Professional Documents

Culture Documents

Static and Dynamic Characteristics of Slotted Cylinder Spring

Uploaded by

Hani Aziz AmeenOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Static and Dynamic Characteristics of Slotted Cylinder Spring

Uploaded by

Hani Aziz AmeenCopyright:

Available Formats

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 2 Issue 12, December - 2013

Static and Dynamic Characteristics of Slotted Cylinder Spring

Ahmed Ibrahim Razooqi(1)

Asst. Prof. Dr. Hani Aziz Ameen(2)

Dr. Kadhim Mijbel Mashloosh(3)

(1) , (2) , (3)

Technical College- Baghdad- Dies and Tools Eng. Dept.

Abstract

IJE

RT

Slotted cylinder spring (SCS) is a unique and unusual spring with special

properties and configuration. There is a little or even no literature on its

behavior under static and dynamic modes of stresses. In this research an attempt

was made to study the characteristics of such a spring under both static and

dynamic loading using a finite element method with the aid of ANSYS11

program. Two cases were studied, one with three slots and the other with four

slots. Five modes shapes of each case were employed. The transient analysis

due to impact and static loadings were presented.

The results showed that the SCS are more complicated in compression with the

conventional helical compression springs regarding the deflection resulted from

applying static or dynamic loads. The SCS is capable of absorbing loads to such

a range which is impossible in the case of conventional spring. It is very clear

that the stiffness of a four slots springs was higher than that of three slots, even

through the distribution of the deflection along the spring was the same. The

natural frequency of the four slots spring is much higher than that of three slots

spring. In the case of the impact loading, the results showed that the response at

the bottom of the spring is zero and gradually increased towardthe top of the

spring. This was more obvious in the case of three slots spring.

Keywords:Spring, slotted cylinder spring, ANSYS, Finite elementmethod,

vibration, dynamic analysis, natural frequency, impact load

1. Introduction

The slotted cylinder spring can be considered as parallel series assembly from

cylindrical pipes having grooves like windows and represented the flat rings,

connected by vertical path. Its equivalent to the compressive spring when

collected on each other and vice versa, and its used in equipments with

different sizes. Like any other spring, the design of the slotted cylinder spring

depends on geometric parameters, material parameters and load- deflection

characterization. The slotted cylinder springs are specified within the rigid

stiffness springs, i.e. with hard axial load, the body of spring displaced

gradually. The slotted cylinder springs used in many fields of industry, like

transducer for the generation of seismic waves, which combined the small and

IJERTV2IS120671

www.ijert.org

3860

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 2 Issue 12, December - 2013

large stiffness of elastic elements in electromechanical equipments and in the

bridges and buildings to damp the earthquakes. Other application is growing

continuously like slotted cylinder spring used in the large press to damp the

impact of the punch on the die.

The most prominent task for which the springs aredesigned in the machine

partsfor energy storage, and rewind for the purpose of achievinga particular act

at a particular time, as an important parameter entry in the design which is the

space occupied by the spring, it is an important factor in the design, and this

might affects the design of the dies. The slotted cylinder spring meets the work

requirements for small spaces and with great local capacity which can not be

provided by springs from other types.In the design of dies there are

complications in the size of the die as a result of the availability of small

powerful springs according to the space available for designer is forced to fight

many complexities in the design of the die. The use ofslotted cylinder springs in

the dies and specially in the cutting dies simplified the design process and

makes it more economical and practical at the same time.

2. Previous Research

IJE

RT

The report ofWilhem A. Schneider, 1963 [1] Its the only one who worked on

the slotted cylinder spring, in this report the unique characteristics of high load

capacity and low deflection in extremely small size was discussed.

Theexperimental and theoretical investigation is reported by Wilhem A.

