Professional Documents

Culture Documents

Cement Industry: Grupo 5 Pilar Delicado Herreras Rebeca Diez Morales Cristina Martín Serrano

Uploaded by

Arfan WigunaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cement Industry: Grupo 5 Pilar Delicado Herreras Rebeca Diez Morales Cristina Martín Serrano

Uploaded by

Arfan WigunaCopyright:

Available Formats

CEMENT INDUSTRY

GRUPO 5

PILAR DELICADO HERRERAS

REBECA DIEZ MORALES

CRISTINA MARTN SERRANO

GENERAL INFORMATION ABOUT

CEMENT INDUSTRY

Cement is a basic material for building and civil

engineering construction.

Cement is a finely ground, non-metallic, inorganic

powder when mixed with water forms a paste that

sets and hardens.

World cement production has grown steadily since

the early 1950s, withincreased production in

developing countries, particularly in Asia.

CEMENT PRODUCTION IN THE UE

AND THE WORLD

Producers in the European Union have increased

cement output per man/year from 1700 tonnes in

1970 to 3500 in 1991.

As a result of the introduction of larger scale

production units.

The number of people employed in the cement

industry in the European Union is now less than

60000.

EMISSIONS

The emissions from cement plants which cause

greatest concern are:

Nitrogen oxides (NO

x

)

Sulphur dioxide (SO

2

)

Dust

Carbon oxides (CO, CO

2

)

Volatile organic compounds

Polychlorinated dibenzodioxins (PCDDs) and

dibenzofurans (PCDFs)

Metals and their compounds

APPLIED PROCESSES AND

TECHNIQUES

It begins with the decomposition of calcium

carbonate (CaCO

3

) at about 900C to leave

calcium oxide (CaO, lime) and liberate

gaseous carbon dioxide (CO

2

).

CALCINATION

MAIN PROCESS ROUTES FOR THE

MANUFACTURE OF CEMENT

There are four main process routes:

1) Dry process: raw materials are ground

and dried to raw meal in the form of a

flowable powder.

2) Semi-wet process: the slurry is first

dewatered in filter presses.

MAIN PROCESS ROUTES FOR THE

MANUFACTURE OF CEMENT

3) Semi-dry process: dry raw meal is

pelletised with water and fed into a grate

preheater before the kiln or to a long kiln

equipped with crosses.

4) Wet process, the raw materials (often with

high moisture content) are ground in water to

form a pumpable slurry.

SUB-PROCESSES

Winning of raw materials

Raw materials storage and preparation

Fuels storage and preparation

Clinker burning

Cement grinding and storage

Packing and dispatch

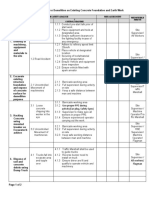

TECHNIQUES TO CONSIDER THE

DETERMINATION OF BAT

Consumption of raw materials

Reduce the total consumption of raw materials.

Use of energy

To optimise the input of energy.

Process selection

The selected process will affect the releases of all pollutants,

and will also have a significant effect on the energy use.

General techniques

Optimisation of the clinker burning process is usually done

to reduce the heat consumption, to improve the clinker

quality and to increase the lifetime of the equipment

Reduction of emissions, such as NOx, SO

2

and dust, are

secondary effects of this optimisation.

TECHNIQUES TO CONSIDER THE

DETERMINATION OF BAT

Careful selection and control of substances entering the kiln

can reduce emissions.

Specific techniques

Control NOx emissions

Control SO

2

emissions

Control dust emissions

Control other emissions to air

DUST EMISSIONS

Main point sources:

Kiln systems

Clinker coolers

Cement mills

Techniques for controlling it:

Electrostatic precipitators

Fabric filters

Fugitive dust abatement

ELECTROSTATIC PRECIPITATORS

Generate an electrostatic field.

The particles become negatively charged and migrate

towards positively charged collection plates.

The collection plates are vibrated periodically,

dislodging the material so that it falls.

CONDITIONS

High temperatures (up to approximately 400C).

