Professional Documents

Culture Documents

Mott-Brown K Values

Uploaded by

lutfi awnOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mott-Brown K Values

Uploaded by

lutfi awnCopyright:

Available Formats

The Mott Souders - George Granger Brown Equation is:

V

max

= (K) [ (r

L

- r

V

) / r

V

]

0.5

where,

V

max

=

the maximum allowable superficial vapor velocity through the vessel = 7.5 ft/sec

r

L

= the density of the liquid entering the vessel = 54.00

lb/ft

3

r

V

= the density of the vapor entering the vessel = 0.06

lb/ft

3

K = an empirical constant whose value depends on the type of vessel, the

use of internals, and the height of the disengaging space above any

mesh employed. = 0.25

Values of "K" are found in Ernest Ludwig's "Applied Process Design for Chemical and Petrochemical Plants",

Volume 1, chapter 4:

(Bottom of mesh shuld be at least 12 inches above the liquid surface)

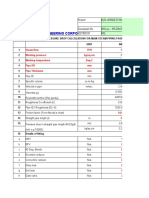

Service Conditions K" Value

Clean fluids, moderate liquid load; fits 90% 0.36 Standard design

of process situations and applications. 0.35 High efficiency (?)

(the rating description is probably backwards) 0.25 Very high efficiency (?)

High viscosity; dirty, suspended solids 0.40 Low density or Herringbone, high

through-put

Vacuum operations:

2" Hg absolute 0.20 Standard design

16" Hg absolute 0.27 High Efficiency

Corrosive chemical 0.21 Plastic coated wire, or plastic strand

3

4

5

6

7

8

9

10

11

12

13

14

This table is from Otto H. York data.

Values based on 12 lb/ft

3

wire mesh. Design practice

normally does not exceed k of 0.4 even for higher

disengaging height.

Additionally, the GPSA Engineering Data Book (11th Edition, electronic) states that vertical separators

0.38

0.40

0.42

0.43

0.29

0.32

Calculation of a Gas-Liquid Separator or Flash Drum

K Values for Knitted Mesh

General type mesh

Variations of K with Disengaging Height

Disengaging height above mesh,

inches

0.35

Allowable "K" value

0.12

0.15

0.19

0.22

0.25

have a K factor (in ft/sec) value of 0.18 to 0.35. It recommends adjustment of the K factor due to system

pressure:

Pressure % of K

atm. 100

150 psi 90

300 psi 85

600 psi 80

1,150 psi 75

For Vertical Separator Design:

100 lb/hr = 0.463 ft

3

/sec

0.062 ft

2

0.28 ft = 3.37 inches

The GPSA states that separators without mist extractors are sized using the above equation with a K

that is typically 1/2 of that used for vessel with mist extractors.

John M. Campbell, in his book "Gas Conditioning and Processing", states: "(Separator sizing).. Is

a semi-empirical approach since one cannot measure things like droplet size and other variables.

Furthermore, many of the assumptions in the derivation of the Souders-Brown equation are not satisfied in

actual practice.

"The value of K depends on all factors that affect separation other than density - such as vortex action,

foaming, pulsating flow, liquid flowing in heads, presence of solids, degree of separation needed, separation

length, varying gas to liquid ratios, and the like. It is not surprising that K varies widely in different

applications. How does one predict it? From experience!

"Do not be nave. Most published capacity curves are for ideal conditions. Use them cautiously. Consider a

factor like pulsating flow from a well head or a two-phase line. The liquid enters in "heads". During this time

the gas rate is low. Between "heads" the gas rate is normal but little liquid enters. Using some average 24

hour gas and liquid rate to size the separator would be criminal, or at least unprofessional. There must be

sufficient capacity to handle properly the instantaneous rates expected.

"The value of K used in the Souders-Brown equation thus varies. The normal range of values is:

Separator cross-sectional area =

Separator inside diameter =

K = 0.06 to 0.35

Maximum vapor flow rate =

Art Montemayor September 30, 2005

Rev: 0

Project:

K Values

SG

liquid

0.464 0.289 ft/sec

SG

gas

0.6571 0.144 ft/sec

P 715 psig 0.231 ft/sec

T -76

o

F

Q 12,800 MScfd

Z 1.0000

r

liquid

= = 28.94 28.94 28.94 lb

f

/ ft

3

(P+14.7)(SG

gas

*28.9625) 3.37 3.37 3.37

Qr

gas

7.43 7.43 7.43

(379.49)(24)(3600)

M

rate

2.20 2.20 2.20

r

gas

K r

liquid

- r

gas

0.79 0.40 0.64

r

gas

V

rate

2.77 5.55 3.47

vel

max

12 4A 22.55 31.89 25.21

p

Vertical Separator Sizing Calculations

r

gas

=

M

rate

=

V

rate

=

vel

max

=

Vertical

Separator

(w/ mist pad)

Vertical

Separator

(w/o mist

pad)

Vertical

Separator

(Compressor)

=

= A =

=

SG

liquid

*62.371

lb

f

/ ft

3

lb

m

/ sec

inches

ft

3

/ sec

ft

2

f

ID

=

Separator (w/ mist pad)

Separator (w/o mist pad)

Compressor Separator

Inlet Conditions:

=

Units

ft / sec

=

=

Z(10.73)(T + 459.67)

Page 3 of 13

FileName: 228901629.xls.ms_office

WorkSheet: Vertical Nat. Gas Sep.

