Professional Documents

Culture Documents

Merkel Firearm Owner's Manual

Uploaded by

dannyjan5080Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Merkel Firearm Owner's Manual

Uploaded by

dannyjan5080Copyright:

Available Formats

O WN E R S

M AN U AL

O WN E R S

M AN U AL

READ THE INSTRUCTIONS IN THIS MANUAL

CAREFULLY BEFORE USING THIS FIREARM!

MERKEL

SIDE BY SIDE

SHOTGUNS

SIDE-BY-SIDE RIFLES & 96K DRILLINGS

SUHLER JAGD-UND SPORTWAFFEN

MERKEL

SIDE BY SIDE

SHOTGUNS

Owners Manual

MERKEL SIDE BY SIDE

SHOTGUNS, DOUBLE RIFLES

AND 96K DRILLINGS

This manual and the warnings contained herein must be

read and understood before using your firearm. This manual

familiarizes the user with the function and the handling of the

firearm and warns of the potential dangers of misuse that may

lead to accidents or injuries. This manual should always

accompany this firearm and be transferred with it upon change

of ownership, or when the firearm is loaned or presented to

another person. THIS MANUAL IS NOT ASUBSTITUTE FOR A

HUNTING SAFETY COURSE OR A FIREARMS SAFETY

COURSE!

WARNING! TREAT EVERY FIREARM AS IF IT

WERE LOADED AT ALL TIMES! REMEMBER, NO

SAFETY IS FOOLPROOF! FIREARMS SAFETY IS

THE RESPONSIBILITY OF THE PERSON WHO

HANDLES FIREARMS AND AMMUNITION!

Dear Customer:

Your Merkel Side-by-Side Shotgun, Double Rifle or 96K

Drilling is manufactured by Merkel to the highest standards.

It has been produced to meet state-of-the-art requirements

for today's hunter. You can expect unsurpassed perfor-

mance, superb quality, optimum user comfort, and long ser-

vice life.

As a result of our thorough quality assurance system,

you can be certain that you have purchased a product of

truly outstanding quality.

Please read this manual and the warnings contained

herein carefully to familiarize yourself with the function and

operation of this firearm.

2

IMPORTANT NOTE:

This manual is for use with Merkel Side-by-Side

Shotguns, Double rifles and 96K Drillings. If you are

unsure of the exact model of your Merkel, please con-

tact GSI, Inc. for identification. Read this manual thor-

oughly and completely familiarize yourself with your

Merkel firearm to get the maximum enjoyment and safety

from your new firearm.

Technical specifications of this firearm may

change without notice.

3

TABLE OF CONTENTS

Essential precautions for the handling of firearms 5

Before shooting your new Merkel firearm9

Bore obstructions WARNING 9

Illustration of major components. 11

Special Note12

Side-by-Side Shotguns 12

Operation of the Shotgun Safety Mechanism12

Side-by-Side Shotgun Double & Single Triggers 14

Top Lever 14

Ejectors 15

Loading & Firing Side-by-Side Shotguns 15

Double Rifles 16

Operation of the Double Rifle Safety Mechanism 16

Double Rifle Trigger Operations 18

Top Lever 18

Ejectors 18

Loading & Firing Double Rifles 19

Drillings 20

Operation of the Drilling Safety Mechanism 20

Drilling Trigger Operations 21

Top Lever 22

Extractors 22

Loading & Firing Drillings 22

Firearm Assembly 24

Gauge, Caliber, Chamber length & Choke Designation 25

Ammunition Warning 26

Choke Identification28

Dry Firing 28

Disassembly 28

Cleaning 29

Notes 31

Quick reference 34

Page

No.

4

ESSENTIAL PRECAUTIONS FOR THE HANDLING OF FIREARMS

THE WARNINGS AND ADVICE GIVEN IN THIS

MANUAL ARE FOR YOUR PROTECTION AS

WELL AS THE SAFETY OF OTHERS. DISRE-

GARDING INFORMATION IN THIS MANUAL

MAY RESULT IN SERIOUS INJURY OR DEATH.