High humidity.

ELECTROSTATIC PRECIPITATORS

Efficiency is affected by:

Flue gas flow rate

Strength of the electric field

Particulate loading rate

SO

2

concentration

Moisture content

Shape and area of the electrodes

ELECTROSTATIC PRECIPITATORS

Electronics precipitators can reduce levels down to

5-15 mg/m

3

as monthly average.

Besides dust, the EP also removes substances that

adsorb to the dust particles, such as dioxins and

metals if present.

EPs are not installed if emissions at startups and

shut downs are very high.

FABRIC FILTERS

Fabric membrane which is permeable to gas but

which will retain the dust.

As the dust cake thickens, the gas pressure drop

across the filter increases Periodic cleaning

The use of modern fabric filters can reduce dust

emissions to below 5 mg/m

3

.

Also removes substances that adsorb to the dust

particles, such as dioxins and metals.

FUGITIVE DUST ABATEMENT

Fugitive emission sources mainly arise from storage

and handling of substances and from vehicle traffic

at the manufacturing site.

Some techniques for fugitive dust abatement are:

Open pile wind protection

Water spray and chemical dust suppressors

Paving, road wetting and housekeeping

Mobile and stationary vacuum cleaning

Ventilation and collection in fabric filters

Closed storage with automatic handling system

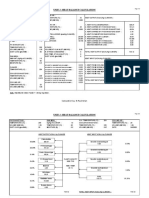

COMPARISON

BEST AVAILABLE TECHNIQUES FOR

THE CEMENT INDUSTRY

The BAT for the production of cement clinker is

considered to be a dry process kiln with multi-stage

preheating and precalcination.

Process control optimisation.

The use of modern, gravimetric solid fuel feed

systems.

Preheating and precalcination to the extent possible,

considering the existing kiln system configuration.

The use of modern clinker coolers.

BEST AVAILABLE TECHNIQUES FOR

THE CEMENT INDUSTRY

Heat recovery from waste gas.

Power management systems.

Grinding equipment and other electricity based

equipment with high energy efficiency.

Careful selection and control of substances entering

the kiln can reduce emissions.

BAT FOR REDUCING DUST

EMISSIONS

The combination of the above described general

primary measures and:

Minimisation/prevention of dust emissions from

fugitive sources.

Efficient removal of particulate matter from point

sources by application of:

- Electrostatic precipitators with fast measuring and

control equipment to minimise thenumber of CO trips.

- Fabric filters with multiple compartments and burst bag

detectors.

The BAT emission level associated with these

techniques is 20-30 mg dust/m

3

on a daily average

basis.

EMERGING TECHNIQUES IN THE

CEMENT INDUSTRY

Fluidised bed cement manufacturing

technology

Staged combustion combined with SNCR

FLUIDISED BED CEMENT

MANUFACTURING TECHNOLOGY

Consists of a suspension preheater (SP), a spouted

bed granulating kiln (SBK), a fluidised bed sintering

kiln (FBK), a fluidised bed quenching cooler (FBK) and

a packed bed cooler.

SP: conventional 4-stage cyclone preheater.

Granulating kiln: granulating the raw meal into

granules of about 1,5-2,5 mm diameter at a 1300C.

FLUIDISED BED CEMENT

MANUFACTURING TECHNOLOGY

The sintering of the granules is completed at a

1400C.

The fluidised bed quenching cooler quickly cools

the cement clinker from 1400 to 1000C.

The cement clinker is cooled down to about 100C

in the packed bed cooler.

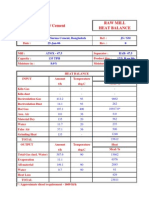

Configuration of the 20

tonnes clinker/day

fluidised bed cement

kiln system:

FLUIDISED BED CEMENT

MANUFACTURING TECHNOLOGY

The final target of the technical development

of the fluidised bed cement kiln system are:

Reduction of heat use by 10-12%.

Reduction of CO

2

emission by 10-12%.

