Professional Documents

Culture Documents

A World in Transformation: ABB Is The World's Largest Transformer Manufacturer and Service Provider

Uploaded by

Dante Filho0 ratings0% found this document useful (0 votes)

33 views5 pagesTransformers were the main reason that the three-phase AC transmission system could establish itself as the main T&D technology around 130 years ago. ABB is the world's largest transformer manufacturer and service provider.

Original Description:

Original Title

06-10 sr101_72dpi

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentTransformers were the main reason that the three-phase AC transmission system could establish itself as the main T&D technology around 130 years ago. ABB is the world's largest transformer manufacturer and service provider.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

33 views5 pagesA World in Transformation: ABB Is The World's Largest Transformer Manufacturer and Service Provider

Uploaded by

Dante FilhoTransformers were the main reason that the three-phase AC transmission system could establish itself as the main T&D technology around 130 years ago. ABB is the world's largest transformer manufacturer and service provider.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

6 ABB review special report

MAX CLAESSENS History is marked by a series of great inventions that have

swept across society, acting as stepping stones in the emergence of the modern

world. Most people would agree that re, the wheel, modern transportation and

communication systems, culminating with the Internet all have a place in this list.

Maybe less obvious but equally pivotal is the large-scale transmission and

delivery of electrical energy over long distances. This breakthrough that would

not have been possible without the transformer. This article takes a brief tour of

the history and technology behind the transformer and looks at the different ways

in which ABB has advanced and applied it.

ABB is the worlds largest transformer

manufacturer and service provider

A world in

transformation

7 A world in transformation

Power transform-

ers were the main

reason that the

three-phase AC

transmission sys-

tem could estab-

lish itself as the

main T&D tech-

nology around

130 years ago.

dreds of volts. In the early 1880s, for

example, the Edison Illuminating Com-

pany supplied 59 customers in Lower

Manhattan with electricity at 110 V DC.

But the energy demand of the fast

growing cities and industrial centers

called for an increase in power trans-

mission capability.

The small steam- and hydro generators

were no longer sufficient and larger

power plants were erected more remote-

ly from the cities. Voltage levels had

to be increased to

keep nominal cur-

rents on the power

lines moderate and

reduce losses and

voltage drops. This

was the time of

the birth of a new

component: the

power transformer.

In a transformer, two coils are arranged

concentrically so that the magnetic field

generated by the current in one coil

induces a voltage in the other. This phys-

A

round 130 years ago a techni-

cal revolution took place that

was to be a vital step in the

development of modern so-

ciety. That revolution was the commer-

cial generation, transmission and usage

of electrical energy. Nobody today can

imagine a world without electricity. How-

ever, this article will start by taking the

reader back to the early days when pio-

neers like Thomas Edison and George

Westinghouse and their ideas were

competing for the transmission system

of the future: Should it be DC or should

it be AC?

Very early electrical installations were

local: The sites of generation and con-

sumption were at most a handful of kilo-

meters apart: Direct connections from

the steam- or hydro generators to the

consumers were in the range of hun-

ical principle can only be applied in AC

systems, as only a time-varying mag-

netic field is able to induce a voltage. By

using a different number of winding turns

in the two coils, a higher or lower voltage

can be obtained. The ability to transform

from one voltage level to another one

was the main reason for the break-

through of AC three-phase transmission

and distribution systems. These AC sys-

tems operate at a frequency high enough

that human short perception does not

see the time variation (flickering) and

low enough that switching equipment

can be operated safely. The best com-

promise was the well-known 50 or 60 Hz

of the todays mains supplies.

Title picture

Transformers are a vital link in the power transmis-

sion and distribution chain.

The power transmission

breakthrough would not have

been possible without the

transformer.

8 ABB review special report

overvoltage impulse of a lightning strike.

New coil designs mitigated these reso-

nance effects.

Transformers are the main current-limit-

ing element in case of short-circuit fail-

ures in the transmission system. The so-

called stray reactance, which represents

the magnetic flux outside of the mag-

netic core limits the increase in current in

such an event. If high currents flow

through the coils uncontrolled, mechani-

cal forces try to press the coils apart,

and may cause damage if the construc-

tion is not sufficiently robust.