Art Montemayor September 30, 2005

Rev: 0

The Specific Gravity of a liquid fluid is defined as the density of the given liquid (at a defined temperature) divided

by the density of water at the reference temperature of 60

o

F ( 62.371 lb/ft

3

)

The Specific Gravity of a gas is defined as the density of the given gas (at a defined temperature and pressure) divided

by the density of dry air at the reference temperature and pressure of 60

o

F and 14.696 psia ( 0.076322 lb/ft

3

). Usually

the Specific Gravity is given for a gas also at 60

o

F.

The Molecular Weight of Dry Air is given as 28.9625 (GPSA Engineering Data Book; 1983)

One lb-mole of an Ideal gas yields a volume of 379.49 ft

3

at 14.696 psia and 60

o

F (GPSA Engineering Data Book.

Specific Gravity of a gas at 60

o

F and 14.696 psia = (gas Molecular Weight) / (28.9625)

The equation used to calculate Natural Gas density is:

where,

r

V

=

Natural Gas density at temperature T, lb/ft

3

MW = Natural Gas Molecular Weight, lbs/lb-mol

P = Natural Gas pressure, psia

T =

Natural Gas temperature,

o

R

Z = Natural Gas Compressibility Factor

r

V

= (MW) (P) / (10.73) (T) (Z)

Page 4 of 13

FileName: 228901629.xls.ms_office

WorkSheet: Vertical Nat. Gas Sep.

Vertical liquid-vapor separators are used primarily to disengage a liquid from a vapor when the volume of liquid is

small compared with the vapor volume. The maximum allowable vapor velocity in a vertical separator, to reduce

liquid carryover, is a function of liquid and vapor density and a constant, K, based on surface tension, droplet size,

and physical characteristics of the system. Usually these K values for vertical vessels vary between 0.1 to 0.35,

if mist eliminators are used to enhance disentrainment. Watkins

(1)

developed a correlation between separation factor

(S Fac) and K value which has proved useful in sizing process liquid-vapor separators. Watkins' data have been fitted

to an equation, and this correlation is used in this program for calculation of K values for a range of separation factors

between 0.006 and 5.0. However, other K values can be entered if desired.

Once the K value and maximum vapor velocity are determined, the cross-sectional area of the separator is calculated

using the equation for Av. Vessel diameter is calculated from cross-sectional area by the equation for D, and

maximum liquid level is calculated from liquid flow rate and surge time using the equations for QL and LL.

It is normally recommended that 36 inches plus one-half the feed nozzle OD (48 inches minimum) be left above the

feed nozzle for vapor disengagement. Below the feed nozzle, leave 12 inches plus one-half the feed nozzle OD for

clearance between the maximum liquid level and the feed nozzle (minimum of 18 inches). At some value between

L/D ratios of 3 and 5 a minimum vessel weight will occur, resulting in minimum cost for the separator's steel material

of construction.

Equations employed:

L

V

V

L

W

W

Fac S

r

r

=

) ( exp

4 3 2

GX FX EX DX B K

V

=

V

V L

Max

K V

r

r r

=

) 3600 (

V

V

V

W

Q

r

=

Max

V

V

V

Q

A =

p

V

A

D

4

=

4

2

D

A

p

=

) 60 (

L

L

L

W

Q

r

=

A

T Q

LL

L

) (

=

Nomenclature:

S Fac = Separation Factor

K

V

= Vapor velocity factor for vertical separators

V

Max

= Maximum allowable vapor velocity, ft/sec

W

L

= Liquid mass flow rate, lb/hr

W

V

= Vapor mass flow rate, lb/hr

r

V

=

Vapor density, lb/ft

3

r

L

=

Liquid density, lb/ft

3

Q

V

=

Vapor volumetric flow rate, ft

3

/sec

D = Separator's internal diameter, ft

A = Separator's cross-sectional flow area, ft

2

A

V

=

Separator's minimum cross-sectional flow area, ft

2

References:

1. Watkins, R.N.: "Sizing Separators and accumulators", Hydrocarbon Processing; November, 1967;

pp. 253-256.

A. Kayode Coker, in his book "Fortran Programs for Chemical Process Design", gives the Watkins Curve which

relates K

V

to (W

L

/W

V

) (r

V

/r

L

)

0.5

. He qualifies the data as based on five percent of the liquid being entrained with

the vapor and at 85 % of flooding.