A NO

x

emission level of 380 mg/m

3

or less

(converted to 10% O

2

).

To maintain the current SO

x

emission level.

Reduction of construction cost by 30%.

Reduction of installation area by 30%.

STAGED COMBUSTION COMBINED

WITH SNCR

In theory, a combination of staged

combustion and SNCR could be comparable

to SCR in performance, that is NO

x

emission

levels of 100-200 mg/m

3

.

This combination is considered very

promising by suppliers but is not yet proven.

CEMENT INDUSTRY

GRUPO 5

PILAR DELICADO HERRERAS

REBECA DIEZ MORALES

CRISTINA MARTN SERRANO

You might also like

- Cement KilnDocument2 pagesCement Kilnamir100% (2)

- IEE Handout 2Document2 pagesIEE Handout 2Sunil DeshmukhNo ratings yet

- 031 Introduction Cement Grinding With Ball Mill SystemsDocument4 pages031 Introduction Cement Grinding With Ball Mill SystemsCesar Orlando Guarniz JustinianoNo ratings yet

- Impact of calcium sulfates on cement properties and concrete workabilityDocument10 pagesImpact of calcium sulfates on cement properties and concrete workabilitycemsavantNo ratings yet

- Snowman FormationDocument1 pageSnowman FormationKEERTHI INDUSTRIES100% (1)

- CM 2 Filling DegreeDocument9 pagesCM 2 Filling DegreeElwathig BakhietNo ratings yet

- The Effects of Oxygen Enrichment On ClinkerDocument9 pagesThe Effects of Oxygen Enrichment On ClinkerNael100% (1)

- V2 Materials Technology 2Document526 pagesV2 Materials Technology 2Liya Nur SholihahNo ratings yet

- LafargeDocument18 pagesLafargeMadan Mohan ReddyNo ratings yet

- Duoflex BurnerDocument6 pagesDuoflex Burnersinghite100% (1)

- Mod 6Document49 pagesMod 6mkpq100% (1)

- Clinker CoolersDocument12 pagesClinker CoolersAkhilesh Pratap SinghNo ratings yet

- Control Cooler Exit Temperature and IKN Grate RestrictionDocument33 pagesControl Cooler Exit Temperature and IKN Grate Restrictionसागर फुकटNo ratings yet

- 1,2,6a - Flames and Gas FiringDocument29 pages1,2,6a - Flames and Gas FiringMohamed SaadNo ratings yet

- Unwanted False Air in Cement Plants Can Be A Big Problem and Has To Be Taken SeriouslyDocument5 pagesUnwanted False Air in Cement Plants Can Be A Big Problem and Has To Be Taken SeriouslyharyantoaditNo ratings yet

- Energy Auditing and Recovery For Dry Type Cement Rotary Kiln Systems A Case StudyDocument12 pagesEnergy Auditing and Recovery For Dry Type Cement Rotary Kiln Systems A Case Study1977julNo ratings yet

- Cement Mill: History Materials Ground Temperature Control Ball MillsDocument5 pagesCement Mill: History Materials Ground Temperature Control Ball MillsAli HadiNo ratings yet

- Effect of Clinker Composition On GrindingDocument5 pagesEffect of Clinker Composition On GrindingAlbar Budiman100% (1)

- Performing A Cement Plant Operations AuditDocument6 pagesPerforming A Cement Plant Operations AuditJa Phe TiNo ratings yet

- Cement Grinding Vertical Roller Mills Versus Ball Mills 1654248086Document17 pagesCement Grinding Vertical Roller Mills Versus Ball Mills 1654248086Salah Romdani100% (1)

- Technological Advancement in Cement Manufacturing Industry: System Length DiameterDocument16 pagesTechnological Advancement in Cement Manufacturing Industry: System Length Diameterfaran100% (3)

- 3500TPD Cement Plant Heat BalanceDocument2 pages3500TPD Cement Plant Heat BalanceIrshad HussainNo ratings yet

- Ghid Coprocesare HolcimDocument135 pagesGhid Coprocesare HolcimnevedemjoiNo ratings yet