Due to the resistance and inductance of

the power lines themselves, the voltage

level may vary depending on load condi-

tions. This means that less voltage

arrives at the receiving end of a power

line when the load is high. To keep the

voltage level within an acceptable range,

power transformers usually include an

on-load tap changer to vary the number

of active winding turns of coil by switch-

ing between different taps. In medium

voltage (MV) distribution, this is usually

done ofine: This means the tap changers

are adjusted once before the transformer

is energized and then remain xed.

The increasing importance in recent

decades of UHV (ultra-high voltage) DC

transmission lines for high power trans-

mission over very long distances (greater

than 1000 km) has made it necessary to

develop UHV-DC converter transformers,

which are a huge challenge especially for

Transformers need an amplifier for the

magnetic field so that the number of

winding turns can be kept low. This am-

plifier is the so-called magnetic core.

It consists of ferromagnetic iron, which

contains microscopic elementary mag-

nets that align to the transformers mag-

netic field as a compass needle aligns to

the Earths magnetic field. The iron core

is made of many thin ferromagnetic steel

sheets that are electrically insulated

against each other and stacked. This

reduces classical eddy losses. The use

of special alloys and manufacturing

methods enables a minimum needed

e nergy to change polarity of the elemen-

tary magnets.

This basic physical principle of trans-

formers is still the same today as it was

130 years ago, but energy density, effi-

ciency, costs, weight and dimensions

have drastically improved. This can be

compared to the history of cars and the

internal combustion engine: Here too the

basic principle has remained unchanged

in 100 years, but technical progress has

transformed the scope of possibilities

almost beyond recognition. During the

first decades of electrification, the main

focus in transformer research and devel-

opment was to increase power capacity

(the power that can be transmitted by

one unit). Furthermore, more and more

effects concerning voltage transients

became known that could endanger the

transformers insulation. These include

resonance effects in the coils that can be

triggered by fast excitations such as the

Power transformer

technology made

tremendous prog-

ress during the last

130 years.

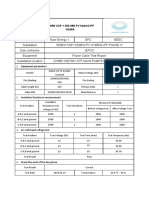

1a The worlds largest transformer in 1942 (220 kV / 120 MVA)

Vrtan substation Stockholm, delivered by ASEA

1b The worlds rst 800 kV UHVDC power transformer for the 2,000 km

Xiangjiaba-Shanghai transmission link, delivered by ABB in 2008

1 Transformer development

9 A world in transformation

usually have a forced internal convection

flow of air to ensure sufficient cooling of

the transformer core.

AMDT (amorphous metal distribution

trans formers) is an upcoming technology

that reduces losses inside the magnetic

core. Although the amorphous materials

are still more expensive than standard

grain oriented steel, their application can

be justified depending on how these

losses are capitalized over the lifetime of

the transformer.

Power transformers

When the transmitted power exceeds

around 10 MVA, special designs are

required to cope with the mechanical

forces of short circuit currents, higher

insulation levels and increased cooling

requirements. For these ratings, liquid-

filled transformers are usually used. The

insulation between the windings be-

comes more and more demanding at

higher voltages. Furthermore, resonance

effects inside the winding itself have to

be considered to avoid insulation failures

during highly dynamic impulse stresses

such as lightning strikes which may

reach amplitudes of one to two thou-

sands kilovolt with a 1 s rise time.

the electric insulation system. The 800 kV

UHV-DC Xiangjiaba-Shanghai line 1,

for example, has a capacity of up to

7200 MVA, which is roughly comparable

to the consumption of Switzer land.

Distribution transformers

On the distribution level (transmitted

power up to 10 MVA) there are two main

categories of transformers 2: Liquid

filled (using mineral oil or replacement

fluids such as synthetic or natural esters)

and dry type. The liquid filled transform-

ers are the most compact and cost effi-

cient solution, whereas dry type trans-

formers are preferred in environments

where fire safety is of special importance

such as, for example, underground sub-

stations, mining sites, marine and some

industrial applications 3, 4.

Standard versions of distribution trans-

formers are cooled passively as the heat

generated by losses is transported away

from the core by natural convection of

the insulation medium. In the case of

liquid filled products, this heat is then

transported through the tank walls by

thermal conduction and removed by the

natural or forced convection of air. Dry

transformers in closed environments

Dry-type trans-

formers are the

preferred technol-

ogy for applica-

tions in which fire

safety is of special

importance.