The data on the curve are as follows:

K

V

0.006 0.23

0.008 0.25

0.01 0.27

0.02 0.41

0.04 0.45

0.06 0.44

0.08 0.43

0.1 0.42

0.2 0.35

0.4 0.28

0.6 0.2

0.8 0.17

1.0 0.14

2.0 0.07

4.0 0.033

I regressed this data using the Datafit program and got a much better equation in:

y = x/(a+b*x-c*x

2

)

a = 0.01746538478

b = 1.620701278

c = -5.47525025

(W

L

/W

V

) (r

V

/r

L

)

0.5

Vertical liquid-vapor separators are used primarily to disengage a liquid from a vapor when the volume of liquid is

small compared with the vapor volume. The maximum allowable vapor velocity in a vertical separator, to reduce

liquid carryover, is a function of liquid and vapor density and a constant, K, based on surface tension, droplet size,

and physical characteristics of the system. Usually these K values for vertical vessels vary between 0.1 to 0.35,

if mist eliminators are used to enhance disentrainment. Watkins

(1)

developed a correlation between separation factor

(S Fac) and K value which has proved useful in sizing process liquid-vapor separators. Watkins' data have been fitted

to an equation, and this correlation is used in this program for calculation of K values for a range of separation factors

Once the K value and maximum vapor velocity are determined, the cross-sectional area of the separator is calculated

using the equation for Av. Vessel diameter is calculated from cross-sectional area by the equation for D, and

maximum liquid level is calculated from liquid flow rate and surge time using the equations for QL and LL.

It is normally recommended that 36 inches plus one-half the feed nozzle OD (48 inches minimum) be left above the

feed nozzle for vapor disengagement. Below the feed nozzle, leave 12 inches plus one-half the feed nozzle OD for

clearance between the maximum liquid level and the feed nozzle (minimum of 18 inches). At some value between

L/D ratios of 3 and 5 a minimum vessel weight will occur, resulting in minimum cost for the separator's steel material

Watkins, R.N.: "Sizing Separators and accumulators", Hydrocarbon Processing; November, 1967;

A. Kayode Coker, in his book "Fortran Programs for Chemical Process Design", gives the Watkins Curve which

relates K

V

to (W

L

/W

V

) (r

V

/r

L

)

0.5

. He qualifies the data as based on five percent of the liquid being entrained with

Art Montemayor

September 30, 2005

Rev: 0

Project:

K Values

SG

liquid

0.550 Separator (w/ mist pad) 0.310 ft/sec

SG

gas

0.7000 Separator (w/o mist pad) 0.155 ft/sec

P 500 psig Filter Separator * 1.300 ft/sec

T 80

o

F

Q 50,000 M Scfd

L 30.0 Feet

r

liquid

= = 34.30 34.30 34.30 lb

m

/ ft

3

(P+14.7)(SG

gas

*28.9625) 1.75 1.75 1.75

Z(10.73)(T+460)

Qr

gas

30.92 30.92 30.92

(379.49)(24)(3600)

M

rate

17.67 17.67 17.67

r

gas

K r

liquid

- r

gas

2.47 1.24 5.61

r

gas

V

rate

7.14 14.29 3.15

vel

max

12 4A 36.19 51.18 24.04 inches

p

Horizontal Separator Sizing Calculations

f

ID

=

A =

vel

max

=

V

rate

=

M

rate

=

r

gas

=

=

=

=

LONE CAMP FILTER SEPARATOR-AT PLANT-HP TURBINES

Inlet Conditions:

* Filter Seps are Proprietary Designs. This is estimate only

SG

liquid

*62.367

Horizontal

Separator

(w/ mist pad)

Horizontal

Separator

(w/o mist pad)

Filter

Separator *

Units

ft

2

ft / sec (L/10)

0.56

lb

m

/ft

3

=

lb

m

/sec

ft

3

/ sec

=

=

Wet Gas in

Gas out

Liquid out

Page 9 of 13

FileName: 228901629.xls.ms_office

WorkSheet: Horizontal Sep

Art Montemayor August 21, 2005

Rev: 0

ANALYTICAL STUDY OF 'LIQUID/VAPOR SEPARATION EFFICIENCY

BY

Dr. W.D. Monnery Dr. W.Y. Svrcek

Chem-Pet Process Technology Ltd. Department of Chemical & Petroleum Engineering

335 Ranchridge Bay NW University of Calgary

Calgary, AB Calgary, AB T2N 1N4

5-Sep-00

SUMMARY

The purpose of this work was to establish the separation efficiency of flare knock-out drums and determine the

expected entrained liquid droplet diameter that is carried over to the flare. This was accomplished by using a

field pilot plant skid at the Prime West East Crossfield gas plant. The skid consisted of gas and liquid inlets test

separators and entrained liquid collection in a filter/coalescer. The raw test data was entrained liquid carryover

amount as a function of gas velocity data.

Experimental results provide incipient entrained liquid carryover velocities. The data show that carryover rises

sharply after the incipient carryover velocity and separation efficiency drops below 99.9%. Experimental results

indicate that entrained liquid carryover average droplet diameters are 200 to 600 microns for flare knock-out

drums at 10 to 100 psig. Calculations show that the maximum stable droplet size can be very large at low

velocities and the calculated liquid droplet size distribution indicates that there can be substantial variance in the

droplet size and that the latter may not be very uniform. In order to verify the estimated droplet sizes and

distributions, further experimental work must include the addition of online droplet size and distribution

measurement equipment.