Before you attempt to use or shoot your new Merkel Firearm,

learn and understand the following basic rules. Your safety and the

safety of others depends upon your safe and careful handling of your

new Merkel firearm.

Any firearm must be considered a potentially dangerous object

requiring particular caution in storage, handling and use.

Make sure to ALWAYS handle and treat every firearm as if it

were loaded.

NEVER place your finger on the trigger unless you intend to fire

a shot. ALWAYS load your Merkel firearm so as to avoid any danger for

by-standers. Adequate firearm safety can only be ensured with the

firearm in clean and mechanically sound condition.

Inexpert handling as well as improper or negligent care may

impair function and safety of the firearm. Unauthorized alterations, mod-

ifications or adjustments to the firearm as well as damage to the firearm

through carelessness will void any claims under the manufacturers ser-

vice agreement.

Any work on the firearm must be done by qualified and autho-

rized gunsmiths, armorers, or factory authorized service facilities.

Firearms must ALWAYS be stored out of the reach of persons

not familiar with firearms, particularly children. NEVER store ammunition

with a firearm.

In order to avoid damage during transport, the firearm should

ALWAYS be transported in the original packing carton or in a suitable

5

commercially available transport case.

ALWAYS keep the muzzle of your firearm pointed in a safe

direction. NEVER point any firearm at anything you do not intend to

shoot. Stay alert and be aware of all persons and property within shoot-

ing range.

NEVER give a loaded firearm to another person. ALWAYS open

the action and inspect the chamber for ammunition, and unload any

firearm before giving the firearm to another person for inspection.

ALWAYS ensure that the safety is in the Safe position. ALWAYS

unload firearms after use to prevent the occurrence of an accidental dis-

charge.

KEEP the barrel, chamber and bore free of all obstructions.

Firing a firearm with a barrel, chamber or bore obstruction can cause

damage to the firearm and injury to the shooter or other persons near-

by, and could result in death. Keep the barrel, chamber and bore free

and clean of mud, snow, cleaning patches, or any other materials which

may clog the barrel.

NEVER drink alcohol or take medications while handling a

firearm. Responsible firearm handling requires a state of mental alert-

ness.

ALWAYS seek a doctors advice if you are taking a medication

to be sure you are fit to shoot and handle a firearm safely.

DO NOT totally and blindly rely on the mechanical safety

devices on any firearm. The mechanical safetys function is to block

sear engagement to prevent accidental discharge of the firearm.

However, should this device fail, it is possible to fire a firearm even

when the safety is in the Safe position. NEVER place your finger on

the trigger when you do not intend to shoot. NEVER place your finger

on the trigger or test any safety device when the muzzle of a firearm is

pointed in an unsafe direction.

NEVER transport a loaded firearm.

ALWAYS wear and encourage others to wear protective shoot-

ing glasses. Flying particles could damage eyes and cause blindness.

Protective shooting glasses could prevent such injury.

ALWAYS wear and encourage others to wear ear protection

when shooting, especially on a range. Without ear protection, the noise

6

of even one shot from a firearm, or other firearms close to you, could

leave a ringing in your ears for some time after firing while the cumula-

tive long term effect could be permanent hearing loss.

ALWAYS use only clean, dry, original high quality commercially

manufactured ammunition in good condition loaded in accordance with

factory standards. Do not use ammunition that has been exposed to

prolonged periods of dampness or moisture. Gun and ammunition man-

ufacturers design their products within exacting engineering safety lim-

its. Handloads and remanufactured ammunition are sometimes outside

those limits and can be so unsafe as to blow up or otherwise damage a

firearm, and cause injury, death or damage to property. If there are any

questions concerning the proper ammunition for your Merkel call or con-

tact GSI, Inc., 108 Morrow Avenue, P.O. Box 129, Trussville, Alabama

35173, Tel. (205)-655-8299. Merkel and GSI, INC. specifically disclaim

any responsibility for damage or injury whatsoever occurring in connec-

tion with, or as a result of, the use of faulty, or non-standard, or reman-

ufactured or handloaded (reloaded) ammunition.