2a Liquid filled

2b Dry-type

3 Dubais 868 m high Burj Khalifa building is

equipped with 78 ABB dry-type transformers

2 Distribution transformers come in two

main categories

4 Single-phase pole-mounted transformers,

for small power classes up to 167 kVA

5 One example of an extreme application is

this 600 MVA / 230 kV phase shifter

10 ABB review special report

Transformers with power ratings above

some ten MVA are a key element in the

supply of large regions or industrial areas.

As a rule of thumb, it can be considered

that one person has an average electrical

power demand of 1 kVA, which means,

that a 400 MVA transformer transfers the

power needed by 400,000, the equivalent

of a medium sized city. Such transformers

have to comply with special requirements

on safety and reliability and also have to

provide a very high efciency and low

sound level. In recent decades, high volt-

age DC lines have also become increas-

ingly important, especially in large coun-

tries such as China where they connect

industrial centers to the remote regions

where the electricity is generated. ABB

now offers standard solutions for DC con-

verter transformers for up to 800 kV DC.

A transformers located directly next to a

power plant is called GSU (Generator

Step-up Unit). A GSU transforms the elec-

tric power from the medium voltage of the

generators to the high voltage transmis-

sion level.

To balance power ow between parallel

power lines, phase shifters can be used.

These are transformers (usually with a 1:1

translation ratio) that adapt and control the

phase angles of voltage and current to

optimize the power transmission capacity

of the lines. Phase shifters exist up to a

power rating of 1,500 MVA 5.

Today transformation efciencies of up to

99.85 percent are achievable by using

special magnetic steel qualities and opti-

mized designs. The heat losses, even at

these high efciencies, are still signicant:

For the 400 MVA unit mentioned above, for

example, it would be still around 600 kW

under full load conditions. The cooling sys-

tem thus remains a challenge. Additionally,

the weight and size of such devices has to

be dimensioned carefully since there are

limitations in the maximum transportation

possibilities in the different countries 6.

Traction and special transformers

Railway vehicles use a special type of

transformer that must be highly compact,

reliable and robust. Operating frequencies

vary (according to countries and systems)

from 16.7 Hz to 60 Hz with power classes

of up to 10 MVA. To permit trains to cross

borders between countries, traction trans-

formers must be compatible with the dif-

ferent frequencies and power systems.

ABB offers optimized solutions for all these

different railway applications, stretching up

to high speed trains with their challenging

needs 7.

Moreover, ABB makes a variety of further

transformers for special applications, for

example for subsea electrication or for

operating variable speed drives.

7 ABB is supplying the traction transformer

for the new Velaro D high speed train

Max Claessens

ABB Power Products, Transformers

Zurich Switzerland

max.claessens@ch.abb.com

6 ABB is the worlds largest transformer manufacturer and service provider, capable of

delivering high-quality durable products and services all over the world

ABB transformers are found wherever electricity is generated, transported and consumed in power

plants and substations skyscrapers and shopping malls, ships and oil platforms, locomotives and

railway lines, wind parks and solar fields, water and wastewater plants. The worlds tallest building,

the 828 meters high Burj Khalifa in Dubai is equipped with 78 dry-type ABB transformers to ensure

power reliability 3. The nearby Dubai Fountain, which is illuminated by 6.600 lights and shoots water

150 meters into the air, is also equipped with ABB transformers.

For almost 120 years, ABB has produced commercial transformers and continued to enhance them

by developing new technologies and materials that raise efficiency, reliability and sustainability to a

new level.

ABB has set the world records for the most powerful many times from the worlds first transformers

of 400 kV and 800 kV in the 1950s and 1960s, to the most powerful UHVDC transformers for the

800 kV, 2000 km Xiangjiaba-Shanghai transmission link in China 2. By developing new high-perfor-

mance materials and using fire-resistant insulation liquids, ABB has improved the efficiency, safety and

environmental friend liness of transformers. The new eco-friendly product lines can achieve energy

savings of 40 50 percent.

For almost 120

years, ABB has

produced commer-

cial transformers.

ABB has set the

world record for

power many times.