Experimental results provide quantitative data for the relationship between horizontal and vertical K factors and

allowable velocities, which has to date been empirical and subjective. These results show that the factor between

horizontal and vertical K factors and allowable velocities vary from about 1.33 to 1.67 as L/D varies from

3.5 to 6.5.

Modeling results based on using the experimental data give entrained liquid average droplet diameters that are

consistent with API 521 for flare knock-out drums (300-600 microns) as well as other open literature. To

avoid carryover, flare knock-out drums should be designed using a droplet size of 300 microns.

1.0 INTRODUCTION/BACKGROUND

This study is part of the Alternative Flaring Technologies program sponsored by Environment Canada, CAPP

and PTAC. This study focuses on the efficiency of gravity separation as it relates to flare knockout drum

design and operation.

One of the critical issues in facilities process design and operation is vapor/liquid separation. This is also an

important issue for the improvement of existing flaring systems. The problem for flaring systems is that with the

uncertainty of design and operating conditions, liquid carryover droplets may be of such a size and composition

that they are incompletely combusted. This results in the emission of many undesirable compounds to the

atmosphere, as has been outlined in previous studies and of the current Government and Industry study

Page 1010 of 13

FileName: 228901629.xls.ms_office

WorkSheet: V-L Separator Analysis

Art Montemayor August 21, 2005

Rev: 0

aimed at mitigating emissions in flares.

There is an abundance of literature available on vapor/liquid separation and equipment design, yet there has never

been a systematic, comprehensive study to verify the accepted design methodology. Liquid vapor separator

design is described in several engineering and operating company guidelines, the GPSA Engineering Data Book

and recent publications such as Svrcek and Monnery (1993) and Monnery and Svrcek (1994). Other

publications of note are Watkins (1967) and Talavera (1990).

The present design philosophy is to simply attempt to be conservative enough so that separation equipment will

work. Unfortunately, the definition of how conservative these designs are remains in question. Furthermore,

equipment that does function properly at design rates may need to be re-rated for increased rates or at off-design

operating conditions and the above mentioned problem appears again (how conservative?). Although general

design methodology is well accepted, it is the subjectivity of some of the separation parameters used in the

models that are in question.

As such, the purpose of the research is to determine the efficiency of gravity separation. Specifically, it is to

determine the velocity at which carryover occurs and to estimate the liquid particle size going to flare. This data

can also be used to check current design criteria and estimate liquid carryover at operating conditions.

1.0 THEORY OF GRAVITY SEPARATION AND SIMPLIFIED COALESCENCE MODELLING

In a liquid-vapor separation vessel, there are typically three stages of separation. The first stage, primary

separation, uses an inlet diverter to cause the largest droplets to impinge by momentum and then drop by gravity.

The next stage is gravity separation of smaller droplets as the gas flows through the vapor disengagement section

of the separator. The final stage is mist elimination, where the smallest droplets are coalesced on an impingement

device, such as a mist pad or vane pack, followed by gravity settling of the larger formed droplets. In vessels

like flare knockout drums, we are primarily concerned with gravity separation since they typically have no

coalescing internals, such as mist pads.

For gravity separation, the allowable velocity is determined so that the required disengagement area can be

determined. For a vertical vessel, performing a force balance on the liquid droplet settling out provides the

necessary relationship. When the net gravity force, given by Eq.1,

.(1)

balances the drag force, given by Eq. 2,

.(2)

the liquid droplets will settle at a constant terminal velocity, U

T

. Equating Eqs. 1 and 2 results in:

c L

V L P

G

g

g M

F

r

r r ) (

=

c

V V P D

D

g

U D C

F

r p

2 2

) 8 / (

=

c

V V P D

D

g

U D C

F

r p

2 2

) 8 / (

=

Page 1111 of 13

FileName: 228901629.xls.ms_office

WorkSheet: V-L Separator Analysis

Art Montemayor August 21, 2005

Rev: 0

The purpose of this work was to establish the separation efficiency of flare knock-out drums and determine the

expected entrained liquid droplet diameter that is carried over to the flare. This was accomplished by using a

field pilot plant skid at the Prime West East Crossfield gas plant. The skid consisted of gas and liquid inlets test

separators and entrained liquid collection in a filter/coalescer. The raw test data was entrained liquid carryover

Experimental results provide incipient entrained liquid carryover velocities. The data show that carryover rises

sharply after the incipient carryover velocity and separation efficiency drops below 99.9%. Experimental results

indicate that entrained liquid carryover average droplet diameters are 200 to 600 microns for flare knock-out

drums at 10 to 100 psig. Calculations show that the maximum stable droplet size can be very large at low

velocities and the calculated liquid droplet size distribution indicates that there can be substantial variance in the

droplet size and that the latter may not be very uniform. In order to verify the estimated droplet sizes and

distributions, further experimental work must include the addition of online droplet size and distribution

Experimental results provide quantitative data for the relationship between horizontal and vertical K factors and

allowable velocities, which has to date been empirical and subjective. These results show that the factor between

horizontal and vertical K factors and allowable velocities vary from about 1.33 to 1.67 as L/D varies from

