Professional Documents

Culture Documents

Propiedades de Aceros

Uploaded by

hombre.muerto5959Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Propiedades de Aceros

Uploaded by

hombre.muerto5959Copyright:

Available Formats

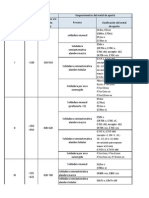

Tabla de equivalencias aproximadas entre los aceros normalizados en Alemania y los aceros fabricados

en Estados Unidos, Espaa, Francia, Inglaterra y Japn

VDEh

ALEMANIA

DIN

RLM

SAE

USA

AISI

AMS

ESPAA

IHA

UNE

FRANCIA

AFNOR FN

INGLATERRA

BS

BSA

DTD

C 10 CK 10

StC 10.61

1100

1010

C 1010

5060 B

F-151

36013

XC 10

EN 32 A

3 S 14

C 15 CK 15

StC 16.61

1105

1015

C 1015

5060 B

F-111

36011

XC 12

EN 2

C 22

StC 25.61

1110

1025

C 1025

5070

F-112

36011

XC 25

EN 4

---

1105

1020

C 1020

---

F-221

36024

XC 18

EN 3 A

C 35 CK 35

StC 35.61

1120

1035

1035

5080

F-113

36011

XC 32

EN 6

5 S.1

C 45

StC 45.61

1130

1050

C 1050

---

F-142

36013

XC 42

EN 43

---

1045

C 1045

---

F-114

---

---

EN 8

---

CK 22

CK 45

C 60 CK 60

---

---

JAPN

JIS

Tipo

---

G 4501

S 9 Ck

S 91

299

G 4501

S15 C

S 77

124 A

G 4501

S25 C

---

---

---

S20 C

305

G 4501

S35 C

137 A

G 3501

SWR 10

---

G 4501

S45 C

StC 60.61

1150

1055

C 1055

---

F-115

36011

XC 55

EN 9

138 A

G 4501

S55 C

Ct 70

---

1182

1070

C 1070

---

F-141

36015

XC 70

EN 42

2 S 79

---

5A

G 3501

SWR 8

100 Cr. 6

---

1256

52100A

52100A

5115

F-131

36012

100 C 6

EN 31

---

---

G 4805

SUJ 2

---

30 Mn. 5

VM 125

---

1335

1335

---

F-411

---

35 M 5

EN 15 A

---

---

---

36 Mn. 5

VM 135

---

1335

1335

---

F-411

---

35 M 5

EN 15 A

---

---

---

14 NiCr.10

ECN 25

1402

3415

---

---

F-154

36013

38 MS 5

---

---

---

---

---

28 (36) NiCr.10

VCN 25w(H)

1412

3435

---

---

F-123

36012

14 NC 11

EN 36

---

519

G 4102

SNC 21

22 (31) NiCr.14

VCN 35w(H)