You might also like

- Tranformers ManufacturingDocument76 pagesTranformers ManufacturingRohit Goyal100% (1)

- ABB SR Transformers-121031Document76 pagesABB SR Transformers-121031Engin YiğitNo ratings yet

- Electric Power Transmission Is The Bulk Transfer ofDocument3 pagesElectric Power Transmission Is The Bulk Transfer ofKarteekNo ratings yet

- Electric Power TransmissionDocument16 pagesElectric Power Transmissionsattar28No ratings yet

- Term Paper of Ele-102: Topic:-Power and Distribution (Transformer'S Application)Document10 pagesTerm Paper of Ele-102: Topic:-Power and Distribution (Transformer'S Application)shailesh singhNo ratings yet

- Electric Popwer TransmissionDocument6 pagesElectric Popwer TransmissionvedNo ratings yet

- Electric Power Transmission - Wikipedia, The Free EncyclopediaDocument18 pagesElectric Power Transmission - Wikipedia, The Free EncyclopediaumarriazNo ratings yet

- Electric Power TransmissionDocument19 pagesElectric Power TransmissionEngr Muhammad Imran KhanNo ratings yet

- Electric-Power Transmission Is The Bulk Transfer ofDocument12 pagesElectric-Power Transmission Is The Bulk Transfer ofriz2010No ratings yet

- Electric-Power Transmission Is The Bulk Transfer Of: o o o oDocument17 pagesElectric-Power Transmission Is The Bulk Transfer Of: o o o oriz2010No ratings yet

- Chapter 1Document48 pagesChapter 1Tang Doan Tu100% (1)

- AC vs. DC Grid ComparisonDocument13 pagesAC vs. DC Grid Comparisonzarun1No ratings yet

- Electric Power TransmissionDocument42 pagesElectric Power TransmissionEarl Jay UayanNo ratings yet

- Intro Transmission Distribution Systems Overview"TITLE"Substation Functions Transform Voltage Distribution GridDocument9 pagesIntro Transmission Distribution Systems Overview"TITLE"Substation Functions Transform Voltage Distribution GridJoydev GangulyNo ratings yet

- PROJECT WORK SubstationDocument91 pagesPROJECT WORK SubstationSai Royals100% (1)

- High-Voltage Direct CurrentDocument13 pagesHigh-Voltage Direct CurrentBrandon ReedNo ratings yet

- Overview of Overhead Power Transmission LinesDocument10 pagesOverview of Overhead Power Transmission LinesHaxfNo ratings yet

- Transmission Line Components and DesignDocument21 pagesTransmission Line Components and Design221 Siddhant shitoleNo ratings yet

- HVDC 4 EncompassDocument2 pagesHVDC 4 EncompassAnkur PathakNo ratings yet

- Electric Power Transmission CompressDocument42 pagesElectric Power Transmission CompressGanesh KotnalaNo ratings yet

- Shunt ReactorDocument4 pagesShunt ReactorShruti JoshiNo ratings yet

- Documents: HVDC ContrDocument92 pagesDocuments: HVDC Contrvenkilaxmi9No ratings yet

- Case Study On 33 11KV Transmission SubstDocument36 pagesCase Study On 33 11KV Transmission SubstHareendralal A.G.No ratings yet

- Electric Power TransmissionDocument16 pagesElectric Power TransmissionEdoh OnoriodeNo ratings yet

- Power SystemDocument155 pagesPower SystemMELVINNo ratings yet

- Transmission Towers Research PaperDocument10 pagesTransmission Towers Research PaperJhn Hnrch TolentinoNo ratings yet

- Flexible AC: Power Electronics Transmission SystemDocument2 pagesFlexible AC: Power Electronics Transmission SystemAnonymous DAjfj9HIBmNo ratings yet

- Ee208 Chapter 2 TransformersDocument15 pagesEe208 Chapter 2 TransformersTinozivasheNo ratings yet

- Full WorkDocument9 pagesFull Workapi-255184670No ratings yet

- Learn More About T& DDocument8 pagesLearn More About T& Darindam90No ratings yet

- Trainning Report of NTPC, BongaigaonDocument24 pagesTrainning Report of NTPC, BongaigaonJayanta KarNo ratings yet

- HVDC Systems in Smart GridsDocument16 pagesHVDC Systems in Smart GridsSimo MilenkovićNo ratings yet

- Types of Transformer - : Power TransformersDocument15 pagesTypes of Transformer - : Power TransformersKunal KumarNo ratings yet

- High Voltage Direct Current ConfigurationsDocument5 pagesHigh Voltage Direct Current ConfigurationsAshish JadhavNo ratings yet

