Professional Documents

Culture Documents

1.0 General: Drafting Manual

Uploaded by

julio_rodriguesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1.0 General: Drafting Manual

Uploaded by

julio_rodriguesCopyright:

Available Formats

Update 69

Gary Whitmire

DRAFTING MANUAL

Gears (Bevel and Hypoid)

Drafting Practice

Section 4.9.1

Page 1

August, 2003

Genium Publishing Corporation

1.0 General

This section provides the basis for uniformity in engineering gears drawings and their technical data for gears

with intersecting axes (bevel gears), and nonparallel, nonintersecting axes (hypoid gears). It also discusses the

method of specifying matched sets on a gear drawing.

2.0 Purpose

It is the purpose of this section to provide formats, nomenclature, and definitions. The minimum data for the

various gear types are defined. Where additional data are required, methods for specifying these data are shown.

Slight deviations for critical applications are allowed, provided general formats are maintained.

2.1 Examples - Various types of gears are illustrated by sample drawings.

2.2 Dimensioning and Notes - Illustrations show only those dimensions which control the gear teeth and their

relation to the specified mounting. All other dimensions and specifications shall conform to recommended

drafting practice. Dimensional values show the number of decimal places recommended in each instance.

Where required to assure calculations, such as for pin measurement or master gears, accurate to the fourth place to

the right of the decimal point, it is necessary to specify the base diameter, pitch diameter, helix angle, and non-

whole number diametral pitch to eight or seven significant places.

2.2.1 Angular Dimensions - All angular dimensions shall be expressed in degrees and decimal portions thereof.

(Where desired, the angle may be given in degrees, minutes and seconds.)

3.0 Applicable Documents

The following reference documents contain additional information and should be used when applicable.

ASME Y14.38 Abbreviations and Acronyms

ASME Y14.1 Decimal Inch. Drawing Sheet Sizes and Format

ASME Y14.1M Metric Drawing Sheet Sizes and Format

ASME Y14.2M Line Conventions and Lettering

ASME Y14.3M Multiview and Sectional View Drawings

ASME Y14.5M Dimensioning and Tolerancing

ASME Y14.36M Surface Texture Symbols

AGMA 112.04 Gear Nomenclature - Terms, Definitions, Symbols, and Abbreviations

Update 69

Gary Whitmire

DRAFTING MANUAL

Gears (Bevel and Hypoid)

Drafting Practice

Section 4.9.1

Page 2

August, 2003

Genium Publishing Corporation

4.0 Gear Drawing Practices

4.1 Arrangement - The gear drawing shall clearly illustrate the general configuration. The method of

manufacture, the quantities involved and the desired inspection method may influence the method of

dimensioning. Illustrations of various gear configurations are provided for guidance only and are not mandatory.

4.1.1 Gear Data - Gear data shall be grouped as illustrated and shall be presented in the order shown. The location

of the gear data on the drawing is optional.

4.1.2 Specifying a Diameter For external gears only, the major diameter is specified as the outside diameter and

the minor diameter is specified as the root diameter. For internal gears the major diameter is specified as the root

diameter and the minor diameter is specified as the inside diameter. This is in keeping with present usage in some

segments of the gear industry.

4.2 Manufacturing Method - The drawing shall clearly depict the product without reference to a manufacturing

or inspection method. This rule may be disregarded only where special situations are involved which do not lend

themselves to exact specifications and tool inspection information is necessary for control.

4.3 Drawing Title - For identification purposes, the title should include the word pinion or gear as applicable.

4.4 Straight Bevel Gear Teeth

4.4.1 Straight bevel gear and pinion teeth are drawn as shown in Figure 1. The mounting distance shown on the

drawing is an assembly dimension and is specified as a reference dimension.

Update 69

Gary Whitmire

DRAFTING MANUAL

Gears (Bevel and Hypoid)

Drafting Practice

Section 4.9.1

Page 3

August, 2003

Genium Publishing Corporation

.XXX

.XXX

(

.XXX

)

(

X.XXXX

)

(

X.XXX

)

Mounting Distance

X.XXX

X.XXX

X.XXX

X.XXX

X.XXXX

X.XXXX

X.XXX

X.XXX

See note 1

See note 1

XX.XX

XX.XX

XX.XX

XX.XX

See note 1

See note 1

XX.XX

XX.XX

FACE APEX

A

.XXX A

AXIS OF

MATING

MEMBER

Note 1: When face angle distance and back angle distance (See Figure 9) are

used for dimensioning the gear blank, the face angle and the back angle should

be given as reference dimensions on the drawing without a tolerance.

Figure 1. Straight Bevel Gear/Pinion

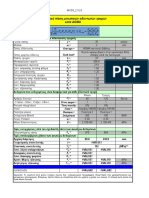

4.4.2 Gear data not included in Figure 1 are tabulated on the drawing as shown in Figure 2. The drawing must

also show material and heat treatment specifications.

NUMBER OF TEETH XX

DIAMETRAL PITCH (See note 1)

(XX.XXX)

PRESSURE ANGLE (XX.XX)

PITCH DIAMETER (X.XXXX)

Update 69

Gary Whitmire

DRAFTING MANUAL

Gears (Bevel and Hypoid)

Drafting Practice

Section 4.9.1

Page 4

August, 2003

Genium Publishing Corporation

ADDENDUM (.XXX) (See note 2)

WORKING DEPTH (.XXX) (See note 2)

WHOLE DEPTH .XXX-.XXX (See note 2)

THEORETICAL OUTSIDE DIAMETER (X.XXX) (See note 2)

THEORETICAL CROWN TO BACK (X.XXX) (See note 2)

PITCH ANGLE (XX.XX) (See note 2)

ROOT ANGLE (XX.XX)

CIRCULAR THICKNESS (.XXXX) (See note 2)

MEAN MEASURING ADDENDUM .XXX (See note 2)

MEAN MEASURING THICKNESS .XXX-.XXX (See note 2)

