Professional Documents

Culture Documents

Irc Specs For Concrete Superstructure

Uploaded by

GoanengineerOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Irc Specs For Concrete Superstructure

Uploaded by

GoanengineerCopyright:

Available Formats

Concrete Superstructure

2300 Concrete Superstructure

Section 2300 2301 DESCRIPTION

Concrete Superstructure

The work shall cover furnishing and providing of concrete super-structure in accordance with the drawings and as per these Specifications or as directed by the Engineer. 2302 MATERIALS

Materials shall conform to Section 1000 of these Specifications. 2303 GENERAL

2303.1 A method statement for construction, indicating the following, shall be submitted by the Contractor for approval of the Engineer, well in advance of the commencement of the construction of superstructure. i) ii) iii) iv) v) vi) vii) viii) Sources of Materials Design, erection and removal of formwork Production, transportation, laying and curing of concrete Prestressing system, if applicable Personnel employed for execution and supervision Tests and sampling procedure Equipment details Any other point

2303.2 Dimensions, lines and levels shall be set out and checked with respect to permanent reference lines and permanent bench mark so that the final product is in accordance with the drawings or as directed by the Engineer. 2303.3 The work shall conform to the following sections besides stipulations in this section with regard to specific type of construction : i) ii) iii) iv) Formwork Steel Reinforcement Structural Concrete Prestressing Section 1500 Section 1600 Section 1700 Section 1800

Additionally, some of the common types of superstructure construction shall have features as described in this Section.

2

Concrete Superstructure

Section 2300

2304 2304.1

REINFORCED CONCRETE CONSTRUCTION Solid Slabs

Where adjacent span of slab has already been cast, the expansion joint and filler board shall be placed abutting the already cast span which shall form the shutter on that slide of the new span to be cast. The whole of the slab shall be cast with reinforcement embedded for the road kerb and railings. No other construction joint shall be allowed except with the express permission of the Engineer. Where wearing coat is required to be provided, after the deck slab has been cast, the surface of the slab shall be finished rough, but true to lines and levels as shown on the drawings, before the concrete has hardened. The areas of construction joints shall be treated in the prescribed manner. The top of the slab shall be covered with clean moist sand as soon as the top surface has hardened. Curing shall be carried out as per Section 1700. Where the slab is resting on bearings, the same shall be placed in position in accordance with the drawings, before casting of deck slab. 2304.2 RCC T-Beam and Slab

Provision of construction joint shall conform to the drawings or as per directions of the Engineer. No construction joint shall be provided between the bottom bulb and the web. If not indicated on the drawing, construction joint may be provided at the junction of the web and the fillet between the web and the deck slab with the permission of the Engineer. The portions of deck slab near expansion joints shall be cast alongwith reinforcements and embedments for expansion joints. For this purpose, the portion of deck slab near expansion joints may be cast in a subsequent stage, if permitted by the Engineer. The surface finish of the deck slab shall be finished rough but true to lines and levels as shown on the drawings before the concrete has hardened. Care shall be taken for setting of bearings as indicated on the drawings. 2305 2305.1 PRESTRESSED CONCRETE CONSTRUCTION PSC Girder and Composite RCC Slab

PSC Girder may be precast or cast-in-situ as mentioned on the drawing or as directed by the Engineer. Girders may be post-tensioned or pre-tensioned. Where precast construction is required to be adopted, selection of casting yard and details of methodology and of equipment for shifting and launching of girders shall be included in the method statement.

3

Section 2300

Concrete Superstructure

In case of cast-in-situ construction, the sequence of construction including side shifting of girders, if applicable, and placing on bearings shall be in accordance with the drawings. The PSC girder constituting the top flange, web and the bottom flange shall be concreted in a single operation without any construction joint. The portions of deck slab near expansion joints shall be cast alongwith reinforcements and embedments for expansion joints. For this purpose, the portion of deck slab near expansion joints may be cast in a subsequent stage, if permitted by the Engineer. The surface finish of the deck slab shall be finished rough but true to lines and levels as shown on the drawings before the concrete had hardened. Care shall be taken for setting of bearings as indicated on the drawings. 2305.2 Box Girder