- Alternating Current - Wikipedia, The Free EncyclopediaDocument5 pagesAlternating Current - Wikipedia, The Free Encyclopediadonodoni0008No ratings yet

- EnvironmentlllDocument5 pagesEnvironmentlllJyoshna IppiliNo ratings yet

- Minor Project Report On Design of A Transmission LineDocument52 pagesMinor Project Report On Design of A Transmission Lineberwalravi88% (8)

- EditedDocument55 pagesEditedMeshack LeeNo ratings yet

- Power ElectronicsDocument20 pagesPower ElectronicsJohn Paul BaquiranNo ratings yet

- Electrical DiplomaDocument44 pagesElectrical DiplomaMukesh SharmaNo ratings yet

- HVDC - TutorialDocument14 pagesHVDC - Tutorialrodrig15No ratings yet

- A New Type of Oil-Free Power Transformer With Low Environmental ImpactDocument6 pagesA New Type of Oil-Free Power Transformer With Low Environmental ImpactOSAMANo ratings yet

- GENERATION AND DISTRIBUTION OF ELECTRIC POWER SIMPLIFIEDDocument127 pagesGENERATION AND DISTRIBUTION OF ELECTRIC POWER SIMPLIFIEDkuchowNo ratings yet

- Automatic Mains Changeover Power SupplyDocument55 pagesAutomatic Mains Changeover Power SupplyAnonymous f9RU7fiNo ratings yet

- HTS For Space Power Transmission LinesDocument19 pagesHTS For Space Power Transmission Linesdamu_99No ratings yet

- Transformador Básico (En Ingles)Document4 pagesTransformador Básico (En Ingles)jona12345No ratings yet

- Electrical Oscillators ExplainedDocument4 pagesElectrical Oscillators Explaineddag57No ratings yet

- Electrical Oscillators, by Nikola Tesla, 1919Document4 pagesElectrical Oscillators, by Nikola Tesla, 1919dag57No ratings yet

- The Smart Grid - Enabling Energy Efficiency and Demand Response - C5Document20 pagesThe Smart Grid - Enabling Energy Efficiency and Demand Response - C5Kiên PhạmNo ratings yet

- Unit-Ii SGTDocument19 pagesUnit-Ii SGTSadhvi ReddyNo ratings yet

- Modul 9 Mesin Listrik 1 PDFDocument22 pagesModul 9 Mesin Listrik 1 PDFaswardiNo ratings yet

- Electric Power Distribution OverviewDocument4 pagesElectric Power Distribution OverviewKiran KumarNo ratings yet

- Superconducting electric lines may transform power gridsDocument6 pagesSuperconducting electric lines may transform power gridsMohammad HosseinNo ratings yet

- SLK G9-Q4wk8 Mongcopa (Refined)Document13 pagesSLK G9-Q4wk8 Mongcopa (Refined)Jeson GaiteraNo ratings yet

- It Is Quite Another Electricity: Transmitting by One Wire and Without GroundingFrom EverandIt Is Quite Another Electricity: Transmitting by One Wire and Without GroundingRating: 4.5 out of 5 stars4.5/5 (2)

- New Approaches to the Design and Economics of EHV Transmission Plant: International Series of Monographs in Electrical EngineeringFrom EverandNew Approaches to the Design and Economics of EHV Transmission Plant: International Series of Monographs in Electrical EngineeringNo ratings yet

- Auto-Transformer Design - A Practical Handbook for Manufacturers, Contractors and WiremenFrom EverandAuto-Transformer Design - A Practical Handbook for Manufacturers, Contractors and WiremenRating: 4 out of 5 stars4/5 (2)

- Small Dynamos and How to Make Them - Practical Instruction on Building a Variety of Machines Including Electric MotorsFrom EverandSmall Dynamos and How to Make Them - Practical Instruction on Building a Variety of Machines Including Electric MotorsNo ratings yet

- Power Electronics and Energy Conversion Systems, Fundamentals and Hard-switching ConvertersFrom EverandPower Electronics and Energy Conversion Systems, Fundamentals and Hard-switching ConvertersNo ratings yet

- Sensors 15 25898 PDFDocument22 pagesSensors 15 25898 PDFDante FilhoNo ratings yet

