Professional Documents

Culture Documents

Design of Beam: (As Per Aci Code)

Uploaded by

Khaled Syfullah0 ratings0% found this document useful (0 votes)

6 views23 pagesdesign of RCC beam

Original Title

Design of Beam Usd Aci 11-01-05

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentdesign of RCC beam

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views23 pagesDesign of Beam: (As Per Aci Code)

Uploaded by

Khaled Syfullahdesign of RCC beam

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 23

DESIGN OF BEAM

(AS PER ACI CODE)

CONTENT

ASSUMPTIONS

EVALUATION OF DESIGN PARAMETERS

MOMENT FACTORS Kn,

STRENGTH REDUCTION FACTOR

BALANCED REINFORCEMENT RATIO

b

DESIGN PROCEDURE FOR SINGLY

REINFORCED BEAM

CHECK FOR CRACK WIDTH

DESIGN PROCEDURE FOR DOUBLY

REINFORCED BEAM

FLANGED BEAMS

T BEAMS

L - BEAMS

ASSUMPTIONS

Plane sections before bending remain plane and perpendicular to

the N.A. after bending

Strain distribution is linear both in concrete & steel and is directly

proportional to the distance from N.A.

Strain in the steel & surrounding concrete is the same prior to

cracking of concrete or yielding of steel

Concrete in the tension zone is neglected in the flexural analysis &

design computation

c=0.003

s = fy / Es

h d

c

0.85fc

a

a/2

d-a/2

b

C

T

TO SLIDE-5

Concrete stress of 0.85fc is uniformly distributed over an equivalent

compressive zone.

fc = Specified compressive strength of concrete in psi.

Maximum allowable strain of 0.003 is adopted as safe limiting value

in concrete.

The tensile strain for the balanced section is fy/Es

Moment redistribution is limited to tensile strain of at least 0.0075

s

y

fy

fs

Idealized

Actual

Es

1

Total compressive force C = 0.85fc ba (Refer stress diagram)

Total Tensile force T = As fy

C = T

0.85fc ba = As fy

a = As fy / (0.85fc b)

= d fy / (0.85 fc) = As / bd

Moment of Resistance, Mn = 0.85fc ba (d a/2) or

Mn = As fy (d a/2)

= bd fy [ d (dfyb / 1.7fc) ]

= fc [ 1 0.59 ] bd

2

= fy / fc

Mn = Kn bd

2

Kn = fc [ 1 0.59 ]

Mu = Mn

= Kn bd

2

= Strength Reduction Factor

EVALUATION OF DESIGN PARAMETERS

TO SLIDE-7

b

= A

sb

/ bd

= 0.85fc a

b

/ (fy. d)

=

1

( 0.85 fc / fy) [ 87,000 / (87,000+fy)]

Balaced Reinforcement Ratio (

b

)

From strain diagram, similar triangles

c

b

/ d = 0.003 / (0.003 + fy / Es) ; Es = 29x10

6

psi

c

b

/ d = 87,000 / (87,000+fy)

Relationship b / n the depth `a of the equivalent rectangular stress block

& depth `c of the N.A. is

a =

1

c

1

= 0.85 ; fc 4000 psi

1

= 0.85 - 0.05(fc 4000) / 1000 ; 4000 < fc 8000

1

= 0.65 ; fc> 8000 psi

In case of statically determinate structure ductile failure is essential

for proper moment redistribution. Hence, for beams the ACI code

limits the max. amount of steel to 75% of that required for balanced

section. For practical purposes, however the reinforcement ratio

( = As / bd) should not normally exceed 50% to avoid congestion of

reinforcement & proper placing of concrete.