DO NOT put your finger on the trigger while unloading, loading,

or any other time before you are ready to shoot. DO NOT dry fire on an

empty chamber - the chamber may not be empty even if you think it is

not loaded! TREAT EVERY FIREARM AS IF IT WERE LOADED!

KNOW your target and backdrop area. BE SURE it is safe to

fire at your target. THINK! What will you HIT if you MISS your intended

target? KNOW the potential range of your firearm and ammunition, and

consider this danger for persons and property within that range. NEVER

fire a firearm in the direction of people, non-game animals or property

that could be injured or destroyed.

MAKE SURE your firearm is unloaded before crossing fences,

climbing trees, jumping over ditches, or passing through or across other

obstacles. DO NOT place or lean a loaded firearm on or against a tree,

fence, automobile, or similar objects.

FAILURE TO FIRE: If your firearm fails to fire when you pull the

trigger, keep the firearm pointed toward the target or a safe open area

and wait for at least two minutes. If a hangfire (slow ignition) has

occurred, the round will probably fire within two minutes. If the round

does not fire, open the breech of the firearm and remove the round. If

the primer of the round is indented, discard the round in a safe manner.

If the primer of the round is not indented, or is lightly indented, or off-

center, have the firearm examined by a competent gunsmith before the

firearm is fired again.

7

USE caution to avoid dropping a loaded firearm. Dropping the

firearm may cause an accidental discharge even if the safety is in the

Safe position. Be extremely careful while hunting or during any other

activity to avoid dropping any firearm. An accidental discharge could

result in serious injury, or death.

TAKE EVERY PRECAUTION to prevent unsafe firearms han-

dling practices around yourself and others. If you witness any unsafe

gun handling practices by other shooters, politely suggest safe proce-

dures for future use.

NEVER DISCHARGE a firearm near flammable material. Flame

and sparks erupt from the firearm when discharged. They could start a

fire or cause flammable liquids and gases to explode.

NEVER SHOOT at a hard surface such as a rock, or a liquid

surface such as water. A projectile may ricochet and travel in any direc-

tion to strike you, or an object you cannot see, causing injury, death or

damage to property.

NEVER WALK, CLIMB OR FOLLOW a companion with your

firearm loaded. When walking, climbing or following a companion,

MAKE SURE the chamber of the firearm is empty, and the safety is in

the Safe position.

ALWAYS instruct children to respect firearms. If your children

shoot, teach them or have them trained by a qualified instructor to treat

and use firearms properly, and always supervise them closely.

NEVER abuse your firearm by using it for any purpose other

than shooting.

NEVER fire your firearm near an animal unless it is trained to

accept the noise. An animals startled reaction could injure it or cause

an accident.

READ, UNDERSTAND, AND PRACTICE all safety procedures

and warnings in this manual. READ, UNDERSTAND AND PRACTICE

all safety procedures and warnings on commercial ammunition cartons

and containers. It is YOUR RESPONSIBILITY to collect, understand

and practice the most up-to-date safe handling procedures for your

firearm. NEITHER MERKEL nor GSI, INC. are responsible for injury,

death or damage to property resulting from either intentional or acciden-

tal discharge of this firearm, or from its function when used for purposes

8

or subjected to treatment for which it was not designed.

KEEP this instruction manual on hand for future reference.

Please include this manual with the firearm in the event you lend, give

or sell this firearm to any other person.

BEFORE SHOOTING YOUR NEW FIREARM

Usually, your Merkel franchised dealer will furnish your firearm

in completely assembled condition. You need only clean the barrel bore

of oil and wipe the bore dry before shooting.

.

BORE OBSTRUCTIONS WARNING!

ANY OBSTRUCTION IN THE BORE OF THE

FIREARM MAY RESULT IN DAMAGE TO THE

FIREARM OR INJURY OR DEATH TO THE SHOOT-

ER AND OR OTHER PERSONS NEARBY. BEFORE

LOADING THE FIREARM, MAKE CERTAIN THE

BORE IS CLEAR AND UNOBSTRUCTED.

