Professional Documents

Culture Documents

Din en Iso 9606 English

Uploaded by

Mert GüzeyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Din en Iso 9606 English

Uploaded by

Mert GüzeyCopyright:

Available Formats

EWMHIGHTEC WELDING GmbH / Dr.Gnter-Henle-Str. 8 / D-56271 Mndersbach / www.ewm-group.

com

/// simply more

Evolution

Blue

Carl Cloos Schweitechnik GmbH | D-35708 Haiger www.cloos.de

World wide

welding!

www.teka.eu 0800 / 8352225 info@teka.eu

DVS_Anzeige_08-2013.indd 1 28.8.2013 09:33:00

Training for a High Quality Standard

GSI - Gesellschaft fr Schweitechnik International mbH www.gsi-slv.de

Anzeige_Poster_Schweissverfahren_engl.indd 1 26.04.2012 15:09:19

WELDING

VALUE

/ Battery Charging Systems / Welding Technology / Solar Electronics

/ Time and again, our revolutionary ideas take the welding community by surprise.

As they did with Cold Metal Transfer (CMT), a weld process that really is cold

compared to conventional MIG/MAG welding. And that ensures a stable arc and exact

process-control. CMT lets you weld joins between aluminium and steel, and light-

gauge sheets from only 0.3 mm (0.01 in) thick. Other advantages: minimal spattering,

excellent gap bridgeability, 100% reproducibility of results. Want to know more?

Check out: www.fronius.com

Issue

03

2011

Third Schweisstec welding trade

fair in the new Landesmesse

Stuttgart in June 2011

Welding ferrous metals:

How can you be sure of

accurate preheat?

Stress corrosion cracking of

carbon steel in ethanol

www.welding-and-cutting.info

Technical journal for welding and allied processes

The Welding

Institute

Precision in Detail

Kjellberg Finsterwalde Plasma und Maschinen GmbH

Germany Leipziger Strae 82 03238 Finsterwalde

Phone: +49 3531 500 0 E-mail: plasma@kjellberg.de

www.kjellberg.de/plasma

Small holes, ne inside and outside contours:

the precision of Contour Cut revolutionises

plasma cutting of mild steel.

A new technology without additional

costs and components!

Because Contour Cut is integrated as

standard in all HiFocus systems.

Issue

03

2011

Third Schweisstec welding trade

fair in the new Landesmesse

Stuttgart in June 2011

Welding ferrous metals:

How can you be sure of

accurate preheat?

Stress corrosion cracking of

carbon steel in ethanol

www.welding-and-cutting.info

Technical journal for welding and allied processes

The Welding Institute

www.welding-and-cutting.info

Get your free issue!

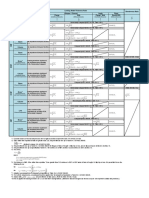

Welders qualification test certificate

ACCORDING TO EN ISO 9606-1:2013

Designation examples of this Standard

INTERNATIONAL

STANDARD

dimension of

test piece

ISO 9606-1 ss nb 141 T BW FM4 S s3.6 D60 PH

welding process

product type

type of weld

fller material

fller material

grouping

welding position

weld details

fller material grouping

welding positions

according to EN ISO 6947

PA fat position

PB horizontal vertical position

PC horizontal position

PD horizontal overhead position

PE overhead position

PF vertical up position

PG vertical down position

H-L045 inclined position welding upwards

J-L045 inclined position welding downwards

PH pipe position for welding upwards

PJ pipe position for welding downwards

weld details

BW butt weld

ss single side welding

mb material backing

nb welding with no material backing

gb gas backing

fb fux backing

bs welding from both sides

ci consumable insert

FW fllet weld

sl single layer

ml multi-layer

311 oxyacetylene welding

lw leftward welding

rw rightward welding

welding processeses

according to EN ISO 4063

111 manual metal arc welding

114 self-shielded tubular cored arc welding

121 submerged arc welding with solid wire electrod (partly mechanized)

125 submerged arc welding with tubular cored electrode (partly mechanized)

