Professional Documents

Culture Documents

03C - Extended Surfaces

Uploaded by

Yuneo NurcahyaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

03C - Extended Surfaces

Uploaded by

Yuneo NurcahyaCopyright:

Available Formats

Chapter 3

Extended Surfaces / Fins

Chapter 3

Extended Surfaces (Fins)

An extended surface (also known as a combined conduction-

convection system or a fin) is a solid within which heat transfer by

conduction is assumed to be one dimensional, while heat is also

transferred by convection (and/or radiation) from the surface in a

direction transverse to that of conduction

36

Chapter 3

Heat Transfer from Extended Surfaces

Extended surfaces may exist in many situations but are commonly

used as fins to enhance heat transfer by increasing the surface

area available for convection (and/or radiation).

37

Chapter 3

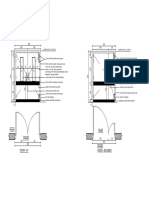

Typical Fin Configurations

38

Chapter 3

Fins of Uniform Cross-Sectional Area

Assuming one-dimensional, steady-state conduction in an extended

surface of constant conductivity and uniform cross-sectional area with

negligible generation and radiation, the fin equation is of the form:

0

2

2

=

) ( T T

kA

hP

dx

T d

c

where p is the fin perimeter

39

= T T

b b

u

= T x T ) ( u

Define:

(3.6.1)

Chapter 3

Boundary Conditions

At the base T = T

b

or u(0)=u

b

At the tip:

Case A: Convection heat transfer

Case B: Adiabatic tip

Case C: Prescribed temperature,

u(L)=u

L

Case D: Infinite fin, T(L)=T or

u(L)=0

Case A

40

Chapter 3

Solutions of Differential Equation

) (

= T T hPkA q

b c f

41

(3.6.2)

Chapter 3

True or False?

Heat is transferred from hot water flowing through a tube to air flowing

over the tube. To enhance the heat transfer rate the fins should be

installed on the tube interior surface (the hot water side)

Fins are particularly beneficial when h is small (typical for a gas or

when only natural convection exists).

Ideally the fin material should have a large thermal conductivity to

minimize temperature variations from its base to its tip.

Chapter 3

Selection of fin material (Example 3.9)

k

Cu

>k

Al

>k

SS

(1)

(2)

(3)

SS

Al

Cu

Chapter 3

Example: Problem 3.116

Assessment of cooling scheme for gas turbine blade.

(a) Determine whether the blade temperature is less than the maximum

allowable value (1050 C) for the prescribed operating conditions

(b) Evaluate blade cooling rate.

Assume that convective heat losses from the surface are negligible, i.e.

adiabatic tip condition.

42

Chapter 3

Fin Performance

Fin effectiveness: Ratio of the fin heat transfer rate q

f

to the heat transfer

rate that would exist without the fin

b b c

f

f

hA

q

u

c

,

=

c

f

should be as large as possible (at least >2)

For a very long (infinite) fin (Case D boundary condition):

2 1/

|

|

.

|

\

|

=

c

f

hA

kP

c

where u

b

=T

b

-T

, and A

c,b

is the fin cross-

sectional area at the base

43

(3.6.3)

(3.6.4)

Chapter 3

Fin Performance

f t

b

f t

b

f

R R

T T

q

, ,

u

=

=

Fin heat transfer rate:

where R

t,f

is the fin resistance

Can express fin effectiveness as a ratio of thermal resistances:

f t

b t

f

R

R

,

,

= c

where R

t,b

is the resistance due to

convection of the exposed base (=1/hA

c,b

)

44

Chapter 3

Fin Performance

Fin efficiency: The ratio of the actual heat transfer rate from the fin to the

maximum rate at which a fin could dissipate energy

b f

f f

f

hA

q

q

q

u

q = =

max

See Table 3.5 and Figures 3.18 and

3.19 for the efficiencies of common fin

shapes

f f

f t

hA

R

q

1

=

,

We can use the

efficiency to

calculate the fin

resistance

45

(3.6.5)

(3.6.6)

Chapter 3

Fin Arrays

Define the overall efficiency, q

o

as

) (

f

t

f

o

A

NA

q q = 1 1

where N is the number of fins in the

array, A

f

the surface area of each

fin and A

t

the total surface area.