NORMAL BACKLASH WITH MATE .XXX-.XXX (See note 2)

BACKLASH VARIATION TOLERANCE (See note 3) .XXXX

SHAFT ANGLE (XX.XX)

FILLET RADIUS .XXX-.XXX (See note 2)

RUNOUT TOLERANCE (See note 3) .XXXX

PITCH TOLERANCE (See note 3) .XXXX

INDEX TOLERANCE (See note 3) .XXXX

TOOTH SURFACE TEXTURE XX AA OR R

a

AGMA QUALITY CLASS XX

TOOTH FORM CONIFLEX OR REVACYCLE

DRIVING MEMBER PINION OR GEAR

DIRECTION OF ROTATION CW AND/OR CCW

MFG SUMMARY NUMBER XXXXXX

PART NUMBER OF MATE XXXXXXXX-X

NUMBER OF TEETH IN MATE XX

Notes 1. For metric drawings, specify module in place of diametral pitch.

2. For metric drawings, reduce by one the number of decimal places to the right.

3. See 5.18.3, 5.23 5.26 for when to specify these values on the gear drawing.

Figure 2. Data Specifications For Straight Bevel Gears

Update 69

Gary Whitmire

DRAFTING MANUAL

Gears (Bevel and Hypoid)

Drafting Practice

Section 4.9.1

Page 5

August, 2003

Genium Publishing Corporation

4.5 Spiral Bevel Gear Teeth

4.5.1 Spiral bevel gear and pinion teeth are drawn as shown in Figure 3.

.XXX

.XXX

(

.XXX

)

(

.XXX

)

(

X.XXXX

)

(X.XXX)

Mounting Distance

X.XXX

X.XXX

X.XXX

X.XXX

X.XXXX

X.XXXX

See note 1

XX.XX

XX.XX

XX.XX

XX.XX

See note 1

See note 1

XX.XX

XX.XX

FACE APEX

A

.XXX

AXIS OF

MATING

MEMBER

Note 1: When face angle distance and back angle distance (See Figure 9) are

used for dimensioning the gear blank, the face angle and the back angle should

be given as reference dimensions on the drawing without a tolerance.

X.XXX

X.XXX

See note 1

.XXX M A

Figure 3. Spiral Bevel Gear/Pinion

Update 69

Gary Whitmire

DRAFTING MANUAL

Gears (Bevel and Hypoid)

Drafting Practice

Section 4.9.1

Page 6

August, 2003

Genium Publishing Corporation

4.5.2 Gear data not illustrated in Figure 3 are tabulated on the drawing as shown in Figure 4. The drawing must

also show material and heat treatment specifications.

NUMBER OF TEETH XX

DIAMETRAL PITCH (See note 1)

(XX.XXX)

NORMAL PRESSURE ANGLE (XX.XX)

MEAN SPIRAL ANGLE (XX.XX)

PITCH DIAMETER (X.XXXX)

ADDENDUM (.XXX) (See note 2)

WORKING DEPTH (.XXX) (See note 2)

WHOLE DEPTH (.XXX) (See note 2)

THEORETICAL OUTSIDE DIAMETER (X.XXX) (See note 2)

THEORETICAL CROWN TO BACK (X.XXX) (See note 2)

PITCH ANGLE (XX.XX)

ROOT ANGLE (XX.XX)

CIRCULAR THICKNESS (.XXXX) (See note 2)

MEAN MEASURING ADDENDUM .XXX (See note 2)

MEAN MEASURING THICKNESS .XXX-.XXX (See note 2)

MEAN MEASURING DEPTH .XXX-.XXX (See note 2)

NORMAL BACKLASH WITH MATE .XXX-.XXX (See note 2)

BACKLASH VARIATION TOLERANCE (See note 3) .XXXX (See note 2)

SHAFT ANGLE (XX.XX)

FILLET RADIUS .XXX-.XXX (See note 2)

RUNOUT TOLERANCE (See note 3) .XXXX

PITCH TOLERANCE (See note 3) .XXXX

INDEX TOLERANCE (See note 3) .XXXX

TOOTH SURFACE TEXTURE XX AA OR R

a

AGMA QUALITY CLASS XX

TOOTH FORM GENERATED OR FORMATE OR

HELIXFORM

DRIVING MEMBER PINION OR GEAR

DIRECTION OF ROTATION CW AND/OR CCW

MFG SUMMARY NUMBER XXXXXX

Update 69

Gary Whitmire

DRAFTING MANUAL

Gears (Bevel and Hypoid)

Drafting Practice

Section 4.9.1

Page 7

August, 2003

Genium Publishing Corporation

PART NUMBER OF MATE XXXXXXXX-X

NUMBER OF TEETH IN MATE XX

V AND H CHECK IN THOUSANDTHS OF AN INCH (OR HUNDREDTHS OF A MILLIMETER) FOR

FINISHED GEARS (See note 4).

Gear Convex Toe Heel Total

V XX XX XX

H XX XX XX

Gear Concave Toe Heel Total

V XX XX XX

H XX XX XX

Notes 1. For metric drawings, specify module in place of diametral pitch.

2. For metric drawings, reduce by one the number of decimal places to the right.

3. See 5.18.3, 5.23 5.26 when to specify these values on the gear drawing.

4. May be specify on matched set drawing. (See Figure 8)

Figure 4. Data Specifications For Straight Bevel Gears

Update 69

Gary Whitmire

DRAFTING MANUAL

Gears (Bevel and Hypoid)

Drafting Practice

Section 4.9.1

Page 8

August, 2003

Genium Publishing Corporation

4.6 Hypoid Gear Teeth

4.6.1 Hypoid pinion and gear teeth are drawn as shown in Figures 5 and 6, respectively.

.XXX

.XXX

.XXX

.XXX

(.XXX)

(X.XXXX)

Mounting Distance

X.XXX

X.XXX

See note 1

See note 1

See note 1

XX.XX

XX.XX

XX.XX

XX.XX

FACE APEX

ROOT APEX

CROSSING POINT

AXIS OF

MATING

MEMBER

Note 1: When face angle distance and back angle distance (See Figure 9) are

used for dimensioning the gear blank, the face angle and the back angle should

be given as reference dimensions on the drawing without a tolerance.