0.75

b

Min. reinforcement is greater of the following:

As

min

= 3fc x b

w

d / fy or 200 b

w

d / fy

min

= 3fc / fy or 200 / fy

For statically determinate member, when the flange is in tension, the

b

w

is replaced with 2b

w

or bf whichever is smaller

The above min steel requirement need not be applied, if at every

section, Ast provided is at least 1/3 greater than the analysis

DESIGN PROCEDURE FOR

SINGLY REINFORCED BEAM

Determine the service loads

Assume `h` as per the support conditions according to Table

9.5 (a) in the code

Calculate d = h Effective cover

Assume the value of `b` by the rule of thumb.

Estimate self weight

Perform preliminary elastic analysis and derive B.M (M),

Shear force (V) values

Compute

min

and

b

Choose between

min

and

b

Calculate , Kn

From Kn & M calculate `d required (Substitute b interms of d)

Check the required `d with assumed `d

Revise & repeat the steps, if necessary

BACK

With the final values of , b, d determine the Total As required

Design the steel reinforcement arrangement with appropriate cover

and spacing stipulated in code. Bar size and corresponding no. of

bars based on the bar size #n.

Check crack widths as per codal provisions

EXAMPLE

DESIGN PROCEDURE FOR

DOUBLY REINFORCED BEAM

Moment of resistance of the section

M

u

= M

u1

+ M

u2

M

u1

= M.R. of Singly reinforced section

= A

s1

fy (d a/2) ; A

s1

= M

u1

/ [ fy (d a/2) ]

Mu2 = A

s2

fy (d d) ; A

s2

= M

u2

/ [ fy (d d) ]

Mu = A

s1

fy (d a/2) + A

s2

fy (d d)

If Compression steel yields,

fy / Es

I.e., 0.003 [ 1 (0.85 fc

1

d) / ((- ) fyd) ] fy / Es

If compression steel does not yield,

fs = Es x 0.003 [ 1 (0.85

fc

1

d) / ((- ) fyd) ]

Balanced section for doubly reinforced section is

b

=

b1

+ (fs / fy)

b1

= Balanced reinforcement ratio for S.R. section

END

Mu = Mn

The design strength of a member refers to the nominal strength

calculated in accordance with the requirements stipulated in the

code multiplied by a Strength Reduction Factor , which is always

less than 1.

DESIGN STRENGTH

Why ?

To allow for the probability of understrength members due to

variation in material strengths and dimensions

To allow for inaccuracies in the design equations

To reflect the degree of ductility and required reliability of the

member under the load effects being considered.

To reflect the importance of the member in the structure

RECOMMENDED VALUE

Beams in Flexure... 0.90

Beams in Shear & Torsion 0.85

BACK

AS PER TABLE 9.5 (a)

Simply

Supported

One End

Continuous

Both End

Continuous

Cantilever

L / 16 L / 18.5 L / 21 L/8

BACK

Values given shall be used directly for members with normal

weight concrete (Wc = 145 lb/ft3) and Grade 60 reinforcement

For structural light weight concrete having unit wt. In range

90-120 lb/ft3 the values shall be multiplied by

(1.65 0.005Wc) but not less than 1.09

For fy other than 60,000 psi the values shall be multiplied by

(0.4 + fy/100,000)

`h` should be rounded to the nearest whole number

RULE OF THUMB

d/b = 1.5 to 2.0 for beam spans of 15 to 25 ft.

d/b = 3.0 to 4.0 for beam spans > 25 ft.

`b` is taken as an even number

Larger the d/b, the more efficient is the section due to less

deflection

BACK

CLEAR COVER

Not less than 1.5 in. when there is no exposure to weather or

contact with the ground

For exposure to aggressive weather 2 in.

Clear distance between parallel bars in a layer must not be

less than the bar diameter or 1 in.

BAR SIZE

#n = n/8 in. diameter for n 8.

Ex. #1 = 1/8 in.

.

#8 = 8/8 i.e., I in.

