Professional Documents

Culture Documents

Bosch Continous Vacuum Pan

Uploaded by

cumpio4254280 ratings0% found this document useful (0 votes)

315 views11 pagessugar crystallization reference

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentsugar crystallization reference

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

315 views11 pagesBosch Continous Vacuum Pan

Uploaded by

cumpio425428sugar crystallization reference

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 11

THE SKIL/BOSCH CVP

Mike Inkson [Sugar Knowledge International] and

Bruce Moor [Bosch Projects]

KEYWORDS

Continuous pans, Crystal quality, Energy efficiency, Heat transfer coefficient

ABSTRACT

Despite their obvious benefits, commercially successful continuous vacuum pans [CVPs]

were only introduced into the sugar industry during the 1970s. Since then they have been

intensively studied and crystal uniformity, energy efficiency and pan availability have been

identified as key performance criteria. This paper discusses these criteria and their

application in the development of a new CVP.

Third party analyses of the performance of the new pans on both high and low grade

massecuites are reported. The results show that the pans have met or exceeded all the

objectives in regard to crystal quality, energy efficiency, operability and availability. The

success is attributed to a sound design, drawing on the best characteristics of conventional

CVPs with the addition of innovative features that enhance performance in critical areas such

as crystal uniformity and heat transfer.

INTRODUCTION

The first proposal for a continuous vacuum pan was a 1931 patent by Werkspoor but it was

another 30 years before the first acceptable [and hence commercially successful] CVP was

produced by Fives Cail Babcock. That used a horizontal cylindrical body with vertical plate

heating elements and subsequently evolved to horizontal tube heating. Much more

successful was the horizontal Tongaat-Hulett CVP with vertical tubes and a babys bottom

cross section. That was the subject of a BSST paper a few years ago.

Last year we had another paper at the BSST AGM about the third main type of CVP: the

BMA vertical arrangement with four or five pans stacked up in a tower [the VKT].

This paper describes a relatively new horizontal CVP, the thinking behind its development

and the first detailed analysis of its performance. It was originally developed under the SKIL

name but the license was subsequently sold to Bosch Projects.

DESIGN OBJECTIVES

The essential duty of any CVP is to accept the seed massecuite and the syrup, molasses

and/or water fed to it and convert these to a well-exhausted strike massecuite with uniformly

larger crystals and of higher brix. For this, an adequate heating surface for the evaporation

duty and an adequate volume (retention time) for the crystal growth are required. However

many other factors need to be correct to sustain efficient production of an acceptable quality

massecuite. The most important are:

crystal quality,

energy efficiency and

pan availability.

These and the related design decisions are discussed below.

2

Crystal Quality

This requirement is listed first, as it is the requirement that failed most of the early

designs and remains a sine qua non for a successful design. The topic involves

consideration of crystal uniformity, plug flow, compartment size, circulation and pan

controls.

Crystal Uniformity

The most serious manifestation of uneven crystal size is false grain. In a batch pan

this can be managed (at some cost) but CVP operations are not so tolerant, so the

design must ensure that false grain is never initiated. However, a narrow size

distribution of the legitimate crystal population is also a vital concern as this directly

affects the permeability of massecuite in curing and any subsequent affination.

Crystal size distribution is expressed as the coefficient of variation (CV).

Plug Flow

For a low CV, it is important that the crystals in the seed all remain in the CVP for the

same length of time, something which is only possible with pure plug flow.

Any continuous reactor can be mathematically modelled as an equivalent number of

continuous stirred tank reactors [CSTRs] in series: totally random flow results from a

single such tank and perfect plug flow would require an infinite number of them.

Thelwall (2000) has used this approach to calculate expected final CV values (from

good seed) against the number of theoretical tanks:

15%

20%

25%

30%

35%

40%

0 5 10 15 20

CSTRs i n Seri es

P

r

e

d

i

c

t

e

d

C

V

Figure 1: Predicted Crystal CV for Theoretical CSTRs

The reduction in incremental benefit as the number of tanks increases is clearly

visible.

A good batch pan approximates to 12 CSTRs in series (Rein et al, 1985, and

Broadfoot et al, 1989) and a practical target for continuous pan design is an

equivalent of 12 to 16 CSTRs in series. CVPs are divided into compartments in order

to assist with achieving plug flow but, as shown in Table 1 [over], the number of

equivalent CSTRs does not necessarily equate to the number of actual compartments

installed:

3

Table 1: Reported Equivalent CSTRs

Factory Source Make -

Duty

Actual

Cells

Equivalent

CSTRs

Ratio

Maidstone Rein et al (1985) T-H - 'C' 12 23 1.9

Maidstone Rein et al (1985) T-H - 'A' 12 17 1.4

Maidstone Rein et al (1985) FCB - 'C' 15 9 0.6

Maryboroug

h

Broadfoot et al (1989) SRI - 'A' 9 12 1.3

Tully

Arcidiacono et

al(1992)

X - 'B' 10 15 1.5

Racecourse Attard (1993) RCSA - 'C' 36 41 1.1

The good Tongaat-Hulett results can be explained by the smooth massecuite flow

path without dead zones or short circuit paths. The Racecourse CVP demonstrated

excellent plug flow characteristics because of its numerous baffles. However the

baffles also caused circulation problems resulting in lump formation.