Modeling results based on using the experimental data give entrained liquid average droplet diameters that are

consistent with API 521 for flare knock-out drums (300-600 microns) as well as other open literature. To

This study is part of the Alternative Flaring Technologies program sponsored by Environment Canada, CAPP

and PTAC. This study focuses on the efficiency of gravity separation as it relates to flare knockout drum

One of the critical issues in facilities process design and operation is vapor/liquid separation. This is also an

important issue for the improvement of existing flaring systems. The problem for flaring systems is that with the

uncertainty of design and operating conditions, liquid carryover droplets may be of such a size and composition

that they are incompletely combusted. This results in the emission of many undesirable compounds to the

Page 1212 of 13

FileName: 228901629.xls.ms_office

WorkSheet: V-L Separator Analysis

Art Montemayor August 21, 2005

Rev: 0

There is an abundance of literature available on vapor/liquid separation and equipment design, yet there has never

been a systematic, comprehensive study to verify the accepted design methodology. Liquid vapor separator

design is described in several engineering and operating company guidelines, the GPSA Engineering Data Book

The present design philosophy is to simply attempt to be conservative enough so that separation equipment will

work. Unfortunately, the definition of how conservative these designs are remains in question. Furthermore,

equipment that does function properly at design rates may need to be re-rated for increased rates or at off-design

operating conditions and the above mentioned problem appears again (how conservative?). Although general

design methodology is well accepted, it is the subjectivity of some of the separation parameters used in the

As such, the purpose of the research is to determine the efficiency of gravity separation. Specifically, it is to

determine the velocity at which carryover occurs and to estimate the liquid particle size going to flare. This data

In a liquid-vapor separation vessel, there are typically three stages of separation. The first stage, primary

separation, uses an inlet diverter to cause the largest droplets to impinge by momentum and then drop by gravity.

The next stage is gravity separation of smaller droplets as the gas flows through the vapor disengagement section

of the separator. The final stage is mist elimination, where the smallest droplets are coalesced on an impingement

device, such as a mist pad or vane pack, followed by gravity settling of the larger formed droplets. In vessels

like flare knockout drums, we are primarily concerned with gravity separation since they typically have no

For gravity separation, the allowable velocity is determined so that the required disengagement area can be

determined. For a vertical vessel, performing a force balance on the liquid droplet settling out provides the

Page 1313 of 13

FileName: 228901629.xls.ms_office

WorkSheet: V-L Separator Analysis

You might also like

- PROYEK MINI LPG PLANT LAPANGAN JATA CALCULATIONDocument6 pagesPROYEK MINI LPG PLANT LAPANGAN JATA CALCULATIONDIANTORONo ratings yet

- LP Gas Amine Contactor Process DataDocument6 pagesLP Gas Amine Contactor Process DataEddy RainNo ratings yet

- Design Calculation of Outbreathing Flowrates and Valve Sizing for an Expansion TankDocument24 pagesDesign Calculation of Outbreathing Flowrates and Valve Sizing for an Expansion Tankvenkatesh801No ratings yet

- Line Sizing For Liquid, (DO IT OWN)Document11 pagesLine Sizing For Liquid, (DO IT OWN)sumitNo ratings yet

- Tank CalcDocument21 pagesTank CalcInggitNo ratings yet

- 2-TWO Phase Separator Design Guide by Manish ShahDocument62 pages2-TWO Phase Separator Design Guide by Manish Shahdennis_ugarteNo ratings yet

- 9 - Horizontal Flare Knock Out Drum Sizing1Document2 pages9 - Horizontal Flare Knock Out Drum Sizing1Anonymous APc7I7100% (1)

- DJM MBA PCS CA 007 Deethanizer Reboiler E 1401 Rev BDocument37 pagesDJM MBA PCS CA 007 Deethanizer Reboiler E 1401 Rev BDIANTORONo ratings yet

- Open TankDocument27 pagesOpen Tankhgagselim2012No ratings yet

- Flare Ko Drum SizingDocument5 pagesFlare Ko Drum SizingSujith Sekar100% (2)

- PVV Cal Sheet LabixDocument45 pagesPVV Cal Sheet LabixPranpath Narupantawart50% (2)

- Vertical Separator SizingDocument8 pagesVertical Separator SizingAnonymous yLPPdPwNo ratings yet

- Seperator Sizing v3Document5 pagesSeperator Sizing v3camasa2011No ratings yet

- Venting calculations for vertical cylinder tank per API 2000 7th editionDocument3 pagesVenting calculations for vertical cylinder tank per API 2000 7th editionKartik PatelNo ratings yet

- Vessel Sizing Calculation Data Sheets: Customer Name: Project Title: Cpe Job #: Document #Document13 pagesVessel Sizing Calculation Data Sheets: Customer Name: Project Title: Cpe Job #: Document #Michael HaiseNo ratings yet

- Separator Sizing SpreadsheetDocument40 pagesSeparator Sizing SpreadsheetRidho MuhtadiNo ratings yet