1415

---

---

F-122

36012

30 NC 11

EN 23

4 S 11

---

G 4102

SNC 2

13 NiCr.18

ECN 45

1404

6252 C

F-153

36013

28 NC 14

EN 30 A

3 S 28

331

G 4102

SNC 3

35 CrNi.18

VCN 45

---

3335

---

F-132

---

12 NC 15

EN 39 A

---

G 4102

SNC 22

18 NiCr.8

ECN 20

---

4317

4317

6292 C

F-158

36013

35 NC 15

EN 30 A

---

G 4102

SNC 3

--3310

E 3310

---

--3 S 28

36 CrNiMn.4

---

1455

9840

9840

6342 A

F-126

36012

18 NCD 6

EN 320

---

---

---

34 CrNiMn.6

---

1455

4340

4340

6342 A

F-128

36012

35 NCD 4

EN 110

S 95

480

G 4103

SNCM 8

---

---

F-432

---

35 NCD 6

EN 110

S 95

480

G 4103

SNCM 8

---

---

12 C 3

EN 207

---

---

EN 18

---

---

---

EN 18

---

---

G 4104

15 Cr.3

34 Cr.4

EC 60

---

-----

5115

---

---

5140

5140

---

---

---

5120

5120

---

F-431

---

1452

4130

4130

6510 A

F-222

36024

20 MC 5

---

---

1454

4135

---

6366

F-125

36012

25 CD 4

---

T 60

178

G 4105

SCM 2

1407

---

---

---

F-155

36013

12 CD 4

---

---

---

G 4105

SCM 21

---

306

---

52 SCV 5 4 A

---

---

87

G 4202

SACM 1

41 Cr.4

VC 140

20 MnCr.5/22 MnCr.6

EC 100

25 CrMo. 4

VCMo 125

34 CrMo. 4

VCMo 135

15 CrMo. 5

ECMo 80

30 CrMo. V9

VCMo 230

1470

---

50 Cr V4

VCV 150

1610

6150

---

1471

---

32 AICrMo 4

X 10 Cr 13

1604

---

---

1570

X 40 Cr 13

---

X 22 CrNi 17

---

X 12 CrNi 178

---

---

---

1552

--1430

51410

51420

51335

51310

51431

30302

30905

30321

30705

X 10 CrNiTi 189

---

X 45 CrNiW 189

---

1440

---

X 45 CrSi 9

---

1545

C 85 W 2

---

---

C 100 W 2

---

---

W 1-1,0C

C 115 W 2

---

---

C 130 W 2

---

C 45 W 3

---

C 60 W 3

---

--38 (45) C 4

---

---

---

F-171

36014

F-143

36015

50 CV 4

EN 47

6470 B

F-174

36014

45 CAD6 - 12

EN 41

403

5610 C

F-311

36016

Z 12 C 13

EN 56 A

2 S 61

53

G 4301

SEC 1

420

5620 C

F-312

36016

Z 35 C 13

EN 56 D

2 S 62

463

G 4301

SEC 4

Z 10 CN 17

EN 57

2 S 80

60 B

---

---

Z 12 CN 18-10

EN 58 A

S 110

176 A

G 4301

SEC 7

Z 8 CNDT 18-08

EN 58 B

---

571

---

---

---

--304

36072

F-313

36016

5560 A

F-314

36016

---

---

5575 B

F-332

---

Z 40 CNWS 14-014

EN 54

S 111

49 B

G 4302

SEH 4

---

5700 A

F-321

36017

Z 40 CSD 10

EN 52

---

13 B

G 4302

SEH 3

silcromel

silcromel

5705 A

F-322

36017

XC 85

EN 4

---

---

G 4401

SK 5

W 1-0,9C

W 1-0,9C

---

F-514

36071

XC 95

EN 5

---

---

G 4401

SK 4

W 1-1,0C

---

F-515

36071

XC 110

EN 6

---

---

G 4401

SK 3

W 1-1,2C

W 1-1,2C

---

F-516

36071

XC 120

EN 7

---

---

G 4401

SK 2

---

W 1-1,2C

W 1-1,2C

---

F-517

36071

XC 55

EN 1

---

---

G 4801

SUP 1

---

1055

C 1055

---

F-511

36071

XC 65

EN 2

---

---

G 4401

SK 7

---

---

W1

W1

---

F-512

36071

XC 70

EN 3

---

---

G 4401

SK 6

C 75 W 3

---

---

W 1-0,8C

W 1-0,8C

---

F-513

36071

XC 85

EN 4

---

---

G 4401

SK 5

C 90 W 3

---

---

W 1-0,9C

W 1-0,9C

---

F-514

36071

XC 55

EN 1

---

---