If you suspect the firearm may have a bore obstruction resulting

from excess oil, grease, packing material, or cosmoline, or from con-

densation or rain, snow or mud in the barrel, or from any other source

whatsoever, inspect the bore to be sure it is clear and unobstructed.

WHENEVER YOU INSPECT THE BORE, MAKE CER-

TAIN THE FIREARM IS NOT LOADED, AND THAT

THE CHAMBER IS EMPTY! THE BORE MAY BE

CHECKED BY VISUALLY INSPECTING THE BARREL

FROM THE RECEIVER END, NOT THE MUZZLE!

REMEMBER, NEVER LOOK DOWN THE MUZZLE

OF THE FIREARM!

Also, remember that a lodged projectile, wad or shot column is

a common form of bore obstruction. They may become lodged in the

bore if (assuming the trigger has been pulled with a live round in the

chamber) the ammunition contains no powder, or the powder fails to

ignite, and only the primer charge ignites, resulting in insufficient force to

propel the projectile, wad or shot column out of the bore. Whenever an

9

obstruction occurs, keep the firearm pointing in a safe direction and pro-

ceed as follows:

Any ammunition should be removed.

Insert a proper size cleaning rod (without a tip or brush) into the bore

from the muzzle and remove the obstruction. If the obstruction does not

readily dislodge, it may be necessary to lightly tap the handle end of the

cleaning rod. Do not attempt to remove an obstruction using blank

ammunition, or ammunition from which the projectile (or shot) has been

removed, or by any other means other than the use of a cleaning rod.

Be certain all loose powder has been removed from the bore before

inserting the rod. If you are unable to remove the obstruction, take the

firearm to the nearest repair facility, or call GSI Inc., 108 Morrow

Avenue, P.O. Box 129, Trussville, Alabama 35173, Tel. (205) 655-8299.

After removing the obstruction, reinspect the bore to be certain it is

free of powder particles or other debris. Clean the mechanism of

unburned powder grains.

REMEMBER! ALWAYS CHECK THE BORE FOR AN OBSTRUC-

TION IF YOU EXPERIENCE DIFFICULTY IN CHAMBERING

AMMUNITION, EXPERIENCE A FAILURE TO EXTRACT, HAVE

A MISFIRE, OR THE FIREARM DOES NOT MAKE A NORMAL

LOUD REPORT ON FIRING. A MISFIRE OR UNUSUAL

REPORT IS ALWAYS A SIGNAL TO CEASE FIRING. FOLLOW-

ING A MISFIRE OR AN UNUSUAL REPORT, KEEP THE

FIREARM POINTED IN A SAFE DIRECTION AND WAIT TWO

MINUTES BEFORE UNLOADING THE CHAMBER AND EXAM-

INING THE BORE OF THE FIREARM.

WARNING! IF LOADED AMMUNITION IS LODGED IN THE

CHAMBER, DO NOT ATTEMPT TO REMOVE THE AMMUNI-

TION BY USING A CLEANING ROD. TAKE THE FIREARM TO

THE NEAREST REPAIR FACILITY, OR CALL GSI, Inc., 108

Morrow Avenue, P.O. Box 129, Trussville, Alabama 35173, Tel.

(205) 655-8299.

10

11

F

o

r

e

a

r

m

B

r

a

c

k

e

t

F

o

r

e

a

r

m

L

a

t

c

h

B

a

r

r

e

l

M

u

z

z

l

e

F

o

r

e

a

r

m

L

u

g

T

r

i

g

g

e

r

(

s

)

B

u

t

t

s

t

o

c

k

H

i

n

g

e

P

i

n

R

e

c

e

s

s

S

a

f

e

t

y

T

o

p

L

e

v

e

r

F

i

g

u

r

e

1

-

P

a

r

t

s

I

d

e

n

t

i

f

i

c

a

t

i

o

n

F

o

r

e

a

r

m

R

e

c

e

i

v

e

r

B

a

r

r

e

l

L

u

g

s

H

i

n

g

e

P

i

n

C

h

a

m

b

e

r

MERKEL

Side-by-Side Shotguns, Double Rifles and Drillings

SPECIAL NOTE:

Unlike most firearms, your Merkel firearm is individually handcrafted by

skilled gun makers who have inherited and acquired their skills from genera-

tions of the master gun makers in Suhl, Germany. Upon assembly you will

notice that the working parts of your firearm will have distinctive tight fit-

ting characteristics and may, therefore, be somewhat difficult to open, close,

and lock the action.