- Maz - Design - Separator Capacity EvaluationDocument5 pagesMaz - Design - Separator Capacity EvaluationNaeem HussainNo ratings yet

- Three Phase Separators - Times DefinitionDocument5 pagesThree Phase Separators - Times DefinitionMohsin MohammedNo ratings yet

- 3phase Separator Size 2010 VerADocument24 pages3phase Separator Size 2010 VerACristina BarbulescuNo ratings yet

- Calculation Sheet For Pump Hydraulic (Fps Unit)Document1 pageCalculation Sheet For Pump Hydraulic (Fps Unit)chemical todiNo ratings yet

- Glycol Drum Sizing CheckDocument2 pagesGlycol Drum Sizing CheckmNo ratings yet

- Vertical SeparatorDocument38 pagesVertical SeparatorSaidFerdjallahNo ratings yet

- Molecular Sieve Sizing Sheet PematangDocument8 pagesMolecular Sieve Sizing Sheet Pematangahmad santosoNo ratings yet

- Pipeline Pressurisation & de Pressurisation CalculationDocument4 pagesPipeline Pressurisation & de Pressurisation Calculationhatakerobot50% (2)

- Circulating Fluidized Bed Boiler Design and OperationDocument9 pagesCirculating Fluidized Bed Boiler Design and OperationSanket BhaleraoNo ratings yet

- Vertical Storage Tank Heat Loss Calcs - Rev.1 31.12.2010Document16 pagesVertical Storage Tank Heat Loss Calcs - Rev.1 31.12.2010jnmanivannanNo ratings yet

- Surface Area Calculations Vessel TanksDocument5 pagesSurface Area Calculations Vessel Tanksdhavalesh1No ratings yet

- 541-PC-1002 Utility Consumption Summary1Document3 pages541-PC-1002 Utility Consumption Summary1svnaik14No ratings yet

- Operating case simulation and hydraulic calculationDocument2 pagesOperating case simulation and hydraulic calculationsri9987No ratings yet

- 2 Phase Horizontal Flow Line Sizing Cal-AUHDocument15 pages2 Phase Horizontal Flow Line Sizing Cal-AUHMike DukasNo ratings yet

- EIND 3184 15 Liquid Flash Vessel SizingDocument20 pagesEIND 3184 15 Liquid Flash Vessel SizingzamijakaNo ratings yet

- Calculation For Steam Blow Rev03Document6 pagesCalculation For Steam Blow Rev03tauqeerNo ratings yet

- 2 Phase Vertical Separator Sizing Calculation-AUHDocument26 pages2 Phase Vertical Separator Sizing Calculation-AUHMike Dukas100% (1)

- Specification Sheet For Separator: Operating Conditions SketchDocument12 pagesSpecification Sheet For Separator: Operating Conditions SketchAngelikaOdimer100% (1)

- Three Phase Separators - Times DefinitionDocument5 pagesThree Phase Separators - Times DefinitionaytihdaNo ratings yet

- Boiling Up Rate For Batch DistillationDocument4 pagesBoiling Up Rate For Batch DistillationKanhaiyalal PatilNo ratings yet

- Line Sizing of The Main Production Header (A Gas / Liquid Two Phase Line)Document12 pagesLine Sizing of The Main Production Header (A Gas / Liquid Two Phase Line)Engr TheyjiNo ratings yet

- Process Calculation: Flare Diameter (D)Document2 pagesProcess Calculation: Flare Diameter (D)kristian08100% (1)

- Half Pipe Coil AgitatedDocument1 pageHalf Pipe Coil AgitatedNITINNo ratings yet

- Data Sheet TEG-Gas Exchanger (E-5050)Document2 pagesData Sheet TEG-Gas Exchanger (E-5050)Elias EliasNo ratings yet

- Spreadsheet To Design SeparatorsDocument21 pagesSpreadsheet To Design SeparatorsreninbabaskiNo ratings yet

- Separator (1) Sizing Spread SheetsDocument21 pagesSeparator (1) Sizing Spread SheetsSteve WanNo ratings yet

- Thermosyphon Reboiler (Horizontal) GPSADocument6 pagesThermosyphon Reboiler (Horizontal) GPSAsyamsudin2006No ratings yet

- C06 006 Process Calculation (02V 6010) RevEDocument6 pagesC06 006 Process Calculation (02V 6010) RevEAlphaEcc EngineeringTeamNo ratings yet

- Combustion CalculationsDocument6 pagesCombustion CalculationsDaniel AriefinNo ratings yet

- Routine Is Based On API 521 Recommended Practice For Sizing of Relief KO DrumsDocument3 pagesRoutine Is Based On API 521 Recommended Practice For Sizing of Relief KO DrumsMohamed Sayed AbdoNo ratings yet

- 3-Phase Separator Sheet (GPSA)Document12 pages3-Phase Separator Sheet (GPSA)WickyNo ratings yet

- PT Synergy Engineering: WarningsDocument1 pagePT Synergy Engineering: Warningsokky wddNo ratings yet

- MPCL Flare KOD Pump 11442-DS-103 - IFC2 18-06-2013Document2 pagesMPCL Flare KOD Pump 11442-DS-103 - IFC2 18-06-2013zohaib_farooqNo ratings yet