Weight, Area and Perimeter of individual bars

inch mm

3 0.376 0.375 9 0.11 1.178

4 0.668 0.500 13 0.20 1.571

5 1.043 0.625 16 0.31 1.963

6 1.502 0.750 19 0.44 2.356

7 2.044 0.875 22 0.60 2.749

8 2.670 1.000 25 0.79 3.142

9 3.400 1.128 28 1.00 3.544

10 4.303 1.270 31 1.27 3.990

11 5.313 1.410 33 1.56 4.430

14 7.650 1.693 43 2.25 5.319

18 13.600 2.257 56 4.00 7.091

Perimeter

(in.)

Stamdard Nominal Dimensions

Bar

No

Wt.per

Foot (lb)

Diameter d

b

C/S Area,

A

b

(in

2

)

BACK

CRACK WIDTH

w = 0.000091.fs.

3

(dc.A)

Where,

w = Crack width

= 0.016 in. for an interior exposure condition

= 0.013 in. for an exterior exposure condition

fs = 0.6 fy, kips

dc = Distance from tension face to center of the row of

bars closest to the outside surface

A = Effective tension area of concrete divided by the

number of reinforcing bars

= A

eff

/ N

A

eff

= Product of web width and a height of web equal to

twice the distance from the centroid of the steel and

tension surface

N = Total area of steel As / Area of larger bar

BACK

d

c

Tension face

d

b

w

A

eff

= b

w

x 2d

BACK

FLANGED BEAMS

EFFECTIVE OVERHANG, r

r r

T BEAM

1. r 8 hf

2. r ln

3. r L

L BEAM

1. r 6 hf

2. r ln

3. r 1/12 L

c=0.003

s = fy / Es

d

c

a

Strain Diagram

b

r

As

Case-1: Depth of N.A `c < hf

0.85fc b a = As fy

a = As fy / [ 0.85fc b]

Mn = As fy (d a/2)

0.85fc

a/2

d-a/2

C

T

Stress Diagram

c=0.003

s = fy / Es

d

c

a

Strain Diagram

Case-2: Depth of N.A `c > hf

i) a < hf

0.85fc b a = As fy

a = As fy / [ 0.85fc b]

Mn = As fy (d a/2)

0.85fc

a/2

d-a/2

C

T

Stress Diagram

b

r

As

c=0.003

s = fy / Es

d

c

a

Strain Diagram

Case-2: Depth of N.A `c > hf

ii) a > hf

Part-1

0.85fc bw a = As

1

fy

Part-2

0.85fc (b-bw) hf = As

2

fy

0.85fc bw a +

0.85fc (b-bw) hf = As fy

a = [As fy - 0.85fc (b-bw) hf ] / [ 0.85fc bw]

0.85fc

a/2

d-a/2

C

T

Stress Diagram

b

r

As

Moment of resistance of the section

M

n

= M

n1

+ M

n2

M

n1

= A

s1

fy (d a / 2)

M

n2

= A

s2

fy (d h

f

/ 2)

Moment Redistribution

For continuous beam members,

Code permits Max of 20%

when et 0.0075 at that section

Balaced Reinforcement Ratio (

b

)

b =

(bw / b) [

b +

f

]

b

= A

sb

/ b

w

d

= 0.85fc a

b

/ (fy. d)

=

1

( 0.85 fc / fy) [ 87,000 / (87,000+fy)]

f

= 0.85fc (b-bw) hf / (fy bw d)

0.75

b

Min. reinforcement is greater of the following:

w

= 3fc / fy or 200 / fy ; for +ve Reinf.

min

= 6fc / fy or 200 / fy ; for -ve Reinf.