G 4801

SUP 1

C 55 W 3

---

---

1055

C 1055

---

F-511

36071

Z 85 WK 18 - 05

EN 81

---

---

G 4403

SKH 3

E 18 Co 5

---

---

T4

T4

---

F-553

46073

Z 85 WK 18 - 18

EN 82

---

---

G 4403

SKH 4A

E 18 Co 10

---

---

T5

T5

---

F-554

36073

---

---

---

---

---

---

ABC II

---

---

---

F-534

36072

---

---

---

---

---

---

---

---

T7

T7

---

F-551

36073

---

---

---

---

---

D Mo 5

---

---

M2

M2

---

---

---

EN 76

---

---

---

---

E Mo 5 V 3

---

---

M4

M4

---

---

---

---

---

---

---

---

B Mo 9

---

---

M1

M1

---

---

---

---

---

---

---

---

SKH 2

EN 74

---

---

---

---

---

F 552

36073

---

B 18

Z 75 W 18

110 Cr 2

100 C 6

110 Cr 6

100 C 6

210 Cr 46

Z 200 C 12

105 MnCr 4

80 M 8

210 CrW 46

Z 200 C 12

130 W 19

120 WC 45-02

---

120 WV 4

100 WC 15-04

35 WCrV 7

45 WCS 18

45 WCrV 7

45 WC 20-04

45 WCrV 77

55 WCrV 7

165 CrMoV 46

40 CrMoV 21

Z 35 CD 05

30 WCrV 15

40 WCDS 35-12

30 WCrV 34 11

Z 30 WC 09-03

37 CrMoW 19.6

55 NiCrMoV 6

G 4403

---

---

Z 75 W 14

Z 85 WD 06 - 06

T1

----T1

---

---

---

---

---

F 533

36072

W5

W5

---

---

---

---

---

---

F 523

36072

L3

L3

---

---

---

---

---

F 521

36072

D3

D3

EN 21

---

---

---

---

---

---

---

EN 35

---

---

---

---

---

F 521

36072

D3

D3

---

---

---

---

---

---

---

F 531

36072

F3

F3

---

---

---

---

---

---

---

---

F 532

36072

F1

F1

---

---

---

---

---

---

---

---

F 525

36072

S3

---

---

---

---

---

---

---

---

F 524

36072

S1

S1

45 WC 20-04

---

---

---

---

---

---

---

---

F 524

36072

S1

S1

45 WC 20-04

---

---

---

---

---

---

---

---

F 524

36072

S1

S1

Z 200 C 12

---

---

---

---

---

---

---

---

---

EN 35

---

---

---

---

---

---

---

---

---

---

---

---

F 527

F 526

60 NCDV 06-02

--G 4407

--G 4407

G 4403

--G 4407

---

---

EN 35

---

---

321

F-535

5615 A

EN 40 B

--SCr 4

6450

6150

---

---

---

--SKD 1

--SKD 1

EN 61

---

---

---

---

---

---

SKD 5

---

EN 57

---

---

---

---

---

---

---

EN 68

---

---

---

---

---

---

-----

--F 528

---

---

---

---

---

---

H 11

H 11

36072

---

---

36072

H 21

H 21

---

H 12

H 12

L6

L6

36072

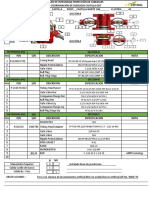

Propiedades Tpicas de Materiales Ferrosos

Resistencias Mximas

MATERIAL

N AISI

ESTADO

Hierro Dulce

C 1010 (k)

C 1015 (k)

C 1020

C 1020

C 1020

C 1020 (k)

C 1022

C 1030

C 1035

C 1045

C 1095

B 1113 (k)

B 1113

C 1118

C 1118 (k)

C 1144

1340

13B45

2317 (e)

2340 (e)

3150

3250 (e)

4063

4130

4130 (e)

4330 (e)

4640 (e)

5140 (e)

5140 (e)

8630

8640

8760

9255

9440

9850

Laminado simple

Estirado en fro

Estirado en fro

Laminado simple

Normalizado

Recocido

Estirado en fro

Laminado simple

Laminado simple

Laminado simple

Laminado simple

Normalizado

Acabado en Fro

Laminado simple

Laminado simple

Estirado en fro

OQT 1000 (538 C)