X.XXX

X.XXX

See note 1

B A

X.XXXX

X.XXXX

X.XXX

X.XXX

(.XXX)

.XXX A - B

Figure 5. Hypoid Pinion

Update 69

Gary Whitmire

DRAFTING MANUAL

Gears (Bevel and Hypoid)

Drafting Practice

Section 4.9.1

Page 9

August, 2003

Genium Publishing Corporation

(.XXX)

(.XXX)

(X.XXXX)

Mounting Distance

X.XXX

X.XXX

X.XXX

X.XXX

X.XXX

X.XXX

X.XXXX

X.XXXX

See note 1

See note 1

XX.XX

XX.XX

See note 1

XX.XX

XX.XX

FACE APEX

ROOT APEX

CROSSING POINT

PITCH APEX

A

.XXX

AXIS OF

MATING

MEMBER

Note 1: When face angle distance and back angle distance (See Figure 9) are

used for dimensioning the gear blank, the face angle and the back angle should

be given as reference dimensions on the drawing without a tolerance.

.XXX M A

.XXX

.XXX

.XXX

.XXX

XX.XX

XX.XX

See note 1

Figure 6. Hypoid Gear

4.6.2 Gear data not included in Figures 5 and 6 are tabulated on the drawing as shown in Figure 7. The drawing

must also show material and heat treatment specifications. Distances from the pitch apex for the gear member

only, face apex, and root apex to the crossing point (centerline of the mating member) are included as reference

Update 69

Gary Whitmire

DRAFTING MANUAL

Gears (Bevel and Hypoid)

Drafting Practice

Section 4.9.1

Page 10

August, 2003

Genium Publishing Corporation

dimensions. Values are positive when the apex is beyond the crossing point and negative when the apex lies

between the gear and crossing point. The pitch diameter and pitch angle are specified on the gear member only.

NUMBER OF TEETH XX

DIAMETRAL PITCH (See note 1)

(XX.XXX)

NORMAL PRESSURE ANGLE GEAR CONVEX (XX.XX)

NORMAL PRESSURE ANGLE GEAR CONCAVE (XX.XX)

MEAN SPIRAL ANGLE (XX.XX)

HAND OF SPIRAL LH OR RH

PINION OFFSET (XX.XX)

DIRECTION OF OFFSET AC OR BC

PITCH DIAMETER (GEAR ONLY) (X.XXXX)

ADDENDUM (GEAR ONLY) (.XXX) (See note 2)

WORKING DEPTH (.XXX) (See note 2)

WHOLE DEPTH (.XXX) (See note 2)

THEORETICAL OUTSIDE DIAMETER (X.XXX) (See note 2)

THEORETICAL CROWN TO BACK (X.XXX) (See note 2)

PITCH ANGLE (GEAR ONLY) (XX.XX)

ROOT ANGLE (XX.XX)

FACE APEX TO CROSSING POINT (.XXX) (See note 2)

PITCH APEX TO CROSSING POINT (GEAR ONLY) (.XXX) (See note 2)

ROOT APEX TO CROSSING POINT (.XXX) (See note 2)

MEAN MEASURING ADDENDUM .XXX (See note 2)

MEAN MEASURING THICKNESS .XXX-.XXX (See note 2)

MEAN MEASURING DEPTH .XXX-.XXX (See note 2)

NORMAL BACKLASH WITH MATE .XXX-.XXX (See note 2)

BACKLASH VARIATION TOLERANCE (See note 3) .XXXX (See note 2)

SHAFT ANGLE (XX.XX)

FILLET RADIUS .XXX-.XXX (See note 2)

RUNOUT TOLERANCE (See note 3) .XXXX

PITCH TOLERANCE (See note 3) .XXXX

INDEX TOLERANCE (See note 3) .XXXX

TOOTH SURFACE TEXTURE XX AA OR R

a

Update 69

Gary Whitmire

DRAFTING MANUAL

Gears (Bevel and Hypoid)

Drafting Practice

Section 4.9.1

Page 11

August, 2003

Genium Publishing Corporation

AGMA QUALITY CLASS XX

TOOTH FORM GENERATED OR FORMATE OR

HELIXFORM

DRIVING MEMBER PINION OR GEAR

DIRECTION OF ROTATION CW AND/OR CCW

MFG SUMMARY NUMBER XXXXXX

PART NUMBER OF MATE XXXXXXXX-X

NUMBER OF TEETH IN MATE XX

V AND H CHECK IN THOUSANDTHS OF AN INCH (OR HUNDREDTHS OF A MILLIMETER) FOR

FINISHED GEARS (See note 4).

Gear Convex Toe Heel Total

V XX XX XX

H XX XX XX

Gear Concave Toe Heel Total

V XX XX XX

H XX XX XX

Notes 1. For metric drawings, specify module in place of diametral pitch.

2. For metric drawings, reduce by one the number of decimal places to the right.

3. See 5.18.3, 5.23 5.26 when to specify these values on the gear drawing.

4. May be specify on matched set drawing. (See Figure 8)

Figure 7 Data Specifications For Hypoid Gears

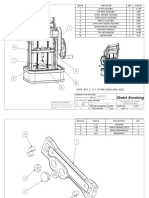

4.7 Matched Sets

4.7.1 Bevel and hypoid gears are frequently maintained as a matched set in assembly. See Figure 8.

4.7.2 Gear sets that have a common factor, should have a specific marking on mating teeth to assure reassembly

of the gears as originally matched. See Figure 8.

4.7.3 Matched set drawings shall contain the following note:

THIS GEAR IS PART OF A MATCHED SET WITH MATE NO. XXXXXX. EACH MATCHED SET IS TO

BE MAINTAINED AS A SET AFTER IDENTITY IS DETERMINED. MARKED TEETH (NON-HUNTING)

MUST BE ASSEMBLED AS SHOWN.