You might also like

- Design of Beam-Aci-11-01-05Document23 pagesDesign of Beam-Aci-11-01-05aomareltayeb100% (1)

- Design of Beam Aci 11-01-05Document23 pagesDesign of Beam Aci 11-01-05MuhammadMuzammilNo ratings yet

- C 0 - 85 F ' C B A T A F: Reference: ACI 318-05 Reinforced Concrete Beam Design DefinitionsDocument116 pagesC 0 - 85 F ' C B A T A F: Reference: ACI 318-05 Reinforced Concrete Beam Design DefinitionsIbrahim El SharNo ratings yet

- Design of Concrete Beam StructuresDocument26 pagesDesign of Concrete Beam StructuresVRKVRK10No ratings yet

- Design of Beam Slide ShareDocument26 pagesDesign of Beam Slide ShareVRKVRK10No ratings yet

- CONTINUOUS BEAMDocument57 pagesCONTINUOUS BEAMZulhilmi MohanapNo ratings yet

- KKKH3353 - Structural Steel Design - Joints 2Document26 pagesKKKH3353 - Structural Steel Design - Joints 2Zeyad Tareq Al SaroriNo ratings yet

- RCD2 - Reinforced Concrete & Signly Reinforced BeamsDocument39 pagesRCD2 - Reinforced Concrete & Signly Reinforced BeamsNelle SarmientoNo ratings yet

- Irregular Section of Beams Reinforced For TensionDocument26 pagesIrregular Section of Beams Reinforced For TensionMadelyn Escaner MorilloNo ratings yet

- Codal Practices RCC Design Part B Design by VkmehtaDocument54 pagesCodal Practices RCC Design Part B Design by Vkmehtavijaymehta345100% (2)

- Chapter # 3Document64 pagesChapter # 3Pharo TotNo ratings yet

- A. Stresses On Inclined Planes: Maximum Normal StressDocument6 pagesA. Stresses On Inclined Planes: Maximum Normal Stressjomarie apolinarioNo ratings yet

- Specific StepsDocument26 pagesSpecific StepsAbdul Hamid BhattiNo ratings yet

- Shear and Development LengthDocument20 pagesShear and Development Lengthjs kalyana rama100% (1)

- AZ024 Lecture 3 (Rev (1) A)Document12 pagesAZ024 Lecture 3 (Rev (1) A)Tong Kin Lun100% (4)

- Topic 6-Beam DesignDocument73 pagesTopic 6-Beam DesignShahrul Syazwan SalimNo ratings yet

- 1994 Composite Beam Design ExampleDocument10 pages1994 Composite Beam Design Examplebalamurali031100% (2)

- CSE30310 Lecture 3Document47 pagesCSE30310 Lecture 3sze yin wongNo ratings yet

- Column Steel DesignDocument37 pagesColumn Steel DesignIlya Joohari100% (1)

- Shear DesignDocument17 pagesShear DesignAyez Sassin100% (1)

- MATH Timber Design and Construction MethDocument6 pagesMATH Timber Design and Construction MethHades HadesNo ratings yet

- Analysis of Section BeamDocument26 pagesAnalysis of Section BeamNur Azrin AzlanNo ratings yet

- Design of Beams To BS 8110Document14 pagesDesign of Beams To BS 8110YAHAMPATH ARACHCHIGE PASAN MADURA YahampathNo ratings yet

- Shear Design Procedures According to EC2 and BS 8110-1:1997Document4 pagesShear Design Procedures According to EC2 and BS 8110-1:1997selina100% (1)

- 6-Prof. Zahid Ahmad Siddiqi Lec-6-Flexural Analysis and Design of BeamsDocument17 pages6-Prof. Zahid Ahmad Siddiqi Lec-6-Flexural Analysis and Design of BeamsMuhammadAboubakarFarooqNo ratings yet

- Aisi Example II-7Document24 pagesAisi Example II-7LauraMilenaHernándezTorresNo ratings yet

- WSM PDFDocument17 pagesWSM PDFSathish SelvaNo ratings yet

- EC2 Bending With or Without Axial ForceDocument11 pagesEC2 Bending With or Without Axial ForceselinaNo ratings yet

- MSCE 509-101 - Strain Limits-Review of RC BEAMSDocument9 pagesMSCE 509-101 - Strain Limits-Review of RC BEAMSOtep TimusNo ratings yet