131 MIG welding with solid wire electrode

135 MAG welding with solid wire electrode

136 MAG welding with fux cored electrode

138 MAG welding with metal cored electrode

141 TIG welding with solid fller material (wire/rod)

142 autogenous TIG welding

143 TIG welding with tubular cored fller material (wire/rod)

145 TIG welding using reducing gas and solid fller material (wire/rod)

15 plasma arc welding

311 oxyacetylene welding

fller material

covered electrodes

Route A

A acid covering

B basic covering or electrode core basic

C cellulosic covering

R rutile covering or electrode core rutile, slow-freezing slag

RA rutile acid covering

RB rutile basic covering

RC rutile cellulosic covering

RR rutile thick covering

Route B

03 rutile basic covering

10 cellulosic covering

11 cellulosic covering

12 rutile covering

13 rutile covering

14 rutile + iron powder covering

15 basic covering

16 basic covering

18 basic + iron powder covering

19 limenite covering

20 iron oxide covering

24 rutile + iron powder covering

27 iron oxide + iron powder covering

28 basic + iron powder covering

45 basic covering

48 basic covering

cored wire

M metal cored electrode or metal powder

P electrode core rutile, fast-freezing slag

V electrode core rutile or basic/fuoride

W electrode core basic/fuoride, slow-freezing slag

Y electrode core basic/fuoride, fast-freezing slag

Z electrode core other types

any other

S solid wire electrode solid rod

nm no fller material

types of weld

BW butt weld

FW fllet weld

BW

FW

product types

T Tube

P Plate

P

T

D

V

S

M

e

d

i

a

G

m

b

H

,

D

s

s

e

l

d

o

r

f

dimensions of test piece

s deposited thickness

t material thickness

D outside tube diameter

t

s

D

www.dvs-ev.de/DVS-Pruefstellen

Notifed bodies for the welders qualifcation test are regulated by European directives,

regulations or standards which apply to approved certifcation personnel or to accreditation

according to DIN EN ISO / IEC 17024 for the holding of the welders qualifcation test.

Group Filler material for welding of Examples of applicable standards

FM1 Non-alloy and fne grain steels ISO 2560, ISO 14341, ISO 636, ISO

14171, ISO 17632

FM2 High-strength steels ISO 18275, ISO 16834, ISO 26304,

ISO 18276

FM3 Creep-resisting steels Cr < 3,75 % ISO 3580, ISO 21952, ISO 24598,

ISO 17634

FM4 Creep-resisting steels 3,75 < Cr < 12 % ISO 3580, ISO 21952, ISO 24598,

ISO 17634

FM5 Stainless and heat-resisting steels ISO 3581, ISO 14343, ISO 17633

FM6 Nickel and nickel alloys ISO 14172, ISO 18247

plate fat position

horizontal

vertical position

horizontal

position

horizontal

overhead position

overhead position

vertical up

position

H-L045

inclined

position

welding

upwards

vertical up

position

vertical down

position

vertical down

position

J-L045

inclined position

welding

downwards

b

u

tt w

e

ld

s

f llet welds

You might also like

- (Iso/tr 17671-5) (Iso/tr 17671-6) (Iso/tr 17671-7) (Iso/tr 17671-8)Document1 page(Iso/tr 17671-5) (Iso/tr 17671-6) (Iso/tr 17671-7) (Iso/tr 17671-8)Ivan Briscoe100% (7)

- Welding-Standards 23-03-2014Document1 pageWelding-Standards 23-03-2014givali100% (7)

- ISO 9606 Revised 4 SeptDocument34 pagesISO 9606 Revised 4 Septaravindan100% (5)

- ISO 6520 Defect Classification GuideDocument27 pagesISO 6520 Defect Classification Guidealinor_tn100% (4)

- Quality requirements for welding standards and testingDocument1 pageQuality requirements for welding standards and testingKristijan GeorgievskiNo ratings yet

- Welding procedure specification guideDocument3 pagesWelding procedure specification guideAnilNo ratings yet

- BS en 15085 - 2quality Requirements For ManufcturersDocument48 pagesBS en 15085 - 2quality Requirements For ManufcturersSubramanian R0% (1)

- CEN ISO TR 20173 - en Grouping Syst - American MaterialDocument61 pagesCEN ISO TR 20173 - en Grouping Syst - American Materialumur kaçamaklı100% (2)

- Iso 3834-5 - 2015Document14 pagesIso 3834-5 - 2015raghulramasamy100% (1)

- Welding Coordination Tasks ISO 14731Document1 pageWelding Coordination Tasks ISO 14731Ion Plesa100% (1)

- Sist en Iso 6848 2015 PDFDocument10 pagesSist en Iso 6848 2015 PDFRahul garjeNo ratings yet

- WPS Format For ISO 15614-1 PQRDocument3 pagesWPS Format For ISO 15614-1 PQRThe Welding Inspections Community100% (2)

- ISO Standards On WeldingDocument22 pagesISO Standards On Weldingmoxshyde100% (1)

- List of Welding Codes PDFDocument3 pagesList of Welding Codes PDFAlienshow100% (2)