No equivalent test results for BMA VKTs were quoted in last years BSST paper and

none was found in the literature but it can be expected that the theoretical tanks

would, by definition, approximate the number of real cells.

It should be noted that CV improves from seed to massecuite provided that the

theoretical number of tanks is greater than 3 to 5, depending on seed CV: this was

always achieved in the Tongaat-Hulett CVPs. Broadfoot (1992) has also pointed out

that a CVP with a narrow residence time distribution can accept a seed of small size,

thereby providing a high overall volumetric efficiency.

Given these advantages, it was an obvious decision that the new CVP should be of

this genre. The pan has a smooth massecuite flow path and typically uses eight

compartments, each with mid-compartment partial baffles. The partial baffles also

serve as structural supports for the tube plate.

Compartment Size

Broadfoot and Allen (1977) showed by modelling that for CSTRs in series, the

optimum CV will result from increasing cell sizes along the pan so as to provide equal

crystal growth (approximately equal residence times) in each cell. This is the reason

for the increasing cell sizes used by FCB and SRI.

However, if the flow within each cell approximates plug flow, there is no merit in

varying the size of cells. The new pan aims for such plug flow within each cell and

therefore uses equal cell sizes along the pan. Strong lateral circulation can be clearly

seen in the pans, vindicating the equal cells decision.

Note that with equal cells, the greater crystal population per cell at the front end of the

pan may require a higher feed rate to these cells but, if so, this is easily

accommodated automatically by the feed controls.

Circulation: Natural and Induced

Rapid growth of crystals requires that they be continuously surrounded by a suitably

supersaturated sucrose solution. For all crystals to grow at an even rate, they must

all be equally exposed to this condition and for equal periods. Paradoxically, it is

therefore vital that the circulation in an equal compartment CVP be constrained in

order to approximate plug flow yet be sufficiently turbulent to mix and replenish the

liquor films bounding the crystals.

4

The boiling process induces natural circulation. The vapour bubbles that form lower

the effective density and cause a bubble lift. Smooth-bored vertical tubes provide

good heat transfer and offer the least hydraulic resistance [maximum bubble-lift] per

unit of heating area. They are generally accepted as the most efficient for circulation.

For the upward circulation to be effective there must also be a sufficient unheated

downcomer area for massecuite return. The ratio of flow area to wall surface in this

area should be high. Long, narrow [high aspect ratio] vessels that are otherwise good

for plug flow cannot meet this requirement and may suffer poor circulation.

Circulation on Maidstones original FCB pan was poor until steam jiggers were

added (Graham and Radford, 1977). Circulation in the long-path, square-tubed

Racecourse CVP was improved considerably when the hydraulic friction was

reduced by the removal of 120 m

2

of baffles (Attard, 1993).

The best natural circulation appears to be achieved by long flow path, multi-cell,

vertical tube pans so the new pan is of this type.

In some circumstances the natural circulation needs augmenting. The VKTs use

mechanical stirrers to prevent conglomerates in high purity boilings. However, the

simplest means to induce circulation is by steam jiggers (a supply of finely dispersed

steam bubbles) beneath the calandria. These have been criticised as being wasteful

of steam energy but this need not be so. The new pan, for instance, has been

specifically designed to use calandria incondensables, supplemented by calandria

vapour, for jigger purposes.

Pan controls

The near steady state of a CVP makes it simpler to control than a batch pan but

accurate and reliable controls are essential because the consequences of any

deviation nucleation of new crystals or lumps from over-brixing for instance are

severe. It is critical that the condition of the massecuite be measured and controlled

along the pan. Depending on the seed, the type of boiling and the size of the CVP,

the most appropriate number of control points may be as few as 6 or as many as 12.

Love (2001) has shown that on/off feed control is technically superior to modulated

control in this application. The accuracy of control attainable from an on-off system is

shown by the trend plots in Figure 2 from the first pan shortly after commissioning.

This system is used on all of the pans, with high grade pans controlled by RF and low

grade usually controlled by lower cost conductivity sensors.

Figure 2: Conductivity Trends, Westfield C pan

5

Steam and Energy Usage

Because of their low boiling heads and their higher heating surface / volume ratio

during the final brixed-up stages of boiling, CVPs can usually operate on a lower

grade of vapour than an equivalent batch pan. They are also more energy efficient

because they take a steady steam flow and do not dissipate energy between boilings.

Many pans suffer from stagnant areas remote from the steam inlet where boiling is

absent or less vigorous than elsewhere. These are usually due to the accumulation

of incondensable gases, often because of poor steam passage design. More venting

can sometimes restore boiling in such areas but this is obviously wasteful. It is better

to ensure that steam velocities are maintained throughout the calandria.

Horizontal steam tubes are probably best in this regard but this compromises the

massecuite flow path. The calandria of the new CVP uses simple internal baffles to

ensure that steam velocities are maintained, even at the end remote from the steam

supply. Numerous outlets are provided to drain the condensate into the special

condensate chamber and, as has been mentioned already, incondensable gases are

used as jigger thereby eliminating energy loss from calandria venting. The pans

can be seen to boil vigorously over the entire calandria surface.

Pan availability

In service, deposits on pan heating surfaces may reduce heat transfer and/or lumps

may impede flow. The pan then has to be taken off line and boiled out on water. Pan

availability is determined by the frequency and difficulty of these boil-outs.