- Design of Single R.C. Beams by Engr. Ben DavidDocument14 pagesDesign of Single R.C. Beams by Engr. Ben DavidElijah Aramburo100% (1)

- New Example 14 Simple FrameDocument6 pagesNew Example 14 Simple FrameminnNo ratings yet

- Rafter To Column Top Connection Design Given DataDocument10 pagesRafter To Column Top Connection Design Given DataSafi Zabihullah SafiNo ratings yet

- Design of Prestressed Concrete Beam Using Single T-BeamsDocument7 pagesDesign of Prestressed Concrete Beam Using Single T-BeamsZohaib AhmadNo ratings yet

- Design of Beams To BS 8110Document14 pagesDesign of Beams To BS 8110Kasun Karunaratne99% (76)

- RC Beam Torsion DesignDocument33 pagesRC Beam Torsion Design2011kumarNo ratings yet

- Steps in Designing A Rectangular BeamDocument8 pagesSteps in Designing A Rectangular BeamIvan GonzalesNo ratings yet

- One-way and Two-way Slab DesignDocument5 pagesOne-way and Two-way Slab DesignMark Kim BadiangNo ratings yet

- Flexural Design of Singly Reinforced Beam Sections by LSMDocument12 pagesFlexural Design of Singly Reinforced Beam Sections by LSMKallem KiranmayiNo ratings yet

- FE Reinforced ConcreteDocument34 pagesFE Reinforced ConcreteAdriano GuedesNo ratings yet

- Design of One Way SlabDocument31 pagesDesign of One Way SlabRam Ingalkar90% (10)

- RC1 Module 5 ANALYSIS OF T BEAMS 2015Document21 pagesRC1 Module 5 ANALYSIS OF T BEAMS 2015Cyrylle ObenzaNo ratings yet

- Shear Strength CalculationDocument4 pagesShear Strength CalculationAnil kumar RNo ratings yet

- Masonry Design Guide for Reinforced and Unreinforced Columns and WallsDocument4 pagesMasonry Design Guide for Reinforced and Unreinforced Columns and WallsAhad Aziz100% (1)

- RC Beam Design Using ACIDocument1 pageRC Beam Design Using ACIdantevariasNo ratings yet

- Engineering Mechanic For Conditioning &refrigeration Dept. First Class Part (1) Strength of MaterialsDocument21 pagesEngineering Mechanic For Conditioning &refrigeration Dept. First Class Part (1) Strength of MaterialsN AbdullahNo ratings yet

- Design of Intermediate Flanged Beam for Classroom HallDocument7 pagesDesign of Intermediate Flanged Beam for Classroom HallWilson PatyalNo ratings yet

- ANALYSIS OF BEAM SECTION UNDER FLEXUREDocument20 pagesANALYSIS OF BEAM SECTION UNDER FLEXUREnasyahrahNo ratings yet

- Eddie Naldoza Engineering Design Beam AnalysisDocument5 pagesEddie Naldoza Engineering Design Beam AnalysisBong-Bong Rodriguez Bianzon100% (1)

- Design of Rectangular Water Tanks Resting On Ground.Document5 pagesDesign of Rectangular Water Tanks Resting On Ground.ganesh.pg. GaniNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- O level Physics Questions And Answer Practice Papers 2From EverandO level Physics Questions And Answer Practice Papers 2Rating: 5 out of 5 stars5/5 (1)

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresFrom EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresRating: 4 out of 5 stars4/5 (1)

- Drawings (Structural) : Project: Cluster - 7 Well Platform ProjectDocument2 pagesDrawings (Structural) : Project: Cluster - 7 Well Platform Projectpareen9No ratings yet

- Access Platforms Stairs and Ladders Administrator Guide PDFDocument40 pagesAccess Platforms Stairs and Ladders Administrator Guide PDFTury IonelNo ratings yet

