Professional Documents

Culture Documents

Materials & Finishes

Uploaded by

ioanchiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Materials & Finishes

Uploaded by

ioanchiCopyright:

Available Formats

Mechanical Design Department Design Standards & Practices

Materials & Finishes

Materials & Finishes..........................................................................................................1 Material Selection.........................................................................................................2 Bosch Extrusion............................................................................................................3 Processing of Bosch Extrusion...................................................................................3 Carbide and custom punches.......................................................................................4 inishes...........................................................................................................................! Finishing and tank sizes .............................................................................................6 Electropolished Sur"aces..............................................................................................#

21546698 .doc !e" date #e$t 11% 2&&6

Mechanical Design Department Design Standards & Practices

Material Selection

1. 'se stock (ateria) sizes *hen e"er $ossi+)e to e)i(inate unnecessar, (achining -See $%3 &a' Materials & Stoc( asteners ) on the Mechanical *ebpage+. Purchasing !a* /ateria)s0 2. 1hen re2uiring too) stee)% 341 distorts *hen heat treating and thus $ro+)e(s *ith not enough (ateria) )eft for grinding% on), use 341 *hen ,ou need so(ething +etter than (i)d stee) +ut do not re2uire heat treating. ," heat treatment o" tool steel is necessar- than use .2. 5f in 2uestion consu)t ,our su$er"isor. 3. !adia) +earing shafting shou)d +e (ade fro( 6ho($son75na7Barden or #u$erior #hafting de$ending on the a$$)ication. 8ertain a$$)ications *i)) re2uire the use of #tress Proof #tee) or 31 -*i)) re2uire a )ot of *ork for finishing. 4. 1here"er $ossi+)e use 9)u(inu(% it *i)) sa"e ti(e and (one,. 96# uses it in se"era) for(s% 6&61466 9)u(inu(% 6&61466 9cracut 9)u(inu( -accurate), cut to *idth.% 8ast 9)u(inu( 6oo)ing P)ate -)ess susce$ti+)e to *ar$age% f)at and tight to)erance in thickness.% and 9)u(inu( ang)e. 1hen +ending a)u(inu( use 3&&34:14 not 6&61466. 9)) of the a+o"e (ateria)s ha"e uni2ue to)erances -see ;<a,o)d2 on :2(ain -=>. under re$orts ? shortcut to $urchasing ra* (ateria)s@.. 5. 6he hardness for too) stee)s *i)) +e )i(ited to three +asic grou$s do not s$ecif, an,thing outside these grou$s un)ess a+so)ute), necessar,A 1. !8 44446 2. !8 54456 3. !8 6&462 4'sed *hen $art shou)d +e tough +ut not necessari), hard. -i.e. shafts% $ins% etc.. 4Benera) $ur$ose *ear ite(s. -i.e. gi+s% s)ides% co"er $)ates% "4s)ides for he$co ro))ers% etc.. 4:ea", *ear surfaces. -i.e. cutters% $unches% for(ing too)s% etc..

6. 6he to)erances of (ateria) stock (ust +e considered in a)) too) designs. -see ;!e$orts on ne*Co+ :2fi)e -B>. under <a,o)d@ ? shortcut to $urchasing ra* (ateria)s@. . Be carefu) *ith ,our use of 8!#. 5t is "er, susce$ti+)e to *ar$age +ecause of itsD interna) stresses. 5t shou)d +e used *here (ini(a) (achining is +eing $erfor(ed. 8. 6he )ist of (ateria) t,$es 96# has standardized on is )i(ited to those )isted in the +a))ooning (acro. =i(it ,our use of (ateria)s to these un)ess other*ise s$ecified. 21546698 .doc !e" date #e$t 11% 2&&6 2

Mechanical Design Department Design Standards & Practices

9. :ot !o))ed #tee) *i)) +e ordered either +)anchard ground or sand +)asted. <o not order it in *ith a sca)e finish% as this *i)) (ake it "er, difficu)t to finish. 1&. 5f ,ou are hardening too) stee) it (ust +e di(ensioned in the detai) dra*ing such that there is grinding a))o*ance -ie. &.365 for 378 (ateria).