Schneider, 1963 [1]. V. Yldrm (2009) [2] studied the free vibration of

cylindrical isotropic helical springs loaded axially. Ikechukwu Celestine

Ugwuoke (2008) [3] studied the dynamic model for the constant-force

compression spring based on the pseudo-rigid-body model.B.Vijaya Lakshmi

and I. Satyanarayana (2012) [4] studied static and dynamic analysis on

composite leaf spring in heavy vehicle, Gaikwad and Kachare (2013) [5],

studied the static analysis of helical compression spring used in two-wheeler

horn.Christine Vehar Jutte and Sridhar Kota (2008) [6] design of nonlinear

springs for prescribed load-displacement functions, they presented a generalized

nonlinear spring synthesis methodology that (i) synthesizes a spring for any

prescribed nonlinear load-displacement function and (ii) generates designs

having distributed compliance.K.A. Saianuraag &BitraguntaVenkataSivaram

(2012)[7] , studied the comparison of static, dynamic & shock analysis for two

& five layered composite leaf spring, the leaf springs are modeled with

unigraphics software NX7.5 and the analysis is carried out using ANSYS 11.G.

Harinath Gowd and E. Venugopal Goud (2012)[8] studied the static analysis

of leaf spring, in this work the analyzing the safe load of the leaf spring, which

will indicate the speed at which a comfortable speed and safe drive is possible.

A typical leaf spring configuration of TATA-407 light commercial vehicle is

chosen for study. Finite element analysis has been carried out to determine the

safe stresses and pay loads.Krzystof Michalczyk(2006) [9]presented the modern

IJERTV2IS120671

www.ijert.org

3861

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 2 Issue 12, December - 2013

construction of slotted springs, it was proven that maximal stresses in such

springs under load have higher values than the stresses calculated with previous

method. Viatcheslav Gnateski (2012) [10] presented a vibration damping

device adapted to receive an electronic component and reduce vibration.

No studies have been devoted to the case of static and dynamic slotted cylinder

spring. This paper presents an investigation theoretically and numerically via

ANSYS software to predict the design characterization of the slotted cylinder

springand have a novel discussionof the dynamic behavior (natural frequencies,

mode shapes and transient response) of the slotted cylinder spring.

3.Theoretical Part

The total deflection of a slotted cylinder spring is reported by Wilhem A.

Schneider, 1963 [1] as follows:

.3 .

.16.. 3 .

.. (1)

IJE

RT

Where :

P..

total compression load

E.. Yongs modulus of elasticity

Ls.. length of slot

nss.. number of slot section

ns.. number of slots per section

b..

wall thickness

h..

height of horizontal path

.. total deflection

4.Numerical Investigation

Numerical simulations allow the analysis of a complex phenomena without

resorting to expensive prototypes and different experimental measurements.

ANSYS is a finite element analysis software package. This program analyzes

and solves a wide range of different problems, such as the modal , harmonic and

transient analysis. The typical analysis in ANSYS involves three distinct

processors [11], (1) the processor (PREP7), (2) (SOLUTION) and (3) following

the general post processor (POST1) and time history postprocessor (POST26).

The processor (PRESP7) contains the commands needs to build a model.

Defining element types (SOLID45), real constant, material properties (Steel

with Young modulus (E)=210 Gpa, possions ratio= 0.33 , and density

() = 7850 /3 ,

( ) = 1030 ), creating model

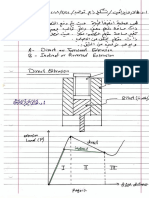

geometry as in Fig.1.

IJERTV2IS120671

www.ijert.org

3862

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 2 Issue 12, December - 2013

IJE

RT

where :

Outer diameter (Do) =50.8 mm

Inner diameter (Di) = 44.45 mm

Height of Horizontal path ( h ) =2.38 mm

Height of slot (hs ) = 0.78 mm

No. of slots = 60

Fig.1 Slotted cylinder spring

Then meshing the created model [12], mesh must be regular, one section is built

and meshed then copy for 60 sections, this is important in minimizing the

solution time and increasing the accuracy when boundary condition is applied.