We can then calculate the heat rate

for the fin array

b t o t

hA q u q =

Thermal resistance of the fin array

t o

o t

hA

R

q

1

=

,

) (

f

t

f

o

A

NA

q q = 1 1

46

b t

t t

o

hA

q

q

q

u

q = =

max

(3.6.7)

(3.6.8)

(3.6.9)

Chapter 3

Fin Manufacturing

Care must be exercised to

ensure that the thermal contact

resistance does not adversely

influence the overall fin

performance

47

Chapter 3

Example

As more components are placed on a single integrated circuit (chip),

the amount of heat dissipated increases. The maximum allowable chip

operating temperature, is approximately 75C. Suggest ways to

maximize heat dissipation.

Top view

Side view

Air, T=20C

48

Chapter 3

Fins in Heat Exchangers

Widely used to achieve large heat rates per unit volume, particularly when one

or both fluids is a gas.

Characterized by large heat transfer surface areas per unit volume (>700

m

2

/m

3

), small flow passages, and laminar flow.

Chapter 3

Fin (extended surface) effects

Fins reduce the resistance to convection heat transfer, by increasing

surface area.

The expression for the overall heat transfer coefficient includes overall

surface efficiency, or temperature efficiency, q

o

, of the finned surface,

which depends on the type of fin (see also Ch. 3.6.5)

h o h o

h f

conduction

c o

c f

c o

hA A

R

R

A

R

hA UA ) ( ) ( ) ( ) (

"

,

"

,

q q q q

1 1 1

+ + + + =

(11.5)

where c is for cold and h for hot fluids respectively

You might also like

- Extended Surface Heat TransferDocument13 pagesExtended Surface Heat TransferDirkMyburghNo ratings yet

- 03C - Chapter 3 - Sec 3.6Document13 pages03C - Chapter 3 - Sec 3.6cmegmhiNo ratings yet

- MAK 302L Experiment 3 Extended Surface Heat Transfer 1. PurposeDocument5 pagesMAK 302L Experiment 3 Extended Surface Heat Transfer 1. PurposeYEe FaNgNo ratings yet

- FINSDocument24 pagesFINSSivakumar SadasivamNo ratings yet

- 1213sem1 Me3122Document14 pages1213sem1 Me3122Nian Wee Wu0% (2)

- Natural Convection Cooling of Finned SurfaceDocument8 pagesNatural Convection Cooling of Finned SurfaceNikita ShresthaNo ratings yet

- Cooling Efficiency: 3.1 ScopeDocument7 pagesCooling Efficiency: 3.1 ScopenorimannNo ratings yet

- Finned TubeDocument4 pagesFinned Tubeknife2008No ratings yet

- Cemi - 321 - Lecture 6 - 2023Document13 pagesCemi - 321 - Lecture 6 - 2023Mare' TaljaardNo ratings yet

- Heat Transfer and Heat - ExchangersDocument6 pagesHeat Transfer and Heat - ExchangersVinh Do ThanhNo ratings yet

- Wolverine Tube Heat Transfer DATA BOOKch5 - 10Document20 pagesWolverine Tube Heat Transfer DATA BOOKch5 - 10ingemarquinteroNo ratings yet

- Heat Transfer and Insulation in Vacuum Furnaces: Harry W. AntesDocument3 pagesHeat Transfer and Insulation in Vacuum Furnaces: Harry W. AntesRajamannar SwamyNo ratings yet

- sm1 54Document1 pagesm1 54awoods12835No ratings yet

- HMT Answer 2 & 16 Marks HMTDocument85 pagesHMT Answer 2 & 16 Marks HMTChandra Sekar100% (3)

- 3.044 Problem Set 1: Heat Conduction Due Monday February 14, 2005Document3 pages3.044 Problem Set 1: Heat Conduction Due Monday February 14, 2005Carlos CastilloNo ratings yet

- Finned Tube Heat ExchangerDocument3 pagesFinned Tube Heat ExchangerShreya Sahajpal KaushalNo ratings yet

- Transient Conduction - Lumped Cap MTD - S1 2013-2014Document40 pagesTransient Conduction - Lumped Cap MTD - S1 2013-2014Elroy LeeNo ratings yet

- BA Graville-Chapter 3Document36 pagesBA Graville-Chapter 3Bhavana ValetiNo ratings yet

- Understanding Heat Flux Limitations CCTI 2010Document8 pagesUnderstanding Heat Flux Limitations CCTI 2010B rgNo ratings yet

- Boiler Heat FluxDocument8 pagesBoiler Heat FluxMubarik Ali100% (1)

- 67-Numerical On Condensation-18-Oct-2019Material - I - 18-Oct-2019 - Numericzls - On - Condensation PDFDocument10 pages67-Numerical On Condensation-18-Oct-2019Material - I - 18-Oct-2019 - Numericzls - On - Condensation PDFsiva yandraNo ratings yet