OQT 1200 (649 C)

OQT 800 (427 C)

OQT 1000 (538 C)

OQT 1000 (538 C)

OQT 1200 (649 C)

QT 1000 (538 C)

OQT 1000 (538 C)

WQT 1100 (539 C)

Estirado en fro

Estirado en fro

OQT 1000 (538 C)

OQT 1000 (538 C)

Estirado en fro

Estirado en fro 10%

OQT 1000 (538 C)

OQT 800 (427 C)

OQT 800 (427 C)

OQT 1000 (538 C)

OQT 1100 (593 C)

MAXIMA

RESISTENCIA

Srup

Trup (d)

kg / cm

kg / cm

3374 (a)

4710

5413

4569

4499

4007

5483

5062

5624

5976

6749

9913

5935

4921

5273

5624

8296

7945

13147

7451

9632

10616

11670

12655

8929

8577

8577

10686

10546

7381

8085

11249

15468

12655

10686

12655

2531

3515

4077

3445

3797*

3023

4077

3797

4218

4499

5062

7381

4359

--3937

4218

6187

5905

9843

5554

7241

7945

8577

9491

6679

6398

6398

7311

7945

5554

6064

8437

11600

9491

7311

9491

RESISTENCIA ALARGAMIENTO

REDUCCION

DE FLUENCIA EN 5,08 cm DE AREA

EN TRACCION

Sf kg / cm

%

%

1757 (a)

3867

4429

3374

3515

2952

4640

3656

3586

3867

4148

5624

5062

3163

3234

5273

5835

6468

12303

4991

8437

9140

10264

11249

8015

7381

7381

9140

8999

6187

7030

10546

14068

11249

9491

11108

35

25

25

36

39

36.5

20

35

32

29

22

8

14

25

32

16

19

21

16

27

22

16

16

14

18

16

15

19

19

18

22

16

12

15

18

15

--57

63

59

69

66

59

67

56

58

45

16

40

40

70

57

46

61

56

72

60

54

52

43

62

45

45

56

55

52

53

55

43

32

61

48

BHN

ROCK.

----170

143

131

111

156

149

179

190

215

285

170

138

149

180

235

229

--220

285

300

340

375

260

248

248

310

300

212

222

330

429

352

311

360

B 60

----B 79

B 74

B 66

B 83

B 81

B 88

B 91

B 96

C 25

B 87

B 76

B 81

--C 22

C 31

C 42

B 97

C 30

C 32

C 36,5

C 40

C 25

--C 33

C 32

----C 35

C 46

C 36

C 33

C 37

---

TABLA DE EQUIVALENCIAS APROXIMADAS DE

LOS ACEROS MAS UTILIZADOS

NORMAS

SAE

AISI

DIN

NCh

1010

1020

1035

1045

1070

1335

4130

4140

4340

5120

5140

6150

C 1010

C 1020

1035

C 1045

C 1070

1335

4130

4140

4340

5120

5140

6150

StC 10.61

StC 20.61

StC 35.61

StC 45.61

--VM 125

VCMo 125

----EC 100

VC 140

VCV 150

A 37 - 22

----A 42 - 27

A 52 - 34

---------------

Nota: Equivalencias en base a la resistencia de los Aceros

You might also like

- Casted - Alloys - Aleaciones de Fundicion EmpleadasDocument1 pageCasted - Alloys - Aleaciones de Fundicion EmpleadasLorena HesterNo ratings yet

- FICHA TECNICA CALIDAD DE MATERIALES Rev. 0Document1 pageFICHA TECNICA CALIDAD DE MATERIALES Rev. 0Jose Humberto ArandaNo ratings yet

- Tabla de Equivalencias de AcerosDocument5 pagesTabla de Equivalencias de AcerosDamian Pino RodriguezNo ratings yet

- Aceros para Tornilleria ST 37.2Document4 pagesAceros para Tornilleria ST 37.2EVA100% (1)