In this work the finite element model is built up manually ( through the APDL )

according to the steps which will be followed, automatic building of the mesh is

possible through a macroprogram [13], in the present work the design and

analysis are concerned for the slotted cylinder spring. Different geometries are

used (three slots and four slots with different geometry parameters). Fig.2

shows the meshing of the slotted cylinder spring.

IJERTV2IS120671

www.ijert.org

3863

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 2 Issue 12, December - 2013

Fig.2 meshing the slotted cylinder spring

IJE

RT

The solution processor (SOLUTION) has the commands that allow to apply the

boundary conditions and loads. Once all the information are made available to

the solution processor, it solves the nodal solution. The solutions to be obtained

depend on the type of analysis that should be performed, in the present work,

three types of analysis are used, STATIC, MODAL, and TRANSIENT. In the

STATIC solution, it can be get the deflection for the slotted cylinder spring

according to equation(2) [14].

= . (2)

Whereas in Modal and Transient analysis , it can be used the following equation

[M]{} [K]{ } {F( t ) } ....(3)

Where:

M

[K] = overall stiffness matrix =

K e

i 1

[M] = overall stiffness matrix = M e

M

i 1

[F(t)] = assemblage of resultant vector of nodal forcing

Parameters

While in the MODAL solution , Hani [15], show the details of the theory used

in this dynamic characteristics, so only basic points are described in brief as

below. In the first step, eigen modes of the slotted cylinder spring are obtained

from the following equation

([ K s ] 2 [M s ]){u} 0 ...(4)

IJERTV2IS120671

www.ijert.org

3864

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 2 Issue 12, December - 2013

the eigen mode of the slotted spring of the n modes from Eq.(4) as follows :

n

u i Ci C

i 1

.... (5)

In the second step, this reduced eigenvalue equation is solved.

In TRANSIENT solution.The impact load is applied as shown in Fig.3

12.00

4.00

IJE

RT

Pressure (N/m2)

8.00

0.00

-4.00

0.00

0.00

0.00

0.01

0.01

0.01

time (sec)

Fig.3 Impact load applied on the slotted cylinder spring

Slotted cylinder springs are very often subjected to transient excitation. A

transient excitation is a highly dynamic, time- dependent force exerted on the

solid or structure, such as earthquake, impact and shocks [16] .

The discrete governing equation system for such a structure is still equation(3),

but it often requires a different solver from that used in eigenvalue analysis. The

widely used method is the so-called direct integration method. The direct

integration method basically uses the finite difference method for time step-ping

to solve equation(3). There are two main types of direct integration method:

implicit and explicit. Implicit methods are generally more efficient for a

relatively slow phenomena, and explicit methods are more efficient for a very

IJERTV2IS120671

www.ijert.org

3865

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 2 Issue 12, December - 2013

fast phenomenon, such as impact and explosion. The most widely used

algorithm is Newmarks method thatused in ANSYS for transient analysis.

5.Results and Discussion

IJE

RT

Slotted cylinder spring model analysis is investigated in which the static

analysis is investigated for each case as shown in Fig.4 , it can be deduced that

the stiffness of the slotted cylinder spring in case of four slots is more than

three slots , but the distribution of the deflection along the spring is the same as

shown in Figs. 5 and 6. Eigenvalue and eigenvector for each case is studied.

Free vibration analysis consists of studying the vibration characteristics of the

slotted spring, such as natural frequency and mode shapes.The natural

frequency and mode shapes of a slotted cylinder spring are very important

parameters in the design of a machine parts and dies and punches for dynamic

loading conditions and minimization of machine and dies failures, Fig.7 shows

the natural frequencies for each case (3 slots and 4 slots)against to five mode

shapes, from this figure it can be deduced that the natural frequency for four

slotted cylinder spring is more higher than that of three slots since the SCS with

four slots have higher stiffness than three slots. Figs. 8 and 9 show the five

mode shapes for each case (3 slots and 4 slots) , it can be seen it is the same

mode shapes. Also a forced vibration is studied by imposing the slotted

cylinder spring to the impact loading (as shown in Fig.3) to show its response

for both cases. Figs.10 and 11 show the response of the slotted cylinder spring

with three slots and four slots respectively, it can be seen that the response at the

bottom is zero and increased toward the top of the spring for each case but the

response of the spring with three slots is more than that four for slots.