These characteristics are typical of quality hand-fitted firearms that are built

to the highest standards of precision machining. After initial firing of 100-

200 rounds the action will begin to work more smoothly and will be easier to

operate.

SERIAL NUMBER

The serial number of your Merkel Firearm is engraved on the receiver and

the barrel. It is a good practice to record the serial number in a separate

ledger for future reference.

SIDE-BY-SIDE SHOTGUNS

GENERAL SPECIFICATIONS

Merkel side-by-side shotguns are two barreled firearms with the barrels

aligned along side each other with the sighting rib positioned between the

barrels. Traditional models are typically equipped with two triggers each of

which correspond to its respective barrel. A single selective trigger model is

also available.

OPERATION OF SHOTGUN "SAFETY" MECHANISM

The firearm safety mechanism is located on the tang of the receiver assembly

just in front of the buttstock on the top side (See figure 2). Merkel Side-by-

Side Shotguns are equipped with Automatic Safeties, that is the safety is

engaged each time the breech is opened. The firearm is in the "Safe" position

when the safety is moved fully rearward and the letter "S" appears on the

12

receiver tang directly in front of the safety. In this position sear engagement

is blocked to prevent discharge under non-firing conditions.

Figure 2 Side-by-Side Safety Mechanism

WARNING! SAFETIES ARE MECHANICAL DEVICES THAT MAY FAIL

OR MALFUNCTION LIKE ANY OTHER MECHANICAL DEVICE!

ALWAYS HANDLE THE SHOTGUN CAREFULLY AND DO NOT PER-

MIT THE SHOTGUN TO POINT IN AN UNSAFE DIRECTION!

ALWAYS TREAT THE SHOTGUN AS IF IT WERE LOADED AND

READY TO FIRE! ALWAYS OBSERVE SAFETY RULES WHEN HAN-

DLING THE SHOTGUN! THE SAFETY SHOULD ALWAYS BE IN THE

SAFE POSITION EXCEPT WHEN THE SHOOTER IS ACTUALLY

FIRING THE GUN. THE SAFETY SHOULD BE MOVED TO THE

SAFE POSITION WHENEVER THE SHOOTER CEASES FIRING,

EVEN TEMPORARILY. KEEP THE MUZZLE OF THE FIREARM

POINTED IN A SAFE DIRECTION AT ALL TIMES!

When the safety is indexed forward to its most forward position the firearm is

in its firing mode. In this condition the trigger(s) can be pulled to fire the

shotgun. The letter "S" inscribed on the tang of the receiver will be covered

and obscured from view in this condition.

When you are not using your shotgun, be sure your gun is pointed in a safe

direction, avoid contact with the trigger and make sure the safety is in its

Safe position to prevent accidental discharge. Maintain the firearm safety

in the "Safe" position at all times, unless you are actually firing the gun.

Safety

13

DOUBLE TRIGGER SHOTGUNS

On firearm models equipped with two triggers, each trigger operates its

own barrel. The front trigger will fire the right barrel and the rear trigger

will fire the left barrel. Do not pull both triggers at the same time in

order to avoid excessive recoil or kick from simultaneous discharge of

both barrels.

SINGLE SELECTIVE TRIGGER SHOTGUNS

Shotguns with single triggers are equipped with a cross-bolt barrel selec-

tor located on the upper portion of the trigger assembly (See figure 3).

The barrel selector can be indexed to the right or left with the firing fin-

ger. The position of the barrel selector controls the firing order of the

two barrels. When the selector is positioned to the right the left barrel

fires first and the right barrel will be subsequently discharged when the

trigger is pulled a second time. The right barrel is fired first when the

selector is positioned on the left side of the trigger. Ensure that the safety

is in the Safe or S position, and be careful to avoid contact with the

trigger mechanism when the barrel selector is being moved.