Bosch Extrusion

#tock at 96# #tandard> 3& E 3& B3#8: EE6!'#53F 45 E 45 B3#8: EE6!'#53F 45 E 9&-=. B3#8: EE6!'#53F 9& E 9& B3#8: EE6!'#53F 45x45 8)ean !oo(> 1F #5FB=E #=36 -45E45 B3#8: EE6. 2F #=36 3PP -45E45 B3#8: EE6. 2FG# #=36# 9<H -45E45 B3#8: EE6. 3F 6!54#=36 -45E45 B3#8: EE6.

Processing of Bosch Extrusion

Guarding (reference Guarding Guidelines) Stock extrusion single manufactured item, qty = 1 Non-stock extrusion Single purchased item; quantify how many 6m lengths required to completed guarding assem ly Non-guarding application Stock extrusion Non-stock extrusion indi!idual manufactured item purchase each piece including length to e cut " purchasing will ta ulate total amount of extrusion to purchase #$ of 6m lengths% create manufactured item for any piece requiring angular cut

Non-guarding extrusion part groupings can e de!eloped as a manufactured assem ly #which will put it in the &&&1-&''' num er range% if it is a S( assem ly file, or )ust simply as a manufactured part if it is drawn using the structural mem ers function in S(* +his will allow designers to create a detail drawing containing a ,-. to show in more detail exactly how the extrusion is to e assem led*

21546698 .doc !e" date #e$t 11% 2&&6

Mechanical Design Department Design Standards & Practices

Carbide and custom punches

1. 9)) car+ide co($onents *i)) +e done outside. 5n /E8: *hen creating the record $)ease $ut 8ar+ide under the (anufacturer and then for descri$tion ca))out $art na(e $er 96# <ra*ing. /nder material on the detail place material and purchase number0 example C2 1,2EM 34%%5. #$ecif, 82 un)ess ,ou need a s$ecific t,$e of car+ide. /anufacturer> Part I> <escri$tion> 8ar+ide EEEE4EEE4&&1 -!e" if needed. Fest $er 96# <ra*ing

2. 9)so $unches -nor(a)), 92 or /2. *i)) +e done outside. 5n /E8: *hen creating the record $)ease $ut 8usto( Punch under the (anufacturer. /nder material on the detail place material and purchase number0 example .2 1,2EM 34%%5. /anufacturer> Part I> <escri$tion> 8usto( Punch EEEE4EEE4&&1 -!e" if needed. 92 $er 96# <ra*ing

Material Compatibilities for Vapori ed !"drogen #eroxide

1. 8o($ati+i)it, is defined as the (ateria)s a+i)it, to undergo ex$osure to "a$orized h,drogen $eroxide *ith no significant changes in $h,sica)% or che(ica) $ro$erties -i.e no changes in strength% f)exi+i)it,% che(ica) co($osition% co)or etc... 8)ick on )ink to "ie* )ist of (ateria)s and their co($ati+i)ities. Gh$co($a.doc.

21546698 .doc !e" date #e$t 11% 2&&6

Mechanical Design Department Design Standards & Practices

$inishes

1. 9)) (ateria)s% if a$$)ica+)e% *i)) s$ecif, a finish. 6he finish is s$ecified during the +a))ooning $rocedure and is noted on the detai) dra*ing. 3$tions for the (ateria) finish is $ro"ided during the +a))ooning $rocedure. 2. 6he fo))o*ing chart s$ecifies the standard 96# finishes. 6he standard finishes are a)so detai)ed in the ;96# <esign #$ecification #u((ar,@. 6ote7 'hen speci"-ing paint0 al'a-s callout paint per .DSS. M.2E&,.8 6a+)e Base Buarding <ucting% E)ectrica) $ane) 9ir :eaders 1e)d(ents -a+o"e ta+)e. 9)u(inu( /i)d #tee) 6oo) #tee) 6a+)e 6o$% :!# ,6,S9 1pre"erred choice5 Paint4 <ark Bre, Paint4 =ight Bre, Paint4 =ight Bre, Paint4 =ight Bre, Paint4 F)at B)ack -8)ear 9nodize.% B)ack 9nodize% :ard 9nodize -B)ack 3xide.% :ard 8hro(e% E)ectro)ess Ficke) -:ard 8hro(e.% B)ack oxide% E)ectro)ess Ficke) Ficke) F)ash