Encrustation, build-ups and lump formation can all be serious problems in CVPs:

encrustation is caused by massecuite splash adhering to surfaces above the

massecuite level, build-ups occur below the massecuite surface and lumps occur

when either of the above break loose. An acceptable pan design needs to inhibit all

of these.

Encrustation

Any hot surfaces are potential encrustation zones and the propensity for encrustation

is much greater with higher purities. Research and operating experience has shown

that no surface finish, additive or material completely prevents encrustation but a

liquor film will prevent it. Broadfoot et al (1989) showed that there was sufficient

condensation on the cooler shell surfaces (even though lagged) to prevent

encrustation.

The design of the new pan counters encrustation by:

minimising internal surfaces in the most susceptible zone [the intermediate

baffles extend only to surface level];

providing cooling along the top of other internal partitions to create a

condensation film;

having no heated surfaces (e.g. steam pipes, incondensable vent lines or feed

pipes) inside the pan above the massecuite level; and

ensuring appropriate and sufficient feed controls and injection points in each

compartment;

Build-ups

Build-ups arise mainly from a poor massecuite flow pattern, poor circulation or

solidification on cool surfaces. In contrast to the situation above, cool surfaces within

the massecuite raise viscosity and reduce or stop the flow.

6

Even in pans with good flow, build-ups often occur at the end of the downflow zone

on the cool lower shell area beneath the calandria, particularly at reduced throughput

rates. These are not easily dissolved by water boiling.

In addition to good flow, the design counters this problem by:

distributing the hot feed liquor injection and some sight glass purging steam

[incondensables] across the lowest surface of the shell;

incorporating large transfer passages between compartments; and

using the unique condensate collection chamber to provide a steam-heated

wall under the massecuite beneath the calandria;

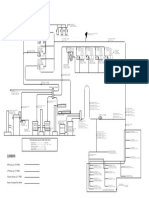

The condensate collection chamber can be seen in the cross-section of the new CVP

[Figure 3]. This not only inhibits build-ups but also provides significant additional

heating surface in the correct area to promote upward circulation into the calandria

tubes.

Feed Feed

Steam and Condensate

Chamber

Figure 3: Steam-heated Surface beneath Calandria

Lumps

No lumps will occur if encrustation or build-ups are prevented. Encrustations usually

break up quickly in turbulent zones and are easily dispersed in the massecuite but

lumps from build-ups are more troublesome, so the prevention of sub-surface build-

ups is particularly important.

RESULTING DESIGN

As discussed above, the most logical and successful genre of CVP is the horizontally

arranged, long flow path, multi-cell type with vertical tubes. The design therefore followed

this blueprint but added a number of innovations to enhance critical performance areas.

7

Unique features of the new CVP are:

Built-in heating beneath calandria: the steam-heated condensate chamber provides

additional heating to the massecuite beneath the calandria, promoting circulation and

inhibiting build-up in this area. [The extra heated area is equal to approximately 5% of

the tube surface].

High heating surface, low steam pressure: the heating surface area / volume ratio

[excluding the additional under-calandria heating area] in the standard designs is higher

than offered by most competitors.

Smooth massecuite flows: the new pan achieves a smooth-flow profile using constant

radii for all curved surfaces.

Mid-compartment baffles: mid-compartment partial baffles in the most active flow zones

above and below the calandria, reinforce plug flow and effectively give the characteristics

of additional cells, without impeding free circulation in the downcomers.

Operator friendly: all valves and controls are easily accessed from control platform

none under the pan or above operator reach. Sight glasses are also at a convenient

level and access for internal inspection is by a large, easily accessible, manway.

Visible condensate flows: the condensate flows from multiple drains along the

calandria which ensure free drainage; the flows can be clearly seen through sight glasses

in the condensate chamber. This is a popular feature for operators.

Baffled calandria steam passages: steam flows through the calandria are guided by

baffles which ensure no dead zones and effective purging of incondensable gases.

Unique feed distribution: the syrup / molasses feed is distributed over the entire area

beneath the calandria, through nozzles that can be easily cleaned if necessary.

No separate jiggers: the syrup / molasses feed arrangements are such that no

independent jigger supplies are needed.

PERFORMANCE OF THE NEW CVPS

As is to be expected, the design concepts were refined as results were obtained from the first

pans put into service.

Early experience

Four of the CVPs had been commissioned by the end of 2002 and all boiled

vigorously, meeting the design evaporation criteria. However, it was noted that

performance on two of the C pans reduced after 3 to 5 weeks: boiling remained

vigorous along the outer parts of the calandria but was flat towards the middle.

When one pan was opened, it was found that some of the tubes along the centre of

the pan had become partially or completely blocked with massecuite. This was of

serious concern, as these pans had been expected to operate for longer periods

between boil-outs.

The cause of the problem was identified as the single line molasses feed position:

flash from the feed was inducing a strong up-flow immediately above the feed point,

effectively cutting off the intended circulation pattern below the calandria and lifting

most of the massecuite through the outer zone of the calandria. Above the calandria,

the high level in this area impeded the outflow from the middle of the pan, resulting in

fairly static massecuite settling and hardening in the middle tubes.

8

The problem was resolved by splitting the feed into two lines, with a small amount

along the original position (to maintain movement in the trough) and the rest injected

about half way across the calandria. Following this change, all of the original pans

now operate well.

