegastothesaleslinedonothaveanyventingemissions

anddonotreporttothispartofSubpartW.Whileitseemscounterintuitivethatwellswithplungerlifts

thatventwouldbeemittingmorethanthosewithoutplungerlifts,ICFinterpretsthisinformationto

indicatethatmostofthewellswiththelargestventingemissionshavealreadyinstalledplungerlifts

whilemostoftheremainingwellsareventinginfrequentlyorventingsmallvolumesthatdonotjustify

thecostofinstallingplungerlifts.Thatsaid,thereareasmallnumberofwellswithoutplungerliftsthat

reportlargerventingemissionsandaccountforadisproportionatefractionoftheventingemissionsfor

wellswithoutplungerlifts,approximately36%oftotalventingemissions.Installingplungerliftsonthese

wellscouldbecosteffectiveandcreatesignificantemissionreductions.Becauseplungerliftsarenot

applicabletoallwells,themeasurewasappliedto30%ofthisemissionsegmentfortheanalysis.

Asnotedabove,wellswithplungerliftsalsoreportsignificantemissionsfromventing.Operationofa

plungerliftiscomplexanditseffectivenessasanemissionreductiontechniquedependsonmany

factorstooperatetheplungerattheoptimumtimetomaximizeproductionandminimizeemissions.

Approachestoplungerliftoperationrangefromadhocmanualoperation,tofixedmechanicaltimers,to

programmablefuzzylogicautomatedcontrollers.Specificdataonthepotentialreductionsfrom

optimizedplungerliftoperationisnotavailablebutitisclearfromindustryexperiencethatan

integratedprogramoftraining,technology,andautomationcanimprovetheperformanceofplunger

liftsforbothproductivityandemissionreductions.Consequently,theremaybeanopportunityfor

significantemissionreductionthroughoptimizationofplungerlifts,whichisnotincludedhereand

wouldbeadditionaltothereductionestimatesthisanalysisprovidesforinstallationofnewplungerlifts.

EconomicAnalysisofMethaneEmissionReductionOpportunitiesintheU.S.OnshoreOilandNaturalGas

Industries

ApproachandMethodology

ICFInternational 319 March2014

StrandedGasVentingfromOilWellsandVentingofOilCompletionGasOilcontainssomeamountof

naturalgas,whichisseparatedatthewellhead.Wherethereisagassaleslineavailable,thegasissent

tosales.Whennonearbysaleslineexists,thegasiseitherventedorflared.Thiscanoccurduringthe

shortperiodafterthewelliscompletedoritcancontinuethroughoutthelifeofthewell,dependingon

theaccesstogatheringinfrastructure.WhileflaringcreatesCO

2

emissionsfromcombustionandsome

unburnedmethane,thetotalgreenhousegasemissionsaremuchlowerthanventingthemethane,with

itshigherglobalwarmingpotential.

Themeasuremodeledhereisflaringofthegasontheassumptionthatthegaswouldbesenttosalesif

theinfrastructurewereavailable.WhileGasSTARandvendorinformationciterelativelylowcostflares,

industrycitedmoreexpensiveflaringequipmentthatisbeingrequiredtomeetregulatory

requirements.ICFadoptedthishigherestimate,assumingacapitalcostof$50,000andafuelcostof

$6,000forignition.Theflareisassumedtobe98%effective.Thecosteffectivenessdependsonthe

amountofgasflared,whichislowerforcompletionemissionsthanflaringofassociatedgasona

continuousbasis.Thecosteffectivenessisestimatedat$1.86/Mcfofmethaneforcompletiongasand

$0.26/Mcfofmethaneforflaringofstrandedassociatedgas.

PipelineVenting(RoutineMaintenance/Upsets)Theseemissionsoccurwhencompaniestake

sectionsofpipelineoutofserviceformaintenanceandventthegasthatisinthepipeline.These

emissionscanbereducedforplannedshutdowns(notemergencyshutdowns)eitherbyusingthe

pipelinecompressorstopumpdownthegasintheaffectedsectionorbyusingleasedmobile

compressorunitswhenthepipelinecompressorsarenotappropriatelylocated.Theanalysisassumeda

combinationofbothmeasuresappliedto10milesectionsofpipeline,basedonaGasSTARanalysis

24

.

Usingthepipelinecompressorrequiresnocapitalcostbutonlythefuelcosttopumpdowntheline.The