3. 5n (ost cases the finish *i)) add to the (ateria) thickness. Jno* the finish and if necessar, consu)t so(eone on the effects of the finish. :ard chro(e> .&&&2 4.&&&5 inch 9nodize> .&&&2 4.&&&4 inch B)ack 3xide> .&&&1 4 .&&&2 inch Ficke) f)ash> .&&&5 4 .&&1& inch E)ectro)ess Ficke)> .&&&4 4 .&&&5 inch -$er 9#6/ B 33% 6,$e 4% #82% 8)ass 1. :ard 9nodize> .&&&5 4.&&&8 inch 4. 5n the design of gauges or setu$ too)s *here there is high to)erance $ieces finish the $ieces *ith B)ack 3xide. 5. 6he finishes s$ecified do not re2uire a $rocess s$ecification. 6he sho$ has detai)ed $rocedures for the finishing $rocesses. 6. 8ertain custo(ers *i)) re2uire their co)or finishes for $ainted co($onents. 6his *i)) +e detai)ed in the ;9<##@.

21546698 .doc !e" date #e$t 11% 2&&6

Mechanical Design Department Design Standards & Practices

. 8ertain a$$)ications re2uire case hardening rather that heat treat. 6hese are re2uired for ite(s that re2uire surface hardening% +ut (a, not *ar$ i.e. in)ines. Exa($)es of case hardening are> 9rcor4P: 4 si(i)ar to tenifer% +ut can go dee$er *ith the hardening -u$ to .&&2 dee$. 6enifer 7 6rinide4 -u$ to .&&&2 dee$. 6itaniu( Fitride -65F. 4 -u$ to .&&&2 dee$. 8. 1e)d(ent dra*ings need to indicate surfaces that are not to +e $ainted.

Finishing and tank sizes

Process 8)ear 9nodize B)ack 9nodize :ard 9nodize B)ack 3xide (Ampere Metal Finishing) (ATS Systems) :ard 8hro(e Ficke) F)ash E)ectro)ess Ficke) Metalon Technologies (steel) Metalon Technologies (aluminum) General Magnaplate (Industrial Processing) *or(ing .rea o" 2an( 1inches5 2& x 5& x 92 2& x 5& x 92 2& x 5& x 92 24 x 4& x 18& 23 x 23 x 24 48 x 48 x 12& 24 x 82 x 92 36 x 48 x 49 16 x 24 x 32 48 x 6& x 96 12 x 36 x 54 *eight &estrictions 1lbs5 2%&&& 2%&&& 2%&&& 2&&& 1%5&& 1%5&& 6%&&& 4%&&& 4&&

21546698 .doc !e" date #e$t 11% 2&&6

Mechanical Design Department Design Standards & Practices

Electropolished Surfaces

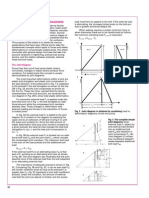

-5nsert fro( 9#6/4938&. E)ectro$o)ished surfaces are extre(e), s(ooth% (acrosco$ica)), f)at% (icrosco$ica)), feature)ess% and exhi+it high high )uster% ref)ecti"it, and +rightness. E)ectro$o)ishing su+stantia)), reduces the surface area a"ai)a+)e for conta(ination $ick4u$ and e)i(inates a)) (icro4cracks and interna) cre"ices. 8o($arison 6a+)e <ifferences Bet*een Po)ished and Buffed /i))ed Finishes% 9+rasi"e Brit Fu(+ers and #urface !oughness -Before and 9fter E)ectro$o)ishing. Before E)ectro$o)ishing #urface !oughness !a /icro(eter 3.56 (ax 1.14 (ax &.64 (ax &.2&4&.51 &.154&.38 &.1&4&.25 9fter E)ectro$o)ishing #urface !oughness !a /icro(eter /icroinches 1. 842.25 &.5 4&. 5 &.324&.4& &.1&4&.26 &.&84&.19 &.&54&.13 &49& 2343& 13416 441& 348 245