That original experience also prompted a detailed review of the entire pan design so

that newer pans are significantly improved, while retaining the unique patented

features: the profile has been smoothed so that no feed is now needed in the trough

and a new well-distributed feed system has been designed. The jigger steam

arrangements have also been changed. The two profiles are compared in Figure 4 :

Figure 4: Comparison of Original and New Profiles

The new profile is remarkably similar to the best profile derived from a recent

computational fluid dynamics analysis of circulation patterns in continuous pans

(Echeverri et al. 2005).

Performance tests

Two of the more recent pans, one an A pan at Flacq United Estates [FUEL],

Mauritius and the other a C pan at Nghe An [NAT&L], Vietnam, have been subject to

detailed independent analysis to measure their performance in the two critical

parameters of crystal size distribution (CV) and heat transfer rate (HTC).

Residence Time Distribution

To evaluate the 8-compartment NAT&L pan, the South African Sugar Milling

Research Institute [SMRI] was commissioned to specify crystal residence time test

procedures. They designed the test and subsequently interpreted the results

according to the procedures described by Rein et al (1985).

The atomic absorption spectrometer lithium analyses were performed by the quality

assurance and testing center of the Vietnam Directorate for Standards and Quality.

The test was conducted over 22 and 23 December 2006. Conditions were not ideal,

being at a time of low and uneven throughput, but the results were nevertheless

good.

9

Figure 5 shows the actual lithium tracer pattern compared to the best fit model, which

was for 18 CSTRs:

-0.5

0

0.5

1

1.5

2

2.5

3

3.5

0 500 1000 1500 2000

Ti me (mi n)

E

(

t

)

E(t) model

E(t) actual

Figure 5 : Actual NAT&L tracer vs. 18 CSTR model

No tracer emerged in the first 3 hours, showing no short circuiting, and the low tail

values indicated minimal hold-up areas. The high number of equivalent CSTRs

confirms that the massecuite flows through the pan in a circulating spiral path with

near to true plug flow.

The ratio of equivalent CSTRs to actual compartments is 2.3, better than any

previously reported [see Table 1].

No lithium tracer testing was done at FUEL because of the special circumstances

there. The pan was specified to handle all the A massecuite after a future factory

expansion but the expansion was deferred. In addition, the factory secured contracts

to supply about 25% of its production as EEC special sugars which required the use

of all the batch pans, including the one which had been intended for conditioning

seed for the continuous pan.

Three of the 12 compartments in the CVP have therefore been temporarily isolated

on the massecuite side and export quality sugar is produced directly from

unconditioned magma produced in a screw conveyor beneath continuous B

centrifugals. SMRI tests have shown that the high CV of the seed material is reduced

by about 7 units through the pans nine compartments.

Heat Transfer Coefficients and Steam Usage

The evaporation rate is an important CVP design parameter and is directly related to

the overall heat transfer coefficient [HTC] achieved. The HTCs achieved at both

FUEL and NAT&L were therefore measured.

HTCs in continuous pans can vary widely, depending mainly on massecuite purity

and brix but other factors include the nature of the impurities, the T between

massecuite and steam, boiling temperature and tube cleanliness. These variables

produce normal ranges of HTCs that cover the results measured from many pans.

10

The Audubon Sugar Institute recently reported average measurements from CVPs in

Louisiana factories that fall neatly within these ranges (Anon, 2005, p.9). However,

the HTCs measured on the new pans were at or significantly above the upper limit as

shown in Table 2:

Table 2 : Comparison of Continuous Pan HTCs [kW/mK]

Normal Range Louisiana SKIL/Bosch

Massecuite Low High

A 0.2 0.44 0.32 0.54

B 0.14 0.30 0.17 n/a

C 0.11 0.22 0.16 0.22

The HTC is related to the T between steam and massecuite: a certain minimum T

being necessary to get any meaningful heat transfer through the overall resistance,

after which the HTC is proportional to T.

It is widely held by technologists that a minimum T of about 25 K is necessary for

satisfactory continuous pan boiling. Confirmation of the high HTC on the FUEL A

pan is that it was boiling vigorously and evaporating at 20.6 kg/m

2

with a T of only

24.5 K when tested. This was four days after a boil-out and no jigger steam was

being used.

The HTC of the NAT&L pan shown in Table 2 is the average of results measured on

nine different daily runs in December 2006 and January 2007. This was a low

throughput period during which the average steam temperature in the calandria was

96.9C and average massecuite temperature 73.9C, giving a T of only 21 K. Jigger

steam was used to maintain vigorous boiling under the exceptionally low T.

Moor (2002) pointed out that CVP circulation can be boosted by using free

incondensable gas jiggers in a suitably designed pan. Although jigger steam is not

usually used on the FUEL. pan, this principle is used in providing purging steam to

the feed sight glasses.

The high HTCs and low Ts on the pans enable the use of low grade vapours for

boiling. The FUEL pan, for instance, boils on vacuum V3 at 93.5 K [80 kPa abs.],

thereby maximising overall factory energy efficiency.

Encrustation and Build-up

A CVPs are most liable to encrustation. There are techniques to extend the cleaning

intervals but they usually need to be boiled out weekly or two-weekly because of

sugar settling in the base, lumps from encrustation in low-circulation tubes or build-up

on surfaces above the massecuite. All of these have been countered in the new

design: FUELs A pan is routinely operated for 3 to 4 weeks between boil-outs.

Boiling out is a short and simple operation.