- Theory and Technology of Instrument Transformers: Training Booklet: 2Document48 pagesTheory and Technology of Instrument Transformers: Training Booklet: 2Xabi AlonsoNo ratings yet

- 4763155Document21 pages4763155Dante FilhoNo ratings yet

- Paper G 14Document5 pagesPaper G 14Dante FilhoNo ratings yet

- Investigation of Insulation Performance of High Voltage Rotating Machines Using Intelligent TechniquesDocument5 pagesInvestigation of Insulation Performance of High Voltage Rotating Machines Using Intelligent TechniquesDante FilhoNo ratings yet

- Magnetizing Current and Harmonics as Indicators of Transformer Core SaturationDocument4 pagesMagnetizing Current and Harmonics as Indicators of Transformer Core SaturationvdaNo ratings yet

- ABB-219-WPO Surviving A StrikeDocument5 pagesABB-219-WPO Surviving A StrikeDante FilhoNo ratings yet

- NucciDocument15 pagesNucciburvanovNo ratings yet

- 12 12 2013 11 58 43 PDFDocument8 pages12 12 2013 11 58 43 PDFDante FilhoNo ratings yet

- 47 - 2000 - PHD - Influence of LI To Insulating Systems PDFDocument174 pages47 - 2000 - PHD - Influence of LI To Insulating Systems PDFDante FilhoNo ratings yet

- Application of Insulators To Withstand Switching Surges in Substations. I PDFDocument5 pagesApplication of Insulators To Withstand Switching Surges in Substations. I PDFDante FilhoNo ratings yet

- Impulse Voltage Test Systems From 100 KV Up To 6 MV - Series L, M, GDocument4 pagesImpulse Voltage Test Systems From 100 KV Up To 6 MV - Series L, M, GDante FilhoNo ratings yet

- 38th Turbo (2009) - Symposium Technical PapersDocument2 pages38th Turbo (2009) - Symposium Technical PapersDante FilhoNo ratings yet

- Testing & Maintaining Power TransformersDocument83 pagesTesting & Maintaining Power Transformerscharleselitb92100% (1)

- Impulse TestDocument6 pagesImpulse Testeng_zidNo ratings yet

- 03 PylarinosDocument23 pages03 PylarinosDante FilhoNo ratings yet

- Solutions For Internal Arc Protection According To IEC 62271-200 in MV SwitchgearDocument5 pagesSolutions For Internal Arc Protection According To IEC 62271-200 in MV Switchgearkyawswarpm100% (1)

- Recent Improvements in K-Factor ModelsDocument19 pagesRecent Improvements in K-Factor ModelsDante FilhoNo ratings yet

- 1lde000038 Rev1b en Ecodry PresentationDocument41 pages1lde000038 Rev1b en Ecodry PresentationDante FilhoNo ratings yet

- Impact of Insulation Monitoring and DiagnosticsDocument10 pagesImpact of Insulation Monitoring and DiagnosticsDante FilhoNo ratings yet

- .. - Apua - Asea - .Document2 pages.. - Apua - Asea - .Dante FilhoNo ratings yet

- Image enDocument28 pagesImage enDante FilhoNo ratings yet

- 7b Europacable For WP3 Workshop Technology Presentation 15 April 2014 CDocument23 pages7b Europacable For WP3 Workshop Technology Presentation 15 April 2014 CDante FilhoNo ratings yet

- 5 OperationandMaintenanceDocument31 pages5 OperationandMaintenanceDante FilhoNo ratings yet

- 2 Continsous Wavelet TransformDocument6 pages2 Continsous Wavelet TransformDante FilhoNo ratings yet

- ABB Power Tap-Changer GuideDocument13 pagesABB Power Tap-Changer GuideSellappan MuthusamyNo ratings yet

- 10 Application of ACSR Trapezoidal Wire Conductor For A 500-KV Transmission LineDocument2 pages10 Application of ACSR Trapezoidal Wire Conductor For A 500-KV Transmission LineDante Filho100% (1)

- Electrical Conductivity - Electricity - Electronics - Physics Equipment - PhysicsDocument3 pagesElectrical Conductivity - Electricity - Electronics - Physics Equipment - PhysicsDante FilhoNo ratings yet

- 3.11 NoiseDocument32 pages3.11 NoiseDante FilhoNo ratings yet

- Flojet 2002 Marine CatalogueDocument12 pagesFlojet 2002 Marine CatalogueRacil EzzedineNo ratings yet