Figure 3- Barrel Selector on Single Trigger Shotguns

TOP LEVER

The top lever operates the locking bolt, which securely aligns and clasps

the barrel assembly shut to the receiver for firing. The locking bolt and

14

Barrel Selector

barrel lugs are designed for gradual wear of locking surfaces and may

therefore exhibit tight fitting characteristics during initial use. The close

tolerances of these locking surfaces ensure that the breech of the firearm

remains tight throughout use.

When closing the breech of the action let the top lever move freely to

its locked (in line with the safety) position (see figure 4). Do not restrain

its travel with your thumb.

It is recommended that the top lever be indexed to the left with slight

finger or thumb pressure to make sure that the bolt is fully closed. If the

bolt does not fully close it is possible dirt or debris have accumulated to a

level preventing full closure of the breech. In this condition, open the

action and unload the firearm. Carefully inspect the action and remove

any dirt or debris. Keep the breech surface clean and lightly lubricated.

EJECTORS

Most Merkel Side-by-Side Shotguns are equipped with automatic ejec-

tors. On these models, spent shells will be thrown out of the chamber

automatically when the action is fully opened after firing. Be careful to

position the breech away from your face when unloading the firearm to

avoid being hit by ejected spent rounds.

LOADING AND FIRING

Before loading the firearm, visually inspect your safety and make sure it

is in the Safe position. Never load the firearm with the safety in the

firing position. Avoid contact with the trigger mechanism while loading

ammunition and at all times prior to firing.

To insert rounds in the chamber, move the top lever to the right with

the thumb of your firing hand and open the breech. Inspect the cham-

bers and barrel bores to be sure they are free of any obstruction. Insert

proper ammunition in each chamber and close the action. Be sure the

round primer and rim is facing rearward when inserting shells in the

chamber.

15

When you close the breech of the action, let the top lever move freely to

its locked position. Do not restrain its travel with your thumb. It is rec-

ommended that the top lever be indexed to the left with slight pressure

to make sure that the bolt is fully closed. (See figure 4).

Figure 4-Closing the Breech

DOUBLE RIFLES

GENERAL SPECIFICATIONS

Merkel Double Rifles are two barreled firearms with the barrels aligned along

side each other with the sighting rib positioned between the barrels, and are

typically equipped with two triggers each of which correspond to its respec-

tive barrel.

OPERATION OF THE DOUBLE RIFLE "SAFETY" MECHANISM

The double rifle safety mechanism is located on the tang of the receiver

assembly just in front of the buttstock on the top side (See figure 5). Some

Merkel Double Rifles are equipped with Automatic Safeties, i.e., the safety is

automatically engaged each time the breech is opened. Double rifles in

.375H&H, .416 Rigby or .470 Nitro Express are not equipped with

automatic safeties because they are designed for dangerous game when

the need for quick reloadingand follow-up shots are critical. The

firearm is in the "safe" position when the safety is moved fully rearward and

the letter "S" appears on the receiver tang directly in front of the safety. In

this position sear engagement is blocked to prevent discharge under non-fir-

ing conditions.

16

Locked (Fully Closed) Position

Figure 5 - Double Rifle Safety Mechanism

WARNING! SAFETIES ARE MECHANICAL DEVICES THAT MAY FAIL

OR MALFUNCTION LIKE ANY OTHER MECHANICAL DEVICE!

ALWAYS HANDLE THE RIFLE CAREFULLY AND DO NOT PERMIT

THE RIFLE TO POINT IN AN UNSAFE DIRECTION! ALWAYS TREAT

THE RIFLE AS IF IT WERE LOADED AND READY TO FIRE! ALWAYS

OBSERVE SAFETY RULES WHEN HANDLING THE RIFLE!

THE SAFETY SHOULD ALWAYS BE IN THE SAFE POSITION

EXCEPT WHEN THE SHOOTER IS ACTUALLY FIRING THE GUN.

THE SAFETY SHOULD BE MOVED TO THE SAFE POSITION ,

WHENEVER THE SHOOTER CEASES FIRING, EVEN TEMPORARILY.