Low grade CVPs can operate for longer periods between boil-outs. The pan at

NAT&L is usually boiled out once or twice during the season with no special

measures taken to reduce the build-up rate.

Exhaustion

In the end though, it is good exhaustion that is required of the pan, whether on A, B

or C duty. Exhaustion data for the two test pans are presented in Table 3 [over]

where

) - 100 *(

* 10000

Liquor Mother Massecuite

Drop

Exhaustion Pan =

11

Table 3 : Exhaustion Data [%]

Pol-Refractometer Purity Exhaustion

Factory Duty Period

Massecuite Mother

Liquor

Drop

Test 87.20 68.80 18.4 67.6

FUEL A

Crop 06 88.50 72.10 16.4 66.4

Test 54.95 31.51 23.4 62.3

NAT&L C

March 07 58.50 32.76 25.7 65.4

The NAT&L figures in Table 3 have been converted from original hydrometer (spindle) brix data

using relationships established by MacGillivray and Graham (1969).

However, so many factors affect exhaustion including feedstock quality and

operating practices beyond the control of the design engineer that comparisons

must be treated with care, even when comparing one pan at different times of the

crop period.

CONCLUSIONS

By drawing on the best features of established designs and adding innovative improvements,

the new pan has been able to meet or exceed conventional performance standards for each

of the key criteria of CVP design.

REFERENCES

Anon. (2005). Audubon Sugar Institute Annual Report, 2004-2005. LSU AgCenter

Communications, Saint Gabriel, LA. 32 p.

Arcidiacono, G., Pike, D., Scanlan, J. and Mclean, R.J.B. (1992). The continuous B

massecuite pan at Tully Mill. Proc. Aust. Soc. Sugar Cane Technol.14: 276-286.

Attard, R.G. (1993). Modifications to the Racecourse continuous pan. Proc. Aust. Soc.

Sugar Cane Technol. 15: 180-185.

Broadfoot, R. (1992). Designing continuous pans for narrow crystal size distributions and

improved cost performance. Proc. Aust. Soc. Sugar Cane Technol. 14: 266-275.

Broadfoot, R., Miller, K.F. and Davies, L.W. (1989). Commissioning trials on the SRI

continuous high grade pan at Maryborough factory. Proc. Aust. Soc. Sugar Cane

Technol. 11:152-161.

Broadfoot, R. and Allen, J.R. (1977). Continuous low grade massecuite boiling studies.

Proc. Int. Soc. Sug. Cane Technol., 16: 2667-2677.

Echeverri, L.F., Rein, P.W. and Acharya, S. (2005). Numerical and experimental study of

the flow in vacuum pans. Proc. Int. Soc. Sug. Cane Technol., 25: 212-222.

Graham, W.S. and Radford, D.J. (1977). A preliminary report on a continuous pan. Proc S

A Sugar Technol Ass 51: 107-111.

Love, D.J. (2001). The use of on/off feed control for pan boiling. Proc S. A. Sugar Technol.

Ass. 75: 292-297.

Moor, B.St.C. (2002). Energy aspects of assisted pan circulation. Presentation at ISSCT

Energy Management Worksop, Berlin, October 2002.

Rein, P.W., Cox, M.G.S. and Love, D.J. (1985). Analysis of crystal residence time

distribution and size distribution in continuous boiling vacuum pans. Proc. S.A. Sugar

Technol. Ass. 59: 58-67.

Thelwall, J.C.deC. (2000). Features of continuous vacuum pan design. Int. Sugar Jnl. 102

No.1224: 630-637.

You might also like

- Performance of An Improved Pan Stirrer A PDFDocument12 pagesPerformance of An Improved Pan Stirrer A PDFbkarakoseNo ratings yet

- Vaccum Pan Circulator PDFDocument10 pagesVaccum Pan Circulator PDFMiguel MurilloNo ratings yet

- 10-Refinery Control, Aug. 09, 2017Document12 pages10-Refinery Control, Aug. 09, 2017jantskieNo ratings yet

- Brix Curve 2022-23.Document6 pagesBrix Curve 2022-23.Mohit SrivastavaNo ratings yet

- Colorants Through Cane Sugar RefiningDocument38 pagesColorants Through Cane Sugar RefiningRaymund GatocNo ratings yet

- Daqahlia Sugar Co. sugar production flow chartDocument15 pagesDaqahlia Sugar Co. sugar production flow chartAhmed M. Abdel HamedNo ratings yet

- Continuous Pan Operation ManualDocument12 pagesContinuous Pan Operation Manualsandi promonoNo ratings yet

- Ign Schematic Block Diagram of Sugar ProcessingDocument1 pageIgn Schematic Block Diagram of Sugar ProcessingTung Bui ThanhNo ratings yet

- Stirrer For Vacuum PanDocument8 pagesStirrer For Vacuum PanLong Bui ThanhNo ratings yet

- 2005 Jounet Falling Film Evaporators in Cane Sugar Mills PDFDocument12 pages2005 Jounet Falling Film Evaporators in Cane Sugar Mills PDFnghiNo ratings yet

- Removal of Suspended Fine Particulate Matter From Raw Juice PPT ScribdDocument45 pagesRemoval of Suspended Fine Particulate Matter From Raw Juice PPT ScribdKunchey JagadeeshNo ratings yet