/i)) Fo. 3 4 8 8

Brit Fo. 6& 12& 18& 24& 32& 5&&

/icroinches 14& (ax 45 (ax 25 (ax 842& 6415 441&

KGa)ues are a$$roxi(ate. E)ectro$o)ishing genera)), reduces surface roughness readings of a non4E)ecro$o)ished surface +, 5& $ercent. #(oothness is not an inde$endent "aria+)e in surface definition. 5t is one factor of an i($ortant su+Cect that is referred to as ;surface (eta))urg,.@ #(oothness s$ecifications% +ased on gages% can +e achie"ed +, +oth E)ecto$o)ishing and +echanica) a+raci"e finishing techni2ues.

21546698 .doc !e" date #e$t 11% 2&&6

You might also like

- Design SummaryDocument20 pagesDesign SummaryAgus HermantoNo ratings yet

- Supply Chain StructureDocument11 pagesSupply Chain StructureMuhammad IqbalNo ratings yet

- Shipbuilding Technology 4th Semester SyllabusDocument30 pagesShipbuilding Technology 4th Semester SyllabusDiploma in Engineering Shipbuilding TechnologyNo ratings yet

- AutoCAD PROJECT REPORT Daksh Cad TechnologyDocument58 pagesAutoCAD PROJECT REPORT Daksh Cad TechnologyPawan Saini100% (1)

- CBC - Shielded Metal Arc Welding NC IIDocument87 pagesCBC - Shielded Metal Arc Welding NC IIEllen Susas86% (22)

- Tutorial OCDocument23 pagesTutorial OCPaul AndreiNo ratings yet

- P & ID Theory 7Document2 pagesP & ID Theory 7atifme022No ratings yet

- The Evaluation of Lean Manufacturing Implementation and Their ImpactDocument10 pagesThe Evaluation of Lean Manufacturing Implementation and Their ImpactmrtgrpcnNo ratings yet

- Small Project Part 4 Minimum RequirementsDocument43 pagesSmall Project Part 4 Minimum RequirementsPoppe MusaNo ratings yet

- Mono WorksDocument9 pagesMono WorksTarun ChopraNo ratings yet

- Checklist - SWM Jpif DBKLDocument4 pagesChecklist - SWM Jpif DBKLPhang S. SunNo ratings yet

- What Sorts of Jobs Does An Vlsi or Asic Engineer Do?Document10 pagesWhat Sorts of Jobs Does An Vlsi or Asic Engineer Do?Uday KumarNo ratings yet

- 3PS Gaw 017Document18 pages3PS Gaw 017ravi00098No ratings yet

- Rev08 - Ilp Hfc-227ea DiomDocument50 pagesRev08 - Ilp Hfc-227ea DiomSheri Wooten PhillipsNo ratings yet

- Demo Weld Cost Calc XLDocument10 pagesDemo Weld Cost Calc XLMarcelo Simão Do ValeNo ratings yet

- Senrigan-GP-45 Brushless Gimbal Instruction ManualDocument17 pagesSenrigan-GP-45 Brushless Gimbal Instruction ManualEduardo Lozano FloresNo ratings yet

- Ohaus Adventurer: Pro BalanceDocument6 pagesOhaus Adventurer: Pro BalanceSham SajaNo ratings yet

- Technical BidDocument50 pagesTechnical BidPerkresht PawarNo ratings yet

- 1202 Detail SheetsDocument61 pages1202 Detail SheetsUcok DedyNo ratings yet

- Guidelines For The Preparation of MDocument6 pagesGuidelines For The Preparation of MShobha KumarNo ratings yet

- HI-TECH Laser Cutting For Electric Motors Development: Aussafer DueDocument1 pageHI-TECH Laser Cutting For Electric Motors Development: Aussafer DueYusuf KarimNo ratings yet

- Lean Manufacturing QuizDocument6 pagesLean Manufacturing QuizsigmasundarNo ratings yet

- (Machine Shop, Lab 1) (Machine Shop, Lab 1)Document2 pages(Machine Shop, Lab 1) (Machine Shop, Lab 1)劉宗昇No ratings yet