Fig.4 Force- Deflection curves for three and four slotted cylinder spring

IJERTV2IS120671

www.ijert.org

3866

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 2 Issue 12, December - 2013

Fig. 6 The distribution of the deflection

along the slotted cylinder spring with

four slots

IJE

RT

Fig.5The distribution of the deflection

along the slotted cylinder spring with

three slots

300.00

three slotted cylinder spring

Natural Frequency (Hz)

four slotted cylinder spring

200.00

100.00

0.00

1.00

2.00

3.00

4.00

5.00

Mode Number

Fig. 7The natural frequencies for three and four slotted cylinder spring

IJERTV2IS120671

www.ijert.org

3867

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 2 Issue 12, December - 2013

Fig.9The modes shape of the slotted

cylinder spring with four slots

IJE

RT

Fig.8The modes shape of the slotted

cylinder spring with three slots

Fig. 11 Response to the impact load at three points on the four slotted cylinder spring

IJERTV2IS120671

www.ijert.org

3868

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

IJE

RT

Vol. 2 Issue 12, December - 2013

Fig. 10 Response to the impact load at three points on the three slotted cylinder spring

6.Conclusions

1- The slotted cylinder springs are more complicated in the manufacturing

process compared to the conventional one, but the former will do jobs

which can never being accomplished with conventional one.

2- It can be deduced from the static analysis that the stiffness of the slotted

cylinder spring in case of four slots is more than three slots, but the

distribution of the deflection along the spring is the same

3- For Modal analysis, it can be deduced that the natural frequency for four

slotted cylinder spring is more higher than that of three slots.

4- At impact load, it can be seen that the response at the bottom of the spring

is zero and increased toward the top of the spring for each case but the

response of the spring with three slots is more than that for four slots.

IJERTV2IS120671

www.ijert.org

3869

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 2 Issue 12, December - 2013

7.References

[1] Wilhelm A. Schneider, Design and application of slotted cylinder springs,

United States Army, USAELRDL Technical Report 2327,1963.

[2] V. Yldrm, Numerical Buckling Analysis of Cylindrical Helical Coil

Springs in A Dynamic Manner, International Journal of Engineering and

Applied Sciences (IJEAS), Vol.1, Issue 120-32,2009.

[3] Ikechukwu Celestine Ugwuoke, A Simplified Dynamic Model for

Constant-Force Compression Spring, Leonardo Journal of Sciences, Issue 13,

July-December, p. 30-43, 2008.

[4] B.Vijaya Lakshmi and I. Satyanarayana , Static And Dynamic Analysis on

Composite Leaf Spring In Heavy Vehicle, International Journal of Advanced

Engineering Research and Studies, IJAERS/ Vol. II / Issue I /Oct.-Dec. , /8084.2012.

IJE

RT

[5] S. S. Gaikwad and P. S. Kachare, Static Analysis of Helical Compression

Spring Used in Two-Wheeler Horn, International Journal of Engineering and

Advanced Technology (IJEAT), Volume-2, Issue-3 February 2013.

[6] Christine Vehar Jutte and Sridhar Kota , Design of Nonlinear Springs for

Prescribed Load-Displacement Functions, Journal of Mechanical Design,

ASME August, Vol. 130.2008.

[7] K.A. Saianuraag &BitraguntaVenkataSivaram, Comparison of Static,

Dynamic & Shock Analysis for Two & Five Layered Composite Leaf Spring,

International Journal of Engineering Research and Applications (IJERA) ,Vol.