- Chemical AnalysisDocument8 pagesChemical Analysisصفاء رجبNo ratings yet

- Advancement in Refractories used for Cement Rotary kiln(CRKDocument75 pagesAdvancement in Refractories used for Cement Rotary kiln(CRKmahendra sen100% (1)

- QUESTIONNAIRE FOR PYROPROCESSING MODIFICATION COMPANYDocument8 pagesQUESTIONNAIRE FOR PYROPROCESSING MODIFICATION COMPANYVijay BhanNo ratings yet

- Impact of ALKALY, SULPHURE and CHLORINE in Kiln Operation and Clinker Quality ?Document11 pagesImpact of ALKALY, SULPHURE and CHLORINE in Kiln Operation and Clinker Quality ?awadallaNo ratings yet

- Boulder Formation in Cement Silos by Chettinad Cement CoDocument11 pagesBoulder Formation in Cement Silos by Chettinad Cement CoWaka OngetiNo ratings yet

- Rueddenklau Snowman PreventionDocument102 pagesRueddenklau Snowman PreventionIonela Dorobantu100% (2)

- SOx Emmissions Absortion FLSDocument14 pagesSOx Emmissions Absortion FLSMartha Carolina Gomez MartinezNo ratings yet

- V5 Process Technology 3Document441 pagesV5 Process Technology 3Pavel ParfenovNo ratings yet

- VRM Heat and Mass BalanceDocument1 pageVRM Heat and Mass BalanceRajeshRockNo ratings yet

- Transcript: Download Granulometry of ClinkerDocument4 pagesTranscript: Download Granulometry of ClinkerfaheemqcNo ratings yet

- Kiln Plant Optimization TechniquesDocument10 pagesKiln Plant Optimization TechniquesPaulo VidasNo ratings yet

- Red RiverDocument16 pagesRed RiverNael100% (1)

- Kiln System Operations - by Gerald L Young and F. M.millerDocument44 pagesKiln System Operations - by Gerald L Young and F. M.millersadatjafari100% (2)

- Click Here To Download Holcim, , Lafarge, Most Importnant Manuals, Most Important ExcelDocument26 pagesClick Here To Download Holcim, , Lafarge, Most Importnant Manuals, Most Important ExcelhamedNo ratings yet

- Ultra tech Cement Tadipatri Plant OverviewDocument18 pagesUltra tech Cement Tadipatri Plant OverviewAshutosh SinghNo ratings yet

- Circulation of Inorganic Elements in Combustion of Alternative Fuels in Cement PlantsDocument85 pagesCirculation of Inorganic Elements in Combustion of Alternative Fuels in Cement PlantsBetonÇimento100% (3)

- Short Note of Cement ChemistryDocument14 pagesShort Note of Cement Chemistrynk_kanchkar80% (5)

- Cement grinding and production overviewDocument9 pagesCement grinding and production overviewMob Morphling KurustienNo ratings yet

- Grinding Media ConsumptionDocument9 pagesGrinding Media ConsumptionMuhammadNo ratings yet

- Clinker Formation ConceptsDocument28 pagesClinker Formation ConceptspashaNo ratings yet

- R A R F U: % Passing Size, M Feed Coarse FinesDocument3 pagesR A R F U: % Passing Size, M Feed Coarse FinesAli HüthütNo ratings yet

- Quality Aspects of Cement Milling: Bob M QuillanDocument18 pagesQuality Aspects of Cement Milling: Bob M QuillanSamehibrahem100% (1)

- Raw Mill Heat BalanceDocument1 pageRaw Mill Heat BalanceElwathig Bakhiet100% (1)

- Clinker FactorDocument4 pagesClinker FactorElwathig Bakhiet100% (1)

- 4 Cement TechnologyDocument43 pages4 Cement TechnologySomu AdityaNo ratings yet

- Pre-Homogenization Factor PDFDocument6 pagesPre-Homogenization Factor PDFAfqan B-v0% (1)