- Two Phase Vertical Separator SizingDocument4 pagesTwo Phase Vertical Separator Sizingkamal100% (2)

- Distillation Column1Document49 pagesDistillation Column1chaitanyavura0% (1)

- Distillation Column Design GuideDocument49 pagesDistillation Column Design GuideMercy John71% (7)

- Gas-Liquid Separator Sizing CalculationsDocument12 pagesGas-Liquid Separator Sizing CalculationsiuiuiooiuNo ratings yet

- Emiss Calc FlaresDocument8 pagesEmiss Calc FlaresTallal joiyaNo ratings yet

- Analytical Study of Liquid/Vapour Separation EfficiencyDocument23 pagesAnalytical Study of Liquid/Vapour Separation Efficiencyra9622No ratings yet

- CBE 417 FlashDrumSizing WankatDocument7 pagesCBE 417 FlashDrumSizing WankatRahmansyah GaekNo ratings yet

- Flare Emission CalculationsDocument8 pagesFlare Emission CalculationsMubarik AliNo ratings yet

- Rate-Base Method For Packed Columns: Capacity Limitations of Trayed TowersDocument34 pagesRate-Base Method For Packed Columns: Capacity Limitations of Trayed Towersscribdtroll1No ratings yet

- A New Approach For Sizing Finger Slug CatcherDocument15 pagesA New Approach For Sizing Finger Slug CatcherHaryadiNo ratings yet

- Vortex Meters For GasDocument5 pagesVortex Meters For GasRicardo Zárate GodinezNo ratings yet

- Heavy Oil Upgrading by The Separation and Gasification of AsphaltenesDocument11 pagesHeavy Oil Upgrading by The Separation and Gasification of Asphalteneslutfi awnNo ratings yet

- E10 Blending Study Final ReportDocument107 pagesE10 Blending Study Final Reportlutfi awnNo ratings yet

- Liquid Pressure DropDocument8 pagesLiquid Pressure Droplutfi awnNo ratings yet

- VISCOSITY CLASSIFICATION GUIDE FOR INDUSTRIAL LUBRICANTSDocument8 pagesVISCOSITY CLASSIFICATION GUIDE FOR INDUSTRIAL LUBRICANTSFrancisco TipanNo ratings yet

- 04 Jet Mixing Design ApplicationsDocument6 pages04 Jet Mixing Design Applicationslutfi awnNo ratings yet

- Bitumen Upgrading Shell Canada LimitedDocument301 pagesBitumen Upgrading Shell Canada Limitedlutfi awnNo ratings yet

- Liquid and Gas Velocity Gas Compressibility and Renolds Number.Document30 pagesLiquid and Gas Velocity Gas Compressibility and Renolds Number.lutfi awnNo ratings yet

- Air Compressor Tools APODocument7 pagesAir Compressor Tools APOlutfi awnNo ratings yet

- Air Compressor Curve ToolDocument14 pagesAir Compressor Curve Toollutfi awnNo ratings yet

- Hydraulic Calculations MKIIDocument8 pagesHydraulic Calculations MKIIlutfi awnNo ratings yet

- Astm D 86Document8 pagesAstm D 86lutfi awnNo ratings yet

- Lubricating Oils: Test Methods Test MethodsDocument32 pagesLubricating Oils: Test Methods Test MethodsCorina StanculescuNo ratings yet

- Water Demand Calculation 1Document2 pagesWater Demand Calculation 1lutfi awnNo ratings yet

- Energy conversion factors and density ranges for petroleum productsDocument2 pagesEnergy conversion factors and density ranges for petroleum productslutfi awnNo ratings yet

- Mixer Tank Jet Pumps Gea - tcm11 34889Document4 pagesMixer Tank Jet Pumps Gea - tcm11 34889Venodaren VelusamyNo ratings yet

- Gas ReservesDocument8 pagesGas Reserveslutfi awnNo ratings yet

- 2011 Chaudhuri U R Fundamentals of Petroleum and PetrochDocument33 pages2011 Chaudhuri U R Fundamentals of Petroleum and Petrochlutfi awnNo ratings yet

- Conversion of Milligrams Per Cubic Meter To PPMDocument2 pagesConversion of Milligrams Per Cubic Meter To PPMlutfi awnNo ratings yet

- Line sizing for gas flow from PCV to flare headerDocument2 pagesLine sizing for gas flow from PCV to flare headerlutfi awnNo ratings yet

- Calculation ExampelDocument21 pagesCalculation Exampellutfi awnNo ratings yet

- Molecular Sieve Dehydration OptimizationDocument24 pagesMolecular Sieve Dehydration Optimizationlutfi awn100% (1)

- H2S RiskDocument6 pagesH2S Risklutfi awnNo ratings yet

- Fonds Bombes - Surface MouilleeDocument3 pagesFonds Bombes - Surface MouilleesegunoyesNo ratings yet

- Plumbing H 2 Osu Pair Gap CalculatorDocument9 pagesPlumbing H 2 Osu Pair Gap Calculatorlutfi awnNo ratings yet