- Welding Qualification SeminarDocument66 pagesWelding Qualification SeminarsoparlNo ratings yet

- Strips and Fluxes for Electroslag and Submerged Arc WeldingDocument0 pagesStrips and Fluxes for Electroslag and Submerged Arc WeldingCarlos Bermejo AlvarezNo ratings yet

- Flux Cored WireDocument38 pagesFlux Cored WireKentDemeterioNo ratings yet

- Welding Course PDFDocument46 pagesWelding Course PDFRogerio Salvagni100% (1)

- List 1 Approved Steelmakers and Manufacturers of Rolled Steel Plates, Strip, Sections & BarsDocument76 pagesList 1 Approved Steelmakers and Manufacturers of Rolled Steel Plates, Strip, Sections & Barskhan4luvNo ratings yet

- Welding GuideDocument48 pagesWelding Guideedu_canete100% (2)

- GM Aw and GT Aw ConsumablesDocument118 pagesGM Aw and GT Aw Consumablessepe00No ratings yet

- Technical Data Handbook of TK CorporationDocument172 pagesTechnical Data Handbook of TK CorporationGerard Adrian Bautista AnonuevoNo ratings yet

- Welding EngineeringDocument338 pagesWelding EngineeringMuhammed Sulfeek100% (3)

- QC General NotesDocument21 pagesQC General NotesBilly Kurniawan100% (2)

- Welding Consumables For The Offshore IndustryDocument24 pagesWelding Consumables For The Offshore IndustryLuis DuarteNo ratings yet

- Aladin SDocument4 pagesAladin SJeffrey BeanNo ratings yet

- Welders Training Program ManualDocument140 pagesWelders Training Program ManualAlmario Sagun100% (1)

- Lloyds Approved Plate ManufacturerDocument82 pagesLloyds Approved Plate ManufacturerUTTAM JAINNo ratings yet

- List1 Lloyd's RegisterDocument74 pagesList1 Lloyd's RegisterAdrian VintilaNo ratings yet

- BK TNG 001 TS PI SP 001 - Piping Specification - Rev 2Document45 pagesBK TNG 001 TS PI SP 001 - Piping Specification - Rev 2Kev TraNo ratings yet

- PDF Engineering) Esab Welding Handbook - 5 EditionDocument143 pagesPDF Engineering) Esab Welding Handbook - 5 Editionmarshall, of course100% (3)

- Cutting Materials, Tools and CoolantsDocument63 pagesCutting Materials, Tools and CoolantsLeonardo BarabasNo ratings yet

- UTP MaintenanceDocument28 pagesUTP MaintenanceAnonymous PkAjjOZBNo ratings yet

- BK - TNG 001 TS PI SP 001 Piping Material Specification Rev.1Document45 pagesBK - TNG 001 TS PI SP 001 Piping Material Specification Rev.1Kev Tra100% (1)

- List 1 Approved Steelmakers and Manufacturers of Rolled Steel Plates, Strip, Sections & BarsDocument75 pagesList 1 Approved Steelmakers and Manufacturers of Rolled Steel Plates, Strip, Sections & Barswyvren88No ratings yet

- Katalogas enDocument20 pagesKatalogas enEman AdelNo ratings yet

- 6 Series Tube FittingsDocument43 pages6 Series Tube FittingsNilesh MistryNo ratings yet

- General Information Theory - LindabDocument27 pagesGeneral Information Theory - LindabaudithanNo ratings yet

- Catalogue MetalweldDocument17 pagesCatalogue MetalweldRadivojevic SasaNo ratings yet

- Welding ElectrodesDocument36 pagesWelding ElectrodesMersudin Saric100% (4)

- General: Part Number: Status: Overview: DescriptionDocument2 pagesGeneral: Part Number: Status: Overview: DescriptionhkchingNo ratings yet

- QC Interview Questions IMPDocument10 pagesQC Interview Questions IMPAnonymous bIe9JSMphsNo ratings yet

- Conexao de Dupla Anilha RotarexDocument68 pagesConexao de Dupla Anilha RotarexElias Barros de FigueiredoNo ratings yet

- Fundamentals MIG WeldingDocument3 pagesFundamentals MIG WeldingSreejith MenonNo ratings yet

- Basic Welding Terms - Lincoln Electric PDFDocument88 pagesBasic Welding Terms - Lincoln Electric PDFpacrabbNo ratings yet

- WeldingDocument71 pagesWeldingg4gohar100% (2)