Update 69

Gary Whitmire

DRAFTING MANUAL

Gears (Bevel and Hypoid)

Drafting Practice

Section 4.9.1

Page 12

August, 2003

Genium Publishing Corporation

Pinion and Gear to be matched in pairs

for proper tooth contact and backlash

and measured mounting distance on

these surfaces. See note 1.

(X.XXXX)

(X.XXXX)

GEAR MOUNTING DISTANCE

PINION MOUNTING DISTANCE

pinion

gear

DRIVING MEMBER PINION OR GEAR

DIRECTION OF ROTATION CW AND / OR CCW

MFG SUMMARY NUMBER XXXXXX

PART NUMBER OF DRIVER XXXXXX

PART NUMBER OF DRIVEN XXXXXX

V AND H CHECK IN THOUSANDTHS OF AN INCH (OR HUNDREDTHS OF A MILLIMETER) FOR

FINISHED GEAR SET

GEAR CONVEX TOE HEEL TOTAL GEAR CONCAVE TOE HEEL TOTAL

V XX XX XX V XX XX XX

H XX XX XX H XX XX XX

X

X

X

MARKED TEETH MUST BE ASSEMBLED AS SHOWN

NOTES:

1. On even or multiple ratios, a pair of meshing teeth should be etched X when in mesh in order that they may be

assembled in the same running position as when manufactured. See paragraph 4.8.2.

2. For metric drawings, the number of places to the right of the decimal point should be reduced by one.

Figure 8. Data Specifications for Bevel gear Matched Set

5.0 Gear Tooth Nomenclature

The following nomenclature is general terms used on the gear drawing. A more complete explanation of terms,

definitions and illustrations is given in American Standard for Gear Nomenclature, ANSI/AGMA 112.05,

published by the American Gear Manufacturers Association.

Update 69

Gary Whitmire

DRAFTING MANUAL

Gears (Bevel and Hypoid)

Drafting Practice

Section 4.9.1

Page 13

August, 2003

Genium Publishing Corporation

5.1 Axial Plane - A plane that contains the gear axis. Figure 9 is an illustration of the axial plane of a bevel gear.

Figure 10 (lower view) is an illustration of the axial plane of a hypoid gear.

Update 69

Gary Whitmire

DRAFTING MANUAL

Gears (Bevel and Hypoid)

Drafting Practice

Section 4.9.1

Page 14

August, 2003

Genium Publishing Corporation

Mounting Distance

Crown to Crossing Point

Crown to

Back

Mounting

Surface

Transverse

Plane

See note 2

Uniform

Clearance

Shaft Angle

Root Angle

Face Apex

PINION

GEAR

Crown

Heel

Front

Angle

Crossing

point

See note 1

Face Angle

of Blank

Toe

A

A

Pitch

Angle

Pitch Diameter

Outside

Diameter

Back Angle

Face Width

Dedendum

Angle

Mean Cone Distance

Outer Cone Distance

Face Angle Distance

Back Cone

Distance

Back Angle

Distance

Back Cone

Pitch Element

NOTE:

1. The pitch apex and the root apex may or may not coincide depending on individual gear design.

2. See Figure 10 for developed view of A-A.

Figure 9. Bevel Gear Nomenclature Axial Plane

Update 69

Gary Whitmire

DRAFTING MANUAL

Gears (Bevel and Hypoid)

Drafting Practice

Section 4.9.1

Page 15

August, 2003

Genium Publishing Corporation

Tooth Fillet

Working

Depth

Root Land

Whole Depth

Top Land

Clearance

Circular Thickness

Backlash

Circular Pitch

Tooth Profile

Addendum

Dedendum

Back Cone Distance

SECTION A-A

Figure 10. Bevel Gear Nomenclature Transverse Plane at Outside Diameter

5.2 Pitch Plane - A plane tangent to the gear pitch surface. For bevel gears, the pitch plane is tangent to the pitch

cone.

5.3 Transverse Plane - A plane perpendicular to both the axial plane and the pitch plane. Figure 11 illustrates the

gear nomenclature in the transverse plane of a bevel gear.

5.4 Normal Plane - A plane perpendicular to the pitch plane and containing a line normal to the tooth surface at

the pitch point. On bevel gears, it usually refers to the plane that passes through the mean point (the section at the

center of the face width). Figure 12 illustrates the gear nomenclature in the normal plane of a bevel gear.

5.5 Tangent Plane - A plane tangent to the tooth surface at a point of contact. As used in the standard, the tangent

plane is taken at the mean point.

5.6 Mean Point - The point on the intersection of the tooth surface with the pitch surface at the middle of the

theoretical face width of a bevel or hypoid gear. See Figures 9 and 13.

Update 69

Gary Whitmire

DRAFTING MANUAL

Gears (Bevel and Hypoid)

Drafting Practice

Section 4.9.1

Page 16

August, 2003

Genium Publishing Corporation

Face Angle Distance

Outside

Diameter

Offset

Back Angle Distance

Face Width

Face Angle

Root Apex to

Crossing Point

Root Angle

Face Apex

to Crossing

Point

Crossing

Point

Back Angle

Shaft Angle

Crossing

Point

Crossing

Point

Root Angle

Pitch Angle

Face Angle

Face Angle Distance

Pitch Diameter

Outside Diameter

Back Angle

B

a

c

k

A

n

g

le

D

is

ta

n

c

e

Face Width

O

u

te

r C

o

n

e

D

is

ta

n

c

e

Pinion

Crown to

Crossing Point

Gear

Mounting

Distance

Gear

Front Crown to Crossing Point

Crown to Crossing Point

Figure 11. Hypoid Gear Nomenclature Axial Plane

Update 69

Gary Whitmire

DRAFTING MANUAL

Gears (Bevel and Hypoid)