2, Issue 5, September- October 2012, pp.692-697,2012.

[8] G. Harinath Gowd and E. Venugopal Goud , Static Analysis of Leaf

Spring, International Journal of Engineering Science and Technology (IJEST),

Vol. 4 No.08 August 2012.

[9] Krzysztof Michalczyk, Stress Analysis in Slotted Springs, Mechanics,

Vol. 25, No. 3, 2006.

[10] Viatcheslav Gnateski, Slotted Spring Vibration Isolator, United States

Patent Application Publication, No. US 2012/0049422 Al, Mar. 1, 2012.

[11] ANSYS help, users manual FEA/ANSYS/ version 11, 2010.

IJERTV2IS120671

www.ijert.org

3870

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 2 Issue 12, December - 2013

[12] Saeed Moaveni , Finite element analysis theory and application with

ANSYS , 2nd edition , 2003.

[13] Y. Nakasone and S. Yoshimoto and T.A. Stolarski, Engineering analysis

with ANSYS software , 1st published, 2006 .

[14] Mario Paz and William Liegh Structural Dynamics theory and

computation , 5th edition, 2004.

[15] Hani Aziz Ameen , The Effect of Coupled Field on the Vibration

Characteristics and Stresses of Turbomachinery System , European Journal of

Scientific Research, ISSN 1450-216X Vol.41 No.4 , pp.606-626, 2010.

IJE

RT

[16] G.R.Liu and S.S. Quek The Finite element method : A practical course

,1st published, 2003 .

IJERTV2IS120671

www.ijert.org

3871

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- 8-High Rate Enfergy Forming-Prof - Dr.haniDocument7 pages8-High Rate Enfergy Forming-Prof - Dr.haniHani Aziz AmeenNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Stess Elasticity Prof - Dr.hani Aziz AmeenDocument53 pagesStess Elasticity Prof - Dr.hani Aziz AmeenHani Aziz AmeenNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Formability of Laser WeldingDocument9 pagesFormability of Laser WeldingHani Aziz AmeenNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- 4-Extrusion Process-Prof - Dr.hani Aziz AmeenDocument42 pages4-Extrusion Process-Prof - Dr.hani Aziz AmeenHani Aziz AmeenNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- 2-Wire Drawing-Prof - Dr.Hani Aziz Ameen PDFDocument15 pages2-Wire Drawing-Prof - Dr.Hani Aziz Ameen PDFHani Aziz AmeenNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- 7-Blanking and Piercing-Prof - Dr.hani AzizDocument4 pages7-Blanking and Piercing-Prof - Dr.hani AzizHani Aziz AmeenNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Rolling Process-Prof - Dr.hani Aziz AmeenDocument18 pagesRolling Process-Prof - Dr.hani Aziz AmeenHani Aziz AmeenNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Effect of Post-Buckling On The Stiffness and Stress of Plate - Hani Aziz AmeenDocument16 pagesEffect of Post-Buckling On The Stiffness and Stress of Plate - Hani Aziz AmeenHani Aziz AmeenNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Manufacturing Cosine Die Profile For Tubes Hydroforming Test (Bulging)Document19 pagesManufacturing Cosine Die Profile For Tubes Hydroforming Test (Bulging)Hani Aziz AmeenNo ratings yet