- Jinan Meide Casting Co. Product CatalogDocument42 pagesJinan Meide Casting Co. Product CatalogAna Carolina SantosNo ratings yet

- Pipelines Welding HandbookDocument64 pagesPipelines Welding HandbookSixto GerardoNo ratings yet

- Welding and Inspection Techniques for MetalsDocument45 pagesWelding and Inspection Techniques for Metalsgaganesan1972100% (1)

- 100 Series PyroDocument8 pages100 Series PyroomkarvadlooriNo ratings yet

- Sample Forms AWS, ASME and APIDocument14 pagesSample Forms AWS, ASME and APIaamirtec301No ratings yet

- 20 Pin Molex 3mmDocument2 pages20 Pin Molex 3mmvighnesh shanbhagNo ratings yet

- Spot Welding Interview Success: An Introduction to Spot WeldingFrom EverandSpot Welding Interview Success: An Introduction to Spot WeldingNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Welding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesFrom EverandWelding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- Iiwhistory1990 2015v1 PDFDocument233 pagesIiwhistory1990 2015v1 PDFvonipkoNo ratings yet

- Selection Chart XZDocument1 pageSelection Chart XZvonipkoNo ratings yet

- Iiwhistory1990 2015v1 PDFDocument233 pagesIiwhistory1990 2015v1 PDFvonipkoNo ratings yet

- Aws Welding Marketplace 2019Document20 pagesAws Welding Marketplace 2019vonipkoNo ratings yet

- Investigation on the Effect of Welding Consumables on Carbon Steel PropertiesDocument11 pagesInvestigation on the Effect of Welding Consumables on Carbon Steel PropertiesvonipkoNo ratings yet

- Welding Codes and How They Re UsedDocument5 pagesWelding Codes and How They Re Usedprasad_kcpNo ratings yet

- Iso 9606-2 2004 PDFDocument40 pagesIso 9606-2 2004 PDFvonipkoNo ratings yet

- FSV Phase2 Overview Report PDFDocument79 pagesFSV Phase2 Overview Report PDFvonipkoNo ratings yet

- Spray TimeDocument24 pagesSpray TimevonipkoNo ratings yet

- Poster Weldingpositions enDocument1 pagePoster Weldingpositions enslowmosquitoNo ratings yet

- 008 2015 en GL BW Bestseller WebDocument48 pages008 2015 en GL BW Bestseller WebNaveen SolankiNo ratings yet

- Welding Quality Control Plan ReqDocument2 pagesWelding Quality Control Plan ReqPaul MathewNo ratings yet

- Welding Research CoolingDocument7 pagesWelding Research CoolingHoangNo ratings yet

- Corus Prevention of Corrosion On Structural Steelwork PDFDocument28 pagesCorus Prevention of Corrosion On Structural Steelwork PDFvonipkoNo ratings yet

- 14 Day KetoDocument37 pages14 Day KetoKrisna May Buhisan PecoreNo ratings yet

- Fro Bro Vs247317 EngDocument4 pagesFro Bro Vs247317 EngvonipkoNo ratings yet

- Weld Inspection and RepairDocument10 pagesWeld Inspection and RepairDeepak Kumar Kant KesriNo ratings yet

- Wpar S690 138Document3 pagesWpar S690 138vonipkoNo ratings yet

- Sarajevo City GuideDocument68 pagesSarajevo City GuidevonipkoNo ratings yet

- ETouch L1Document42 pagesETouch L1vonipkoNo ratings yet

- MNL46 ForewordDocument16 pagesMNL46 ForewordvonipkoNo ratings yet

- EBSCO Egs CoverageDocument39 pagesEBSCO Egs CoveragevonipkoNo ratings yet

- Crude Oil Storage Tanks-BasicsDocument176 pagesCrude Oil Storage Tanks-BasicsPandipperumal Sankaralingam100% (44)

- ESIS Newsletter #55 SummaryDocument25 pagesESIS Newsletter #55 SummaryvonipkoNo ratings yet

- Implement ISO 3834 welding standardsDocument34 pagesImplement ISO 3834 welding standardschowhkNo ratings yet

- AWS Welders Training Sense - Presentation PDFDocument24 pagesAWS Welders Training Sense - Presentation PDFvonipkoNo ratings yet

- Targus SpecificationDocument23 pagesTargus SpecificationvonipkoNo ratings yet

- Hist QA Module 2Document7 pagesHist QA Module 2vonipkoNo ratings yet

- DX DT Dy DT DX DT Dy DT DX DT Dy DT DX DT Dy DT DX DT Dy DT DX DT Dy DTDocument16 pagesDX DT Dy DT DX DT Dy DT DX DT Dy DT DX DT Dy DT DX DT Dy DT DX DT Dy DTMimosaNo ratings yet