- Zone 5: Adah Stadium Al Nahda Dubai A Irpor TFZ Usais Etisala TDocument1 pageZone 5: Adah Stadium Al Nahda Dubai A Irpor TFZ Usais Etisala Tpareen9No ratings yet

- SmartPlant License ManagerDocument86 pagesSmartPlant License Managerbarcelata_antonioNo ratings yet

- Basic Electronics - BookDocument486 pagesBasic Electronics - BookulahannanNo ratings yet

- Design of Offshore StructuresDocument11 pagesDesign of Offshore StructuresInayath Hussain100% (1)

- Wave Theory Offshore StructuresDocument62 pagesWave Theory Offshore Structuresamal_millstone07@yahoo.com100% (5)

- Connection Design-Design RequirementsDocument14 pagesConnection Design-Design Requirementsqatarstructz30No ratings yet

- Offshore StructuresDocument23 pagesOffshore Structurespareen9No ratings yet

- Catalog Ode Concept OsDocument19 pagesCatalog Ode Concept OsJose Luis GutierrezNo ratings yet

- 05 GB Simple ConnectionsDocument11 pages05 GB Simple Connectionspjustino70No ratings yet

- Seismic Beam Column Detail PDFDocument7 pagesSeismic Beam Column Detail PDFUğur YıldırımNo ratings yet

- How Interest Will Be Levied Example OptionDocument2 pagesHow Interest Will Be Levied Example Optionpareen9No ratings yet

- Steel ConnectionsDocument56 pagesSteel ConnectionsTejas Patel94% (16)

- Staad PDFDocument109 pagesStaad PDFOktayNo ratings yet

- Economical Structural Steel Work 1Document117 pagesEconomical Structural Steel Work 1James Sabmeethavorn100% (21)

- Structural Member Properties ExplainedDocument19 pagesStructural Member Properties Explainedpareen9No ratings yet

- Water Tank DesignDocument58 pagesWater Tank DesignMoHaMmAd WaHeEd88% (17)

- Sliding and Fixed Saddle Reactions with EarthquakesDocument2 pagesSliding and Fixed Saddle Reactions with Earthquakespareen9No ratings yet

- Quick and easy symbol creation for Smart 3DDocument1 pageQuick and easy symbol creation for Smart 3Dpareen9No ratings yet

- Smartplant Reference Data: Setup and User'S GuideDocument35 pagesSmartplant Reference Data: Setup and User'S Guidepareen9No ratings yet

- Product Handbook Structureal Steel PDFDocument175 pagesProduct Handbook Structureal Steel PDFRanu JanuarNo ratings yet

- StructDocument29 pagesStructMontu PrashantNo ratings yet

- Use Case 1 - 3D SymbolDesigner (En)Document1 pageUse Case 1 - 3D SymbolDesigner (En)pareen9No ratings yet

- Shell and Tube Heat Exchanger DesignDocument41 pagesShell and Tube Heat Exchanger DesignAhmad Budiman100% (2)

- Civiconcepts Name of WorkDocument30 pagesCiviconcepts Name of Workpareen9No ratings yet

- Member Assembly Connections Place Assembly Connection Ribbon Modify Auxiliary Parts RibbonDocument8 pagesMember Assembly Connections Place Assembly Connection Ribbon Modify Auxiliary Parts Ribbonpareen9No ratings yet

- Structural Member Properties ExplainedDocument19 pagesStructural Member Properties Explainedpareen9No ratings yet

- Diff BWT Is 800 101Document96 pagesDiff BWT Is 800 101tops123No ratings yet

- Explorador Ww90j6410cwec Version 02Document13 pagesExplorador Ww90j6410cwec Version 02Cristi PopescuNo ratings yet

- DseDocument20 pagesDsebrawijaya100% (1)