- Vacuum PanDocument7 pagesVacuum Pananon_33049728No ratings yet

- Effect of Non-PolDocument6 pagesEffect of Non-PolKevynNo ratings yet

- LionnetDocument537 pagesLionnetYadav Shweta100% (2)

- 07-Refined Sugar Boiling, Jul. 26, 2017Document16 pages07-Refined Sugar Boiling, Jul. 26, 2017jantskie100% (1)

- 21Document29 pages21Remington SalayaNo ratings yet

- Sugarcane ComputeDocument12 pagesSugarcane ComputeJun Burias Padilla100% (1)

- SRI Jigger Tubes System: Design, Installation and Commissioning ManualDocument16 pagesSRI Jigger Tubes System: Design, Installation and Commissioning ManualSebastiánSaltarenNo ratings yet

- C-Massecuite Reheater: A Member ofDocument2 pagesC-Massecuite Reheater: A Member ofDave C100% (1)

- Material & Energy Balance (Jaggery)Document1 pageMaterial & Energy Balance (Jaggery)Arif ShafiNo ratings yet

- Trials of A New Stirrer-Less Juice Sulphiter at Experimental Sugar FactoryDocument4 pagesTrials of A New Stirrer-Less Juice Sulphiter at Experimental Sugar FactoryInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- 1974 Murray Filtering Quallity of RAw Sugar - Mechanism of Starch Influence in CarbonatationDocument11 pages1974 Murray Filtering Quallity of RAw Sugar - Mechanism of Starch Influence in CarbonatationnghiNo ratings yet

- Multiple Effect Evaporator Online CalculationsDocument1 pageMultiple Effect Evaporator Online CalculationsRajdeepsinhNo ratings yet

- Triple Effect Evaporators Heating Surface AreaDocument2 pagesTriple Effect Evaporators Heating Surface AreaArif ShafiNo ratings yet

- Milk or Lime or Lime Saccharate PDFDocument2 pagesMilk or Lime or Lime Saccharate PDFAnand AtreNo ratings yet

- Quadruple Evaporator EvaluationDocument8 pagesQuadruple Evaporator EvaluationRemington SalayaNo ratings yet

- Instrumentation & Control of Continuous Vacuum Pans: by M.A. GetazDocument28 pagesInstrumentation & Control of Continuous Vacuum Pans: by M.A. GetazJavier Manuel IbanezNo ratings yet

- Chemical Control (Ansi Sugar Tech. Third Year) : by Dr. Jahar Singh Apst NsikanpurDocument24 pagesChemical Control (Ansi Sugar Tech. Third Year) : by Dr. Jahar Singh Apst NsikanpurSameer Agale100% (1)

- KJHGDocument18 pagesKJHGSandeep Yäðäv100% (1)

- Design and Development of Sand Bed FilterDocument22 pagesDesign and Development of Sand Bed FilterAncuta TrifoiNo ratings yet

- 1997 - Walthew - Chemical Cleaning of Evaporators PDFDocument8 pages1997 - Walthew - Chemical Cleaning of Evaporators PDFsanjay ukalkarNo ratings yet

- Optimization of Milling Performance of A Sugar Mill by UsingDocument12 pagesOptimization of Milling Performance of A Sugar Mill by Usingduraiprakash830% (1)

- RAPIDORRDocument12 pagesRAPIDORRKris FloraNo ratings yet

- 1999 - Peaceock - Robust Designs Evaporator Station - 2 PDFDocument14 pages1999 - Peaceock - Robust Designs Evaporator Station - 2 PDFnghiNo ratings yet

- Sugar Cane Juice EvaporatorDocument9 pagesSugar Cane Juice EvaporatornghiNo ratings yet

- 1994 Gibbon Cad Thrashplate DesignDocument3 pages1994 Gibbon Cad Thrashplate DesignnghiNo ratings yet

- Chemical Control PDFDocument85 pagesChemical Control PDFHarshit Khare100% (1)

- Blowdown Economizer CalculationDocument2 pagesBlowdown Economizer CalculationSajjad AhmedNo ratings yet

- Cozimiento COLOMBIADocument10 pagesCozimiento COLOMBIAJavier Manuel IbanezNo ratings yet

- Modeling Sucrose Crystallization Responses to Process FluctuationsDocument18 pagesModeling Sucrose Crystallization Responses to Process FluctuationsArtit BoonkoomNo ratings yet

- SRI Jigger Tubes System Delivers Improved Vacuum Pan PerformanceDocument2 pagesSRI Jigger Tubes System Delivers Improved Vacuum Pan PerformanceRoberto Rasgado MarroquinNo ratings yet

- Steam Temp. Required Steam Temp. Initial Steam Pressure. Final Steam Pressure. Added Water TempDocument3 pagesSteam Temp. Required Steam Temp. Initial Steam Pressure. Final Steam Pressure. Added Water TempBrijesh SrivastavNo ratings yet

- Brine Recovery in Sugar Refinery Using Poresep Membrane SolutionDocument3 pagesBrine Recovery in Sugar Refinery Using Poresep Membrane SolutionLalit VashistaNo ratings yet

- Evaporator: Department of Chemical EngineeringDocument16 pagesEvaporator: Department of Chemical EngineeringspidyNo ratings yet

- Liquid - Liquid Heater (Condensate or Duplex Juice Heater) CalculationDocument8 pagesLiquid - Liquid Heater (Condensate or Duplex Juice Heater) CalculationYounas SardarNo ratings yet