Drafting Practice

Section 4.9.1

Page 17

August, 2003

Genium Publishing Corporation

Measured Whole

Depth

Measuring

Addendum

Measuring

Thickness

Normal

Backlash

Figure 12. Bevel Gear Nomenclature Normal Plane at the Mean Point

Update 69

Gary Whitmire

DRAFTING MANUAL

Gears (Bevel and Hypoid)

Drafting Practice

Section 4.9.1

Page 18

August, 2003

Genium Publishing Corporation

5.7 Tooth Trace - The curve of intersection between the pitch surface and tooth surface. See Figure 13.

Mean Spiral Angle

Pitch Apex

Section Through Tooth

on Pitch Cone

Concave Side of Tooth

Tooth Trace

Convex Side of Tooth

Mean Point of Tooth

Element of

Pitch Cone

Figure 13. Mean Spiral Angle

5.8 Diametral Pitch - The ratio of the number of teeth to the pitch diameter in inches. Unless otherwise specified,

the transverse diametral pitch (specified in the transverse plane) is implied. For hypoid gears, it is the transverse

diametral pitch of the gear member.

5.9 Module (Metric) - The ratio of the pitch diameter in millimeters to the number of teeth. Unless otherwise

specified, the transverse module (specified in the transverse plane) is implied. For hypoid gears, it is the

transverse module of the gear member.

5.10 Pressure Angle - The angle at the pitch point between a line normal to the tooth profile and the pitch plane.

See Figure 14. Unless otherwise specified for bevel and hypoid gears, the normal pressure angle (measured in the

normal plane at the mean point) is implied. The normal pressure angle is that angle in the normal plane at the

pitch point between the tangent plane and a radial line to the gear center. On most types of gears the pressure

angles on both sides of the gear tooth profile are equal. An exception to this is in designs of gears with buttress

Update 69

Gary Whitmire

DRAFTING MANUAL

Gears (Bevel and Hypoid)

Drafting Practice

Section 4.9.1

Page 19

August, 2003

Genium Publishing Corporation

teeth, such as hypoids. Hypoid gear teeth, because of their asymmetric relationship, do not naturally have equal

pressure angles on their two sides. With spiral bevel gears, the designer may deliberately unbalance the pressure

angles to produce a buttressed tooth. On spiral bevel and hypoid gears, the teeth are cut with lengthwise curvature.

One tooth surface is concave; the other is convex. These two terms are used to identify the two sides of the gear

teeth. See Figure 13.

Trace of

Tangent Plane

Radial Line

Through

Pitch Point

Pressure Angle

Pitch Plane

Pitch Point

Figure 14. Pressure Angle

5.11 Spiral Angle - The angle between the tooth trace and an element of the pitch cone. See Figure 13. The spiral

angle is at the mean point, unless otherwise specified. On hypoid gears, the spiral angles on gear and mating

pinion are unequal.

5.12 Hand of Spiral - The direction of inclination of the teeth as viewed by an observer looking at the face of the

gear. A left-hand spiral is one in which the outer half of the teeth are inclined in a counterclockwise direction. A

right-hand spiral is one in which the outer half of the teeth are inclined in a clockwise direction. See Figure 15.

With the exception of a few relatively rare hypoid gear designs, a gear and mating pinion have opposite hands of

spiral.

Update 69

Gary Whitmire

DRAFTING MANUAL

Gears (Bevel and Hypoid)

Drafting Practice

Section 4.9.1

Page 20

August, 2003

Genium Publishing Corporation

Offset

Offset

Offset

Offset

Offset Below Center LH Pinion RH Gear

Offset Above Center RH Pinion LH Gear

(a)

(c)

(b)

(d)

Figure 15. Hand of Spiral and Pinion Offset

5.13 Hypoid Pinion Offset - The perpendicular distance between the axes of a hypoid gear set. Hypoid gears and

pinions, shown in Figure 15(a) and (b), are referred to as having a pinion offset below center, while those

shown in Figure 15(c) and (d) have a pinion offset above center. The direction of pinion offset is determined by

viewing the face of the gear with the pinion at the right.

5.14 Direction of Rotation - The direction of rotation is determined by viewing the gear or pinion from its back.

The direction of rotation of gear and mating pinion are either clockwise or counterclockwise and always opposite

to each other.

5.15 Tooth Form - The shape of the tooth profile. Since bevel and hypoid gears are manufactured with a variety

of tooth forms, it is essential to specify the desired form on the gear drawing.

Update 69

Gary Whitmire

DRAFTING MANUAL

Gears (Bevel and Hypoid)

Drafting Practice

Section 4.9.1

Page 21

August, 2003

Genium Publishing Corporation

5.15.1 Generated - A tooth form where both members have tooth profiles produced with a relative motion

between the cutting tool and the work in addition to the cutting action.

5.15.2 Non-Generated - A tooth form where the gear tooth profile is produced without a generating motion

between the cutting tool and the work. The mating pinion must be generated.

5.15.3 CONIFLEX - A trade name applied to generated straight bevel gears whose teeth have lengthwise

crowning.

5.15.4 REVACYCLE - A trade name applied to straight bevel gears produced with circular arc tooth profiles.

5.15.5 FORMATE - A trade name applied to non-generated spiral and hypoid gears in which the tooth profiles

are straight. The mating pinions are generated to be conjugate to the gears.

5.15.6 HELIXFORM - A trade name applied to non-generated spiral bevel and hypoid gears in which the tooth

surfaces are heicoidal in form.

5.15.7 ZEROL - A trade name applied to spiral bevel gears with zero spiral angle at some point along the tooth

length.

5.16 Depthwise Tooth Taper - The difference in tooth depth at the inner and outer ends of the teeth. Standard

depthwise tooth taper refers to gears in which the tooth depth is proptiena1 to the distance from the pitch apex.

Zero depthwise taper refers to teeth with constant depth. Frequently conical gears are designed with tilted root

lines. This generally refers to a depthwise tooth taper which is deeper at the outer end of the tooth and shallower

at the inner end of the tooth than that resulting from standard taper. Tilting the root lines is done to improve the

point width of the cutting tools.