- Rotary Kilns: Transport Phenomena and Transport ProcessesFrom EverandRotary Kilns: Transport Phenomena and Transport ProcessesRating: 4.5 out of 5 stars4.5/5 (4)

- Advances in Cement Technology: Critical Reviews and Case Studies on Manufacturing, Quality Control, Optimization and UseFrom EverandAdvances in Cement Technology: Critical Reviews and Case Studies on Manufacturing, Quality Control, Optimization and UseRating: 4.5 out of 5 stars4.5/5 (12)

- Combustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasFrom EverandCombustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasNo ratings yet

- CeramicsDocument31 pagesCeramicsMuhammad FakhruddinNo ratings yet

- Cement and Lime, GypsumDocument10 pagesCement and Lime, GypsumAliceNo ratings yet

- Cement and LimeDocument127 pagesCement and LimeEhab Anwer HassanNo ratings yet

- Manualul Pentru Incalzire Danfoss - Chapter2Document20 pagesManualul Pentru Incalzire Danfoss - Chapter2valicanNo ratings yet

- Cement manufacturing emissions guidelinesDocument4 pagesCement manufacturing emissions guidelinesSambhu YadavNo ratings yet

- Ijfeat: Application of Electrostatic Precipitator in Cement PlantDocument7 pagesIjfeat: Application of Electrostatic Precipitator in Cement PlantElwathig BakhietNo ratings yet

- 04 - Process Functions RevABDocument34 pages04 - Process Functions RevABAhmed MahmoudNo ratings yet

- Pneumatic Actuators: For Power, Motion and ControlDocument162 pagesPneumatic Actuators: For Power, Motion and ControlS.Dharanipathy100% (5)

- HB Eng PDocument277 pagesHB Eng PAhmed MahmoudNo ratings yet

- Orifice Flow CalculationDocument41 pagesOrifice Flow Calculationkumarram7650% (2)

- Rotating Equipment MeasurementDocument15 pagesRotating Equipment MeasurementAndinata SitepuNo ratings yet

- Ghid Coprocesare HolcimDocument135 pagesGhid Coprocesare HolcimnevedemjoiNo ratings yet

- White Paper On Increasing Co-Processing in Indian Cement PlantsDocument22 pagesWhite Paper On Increasing Co-Processing in Indian Cement PlantsAhmed MahmoudNo ratings yet

- Applying Open Gear LubricantsDocument6 pagesApplying Open Gear LubricantsAhmed MahmoudNo ratings yet

- Failure Modes and Effects Analysis for 5 Ton Acco Wright HoistDocument44 pagesFailure Modes and Effects Analysis for 5 Ton Acco Wright HoistAhmed MahmoudNo ratings yet

- Best Practice 10.lubricant Selection For GearsDocument5 pagesBest Practice 10.lubricant Selection For GearsAhmed MahmoudNo ratings yet

- 4713004Document11 pages4713004Ahmed MahmoudNo ratings yet

- Fan Source BookDocument92 pagesFan Source Bookapi-3808778100% (10)

- Shaft Alignment ProcedureDocument64 pagesShaft Alignment ProcedureParas Thakur100% (1)

- Romanian Power Grid Substation Refitting StrategyDocument16 pagesRomanian Power Grid Substation Refitting StrategyParmeshwar MbNo ratings yet

- 1990 2004.yamaha - Yfm350x.warrior - Factory.service - ManualDocument3 pages1990 2004.yamaha - Yfm350x.warrior - Factory.service - ManualBobbi Jo Bach-Oachs50% (2)

- MESL - Differential Equation 2Document9 pagesMESL - Differential Equation 2Mark-Lorie Duculan NonesNo ratings yet

- Emergency Braking SystemDocument4 pagesEmergency Braking Systemieee4mybusinessonlyNo ratings yet

- What Is Transmission Channel ?Document12 pagesWhat Is Transmission Channel ?tusharNo ratings yet