- Catálogo en Breve 2018Document38 pagesCatálogo en Breve 2018Maxwell Alexander VeintimillaNo ratings yet

- Materia para La Prueba 3er ParcialDocument93 pagesMateria para La Prueba 3er ParcialOscar100% (1)

- AcerosDocument120 pagesAcerosDavid Fernandez ZapataNo ratings yet

- Analisis de MANUAL de MaplocaDocument10 pagesAnalisis de MANUAL de MaplocajohajohacNo ratings yet

- Dades Steel C35EDocument2 pagesDades Steel C35EoscarhereNo ratings yet

- Tabla Designacion de MaterialesDocument4 pagesTabla Designacion de MaterialesCaballeroGiovanniNo ratings yet

- Aceros (Clasificacion, Aleantes, Produccion)Document15 pagesAceros (Clasificacion, Aleantes, Produccion)Alfredo Merizalde AvilesNo ratings yet

- Acero Al C-Mo y Cr-MoDocument1 pageAcero Al C-Mo y Cr-MoRoberto Alfredo Avila VidalNo ratings yet

- Normas-De-Aceros (Bueno) PDFDocument9 pagesNormas-De-Aceros (Bueno) PDFGincNo ratings yet

- Universidad Tecnologica Nacional: Facultad Regional HaedoDocument10 pagesUniversidad Tecnologica Nacional: Facultad Regional HaedoOrlando Pena ZamoranoNo ratings yet

- 17propiedades MaterialesDocument4 pages17propiedades Materialesbelarra71100% (1)

- Tablas de Acero AsmeDocument1 pageTablas de Acero AsmetyronepNo ratings yet

- Relación Metal Base-Metal de AporteDocument2 pagesRelación Metal Base-Metal de AporteRaimundo Ignacio Valenzuela Serrano100% (1)

- Formato Insp - Can 108Document1 pageFormato Insp - Can 108Juan david Rey sanchezNo ratings yet

- Materiales de Soldadura de Aporte Aceros XAR PDFDocument1 pageMateriales de Soldadura de Aporte Aceros XAR PDFbernardoNo ratings yet

- Colada de Los AcerosDocument110 pagesColada de Los AcerosducoviNo ratings yet

- Manual Curso Operacion Del Volteador de Vagones PMHDocument42 pagesManual Curso Operacion Del Volteador de Vagones PMHJesus BarrosoNo ratings yet

- Especiales BohlerDocument4 pagesEspeciales BohlerSalvadorNo ratings yet

- Cuadro Comparativo de ElectrodosDocument3 pagesCuadro Comparativo de ElectrodosOscar AdrianNo ratings yet

- ACEROSDocument1 pageACEROSDan MtzNo ratings yet

- Tablas de Equivalencias Internacionales PDFDocument20 pagesTablas de Equivalencias Internacionales PDFDAG DKNo ratings yet

- Características de pinturas epoxi Sigma CoatingsDocument2 pagesCaracterísticas de pinturas epoxi Sigma CoatingsStefano CostaNo ratings yet

- Acero 2316Document8 pagesAcero 2316DanielJoseLancherosNo ratings yet

- Aceros en PlanchasDocument9 pagesAceros en Planchasmanuel floresNo ratings yet

- Examen Radiográfico y Ultrasónico - Asme Viii (Uw-11)Document2 pagesExamen Radiográfico y Ultrasónico - Asme Viii (Uw-11)Nanu Iula100% (1)

- Diseño Del CiclonDocument9 pagesDiseño Del CiclonGreys JimenezNo ratings yet

- Procedimiento de Proceso de Soldadura SAWDocument67 pagesProcedimiento de Proceso de Soldadura SAWCarlos Nina OchoaNo ratings yet

- Diagrama de FasesDocument50 pagesDiagrama de Fasesquimicocad9891100% (1)

- Calderas MantenimientoDocument68 pagesCalderas MantenimientoGustavo JaimeNo ratings yet