- Thermo-Fluid Engineering: Prof. XI Guannan (喜冠南)Document34 pagesThermo-Fluid Engineering: Prof. XI Guannan (喜冠南)noyakhalibivagh chaiNo ratings yet

- 6 Heat TransferDocument19 pages6 Heat TransferPrecious Mae Cuerquis BarbosaNo ratings yet

- Chapter 3 FinsDocument46 pagesChapter 3 Finssohaib389892No ratings yet

- Maximum Allowable Chip Power from Convection and RadiationDocument36 pagesMaximum Allowable Chip Power from Convection and RadiationSridhar RaoNo ratings yet

- Solutions From OnlineDocument36 pagesSolutions From OnlineNiniGooseNo ratings yet

- Chapter 4 External ConvectionDocument68 pagesChapter 4 External Convectionpvr2k1No ratings yet

- Transport Phenomena II: Cairo University Faculty of Engineering Chemical Engineering Department Pre-Masters CoursesDocument45 pagesTransport Phenomena II: Cairo University Faculty of Engineering Chemical Engineering Department Pre-Masters Coursesremo senNo ratings yet

- Delhi Technological University: Heat and Mass Transfer (ME-302) Group: M4Document190 pagesDelhi Technological University: Heat and Mass Transfer (ME-302) Group: M4Subhash SharmaNo ratings yet

- Heat TransgerDocument56 pagesHeat TransgerShusha Shomali67% (3)

- Reactor Sizing FinalDocument34 pagesReactor Sizing FinalJobb Six-steps MatheusNo ratings yet

- Estimation of Over-All Heat TransferDocument10 pagesEstimation of Over-All Heat TransferAllan Troy SalazarNo ratings yet

- Optimization of Composite Patch Repair Processes With The Use of Genetic AlgorithmsDocument7 pagesOptimization of Composite Patch Repair Processes With The Use of Genetic AlgorithmsGhouse ShaikNo ratings yet

- Week 5 Heat Transfer LectureDocument31 pagesWeek 5 Heat Transfer LectureHenry HongNo ratings yet

- Steady State Temperature Distribution of Cast Resin Dry Type Transformer Based On New Thermal Model Using Finite Element MethodDocument5 pagesSteady State Temperature Distribution of Cast Resin Dry Type Transformer Based On New Thermal Model Using Finite Element MethodAnonymous sAmJfcVNo ratings yet

- Extended SurfacesDocument12 pagesExtended SurfacesAjay YadavNo ratings yet

- Thermal Analysis of Electrical Machines Limits and Heat Transfer PrinciplesDocument2 pagesThermal Analysis of Electrical Machines Limits and Heat Transfer PrinciplesAnonymous sAmJfcVNo ratings yet

- Heat Transfer and Friction in Rectangular Duct With Pin-Fin ArraysDocument6 pagesHeat Transfer and Friction in Rectangular Duct With Pin-Fin ArraysSwati KarNo ratings yet

- Horizontal Shell-and-Tube Condenser CapacityDocument4 pagesHorizontal Shell-and-Tube Condenser Capacitykero_the_heroNo ratings yet

- ME3122 Tutorial 1 - Conduction-SolutionsDocument9 pagesME3122 Tutorial 1 - Conduction-SolutionsUnknown uploaderNo ratings yet

- Heat Transfer Analysis On A Straight Triangular Fin BB - Draft - 1Document15 pagesHeat Transfer Analysis On A Straight Triangular Fin BB - Draft - 1Ratandeep PandeyNo ratings yet

- Mech302hw3s PDFDocument7 pagesMech302hw3s PDFSUMANTNo ratings yet

- 3 Heat Transfer 2021Document30 pages3 Heat Transfer 2021Ahmed KingNo ratings yet

- 16429 2023 Coursework FinalDocument9 pages16429 2023 Coursework FinalshaanyeshpalNo ratings yet

- 10 1 1 498 9181 PDFDocument14 pages10 1 1 498 9181 PDFMUKUL KHARVANo ratings yet

- Experiment No. 03 Aim: To Determine The Heat Transfer Coefficient in Natural ConvectionDocument6 pagesExperiment No. 03 Aim: To Determine The Heat Transfer Coefficient in Natural Convectionpriya3939No ratings yet

- Files-5-Exams Quizzes Examples Problems Me315Document44 pagesFiles-5-Exams Quizzes Examples Problems Me315AndrestorpNo ratings yet

- Files-5-Exams Quizzes Examples Problems Me315Document44 pagesFiles-5-Exams Quizzes Examples Problems Me315TortelliniTimNo ratings yet