Box girders may be simply supported or continuous. Simply supported box girders shall have minimum construction joints as approved by the Engineer. In the case of continuous box girders the sequence of construction and location of construction joints shall strictly follow the drawings. The box section shall be constructed with a maximum of one construction joint located in the web below the fillet between the deck slab and web. If permitted by the Engineer, one additional construction joint may be permitted and this construction joint shall be located in the web above the fillet between the soffit slab and web. The portions of deck slab near expansion joints shall be cast alongwith reinforcements and embedments for expansion joints. For this purpose, the portion of deck slab near expansion joints may be cast in a subsequent stage, if permitted by the Engineer. The surface finish of the deck slab shall be finished rough but true to lines and levels as shown on the drawings before the concrete has hardened. Care shall be taken for setting of bearings as indicated on the drawings. 2305.3 Cantilever Construction

Continuity of untensioned reinforcement from one segment to the next must be ensured by providing full lap length as necessary. The design of the superstructure shall take into account the following aspects which form an integral part of the construction operations : a) Stability against over-turning for each statical condition through which the assembly passes, shall be checked.

4

Concrete Superstructure

Section 2300

b)

Stresses at each preceding segment joint with the addition of every segment or change of statical conditions shall be checked. The load of equipment as well as construction live load shall be taken into account. Precambering of the superstructure during construction shall be done in such a manner that the finally constructed structure under permanent load attains the final profile intended in the drawings.

c)

2306 2306.1

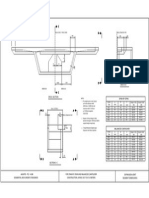

TOLERANCES Precast Concrete Superstructure

Variation in cross-sectional dimensions : a) b) Variation in thickness or variation in depth Variation in length overall and length between bearings : : + 5 mm shall not exceed + 10 mm or + 0.1 percent of the span length, whichever is less

c)

Permissible surface irregularities when measured with a 3 m straight edge or template

5 mm

2306.2

Cast-in-Situ Superstructure a) Variations in thickness of top and : -5 mm to +10 mm for box girders, top and bottom flange for T-girders or slabs Variations in web thickness Variations in overall depth or width : : -5 mm to +10 mm + 5 mm

b) c) d)

Variation in length overall and length : shall not exceed + 10 mm between bearings or +0.1 percent of the span length, whichever is lesser Permissible surface irregularities : 5 mm measured with a 3 m straight edge or template

e)

Section 2300 2307 TEST AND STANDARDS OF ACCEPTANCE

Concrete Superstructure

2307.1 The materials shall be tested in accordance with these Specifications and shall meet the prescribed requirements. 2307.2 The work shall conform to these specifications and shall meet the prescribed standards of acceptance. 2308 MEASUREMENT FOR PAYMENT

2308.1 Concrete in superstructure shall be measured in accordance with Section 1700, based on the quantity ordered or as shown on the drawings. 2308.2 Steel reinforcement (untensioned) in superstructure shall be measured in accordance with Section 1600, based on the quantity ordered or as shown on the drawings. 2308.3 High tensile steel (prestressing) in superstructure shall be measured in accordance with Section 1800, based on the quantity ordered or as shown on the drawings. 2309 RATE

The contract unit rates for concrete, steel reinforcement (untensioned) and high tensile steel (prestressing) shall include all works as given in respective sections of these Specifications and cover all incidental items for furnishing and providing superstructure as mentioned in these Specifications.

Concrete Superstructure

Section 2300

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- FQP PileDocument18 pagesFQP PileGoanengineer100% (1)

- Goa Board of Secondary & Higher Secondary EducationDocument4 pagesGoa Board of Secondary & Higher Secondary EducationGoanengineerNo ratings yet

- Expansion JointDocument1 pageExpansion JointGoanengineerNo ratings yet

- Pune: City Development Plan (CDP) : An Appraisal ReportDocument4 pagesPune: City Development Plan (CDP) : An Appraisal ReportGoanengineerNo ratings yet

- Well Pile Foundation PDFDocument17 pagesWell Pile Foundation PDFlingamkumarNo ratings yet

- Fabrication DrawingDocument1 pageFabrication DrawingGoanengineerNo ratings yet

- Rashtriya Chemicals & Fertilizers LTDDocument6 pagesRashtriya Chemicals & Fertilizers LTDGoanengineerNo ratings yet