- Project CompleteDocument14 pagesProject CompleteMia Ivančić100% (1)

- Energy Consumption Calculator Project ReportDocument70 pagesEnergy Consumption Calculator Project ReportMuhammad Bilal DhudiNo ratings yet

- CBC-RAC Servicing (Domestic) NC IIDocument99 pagesCBC-RAC Servicing (Domestic) NC IIBinalonan Pangasinan100% (2)

- PlanPipe - Basic Modul - User ManualDocument36 pagesPlanPipe - Basic Modul - User ManualSamirHasicNo ratings yet

- Defining Global Macros: by Joyjit Ghosh, IBM IndiaDocument34 pagesDefining Global Macros: by Joyjit Ghosh, IBM IndiasaaikumarNo ratings yet

- Design and Drafting Standards Manual - APS AESDocument64 pagesDesign and Drafting Standards Manual - APS AEShombre.muerto5959No ratings yet

- 46 017226r05Document36 pages46 017226r05Artie VázquezNo ratings yet

- SUB: Application For The Post of "Piping Design Engineer"Document4 pagesSUB: Application For The Post of "Piping Design Engineer"vermaakash22No ratings yet

- Tricking Out HF 9x20 LatheDocument48 pagesTricking Out HF 9x20 LatheCliff Miller100% (1)

- Handwheels: Product Details Order / Inquiry CAD DataDocument1 pageHandwheels: Product Details Order / Inquiry CAD DataDaniel MikicNo ratings yet

- ME 470: Senior DesignDocument5 pagesME 470: Senior DesignCam MillerNo ratings yet

- Gosa Adrian Vasile TCM 141Document6 pagesGosa Adrian Vasile TCM 141Purdea BogdanNo ratings yet

- Qdoc - Tips Electrical Panel Board Project ReportDocument18 pagesQdoc - Tips Electrical Panel Board Project Reportsampath rajannaNo ratings yet

- Dry Film Thickness Measurement ProcedureDocument5 pagesDry Film Thickness Measurement ProcedureKhepa BabaNo ratings yet

- The Measurement of Dry Film Thickness of Coatings On Structural Steelwork (Abrasive Blast Cleaned) TP913Document5 pagesThe Measurement of Dry Film Thickness of Coatings On Structural Steelwork (Abrasive Blast Cleaned) TP913rudrakrNo ratings yet

- Eplc Project Charter TemplateDocument14 pagesEplc Project Charter TemplateNurul JannahNo ratings yet

- IT Lab Assignment: (LP Models and Formulations)Document13 pagesIT Lab Assignment: (LP Models and Formulations)Lamont ClintonNo ratings yet

- Engineering Graphics BasicsDocument55 pagesEngineering Graphics Basicsamru23No ratings yet

- This Page Is An Extension of Erwin's SG Work Shop: IndexDocument8 pagesThis Page Is An Extension of Erwin's SG Work Shop: IndexmungluisNo ratings yet

- Coconut Wood-Fiber Cement BoardsDocument9 pagesCoconut Wood-Fiber Cement BoardsFrank DagohoyNo ratings yet

- Manufacturing Engineering: General IntroductionDocument26 pagesManufacturing Engineering: General IntroductionsyedamiriqbalNo ratings yet

- Sample BudgetDocument4 pagesSample BudgetDs SwapneilNo ratings yet

- Ch2b TragetCosting QDocument5 pagesCh2b TragetCosting QNayab AwanNo ratings yet

- UMTS Performance Trouble Shooting and Optimization Guidelines NSN ThroughputDocument50 pagesUMTS Performance Trouble Shooting and Optimization Guidelines NSN ThroughputUday Kumar ReddyNo ratings yet

- Voco 2011Document42 pagesVoco 2011pgrvillavicencioNo ratings yet

- Illinois VOC and LEED 2009 LimitsDocument5 pagesIllinois VOC and LEED 2009 LimitsspecmasterNo ratings yet

- Final PPT Analysis and Design of T-Beam Girder and Box Girder SuperstructureDocument34 pagesFinal PPT Analysis and Design of T-Beam Girder and Box Girder Superstructureamit_saxena_1075% (4)