- Deep Drawing - Prof - Dr.hani Aziz AmeenDocument17 pagesDeep Drawing - Prof - Dr.hani Aziz AmeenHani Aziz AmeenNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- RESIDUAL ELASTO-PLASTIC STRESSES ANALYSIS OF POLYMERIC THICK - WALLED PRESSURIZED CYLINDER - Hani Aziz AmeenDocument14 pagesRESIDUAL ELASTO-PLASTIC STRESSES ANALYSIS OF POLYMERIC THICK - WALLED PRESSURIZED CYLINDER - Hani Aziz AmeenHani Aziz AmeenNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Finite Element Analysis of Large Diameter Concrete Spherical Shell Domes - Hani Aziz AmeenDocument16 pagesFinite Element Analysis of Large Diameter Concrete Spherical Shell Domes - Hani Aziz AmeenHani Aziz AmeenNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- شهادة تقديرية - دكتور هاني عزيز أمين PDFDocument1 pageشهادة تقديرية - دكتور هاني عزيز أمين PDFHani Aziz AmeenNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Effect of Coupled Field On The Vibration Characteristics and Stresses of Turbomachinery System - Hani Aziz AmeenDocument21 pagesThe Effect of Coupled Field On The Vibration Characteristics and Stresses of Turbomachinery System - Hani Aziz AmeenHani Aziz AmeenNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Experimental and Theoretical Investigation of Impact Dynamic Plasticity For CK45 - Hani Aziz AmeenDocument9 pagesExperimental and Theoretical Investigation of Impact Dynamic Plasticity For CK45 - Hani Aziz AmeenHani Aziz AmeenNo ratings yet

- Finite Element Analysis of The Dish Multi-Point FormingDocument10 pagesFinite Element Analysis of The Dish Multi-Point FormingHani Aziz AmeenNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Effect of Coupled Field On The Vibration Characteristics and Stresses of Turbomachinery System - Hani Aziz AmeenDocument21 pagesThe Effect of Coupled Field On The Vibration Characteristics and Stresses of Turbomachinery System - Hani Aziz AmeenHani Aziz AmeenNo ratings yet

- Ansys Analysis of Concrete Planter Round PDFDocument6 pagesAnsys Analysis of Concrete Planter Round PDFHani Aziz AmeenNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Effect of Loading Path On Stress DistributionDocument12 pagesEffect of Loading Path On Stress DistributionHani Aziz AmeenNo ratings yet

- Slotted Cylinder SpringDocument11 pagesSlotted Cylinder SpringHani Aziz AmeenNo ratings yet

- ANSYS of Groundwater Flow Problem-Hani Aziz AmeenDocument10 pagesANSYS of Groundwater Flow Problem-Hani Aziz AmeenHani Aziz Ameen100% (2)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Professor DR Hani Aziz AmeenDocument1 pageProfessor DR Hani Aziz AmeenHani Aziz AmeenNo ratings yet

- Manufacturing Cosine Die Profile For Tubes Hydroforming Test (Bulging)Document19 pagesManufacturing Cosine Die Profile For Tubes Hydroforming Test (Bulging)Hani Aziz AmeenNo ratings yet

- Hani Aziz Ameen هاني عزيز امينDocument3 pagesHani Aziz Ameen هاني عزيز امينHani Aziz AmeenNo ratings yet

- PDF Created With Pdffactory Pro Trial VersionDocument1 pagePDF Created With Pdffactory Pro Trial VersionHani Aziz AmeenNo ratings yet

- Moving and Repeating Load in Ansys APDL - Hani Aziz AmeenDocument4 pagesMoving and Repeating Load in Ansys APDL - Hani Aziz AmeenHani Aziz AmeenNo ratings yet

- Hani Aziz Ameen هاني عزيز امينDocument3 pagesHani Aziz Ameen هاني عزيز امينHani Aziz AmeenNo ratings yet

- Hani Aziz Ameen هاني عزيز امينDocument3 pagesHani Aziz Ameen هاني عزيز امينHani Aziz AmeenNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- PDF Created With Pdffactory Pro Trial VersionDocument1 pagePDF Created With Pdffactory Pro Trial VersionHani Aziz AmeenNo ratings yet

- Case Study Volcano MTDocument2 pagesCase Study Volcano MTANIA GONZALEZ VALLESNo ratings yet

- Bhuj2011 AbstractvolumeDocument168 pagesBhuj2011 AbstractvolumeRajendra ShahNo ratings yet