- Tutorial 1Document2 pagesTutorial 1David Ng Qing KaiNo ratings yet

- HT T5Document5 pagesHT T5Rohit MehtaNo ratings yet

- Heat Exchangers: Effectiveness-NTU Method Chapter SectionsDocument15 pagesHeat Exchangers: Effectiveness-NTU Method Chapter SectionsrajindoNo ratings yet

- 2021 July CHT204-ADocument4 pages2021 July CHT204-ANikhilNo ratings yet

- Solution of Transient 2D Heat Conduction Problem Using Freefem++Document4 pagesSolution of Transient 2D Heat Conduction Problem Using Freefem++Chicca PantanoNo ratings yet

- Assignment 6 - External Flow-1Document2 pagesAssignment 6 - External Flow-1Saiyam AjmeraNo ratings yet

- Heat Transfer Chapter 3Document45 pagesHeat Transfer Chapter 3Gregory Simmon100% (1)

- MM321 Lab N# 4: Bypass Factor of A Heating CoilDocument7 pagesMM321 Lab N# 4: Bypass Factor of A Heating CoilSiddhant Vishal ChandNo ratings yet

- E Catalogue of Hitachi Power SDocument1 pageE Catalogue of Hitachi Power SYuneo NurcahyaNo ratings yet

- Offshore Structures - Analysis and Design by Dr.S.nallayarasuDocument115 pagesOffshore Structures - Analysis and Design by Dr.S.nallayarasumariusz19781103100% (9)

- Design of HT HP Pipeline Againts Lateral Buckling PDFDocument14 pagesDesign of HT HP Pipeline Againts Lateral Buckling PDFYuneo NurcahyaNo ratings yet

- 03C - Extended SurfacesDocument18 pages03C - Extended SurfacesYuneo NurcahyaNo ratings yet

- Bypass Perpan2 SoalDocument1 pageBypass Perpan2 SoalYuneo NurcahyaNo ratings yet

- Load Cell Application Test Guideline April 2010Document29 pagesLoad Cell Application Test Guideline April 2010PIY777No ratings yet

- VSHP090041 Pelton T3341e 72dpiDocument8 pagesVSHP090041 Pelton T3341e 72dpiJose Fuentes MendezNo ratings yet

- Fundamental of Heat Exchanger DesignDocument972 pagesFundamental of Heat Exchanger Designabiy12791% (44)

- Mekatronika: Oleh: Liman Hartawan Jurusan Teknik Mesin Fakultas Teknologi Industri Institut Teknologi NasionalDocument51 pagesMekatronika: Oleh: Liman Hartawan Jurusan Teknik Mesin Fakultas Teknologi Industri Institut Teknologi NasionalYuneo NurcahyaNo ratings yet

- Fundamental of Heat Exchanger DesignDocument972 pagesFundamental of Heat Exchanger Designabiy12791% (44)

- 02-Prinsip Dasar Perpindahan PanasDocument20 pages02-Prinsip Dasar Perpindahan PanasYuneo NurcahyaNo ratings yet

- Compound Interest TableDocument1 pageCompound Interest TableYuneo NurcahyaNo ratings yet

- Measurement Systems: Black Box Which Is Used For Making Measurements. in General, Made Up of Three ElementsDocument13 pagesMeasurement Systems: Black Box Which Is Used For Making Measurements. in General, Made Up of Three ElementsYuneo NurcahyaNo ratings yet

- Introduction to Mechatronics SystemsDocument27 pagesIntroduction to Mechatronics SystemsYuneo NurcahyaNo ratings yet

- Mekatronika: Oleh: Liman Hartawan Jurusan Teknik Mesin Fakultas Teknologi Industri Institut Teknologi NasionalDocument22 pagesMekatronika: Oleh: Liman Hartawan Jurusan Teknik Mesin Fakultas Teknologi Industri Institut Teknologi NasionalYuneo NurcahyaNo ratings yet

- Centrifugal Pumps - Basic Hydraulics PDFDocument16 pagesCentrifugal Pumps - Basic Hydraulics PDFYuneo NurcahyaNo ratings yet

- Failure Analysis in BoilerDocument24 pagesFailure Analysis in BoilerYuneo Nurcahya100% (1)

- Sistem Bahan Bakar DieselDocument38 pagesSistem Bahan Bakar DieselYuneo NurcahyaNo ratings yet

- 1 Basic Compressor PrinciplesDocument45 pages1 Basic Compressor PrinciplesYuneo NurcahyaNo ratings yet