- P&ID Check ListDocument2 pagesP&ID Check ListHadi ShahsavanNo ratings yet

- Transmission Line Surveyors Face Challenges in Projecting Data onto MapsDocument3 pagesTransmission Line Surveyors Face Challenges in Projecting Data onto MapsTATAVARTHYCH HANUMANRAONo ratings yet

- 7216Document8 pages7216siicmorelosNo ratings yet

- Technical Data Demag Hoist Units Volume 2: Double-Rail Crab EZDH 600 - EZDH 1000 Double-Rail Crab EZLDH 600 - EZLDH 2000Document88 pagesTechnical Data Demag Hoist Units Volume 2: Double-Rail Crab EZDH 600 - EZDH 1000 Double-Rail Crab EZLDH 600 - EZLDH 2000mohammad khoraminiaNo ratings yet

- ULSADO-JSA-Demolation Existing Concrete FoundationDocument2 pagesULSADO-JSA-Demolation Existing Concrete FoundationKelvin Tan75% (4)

- Price ListDocument2 pagesPrice ListCHeng SOngco TAlosigNo ratings yet

- DV2P Prog ManualDocument75 pagesDV2P Prog ManualDavis Arturo Pinto PérezNo ratings yet

- Basic Electronics PowerpointDocument16 pagesBasic Electronics PowerpointEarle Sean MendozaNo ratings yet

- QSEE6800+H Signal Monitor Video and Thumbnail Streamer: Installation and Operation ManualDocument86 pagesQSEE6800+H Signal Monitor Video and Thumbnail Streamer: Installation and Operation ManualTechne PhobosNo ratings yet

- Louie Langas Resume 2019Document1 pageLouie Langas Resume 2019Louie LangasNo ratings yet

- Hotpoint Service Manual Fridge FreezerDocument36 pagesHotpoint Service Manual Fridge FreezerMANUEL RODRIGUEZ HERRERA100% (1)

- Fluid Mechanics Subjective QuestionsDocument3 pagesFluid Mechanics Subjective QuestionsCrewdex ProNo ratings yet

- Domino A Series Classic Spares CatalogueDocument137 pagesDomino A Series Classic Spares CatalogueKoos Roets100% (2)

- Local buckling classificationDocument10 pagesLocal buckling classificationHaya BakerNo ratings yet

- An Introduction To Orgone Matrix Material (Jon Logan)Document42 pagesAn Introduction To Orgone Matrix Material (Jon Logan)Jose CiprianiNo ratings yet

- Instruction Manual Manuel D'Instruction Manual de InstruccionesDocument136 pagesInstruction Manual Manuel D'Instruction Manual de InstruccionesPrabish KumarNo ratings yet

- BCN 3224 - Exam 3 ReviewDocument34 pagesBCN 3224 - Exam 3 Reviewmgwin17No ratings yet

- Basic Metatrader 5 GuideDocument22 pagesBasic Metatrader 5 GuideDavid Al100% (1)

- GRI - GM22 SpecificationDocument30 pagesGRI - GM22 SpecificationГригорий ЛевашовNo ratings yet

- WRCLA Designers HandbookDocument11 pagesWRCLA Designers HandbookHoang NguyenNo ratings yet

- Underfloor Wheelset Lathe: Operating / Maintenance ManualDocument84 pagesUnderfloor Wheelset Lathe: Operating / Maintenance ManualMinh Canh100% (1)

- Turbo Machines and Propulsion Exam Questions on Pumps, Turbines, Pipe FlowDocument3 pagesTurbo Machines and Propulsion Exam Questions on Pumps, Turbines, Pipe FlowAdams100% (1)

- Rcs454: Python Language Programming LAB: Write A Python Program ToDocument39 pagesRcs454: Python Language Programming LAB: Write A Python Program ToShikha AryaNo ratings yet

- John Deere 9650 Sts Parts CatalogDocument20 pagesJohn Deere 9650 Sts Parts CatalogDennis100% (56)

- AWS CWI For NSRP at NSRP PDFDocument7 pagesAWS CWI For NSRP at NSRP PDFTuấn PhạmNo ratings yet