5.17 Clearance - The space between the top land of the tooth of one gear and the root land of the mating gear.

See Figures 11 and 12.

5.18 Backlash - The space between mating tooth surfaces. For purposes of measurement and calculation,

backlash is the amount by which the width of a tooth space exceeds the thickness of an engaging tooth. Numerical

values of backlash on bevel and hypoid gears are measured at the tightest point of mesh on the pitch circle at the

outer end of the tooth with gears assembled at their specified mounting distances. See Figure 12. Unless otherwise

specified, the term backlash denotes normal backlash; that is, backlash measured in a direction perpendicular to

the tooth surface.

5.18.1 Backlash Tolerance - The allowable variation in the backlash measured at the tightest point of mesh

among all pairs of gears of a given population as a result of tooth size variation. Backlash tolerance is used as a

control of tooth size in production and is specified on the drawing.

Update 69

Gary Whitmire

DRAFTING MANUAL

Gears (Bevel and Hypoid)

Drafting Practice

Section 4.9.1

Page 22

August, 2003

Genium Publishing Corporation

5.18.2 Backlash Variation - The difference in backlash between the tightest and loosest points of mesh in one

pair of gears as a result of runout, index variation, and profile variation.

5.18.3 Backlash Variation Tolerance - The allowable variation in backlash in a single pair of gears. Backlash

variation tolerance is only specified if backlash variation is critical.

5.19 Circular Thickness - The length of arc between the two sides of a gear tooth on the pitch circle. It is the

transverse circular thickness at the outer ends of the teeth. See Figure 11.

5.20 Measuring Addendum - The height from the top of the tooth to the chord subtending the circular-thickness

arc in the normal plane. The mean measuring addendum is the value at the center of the tooth length.

5.21 Measuring Thickness - The length of the chord subtending a circular-thickness arc in the normal plane. The

mean measuring thickness is the value used at the center of the tooth length.

5.22 Mean Measuring Depth - The depth of the tooth at the center of the tooth length.

5.23 Runout Tolerance - The total allowable variation of the distance between a surface of revolution and an

indicated surface measured perpendicular to the surface of revolution. Unless otherwise specified, it refers to

radial runout of the gear teeth; that is, in a direction perpendicular to the axis of gear rotation. This value is

specified on the drawing when AGMA quality class numbers are not available.

5.24 Pitch Tolerance - The difference between the pitch and the measured distance between any two adjacent

teeth. This value is specified on the drawing for gears requiring high accuracy.

5.25 Index Tolerance - The displacement of any tooth from its theoretical angular or linear position relative to a

datum tooth. This value is specified on the drawing for gears used for accurate positioning, such as index drives.

5.26 Composite Tolerance - Tooth-to-tooth composite tolerance and total composite tolerance may be specified

in place of runout tolerance and pitch tolerance for gears of 20 diametral pitch and finer. These values are

specified on the drawing when AGMA quality class numbers are not available.

5.27 Tooth Surface Texture - The texture of the finish on the working tooth surface of a gear tooth; expressed

either as an arithmetical average deviation (AA) or an arithmetical mean deviation (Ra).

5.28 AGMA Quality Class - The classification number established by the American Gear Manufacturers

Association to designate the quality requirements of a gear. See AGMA 390.03 - AGMA Gear Handbook,

Volume 1, Gear Classification, Materials and Measuring Methods For Unassembled Gears.

5.29 V and H Check - A check used for production control of the tooth contact pattern on gears after sample

gears have been established which are known to function properly. The V and H check gives the relative vertical

(V) and horizontal (H) displacements on a testing machine to position the tooth contact pattern at both the inner

Update 69

Gary Whitmire

DRAFTING MANUAL

Gears (Bevel and Hypoid)

Drafting Practice

Section 4.9.1

Page 23

August, 2003

Genium Publishing Corporation

(toe) and outer (heel) end of the tooth while maintaining the contact pattern in the middle of the tooth profile. For

control purposes, the tooth contact pattern should duplicate the pattern on the sample pair of gears when similarly

positioned in the testing machine. These data are optional on a gear drawing and specified when a satisfactory

development has been achieved. See Figures 4 and 7.

5.30 Face Angle Distance - The perpendicular distance from the intersection of the gear axis with the locating

surface at the back of a bevel or hypoid gear to the face cone element. See Figures 9 and 10.

5.31 Back Angle Distance - The perpendicular distance from the intersection of the gear axis with the locating

surface at the back of a bevel or hypoid gear to the back cone element. See Figures 9 and 10.

You might also like

- Involute Inspection Methods and Interpretation of Inspection ResultsDocument7 pagesInvolute Inspection Methods and Interpretation of Inspection Resultsvijay_khandgeNo ratings yet

- Types of InvoluteDocument4 pagesTypes of InvoluteBa Bu100% (1)

- A Kinematic Analysis of Meshing Polymer Gear TeethDocument16 pagesA Kinematic Analysis of Meshing Polymer Gear TeethsandeepNo ratings yet

- GB/T 10095.2-2008 Cylindrical Gears Accuracy StandardDocument5 pagesGB/T 10095.2-2008 Cylindrical Gears Accuracy StandardtaghdirimNo ratings yet

- Design and Analysis Procedures For Shafts and Splines: Paul E. BurkeDocument21 pagesDesign and Analysis Procedures For Shafts and Splines: Paul E. BurkeBalasrinivasan Murugan100% (3)

- Quality Gear Inspection - Part II PDFDocument4 pagesQuality Gear Inspection - Part II PDFsurawutwijarn100% (1)

- Cycloid Drive - Replaced by Planocentric Involute GearingDocument6 pagesCycloid Drive - Replaced by Planocentric Involute GearingMax GrandeNo ratings yet

- Tseng 2004 Mechanism and Machine TheoryDocument15 pagesTseng 2004 Mechanism and Machine TheoryKhanh VqNo ratings yet