- Reference Control PhilosophyDocument22 pagesReference Control PhilosophyReno MurdaNo ratings yet

- DMRDocument4 pagesDMRkyamanywa richardNo ratings yet

- 02 Affination Mingling Centrifugation MeltingDocument2 pages02 Affination Mingling Centrifugation MeltingjantskieNo ratings yet

- In Line Shredder: Keep Your CarrierDocument2 pagesIn Line Shredder: Keep Your CarrierOmar Ahmed ElkhalilNo ratings yet

- 5000tcd PDFDocument114 pages5000tcd PDFAli HyderNo ratings yet

- An Experience of (04) Massecuite Boiling System at Sanghar Sugar Mills LTDDocument11 pagesAn Experience of (04) Massecuite Boiling System at Sanghar Sugar Mills LTDHayat Ur Rahim KhanNo ratings yet

- Selection of The Operating Parameters in SugarDocument18 pagesSelection of The Operating Parameters in SugarJavier Manuel IbanezNo ratings yet

- Capacity Curing Management of Continuous Centrifugal MachinesDocument42 pagesCapacity Curing Management of Continuous Centrifugal MachinesArun GuptaNo ratings yet

- Short Notes For InterviewDocument15 pagesShort Notes For InterviewMuhammad Arif ShafiNo ratings yet

- Mechanical vapor recompression and multiple effect evaporator system reduces steam usageDocument13 pagesMechanical vapor recompression and multiple effect evaporator system reduces steam usageMariAle Droz CastroNo ratings yet

- Steam Balance Layout (TPH) ModelDocument1 pageSteam Balance Layout (TPH) ModelRemington SalayaNo ratings yet

- Maximizing Throughput of a 9m TowerDocument18 pagesMaximizing Throughput of a 9m TowerTheodoros AtheridisNo ratings yet

- 2019 Moor BSTC and Du Plessis N. Refereed Paper. Strategies To Optimise Continuous Pan PerformanceDocument9 pages2019 Moor BSTC and Du Plessis N. Refereed Paper. Strategies To Optimise Continuous Pan Performancemarcio_limaNo ratings yet

- Dec06feature PDFDocument4 pagesDec06feature PDFAmgad_SNo ratings yet

- Typical Outloading SystemDocument1 pageTypical Outloading Systemcumpio425428No ratings yet

- Storm Surge Typhoon RubyDocument5 pagesStorm Surge Typhoon Rubycumpio425428No ratings yet

- Barchart SteleronDocument4 pagesBarchart Steleroncumpio425428No ratings yet

- Outloading SystemDocument1 pageOutloading Systemcumpio425428No ratings yet

- PPA Panganiban PortDocument1 pagePPA Panganiban Portcumpio425428No ratings yet

- Jetty Draft SurveyDocument1 pageJetty Draft Surveycumpio425428No ratings yet

- 30,000 DWT Dolomite Outloading FacilityDocument2 pages30,000 DWT Dolomite Outloading Facilitycumpio425428No ratings yet

- Auxin Price Itugon (Sangilo) Rev. 3Document3 pagesAuxin Price Itugon (Sangilo) Rev. 3cumpio425428No ratings yet

- Weight Per Course Tank ADocument1 pageWeight Per Course Tank Acumpio425428No ratings yet

- Letter Cash Advances of MonsantoDocument2 pagesLetter Cash Advances of Monsantocumpio425428No ratings yet

- Auxin Price MargaritaDocument2 pagesAuxin Price Margaritacumpio425428No ratings yet

- Rice Mill Final Set-up2-ModelDocument1 pageRice Mill Final Set-up2-Modelcumpio425428No ratings yet

- Abcumpio MJV DP BillingDocument1 pageAbcumpio MJV DP Billingcumpio425428No ratings yet

- Telequip Inc. bid proposal review September 2015Document1 pageTelequip Inc. bid proposal review September 2015cumpio425428No ratings yet

- Weight of Steel PlateDocument1 pageWeight of Steel Platecumpio425428No ratings yet

- Fire Protection Labor Cost Final (Riofil Ref)Document2 pagesFire Protection Labor Cost Final (Riofil Ref)cumpio425428No ratings yet

- A.B. Cumpio Engineering Services: Agro Power PhilippinesDocument3 pagesA.B. Cumpio Engineering Services: Agro Power Philippinescumpio425428No ratings yet

- SDP of Dump PitDocument1 pageSDP of Dump Pitcumpio425428No ratings yet

- 12.5 Ton Per Hour Sugar RefineryDocument1 page12.5 Ton Per Hour Sugar Refinerycumpio425428No ratings yet

- You Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterDocument7 pagesYou Created This PDF From An Application That Is Not Licensed To Print To Novapdf Printercumpio425428No ratings yet

- Affidavit of LossDocument1 pageAffidavit of LossNowhere Man100% (1)

- Price Proposal For Pulp SamplerDocument2 pagesPrice Proposal For Pulp Samplercumpio425428No ratings yet

- CC F 02262015Document1 pageCC F 02262015cumpio425428No ratings yet

- Proposed Outloading Facilities of OreDocument1 pageProposed Outloading Facilities of Orecumpio425428No ratings yet

- CCF02212015 0001Document1 pageCCF02212015 0001cumpio425428No ratings yet

- Ore Asia Thickener QuoteDocument2 pagesOre Asia Thickener Quotecumpio425428No ratings yet