- Valve Sizing Worksheet InstructionsDocument11 pagesValve Sizing Worksheet Instructionslutfi awnNo ratings yet

- GOR Vs GVFDocument8 pagesGOR Vs GVFlutfi awnNo ratings yet

- PumpDocument31 pagesPumpkajale_shrikant2325No ratings yet

- Centrifugalcompressorpower Si UnitsDocument4 pagesCentrifugalcompressorpower Si UnitsJoshi DhvanitNo ratings yet

- Gas TurbDocument10 pagesGas Turblutfi awnNo ratings yet

- ZM KV Idag eDocument6 pagesZM KV Idag elutfi awnNo ratings yet

- SolutionsDocument61 pagesSolutionsAman PareekNo ratings yet

- Assignment Thermal UiTMDocument26 pagesAssignment Thermal UiTMAmirul 'Pit'No ratings yet

- Heat Transfer in Olga 2000Document11 pagesHeat Transfer in Olga 2000Akin MuhammadNo ratings yet

- CALDURI Specifice GAZEDocument2 pagesCALDURI Specifice GAZEDan SabadusNo ratings yet

- CMY 117 For VSEPR and Molecular GeometryDocument8 pagesCMY 117 For VSEPR and Molecular GeometryJack WilliamsNo ratings yet

- Triangular GraphsDocument4 pagesTriangular GraphsBen Anthony JosephsNo ratings yet

- Starting Cargo Compressor Reliquification ProceduresDocument2 pagesStarting Cargo Compressor Reliquification ProceduresnaveenNo ratings yet

- Chapter 2-5Document26 pagesChapter 2-5CcneneNo ratings yet

- SemiconductorDocument8 pagesSemiconductorritamnath337No ratings yet

- FTMCDocument12 pagesFTMCELLIN GAMINGNo ratings yet

- UPVC Pipe Fitting & CPVC Pipe Fitting & PVC Valve: Price List EFFECTIVE Dt. 11/11/2017 Upvc ProductDocument7 pagesUPVC Pipe Fitting & CPVC Pipe Fitting & PVC Valve: Price List EFFECTIVE Dt. 11/11/2017 Upvc ProductRavi ShankarNo ratings yet

- Hypothetical Process PathsDocument9 pagesHypothetical Process Pathsifiok100% (1)

- Flow Meter Orifice CalculationDocument27 pagesFlow Meter Orifice CalculationLaksono BudiNo ratings yet

- Oule-Thomson Effect (焦耳-湯普森擴散效應)Document38 pagesOule-Thomson Effect (焦耳-湯普森擴散效應)augur886No ratings yet

- Phys 211 11a.law of Heat Exchange and Change of PhaseDocument6 pagesPhys 211 11a.law of Heat Exchange and Change of PhaseRegina May Dela CruzNo ratings yet

- VasimrDocument12 pagesVasimrRishikesh DineshNo ratings yet

- Improvement in Patel Teja Eqn of StatesDocument10 pagesImprovement in Patel Teja Eqn of StatesSumukh VermaNo ratings yet

- MicellsDocument12 pagesMicellsZunairaNo ratings yet

- 4.1chemical Bonding TeacherDocument5 pages4.1chemical Bonding TeacherMichelle NgNo ratings yet

- Pressurized Glycol Dehy SystemsDocument11 pagesPressurized Glycol Dehy SystemsJagan BoseNo ratings yet

- Current Applied Physics: Shalom Ann Mathews, D. Rajan BabuDocument15 pagesCurrent Applied Physics: Shalom Ann Mathews, D. Rajan BabuSoham MukherjeeNo ratings yet

- Brunner-Emmett-Teller Theory: Presented By: Tehseen Zehra Uswa Zahra Muntaha Nasir Summayya ShafiqueDocument22 pagesBrunner-Emmett-Teller Theory: Presented By: Tehseen Zehra Uswa Zahra Muntaha Nasir Summayya ShafiqueSummayya ShafiqueNo ratings yet

- Ejector Vs EductorDocument3 pagesEjector Vs Eductorok barve100% (4)

- Thermal Physics 12 GradeDocument42 pagesThermal Physics 12 GradeAmri Ramadhan D'classicNo ratings yet

- Is 5760 1998Document14 pagesIs 5760 1998Prabakaran BalaramanNo ratings yet

- Variable Head Type FlowmetersDocument32 pagesVariable Head Type FlowmetersAnuNarayan R100% (2)

- 2100 Nold DeAeratorDocument18 pages2100 Nold DeAeratorTantai RakthaijungNo ratings yet

- E1719-Standard Test Method For Vapor Pressure of Liquids by EbulliometryDocument7 pagesE1719-Standard Test Method For Vapor Pressure of Liquids by EbulliometryrezaNo ratings yet

- DV03PUB1 Study GuideDocument5 pagesDV03PUB1 Study Guideprasaad08No ratings yet

- 1 s2.0 S0360319922007297 Main - 2Document17 pages1 s2.0 S0360319922007297 Main - 2DEV RAJNo ratings yet