- Design For Manufacturing and AssemblyDocument168 pagesDesign For Manufacturing and Assemblygnanasekar100% (2)

- A Review of Mesoscopic Magmatic Structures and Their Potential For Evaluating The Hypersolidus EvolutionDocument14 pagesA Review of Mesoscopic Magmatic Structures and Their Potential For Evaluating The Hypersolidus EvolutionMateo Ospino DíazNo ratings yet

- Shukla Sivakugan Das IJGE Jan 2009-89-108Document21 pagesShukla Sivakugan Das IJGE Jan 2009-89-108Enrique BarragánNo ratings yet

- Curriculum Vitae for Electrical EngineerDocument2 pagesCurriculum Vitae for Electrical EngineerMeheryar KhanNo ratings yet

- O Level Physics 2018 MarkschemeDocument10 pagesO Level Physics 2018 MarkschemefordalNo ratings yet

- Fluid Flow Velocity Steel Pipe Schedule 40 Metric UnitsDocument1 pageFluid Flow Velocity Steel Pipe Schedule 40 Metric UnitsRobert ThanhNo ratings yet

- Corrected Cad Lab ManualDocument42 pagesCorrected Cad Lab ManualSanjithRNairNo ratings yet

- Experimental Study On Steel Shear Wall With SlitsDocument10 pagesExperimental Study On Steel Shear Wall With SlitsTY ZNo ratings yet

- Ko and Gravity Switch ProcedureDocument4 pagesKo and Gravity Switch ProcedureTrung NgocNo ratings yet

- Electronic Controls in KnittingDocument20 pagesElectronic Controls in KnittingProfessorTextechNo ratings yet

- Yash (08310102819) DRDO Internship ReportDocument42 pagesYash (08310102819) DRDO Internship ReportYash100% (1)

- Advances in Engineering Software: Gürol Yıldırım, Vijay P. SinghDocument8 pagesAdvances in Engineering Software: Gürol Yıldırım, Vijay P. SinghMartin VenichNo ratings yet

- APlus DatasheetDocument5 pagesAPlus DatasheetMuhamad RadzmanNo ratings yet

- Zeemaneffect ManualDocument12 pagesZeemaneffect ManualArun PandiyanNo ratings yet

- 1 N 4154Document4 pages1 N 4154ECEOCETNo ratings yet

- IEEE Xplore Download 135Document9 pagesIEEE Xplore Download 135Madalina MejdreaNo ratings yet

- LF Solar Panels Datasheet - July 2022 - Preview FileDocument9 pagesLF Solar Panels Datasheet - July 2022 - Preview FileMayur HiwarkarNo ratings yet

- Minor Project For Civil EngineeringDocument52 pagesMinor Project For Civil EngineeringRupesh GenesisNo ratings yet

- Laser Welding Steel Wheel RimsDocument5 pagesLaser Welding Steel Wheel RimsSamanthaPereraNo ratings yet

- 1-Universal Vibrational Spectrum - Online CoursesDocument9 pages1-Universal Vibrational Spectrum - Online CoursesPanther Panther25% (4)

- AISC RequirementsDocument1 pageAISC Requirementsparag7676No ratings yet

- (Kang Gi Don) 1. Con'c Girder Bridge - MKr01 - SODocument13 pages(Kang Gi Don) 1. Con'c Girder Bridge - MKr01 - SOJohn JimmyNo ratings yet

- Turbo GelDocument1 pageTurbo GelWilliam David LopezNo ratings yet

- ChairDocument7 pagesChairapi-487109487No ratings yet

- Keller EtdDocument191 pagesKeller EtdTimothy FieldsNo ratings yet

- High Frequency ElectronicsDocument2 pagesHigh Frequency ElectronicsdvsNo ratings yet

- Lihardo Rotua Sinaga. Maulidatul Fadhilah. Maria Angel Aftritesia. BilPhys19. Thermodynamics. Mini ResearchDocument14 pagesLihardo Rotua Sinaga. Maulidatul Fadhilah. Maria Angel Aftritesia. BilPhys19. Thermodynamics. Mini ResearchFitri handayaniNo ratings yet

- 7th Semester UET TaxilaDocument4 pages7th Semester UET TaxilaRameez AnwarNo ratings yet

- 952 - Comparative Statement - Electrical - Rev 00Document8 pages952 - Comparative Statement - Electrical - Rev 00clickanant4171No ratings yet