- CC F 02112015Document1 pageCC F 02112015cumpio425428No ratings yet

- Bangladesh Turbo GeneratorDocument1 pageBangladesh Turbo Generatorcumpio425428No ratings yet

- TVI Venture Nickel Outloading Facilities-ModelDocument1 pageTVI Venture Nickel Outloading Facilities-Modelcumpio425428No ratings yet

- Adsorption Tank DesignDocument4 pagesAdsorption Tank Designcumpio425428No ratings yet

- Absorption Cooling and On - Energy Dynamics LimitedDocument122 pagesAbsorption Cooling and On - Energy Dynamics Limitedjamesbrown100100% (2)

- Light EnergyDocument23 pagesLight EnergySarveshrau Sarvesh100% (1)

- Chemical Feed Rate Calculations: Equation 1Document2 pagesChemical Feed Rate Calculations: Equation 1Tifano KhristiyantoNo ratings yet

- Course Pac PDFDocument150 pagesCourse Pac PDFfadelNo ratings yet

- Periodic Table Unit TestDocument4 pagesPeriodic Table Unit Testapi-303120399No ratings yet

- pH Properties of Acids, Bases, and SaltsDocument30 pagespH Properties of Acids, Bases, and SaltsFiroz Bakht Ahmed50% (2)

- Evaluation Performance of Different Types Catalysts of An Industrial Secondary Reformer Reactor in The Ammonia PlantsDocument9 pagesEvaluation Performance of Different Types Catalysts of An Industrial Secondary Reformer Reactor in The Ammonia PlantsERIKO DARMAWANNo ratings yet

- COMSOL Model of Halothane Vaporizer For The Developing WorldDocument19 pagesCOMSOL Model of Halothane Vaporizer For The Developing Worldapi-318956624No ratings yet

- Particulate Pollutants Emission Control TechnologiesDocument72 pagesParticulate Pollutants Emission Control TechnologiesalyaNo ratings yet

- Eagle Brochure 5Document3 pagesEagle Brochure 5Adnan KhalidNo ratings yet

- AP Chemistry Course OverviewDocument1 pageAP Chemistry Course OverviewhersheymkmNo ratings yet

- Entropy Balance: Prof. Dr. Uğur AtikolDocument14 pagesEntropy Balance: Prof. Dr. Uğur AtikolRajesh ShuklaNo ratings yet

- Co (NH3) 6Document1 pageCo (NH3) 6Ayotunde OnasanyaNo ratings yet

- Optimizing Relative Humidity Based On The Heat Transfer Terms of The Thermoelectric Atmospheric Water Generator (AWG) : Innovative DesignDocument10 pagesOptimizing Relative Humidity Based On The Heat Transfer Terms of The Thermoelectric Atmospheric Water Generator (AWG) : Innovative Designmmk.mech59No ratings yet

- Gas Dispersed EquipmentDocument20 pagesGas Dispersed EquipmentAshish SrivastavaNo ratings yet

- LAB - 6 - Factors That Affect Enzyme ActivityDocument2 pagesLAB - 6 - Factors That Affect Enzyme ActivityRaqsNo ratings yet

- Chem XRD Diff Lecture 6Document71 pagesChem XRD Diff Lecture 6Công Bùi ChíNo ratings yet

- Le Châtlier’s Principle EquilibriumDocument4 pagesLe Châtlier’s Principle EquilibriumirfanNo ratings yet

- Directional Anisotropy of The Vibrational Modes in 2D-Layered PerovskitesDocument9 pagesDirectional Anisotropy of The Vibrational Modes in 2D-Layered PerovskitesDibyajyoti GhoshNo ratings yet

- 1099 06902920003C25013Aaid Ejoc25013b2 SDocument6 pages1099 06902920003C25013Aaid Ejoc25013b2 SmeitaNo ratings yet

- FORINSTDocument7 pagesFORINSTYoMomma PinkyNo ratings yet

- Lyophilization/Freeze Drying - An Important Pharmaceutical ProcessDocument12 pagesLyophilization/Freeze Drying - An Important Pharmaceutical ProcessavrupaveasyaNo ratings yet

- DifusionDocument5 pagesDifusionDiego Ignacio Valderrama SotoNo ratings yet

- Handbook of Heterogeneous Catalysis, G. Ertl, H. Közinger, J. WeitkampDocument40 pagesHandbook of Heterogeneous Catalysis, G. Ertl, H. Közinger, J. WeitkampFederico BogettiNo ratings yet

- 1 s2.0 S2772801322000185 Main 2Document17 pages1 s2.0 S2772801322000185 Main 2Mani VrsNo ratings yet

- Solute Solvent Interactions PPI BPII - IDocument32 pagesSolute Solvent Interactions PPI BPII - IYuppie Raj100% (2)

- Elektrogravimetri PDFDocument13 pagesElektrogravimetri PDFYuliaKamilawatiIINo ratings yet

- Binary Distillation: SHR Chapter 7Document17 pagesBinary Distillation: SHR Chapter 7Astrid CastellanoNo ratings yet

- WS1.3 MeABP IterationDocument19 pagesWS1.3 MeABP Iteration李天No ratings yet

- Chapter A 06 RefrigerationDocument18 pagesChapter A 06 RefrigerationСергей КороткийNo ratings yet