- Material Aporte SoldaduraDocument24 pagesMaterial Aporte SoldaduraTavo Rojas JNo ratings yet

- 02 Manometro ETSA Modelo 643Document2 pages02 Manometro ETSA Modelo 643Omar BecerrilNo ratings yet

- Designacion Numerica para AcerosDocument12 pagesDesignacion Numerica para AcerosAlfredo Van HousteNo ratings yet

- 5 Conceptos de Ajustes y ToleranciasDocument30 pages5 Conceptos de Ajustes y ToleranciasClau AvendañoNo ratings yet

- Anexo-Tabla de Propiedades Del Acero Empleado en Los Ejes PDFDocument1 pageAnexo-Tabla de Propiedades Del Acero Empleado en Los Ejes PDFElvis RodriguezNo ratings yet

- Equivalencias de Aceros enDocument2 pagesEquivalencias de Aceros enJose Manuel SanchezNo ratings yet

- Urssa Tecnica EquivalenciasDocument4 pagesUrssa Tecnica EquivalenciasDidier CardenasNo ratings yet

- Código ASME Sección IX interpretación normas soldaduraDocument59 pagesCódigo ASME Sección IX interpretación normas soldaduraMiguel IzaguirreNo ratings yet

- Ferromanganeso Alto CarbónDocument5 pagesFerromanganeso Alto CarbónGabriela Mendoza Hernández100% (1)

- Sms ConexionesDocument4 pagesSms ConexionesChemicalProgrammerNo ratings yet

- Tabla Dureza BulonesDocument16 pagesTabla Dureza Bulonesfbenitez738No ratings yet

- Cuestionario, Materiales Usasdos en La IndustriaDocument6 pagesCuestionario, Materiales Usasdos en La IndustriaJuliana Ramirez100% (1)

- Tratamiento de Precalentamiento y PoscalentamientoDocument5 pagesTratamiento de Precalentamiento y PoscalentamientoArnaldoNo ratings yet

- Equivalencias Más Cercanas de Calidades y NormasDocument1 pageEquivalencias Más Cercanas de Calidades y NormasskylineshareNo ratings yet

- Ficha Tecnica Electrodo ExcalibuR - 8018C1 - MR - ES-MX PDFDocument2 pagesFicha Tecnica Electrodo ExcalibuR - 8018C1 - MR - ES-MX PDFClaudio Israel Godinez SomeraNo ratings yet

- Clasificacion Aws para Materiales de AporteDocument41 pagesClasificacion Aws para Materiales de AportelucdaveaNo ratings yet

- La Tecnología GOLDD EspañolDocument3 pagesLa Tecnología GOLDD EspañolEddy Norman Benites DelgadoNo ratings yet

- Equivalencias de AcerosDocument1 pageEquivalencias de AcerosRuben Fuentes FuentesNo ratings yet

- Tabla de Equivalencias de Aceros 1Document5 pagesTabla de Equivalencias de Aceros 1Denilson Roa100% (1)

- Propiedades AceroDocument4 pagesPropiedades AceroJorge De FezNo ratings yet

- Placas de Fijacion Mecanica de PCD-CBNDocument45 pagesPlacas de Fijacion Mecanica de PCD-CBNAsem Herramientas Luis AnchueloNo ratings yet

- Corespondente OtelDocument8 pagesCorespondente Otelsimo96No ratings yet

- Tabela de Equivalencias de MateriaisDocument2 pagesTabela de Equivalencias de Materiaispaula_gfrancaNo ratings yet

- Tabla Comparativa SoldadurasDocument3 pagesTabla Comparativa SoldadurasWelder Welder Cobos88% (8)

- Tabla de Equivalencias de AcerosDocument1 pageTabla de Equivalencias de AcerosMario Enriquez100% (2)

- Tabla Comparacion MaterialesDocument7 pagesTabla Comparacion MaterialesarmandogavinoNo ratings yet

- ChapasDocument13 pagesChapasglarrea5535No ratings yet