- Diseños de EngranajesDocument26 pagesDiseños de EngranajesTarja Turunen MexicoNo ratings yet

- Gear TechnologyDocument52 pagesGear TechnologyJithinNo ratings yet

- Worm DriveDocument6 pagesWorm DriveRavi Kiran MeesalaNo ratings yet

- DIN-58405-3-1972 Spur Gear Drives For Fine Mechanics - Indication in Drawings, Examples For Calculation PDFDocument20 pagesDIN-58405-3-1972 Spur Gear Drives For Fine Mechanics - Indication in Drawings, Examples For Calculation PDFthaivinhtuyNo ratings yet

- Precision Involute Gear Hob DesignDocument11 pagesPrecision Involute Gear Hob DesignKalyan ChakravarthyNo ratings yet

- 6.6 Gear Manufacturing: Form MillingDocument6 pages6.6 Gear Manufacturing: Form MillingDeepak ChandhokNo ratings yet

- Gearsand GearingDocument57 pagesGearsand Gearingcamohunter71No ratings yet

- NTN Tapered Roller BearingsDocument42 pagesNTN Tapered Roller BearingsVarsha SinghNo ratings yet

- Content NormDocument15 pagesContent Normem07150No ratings yet

- Straight Sided Serrations SpecificationsDocument2 pagesStraight Sided Serrations SpecificationsMarcel Dandaro100% (1)

- A4 Paper Format - International Standard Paper SizesDocument20 pagesA4 Paper Format - International Standard Paper SizesJames Jam100% (1)

- AISI 440 Martensit PDFDocument4 pagesAISI 440 Martensit PDFJimmyVargasNo ratings yet

- Rating of Asymmetric Tooth Gears: Alex L. Kapelevich and Yuriy V. ShekhtmanDocument6 pagesRating of Asymmetric Tooth Gears: Alex L. Kapelevich and Yuriy V. ShekhtmanDavide MaranoNo ratings yet

- Approximate Equation For The Addendum Modification Factors For Tooth Gears With Balanced Specific SlidingDocument11 pagesApproximate Equation For The Addendum Modification Factors For Tooth Gears With Balanced Specific SlidingCan CemreNo ratings yet

- Ansi Agma 2000 A88Document4 pagesAnsi Agma 2000 A88MickloSoberanNo ratings yet

- Cone Tolerance PDFDocument21 pagesCone Tolerance PDFsosu_sorin3904No ratings yet

- Thermal Lead Correction For High-Speed Gears: Sinto America, IncDocument92 pagesThermal Lead Correction For High-Speed Gears: Sinto America, IncRongbaaz BongNo ratings yet

- Martin: Sprocket & Gear, IncDocument32 pagesMartin: Sprocket & Gear, IncarduanaNo ratings yet

- Cycloid Drive - Replaced by Planocentric Involute Gearing PDFDocument6 pagesCycloid Drive - Replaced by Planocentric Involute Gearing PDFMax GrandeNo ratings yet

- The Application of Bevel GearsDocument6 pagesThe Application of Bevel GearsPrasanth ThiagarajanNo ratings yet

- Din 5480-2 - 2006-05Document40 pagesDin 5480-2 - 2006-05Luiz Munari100% (2)

- Gears KinematicsDocument19 pagesGears Kinematicsavinashn12No ratings yet

- Semi-Topping Shaper CuttersDocument4 pagesSemi-Topping Shaper CuttersalemarlonstosNo ratings yet

- A Comparison of The AGMA Gear Design Stresses, The LewisDocument41 pagesA Comparison of The AGMA Gear Design Stresses, The LewisJulendra AriatedjaNo ratings yet

- Estimating Lifetime for Plastic GearsDocument19 pagesEstimating Lifetime for Plastic GearsBakkiyaraj VeluNo ratings yet

- A Crowning Achievement For Automotive ApplicationsDocument10 pagesA Crowning Achievement For Automotive ApplicationsCan CemreNo ratings yet

- Characteristics of Trochoids and Their Application To Determining Gear Teeth Fillet ShapesDocument14 pagesCharacteristics of Trochoids and Their Application To Determining Gear Teeth Fillet ShapesJohn FelemegkasNo ratings yet

- Analyzing Taper Fits For ManufacturingDocument7 pagesAnalyzing Taper Fits For Manufacturingsalgado_24No ratings yet

- Automobile Vibration AnalysisDocument18 pagesAutomobile Vibration AnalysisDavid PomaNo ratings yet

- Calculation of Load Capacity of Spur and Helical Gears - Calculation of Tooth Bending StrengthDocument2 pagesCalculation of Load Capacity of Spur and Helical Gears - Calculation of Tooth Bending StrengthКирилл0% (1)

- 1 MetricGears PDFDocument9 pages1 MetricGears PDFGerardo Franco Rava0% (1)

- Speed Reducer GearboxDocument14 pagesSpeed Reducer Gearboxعبد للهNo ratings yet

- April 2014Document86 pagesApril 2014Delian KurniawanNo ratings yet

- Bonfiglioli Geared MotorDocument584 pagesBonfiglioli Geared MotorProdip SarkarNo ratings yet

- Σχεδιασμός σε επιφανειακή πίεση μετωπικών οδοντωτών τροχών κατά AGMADocument1 pageΣχεδιασμός σε επιφανειακή πίεση μετωπικών οδοντωτών τροχών κατά AGMAkstayroskNo ratings yet

- Bearings JournalDocument11 pagesBearings JournalUlfa Luqman100% (1)

- Typical Heat Treatment Defects of GearsDocument8 pagesTypical Heat Treatment Defects of GearsRamon BrownNo ratings yet

- Design of Bearings & Miscellaneous ElementsDocument14 pagesDesign of Bearings & Miscellaneous ElementsjvanandhNo ratings yet

- Taper Pins, Dowel Pins, Straight Pins, Grooved Pins, and Spring Pins (Inch Series)Document50 pagesTaper Pins, Dowel Pins, Straight Pins, Grooved Pins, and Spring Pins (Inch Series)Joel CieltoNo ratings yet