- SPINTRONICSDocument33 pagesSPINTRONICSSyam Pradeep ReddyNo ratings yet

- Case Study-R12 12Document81 pagesCase Study-R12 12ranjitpandeyNo ratings yet

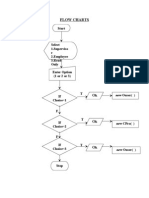

- Flow Charts Option: StartDocument13 pagesFlow Charts Option: StartbalabooksNo ratings yet

- Environmental Quality Control of Emission From Diesel Engines Regulations 1996 - P.U.a 429-96Document22 pagesEnvironmental Quality Control of Emission From Diesel Engines Regulations 1996 - P.U.a 429-96scribdledeeNo ratings yet

- Wheel Loader L50E: 2 EngineDocument4 pagesWheel Loader L50E: 2 EngineInjeletro Diesel100% (1)

- Vernier, Dial, and Electronic Digital Calipers: Session 3Document40 pagesVernier, Dial, and Electronic Digital Calipers: Session 3Emman Bosito100% (1)

- Final Defence 2078Document43 pagesFinal Defence 2078XxxNo ratings yet

- KB Rebar BrochureDocument4 pagesKB Rebar BrochureJun Xian Wai100% (1)

- The Properties of WaterDocument6 pagesThe Properties of WaterannisyaNo ratings yet

- Evaporative Pre CoolerDocument46 pagesEvaporative Pre CoolerLizbeth Ramirez AlanyaNo ratings yet

- BDOs SheetsDocument25 pagesBDOs Sheets3J Solutions BDNo ratings yet

- The History of PumpsDocument8 pagesThe History of Pumpsdhanu_aquaNo ratings yet

- Hdfs Default XML ParametersDocument14 pagesHdfs Default XML ParametersVinod BihalNo ratings yet

- Chapter 15. Applications of Integration: Exercises 15.2Document2 pagesChapter 15. Applications of Integration: Exercises 15.2Donghyun AhnNo ratings yet

- Grove GMK 4080Document6 pagesGrove GMK 4080Deiver BarrazaNo ratings yet

- Stop Motion Pre Production - Negotiated BriefDocument10 pagesStop Motion Pre Production - Negotiated Briefp4nd3m0n1c100% (1)

- Multi-disciplinary profile of IS/IT outsourcing researchDocument47 pagesMulti-disciplinary profile of IS/IT outsourcing researchIsabel MirandaNo ratings yet

- Effectiveness Ntu MethodDocument4 pagesEffectiveness Ntu MethodBen Musimane100% (1)

- Plant Cost EstimationDocument49 pagesPlant Cost EstimationAlpianto100% (1)

- Novajet Refference GuideDocument74 pagesNovajet Refference GuideoralbnetworkNo ratings yet

- P613 HW # 2 Solutions for a 2D Electron GasDocument4 pagesP613 HW # 2 Solutions for a 2D Electron GasRakeshNo ratings yet

- Variable Frequency Drive Using IR215xDocument7 pagesVariable Frequency Drive Using IR215xartyomNo ratings yet

- Instructions For Installation, Operating and Maintenance InstructionDocument30 pagesInstructions For Installation, Operating and Maintenance InstructionmilacronNo ratings yet

- Scallops Are Cut Outs in Weld Corners Which Are Used in Many Structures As in BridgesDocument3 pagesScallops Are Cut Outs in Weld Corners Which Are Used in Many Structures As in BridgesJanuel BorelaNo ratings yet

- Price Quotation: Quote/Project Description Ref. Details: Project DetailDocument3 pagesPrice Quotation: Quote/Project Description Ref. Details: Project DetailAhmad AyyoubNo ratings yet

- Engineering Structures: SciencedirectDocument8 pagesEngineering Structures: SciencedirectFeleki AttilaNo ratings yet

- Husky Air Assignment 5 and 6Document15 pagesHusky Air Assignment 5 and 6varunkalra6No ratings yet

- Ansul Wheeled RedLine 150lb F-2002046Document4 pagesAnsul Wheeled RedLine 150lb F-2002046German Duvan HernandezNo ratings yet