- Factory Layout Principles: UK-RF Closed Nuclear Cities PartnershipDocument14 pagesFactory Layout Principles: UK-RF Closed Nuclear Cities PartnershipSikander GirgoukarNo ratings yet

- Expansion JointsDocument4 pagesExpansion Jointsjeff501No ratings yet

- Business Blueprint: Material Master: SAP R/3 Implementation Project ofDocument35 pagesBusiness Blueprint: Material Master: SAP R/3 Implementation Project ofbluesaphiresNo ratings yet

- Steps in Facility DesignDocument20 pagesSteps in Facility DesignVarun MehrotraNo ratings yet

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successFrom EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successRating: 4.5 out of 5 stars4.5/5 (3)

- Engineering Applications: A Project Resource BookFrom EverandEngineering Applications: A Project Resource BookRating: 2.5 out of 5 stars2.5/5 (1)

- Divided States: Strategic Divisions in EU-Russia RelationsFrom EverandDivided States: Strategic Divisions in EU-Russia RelationsNo ratings yet

- Ussr Germany NDocument110 pagesUssr Germany NioanchiNo ratings yet

- Img 151021142309Document1 pageImg 151021142309ioanchiNo ratings yet

- Materials SelectionDocument3 pagesMaterials SelectionioanchiNo ratings yet

- Ball Screw TutorialDocument73 pagesBall Screw TutorialIvan Aryo ZaoldyeckNo ratings yet

- The Prehistoric Background of Illyrian A PDFDocument11 pagesThe Prehistoric Background of Illyrian A PDFioanchiNo ratings yet

- Solidworks K-Factors Sheet for Bending CalculationsDocument9 pagesSolidworks K-Factors Sheet for Bending CalculationsashkansoheylNo ratings yet

- Spline DIN 5480Document27 pagesSpline DIN 5480ewillia13100% (3)

- COG VT Operating ManualDocument7 pagesCOG VT Operating ManualioanchiNo ratings yet

- Afghanistan 1979, The War That Changed The World: Director(s) : Gulya MIRZOEVA Writer(s) : Gulya MIRZOEVADocument2 pagesAfghanistan 1979, The War That Changed The World: Director(s) : Gulya MIRZOEVA Writer(s) : Gulya MIRZOEVAioanchiNo ratings yet

- 05 Rope Cable TerminationsDocument64 pages05 Rope Cable TerminationsFariz SafarullaNo ratings yet

- Mechanical Engineering Quick ReferencesDocument44 pagesMechanical Engineering Quick ReferencesioanchiNo ratings yet

- Bucket ElevatorsDocument36 pagesBucket Elevatorsioanchi100% (1)

- Bolt Joint-DiagramsDocument6 pagesBolt Joint-Diagramskulov1592No ratings yet

- Twelve Systems Engineering RolesDocument12 pagesTwelve Systems Engineering RolesioanchiNo ratings yet

- Mig Welding HandbookDocument20 pagesMig Welding HandbookMomentumm100% (5)

- LeanBooklet in OrderDocument32 pagesLeanBooklet in OrderioanchiNo ratings yet

- MD-002 Material SelectionDocument14 pagesMD-002 Material Selectionioanchi100% (1)

- Initial Design ConsiderationsDocument8 pagesInitial Design ConsiderationsioanchiNo ratings yet

- Precision FL SpecDocument2 pagesPrecision FL SpecioanchiNo ratings yet

- Balancing BasicsDocument14 pagesBalancing BasicspbharrisNo ratings yet

- BosDocument29 pagesBosioanchiNo ratings yet

- CSC Catalog ColorDocument16 pagesCSC Catalog ColorMauricio Mpinto100% (1)

- ATS Laser and Waterjet Cutting CapabilitiesDocument5 pagesATS Laser and Waterjet Cutting CapabilitiesioanchiNo ratings yet

- BUSSINES-Risk Assessment 08feb12Document17 pagesBUSSINES-Risk Assessment 08feb12ioanchiNo ratings yet

- Mechanical Design Standards: Bending Guidelines 1Document9 pagesMechanical Design Standards: Bending Guidelines 1ioanchiNo ratings yet