- Centrifugal Pumps - System Resistance Head CurveDocument34 pagesCentrifugal Pumps - System Resistance Head CurveYuneo NurcahyaNo ratings yet

- Concrete Behavior Under High Loading RatesDocument48 pagesConcrete Behavior Under High Loading RatesTugce CeranNo ratings yet

- PPG Datasheets ListDocument70 pagesPPG Datasheets ListZoebairNo ratings yet

- Prysmian Fire Rated CableDocument1 pagePrysmian Fire Rated Cablezisis81No ratings yet

- Safeguarding Memo ExplainedDocument6 pagesSafeguarding Memo ExplainedmzqaqilaNo ratings yet

- Door - D1 Door - Ds1 (Mep) : Inside InsideDocument1 pageDoor - D1 Door - Ds1 (Mep) : Inside InsideSaZanAwalNo ratings yet

- PHD ThesisDocument8 pagesPHD ThesisSameer SonuNo ratings yet

- TDS - Total - Dacnis 68 - 25o - 202008 - enDocument1 pageTDS - Total - Dacnis 68 - 25o - 202008 - enMuhammmad Naqi RazaNo ratings yet

- Processing of Polymers and Polymer Composites Course OverviewDocument14 pagesProcessing of Polymers and Polymer Composites Course Overviewdontaskme18No ratings yet

- Albio 235 CatalogueDocument122 pagesAlbio 235 CatalogueBogdan AndreiNo ratings yet

- Nanoindentation DmaDocument8 pagesNanoindentation DmaDildeep PallipadNo ratings yet

- I R C - S P 13 - 2004 With PlatesDocument152 pagesI R C - S P 13 - 2004 With PlatesMuthusamy ArumugamNo ratings yet

- Window Details W4: Plan Elevation SectionDocument1 pageWindow Details W4: Plan Elevation SectionNagabharan GowdaNo ratings yet

- Engineering Standards for Protective CoatingsDocument25 pagesEngineering Standards for Protective CoatingsAnonymous S9qBDVkyNo ratings yet

- ALS PolycarbonateInstallationInstructions Laserlite Dec2011Document3 pagesALS PolycarbonateInstallationInstructions Laserlite Dec2011patlolanugmailcomNo ratings yet

- Appendix H-Properties of MaterialsDocument5 pagesAppendix H-Properties of MaterialsSamnang HangNo ratings yet

- Estimate of Welding Rod Consumption - Piping StudyDocument3 pagesEstimate of Welding Rod Consumption - Piping Studysaroat moongwattanaNo ratings yet

- Prof Jean Mulopo's memo on heat integration and area targetingDocument11 pagesProf Jean Mulopo's memo on heat integration and area targetinglalelaNo ratings yet

- Lecture 6Document36 pagesLecture 6keiNo ratings yet

- KERTASIVE E-Catalogue (March 2022)Document30 pagesKERTASIVE E-Catalogue (March 2022)Winadi KurniawanNo ratings yet

- Vulcathene Product CatalogueDocument21 pagesVulcathene Product CatalogueFLYNAS LOGISTICSNo ratings yet

- Assessment and Strengthening of Distressed Diaphragm WallDocument8 pagesAssessment and Strengthening of Distressed Diaphragm WallfreezefreezeNo ratings yet

- Fosroc Conplast CNI: Constructive SolutionsDocument2 pagesFosroc Conplast CNI: Constructive SolutionsVincent JavateNo ratings yet

- A Comparative Study Zinc Phosphate-Soapcoatingversus Polymer Based Coati..Document6 pagesA Comparative Study Zinc Phosphate-Soapcoatingversus Polymer Based Coati..mirosekNo ratings yet

- Marvin Elevate-Catalog Feb 2023 19981914Document27 pagesMarvin Elevate-Catalog Feb 2023 19981914DiegoNo ratings yet

- Elastic Mechanics AssignmentsDocument8 pagesElastic Mechanics AssignmentsEng Bagaragaza Romuald100% (2)

- A Guide To Engineered Wood ProductsDocument12 pagesA Guide To Engineered Wood ProductsCeyanezNo ratings yet

- Chapter 03 - Flow in PipesDocument83 pagesChapter 03 - Flow in PipesSamnang HangNo ratings yet

- BSR 221 IndividualDocument24 pagesBSR 221 IndividualMUHAMMAD FARIS IQBAL BIN RIDUANNo ratings yet

- Iso 6362 1 2012 en PDFDocument8 pagesIso 6362 1 2012 en PDFcongnghe lyNo ratings yet

- Floor Heating System DetailDocument10 pagesFloor Heating System Detaildak1shaNo ratings yet