- Interlloy 440C MartensiticDocument4 pagesInterlloy 440C MartensiticGuillaume BoyerNo ratings yet

- A Comparison of Current AGMA ISO API Gear Rating Methods PDFDocument84 pagesA Comparison of Current AGMA ISO API Gear Rating Methods PDFNARENDRASINH PARMARNo ratings yet

- Dynamic Factor FormulaeDocument15 pagesDynamic Factor FormulaeShubham More0% (1)

- gt0519 PDFDocument68 pagesgt0519 PDFАндрей ГайнановNo ratings yet

- Module IV: Gears and Gear TrainsDocument38 pagesModule IV: Gears and Gear TrainsSuraj VinayNo ratings yet

- Axial movement assembly limitsDocument385 pagesAxial movement assembly limitsA.Rishi sivaNo ratings yet

- I. Design Standard and SpecificationDocument25 pagesI. Design Standard and SpecificationChanna SannNo ratings yet

- Turbocharger Bearing End PlayDocument10 pagesTurbocharger Bearing End PlayPercyNo ratings yet

- Combined Footing (With Beam) - Excel - R0.0Document4 pagesCombined Footing (With Beam) - Excel - R0.0VIJAY PARMARNo ratings yet

- LG Design CalculationsDocument48 pagesLG Design CalculationsjonesNo ratings yet

- Abs 5057Document9 pagesAbs 5057Gael CadenaNo ratings yet

- ETABS 2016 Concrete Frame Design: ACI 318-08 Column Section DesignDocument2 pagesETABS 2016 Concrete Frame Design: ACI 318-08 Column Section DesignAlpha ScimathNo ratings yet

- Internal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsFrom EverandInternal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsNo ratings yet

- DMS PPTDocument116 pagesDMS PPTAyush BhardwajNo ratings yet

- Section E Radius Gauges E40-E41Document2 pagesSection E Radius Gauges E40-E41ALEJANDRO IPATZINo ratings yet

- Gear Box Catalogue PDFDocument7 pagesGear Box Catalogue PDFPiyush Anand100% (2)

- RepuestosDocument4 pagesRepuestoscarlos puertoNo ratings yet

- APUNTES - GLEASSON - Basics of Spiral Bevel & Hypoid GearsDocument144 pagesAPUNTES - GLEASSON - Basics of Spiral Bevel & Hypoid GearsCarlosQuelart100% (1)

- Chapter 11 Thread FastenerDocument54 pagesChapter 11 Thread FastenerShadab AlamNo ratings yet

- Diy - CNC Router TableDocument53 pagesDiy - CNC Router Tablezaoioaz100% (4)

- Geartrax For Solidworks 2016 471instmankl PDFDocument2 pagesGeartrax For Solidworks 2016 471instmankl PDFJenniferNo ratings yet

- Chapter 1-Gear SystemDocument27 pagesChapter 1-Gear SystemDanielRao100% (2)

- Cylinder Connections GuideDocument1 pageCylinder Connections GuideВикторNo ratings yet

- Juki MF-7800-UT25 PDFDocument12 pagesJuki MF-7800-UT25 PDFJaime TorresNo ratings yet

- JKUISDFDocument21 pagesJKUISDFShahed HusaainNo ratings yet

- Planetary Gears PosterDocument1 pagePlanetary Gears PosterImran NisarNo ratings yet

- RBX1 Assembly Hardware V1.0Document10 pagesRBX1 Assembly Hardware V1.0Mohamed ReGaiegNo ratings yet

- Tap Drill Chart for Common Tap SizesDocument1 pageTap Drill Chart for Common Tap Sizesdharmesh patelNo ratings yet

- Technical guide to metric, imperial, and other industrial thread standards and sizesDocument1 pageTechnical guide to metric, imperial, and other industrial thread standards and sizesNusrat IqbalNo ratings yet

- Parts Assembly DrawingDocument62 pagesParts Assembly Drawingsudharshan100% (1)

- Module 1 - Activity No. 1 (Prelim)Document2 pagesModule 1 - Activity No. 1 (Prelim)Leyzer MalumayNo ratings yet

- Juk LK-1952 1953 1954Document46 pagesJuk LK-1952 1953 1954RHoskaNo ratings yet

- K4 UT+Parts+ManualDocument132 pagesK4 UT+Parts+ManualJosue Silva CastroNo ratings yet

- Complete Parts List 2020-06Document324 pagesComplete Parts List 2020-06antoniohnetNo ratings yet

- Dynamic Characteristics of Epicyclic Gear SystemDocument77 pagesDynamic Characteristics of Epicyclic Gear Systemkaajemaina195No ratings yet

- Class 5 Science Chapter 11 Simple Machines Ms. Subhashree RoutDocument3 pagesClass 5 Science Chapter 11 Simple Machines Ms. Subhashree Routshivang guptaNo ratings yet

- Spare Parts Book: FRDP-14-S Rear AxleDocument21 pagesSpare Parts Book: FRDP-14-S Rear AxleАлексейNo ratings yet

- Iso 68-1-1998Document4 pagesIso 68-1-1998Sirous EghlimiNo ratings yet

- List of Standards - Fastening Elements - Part2Document1 pageList of Standards - Fastening Elements - Part2strijelavremenaNo ratings yet

- Gear System Fundamentals: Types, Applications & Power TransmissionDocument28 pagesGear System Fundamentals: Types, Applications & Power Transmissionazim100% (1)

- ASME B1.13M 2005 Metric Screw Threads M ProfileDocument84 pagesASME B1.13M 2005 Metric Screw Threads M ProfileQualidadeTFNo ratings yet

- Sci6 Q3 As Wk7 Simple Machines MatiasDocument9 pagesSci6 Q3 As Wk7 Simple Machines Matiasjose fadrilanNo ratings yet

- Helical Gears IntroductionDocument14 pagesHelical Gears IntroductionIssan GouthamNo ratings yet