- Vat NvatDocument35 pagesVat NvatioanchiNo ratings yet

- GT&C Canadian ConstructionDocument34 pagesGT&C Canadian ConstructionioanchiNo ratings yet

- A Practical Guide To Machine Safety ApplicationDocument80 pagesA Practical Guide To Machine Safety ApplicationpavilamNo ratings yet

- Application Story 2 Howmet Turbine Blade GaugingDocument1 pageApplication Story 2 Howmet Turbine Blade GaugingjoaoluNo ratings yet

- Forecast StudyDocument234 pagesForecast Studyjayakumargj0% (1)

- Assignment Supplier Relationship ManagementDocument2 pagesAssignment Supplier Relationship Managementeeit_nizam100% (1)

- Sample Sap PP Business BlueprintDocument36 pagesSample Sap PP Business BlueprintVenkateswararao Pothini100% (2)

- Sap External OperationDocument27 pagesSap External Operationchandra9000No ratings yet

- Jit and LeanDocument26 pagesJit and LeanMarnelli CatalanNo ratings yet

- Chapter 04 ThompsonDocument27 pagesChapter 04 ThompsonCynthia Penoliar33% (3)

- Production: Varian, Chapter 31Document43 pagesProduction: Varian, Chapter 31Alex BroadbentNo ratings yet

- Expansion PathDocument8 pagesExpansion PathAnita PanthiNo ratings yet

- Mechanical Engineering Computer-Integrated-manufacturing-systems Introduction NotesDocument29 pagesMechanical Engineering Computer-Integrated-manufacturing-systems Introduction NotesPranav SinghNo ratings yet

- Contoh Implementasi QMSDocument8 pagesContoh Implementasi QMSIINNo ratings yet

- SHEET STEEL SPECIFICATION FOR STAMPINGS AND COMMON STEELDocument5 pagesSHEET STEEL SPECIFICATION FOR STAMPINGS AND COMMON STEELMike Fioren100% (1)

- FIFO COGSDocument8 pagesFIFO COGSTet GomezNo ratings yet

- Group Technology (GT) - Organizing Production Into Part FamiliesDocument19 pagesGroup Technology (GT) - Organizing Production Into Part Familiesraj mNo ratings yet

- Prospectus InnerDocument63 pagesProspectus InnerChathura SrinayakaNo ratings yet

- Project Quality Template (Att. IV)Document16 pagesProject Quality Template (Att. IV)aslam.ambNo ratings yet

- qmjzg621 PDFDocument2 pagesqmjzg621 PDFAishwaryaNo ratings yet

- Topic 7 - EOQ and ROPDocument3 pagesTopic 7 - EOQ and ROPMai Mai VarelaNo ratings yet

- Content Final ReportDocument61 pagesContent Final ReportYew Wooi Jing100% (1)

- Siemens PLM EASi Cs z3Document2 pagesSiemens PLM EASi Cs z3rasgeetsinghNo ratings yet

- APQP Documents and TimelineDocument72 pagesAPQP Documents and Timelinesaby aroraNo ratings yet

- Chapter 5Document11 pagesChapter 5El jokerNo ratings yet

- Chapter 01 Russel & Taylor - Operations ManagementDocument48 pagesChapter 01 Russel & Taylor - Operations Managementimran_chaudhry67% (3)

- Brunel Hardness TestDocument8 pagesBrunel Hardness TestSalam AlbaradieNo ratings yet

- Cost Accounting Process Costing System Exercises and Problems PDFDocument10 pagesCost Accounting Process Costing System Exercises and Problems PDFMahlet AbrahaNo ratings yet

- Chapter 5 Process Selection NewDocument17 pagesChapter 5 Process Selection NewRedae AlemayehuNo ratings yet

- Managerial Accounting - Assignment Week 3 Attempt 2Document22 pagesManagerial Accounting - Assignment Week 3 Attempt 2sandeep_416No ratings yet

- EconomicsDocument22 pagesEconomicsShonit kediaNo ratings yet

- 0005 MM Syllabus UCPL TechDocument3 pages0005 MM Syllabus UCPL TechRoking KumarNo ratings yet