- 4 SolidControlDocument27 pages4 SolidControlJorge VidaurreNo ratings yet

- Reverse Engineering Toy Fan Report 1Document6 pagesReverse Engineering Toy Fan Report 1api-296692918No ratings yet

- Energy Conservation and ManagementDocument2 pagesEnergy Conservation and ManagementkannanchammyNo ratings yet

- HTF Buildigng Cable Hippot Test From VFD To MotorDocument20 pagesHTF Buildigng Cable Hippot Test From VFD To Motorمحمد ابن علیNo ratings yet

- Luchtmassameter StoringDocument4 pagesLuchtmassameter StoringpepeladazoNo ratings yet

- Cotech SurubelnitaDocument28 pagesCotech SurubelnitacipyyyyNo ratings yet

- PetrochemicalDocument20 pagesPetrochemicalabdulqadirNo ratings yet

- Cat c7 DiagramaDocument2 pagesCat c7 DiagramaJose F Rivera Morales89% (27)

- 1 PDFDocument2 pages1 PDFRandy MorcoNo ratings yet

- Everest Group RFP Questionnaire For ESG AttributesDocument7 pagesEverest Group RFP Questionnaire For ESG AttributesAbhijeet ShindeNo ratings yet

- BMC Brochure WebDocument4 pagesBMC Brochure WebVikram Pratap SinghNo ratings yet

- Wood Thermal PropertiesDocument6 pagesWood Thermal PropertiesKevonSingh1No ratings yet

- Safety EN IEC 60335 1 Cyrix PDFDocument106 pagesSafety EN IEC 60335 1 Cyrix PDFGiuseppe FerrariNo ratings yet

- 3.publication - Green ReviewDocument4 pages3.publication - Green ReviewDr Reema AgrawalNo ratings yet

- Journal of Molecular Liquids: Mohammad Hatami Maryam Hasanpour, Dengwei JingDocument22 pagesJournal of Molecular Liquids: Mohammad Hatami Maryam Hasanpour, Dengwei JingSugam KarkiNo ratings yet

- TL 071Document85 pagesTL 071Angel baez gonzalezNo ratings yet

- Emerson Digital Scroll-Catalogue 2012 enDocument256 pagesEmerson Digital Scroll-Catalogue 2012 enHarsh Vani AroraNo ratings yet

- Motor Sizing CalculationDocument3 pagesMotor Sizing CalculationRizwan TahirNo ratings yet

- My Vision For India-Dr. A. P. J. Abdul KalamDocument8 pagesMy Vision For India-Dr. A. P. J. Abdul KalamSandeep SagarNo ratings yet

- B-3801 IOM - Rev - 2011-09-02 (1) MidlandDocument23 pagesB-3801 IOM - Rev - 2011-09-02 (1) MidlandLucas MonteNo ratings yet

- EMEA - APAC Valves & Actuators Catalog 2018 F-27878Document110 pagesEMEA - APAC Valves & Actuators Catalog 2018 F-27878aathifNo ratings yet

- Dt466e Wiring SchematicDocument2 pagesDt466e Wiring SchematicAntonio Palomo18% (17)

- Bank Guarantee format for EMDDocument2 pagesBank Guarantee format for EMDMohit YadavNo ratings yet

- Cross Hole TestDocument13 pagesCross Hole TestLOVKESH SHIVANI 18210047No ratings yet

- PBD Assessment Physics Form 5 Chapter 1Document8 pagesPBD Assessment Physics Form 5 Chapter 1Nor ShuhadaNo ratings yet

- Molar Mass of ButaneDocument11 pagesMolar Mass of ButaneReena0% (1)

- Modularization in Chemical Processing: Special Section: Process IntensificationDocument9 pagesModularization in Chemical Processing: Special Section: Process IntensificationJohn AnthoniNo ratings yet

- Roof Insulation: Southern California Gas Company New Buildings Institute Advanced Design Guideline SeriesDocument31 pagesRoof Insulation: Southern California Gas Company New Buildings Institute Advanced Design Guideline Seriesapi-19789368100% (1)

- HEC Pakistan Syllabus For B.S. & M.S.physics 2005Document75 pagesHEC Pakistan Syllabus For B.S. & M.S.physics 2005Jehan Zaib Ali Khan100% (2)