- S9 B.Arch Syllabus 2017 SchemeDocument19 pagesS9 B.Arch Syllabus 2017 SchemeROSENo ratings yet

- Changing Landforms BookDocument14 pagesChanging Landforms Bookapi-298672230No ratings yet

- Fhwa HRT 05 067Document371 pagesFhwa HRT 05 067aapennsylvaniaNo ratings yet

- Lesson 7 Earthquake Hazard and PreparednessDocument83 pagesLesson 7 Earthquake Hazard and PreparednessAndrea Marie Santiago-RayoNo ratings yet

- Calculation Report - Lap PoolDocument28 pagesCalculation Report - Lap PoolmantongsNo ratings yet

- Report of Building of Nilkantha Agrawal, Itahari-6, SunsariDocument17 pagesReport of Building of Nilkantha Agrawal, Itahari-6, SunsariRabin BhattaraiNo ratings yet

- 2010Document23 pages2010Anonymous 6v4TnExUcdNo ratings yet

- Geological Forces That Shape The EarthDocument9 pagesGeological Forces That Shape The EarthAnjo Pasiolco CanicosaNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Contoh Soal Uts 1Document5 pagesContoh Soal Uts 1yudisNo ratings yet

- Swiss Re - FloodDocument28 pagesSwiss Re - Floodjulienlours100% (1)

- Earth QuakeDocument16 pagesEarth QuakeJoseph ZotooNo ratings yet

- Detailed Syllabus of VII - X SEM B.arch. (VTU - CBCS - 2015 Scheme)Document40 pagesDetailed Syllabus of VII - X SEM B.arch. (VTU - CBCS - 2015 Scheme)Sandra Moses100% (1)

- NSTP ActivityDocument1 pageNSTP ActivityKelsy Laye Khloe' RamirezNo ratings yet

- Secondary 3 Geography Manual Practice BookDocument32 pagesSecondary 3 Geography Manual Practice BookKate YatiNo ratings yet

- Unit3Document291 pagesUnit3mongkol_1001No ratings yet

- Mayan Calendar PropheciesDocument198 pagesMayan Calendar PropheciesCarol Markus100% (2)

- Prediction of Strong Ground Motion at Somnath TempDocument13 pagesPrediction of Strong Ground Motion at Somnath TempshivaNo ratings yet

- Seismic Vulnerability Analysis of The Historic Sultaniya DomeDocument12 pagesSeismic Vulnerability Analysis of The Historic Sultaniya DomemanjunathNo ratings yet

- LP RankingDocument9 pagesLP RankingEdmar Cielo SarmientoNo ratings yet

- Disaster Awareness and Preparedness of PDocument5 pagesDisaster Awareness and Preparedness of PChristine T. MompolNo ratings yet

- 2013Document302 pages2013Alexandra Dumitrescu100% (1)

- SIGNS OF JESUS RETURN, How Close?Document17 pagesSIGNS OF JESUS RETURN, How Close?jeanpeskyNo ratings yet

- Holtar 2000 m73ch29Document18 pagesHoltar 2000 m73ch29Herbert MohriNo ratings yet

- Retrofitting and Strengthening of StructuresDocument73 pagesRetrofitting and Strengthening of StructuresBori GeorgeNo ratings yet

- KH - Design CriteriaDocument8 pagesKH - Design Criteriamohamed_126193901No ratings yet

- RefsDocument38 pagesRefsLê TrungNo ratings yet

- Design of Steel StructuresDocument62 pagesDesign of Steel StructuresMayur GajeraNo ratings yet

- Chọn phương án (A, B, C hoặc D) ứng với từ có trọng âm chính nhấn vào âm tiết có vị trí khác với 3 từ còn lại trong mỗi câuDocument7 pagesChọn phương án (A, B, C hoặc D) ứng với từ có trọng âm chính nhấn vào âm tiết có vị trí khác với 3 từ còn lại trong mỗi câuDinh HoaiNo ratings yet