KEEP THE MUZZLE OF THE FIREARM POINTED IN A SAFE DIREC-

TION AT ALL TIMES!

When the safety is indexed forward to its most forward position the rifle is in

its firing mode. In this condition the triggers can be pulled to fire the rifle.

The letter "S" inscribed on the tang of the receiver will be covered and

obscured from view in this condition.

When you are not using your firearm, be sure your gun is pointed in a safe

direction, avoid contact with the trigger and make sure the safety is in its

Safe position to prevent accidental discharge. Maintain the firearm safety

in the "Safe" position at all times, unless you are actually firing the rifle.

17

Safety

DOUBLE TRIGGER OPERATIONS

Each trigger on the double rifle operates its own barrel. The front trigger

will fire the right barrel and the rear

trigger will fire the left barrel. Do not

pull both triggers at the same time in

order to avoid excessive recoil or kick

from simultaneous discharge of both

barrels. The front trigger on some

models is a set trigger and can be set by

pushing the trigger forward. NEVER

fire the rear trigger with the front trigger in the set position as both

barrels may fire simultaneously. Set triggers are not available on double

rifles in .375H&H, .416 Rigby or .470 Nitro Express.

TOP LEVER

The top lever operates the locking bolt, which securely aligns and clasps

the barrel assembly shut to the receiver for firing. The locking bolt and

barrel lugs are designed for gradual wear of locking surfaces and may

therefore exhibit tight fitting characteristics during initial use. The close

tolerances of these locking surfaces ensure that the breech of the firearm

remains tight throughout use.

When closing the breech of the action let the top lever move freely to

its locked (in line with the safety) position (see figure 6). Do not restrain

its travel with your thumb.

It is recommended that the top lever be indexed to the left with slight

finger or thumb pressure to make sure that the bolt is fully closed. If the

bolt does not fully close it is possible that dirt or debris has accumulated

to a level preventing full closure of the breech. In this condition, open

the action and unload the firearm. Carefully inspect the action and

remove any dirt or foreign matter. Keep the polished breech surface

clean and lightly lubricated.

EJECTORS

As an option Merkel double rifles are available with automatic ejectors.

On these models, spent shells will be thrown out of the chamber auto-

18

Set

Trigger

matically, when the action is fully opened after firing. Be careful to posi-

tion the breech away fromyour face when unloadingthe firearmto

avoid beinghit by ejected spent rounds. Ejectors are not available on

double rifles in .375H&H, .416 Rigby or .470 Nitro Express.

EXTRACTORS

Merkel Double Rifles not fitted with optional ejectors are fitted with extrac-

tors. When the action is opened on these models the fired cases are elevated

above the chamber for removal by hand. All .375H&H, .416 Rigby or .470

Nitro Express, double rifles are equipped with extractors.

LOADING AND FIRING

Before loading the rifle, visually inspect your safety and make sure it is in

the Safe position. Never load the rifle with the safety in the firing posi-

tion. Avoid contact with the trigger mechanism while loading ammuni-

tion and at all times prior to firing.

To insert cartridges in the chamber, move the top lever to the right with

the thumb of your firing hand and open the breech. Inspect the cham-

bers and barrel bores to be sure they are free of any obstruction. Insert a

cartridge in each chamber and close the action. Be sure the round primer

and rim is facing rearward when inserting cartridges in the chamber.

When you close the breech of the action, let the top lever move freely to

its locked position. Do not restrain its travel with your thumb. It is rec-

ommended that the top lever be indexed to the left with slight pressure

to make sure that the bolt is fully closed. (See figure 6).

Figure 6-Closing the Breech 19

Locked (Fully Closed) Position

DRILLINGS

GENERAL SPECIFICATIONS

Merkel Drillings differ from side-by-side shotguns in that in addition to two

side-by-side shotgun barrels there is a rifle barrel centered directly under the

two shotgun barrels.

OPERATION OF THE DRILLING"SAFETY" MECHANISM

There are three positions: 1. Safe 2. Fire for Shotgun barrels 3. Fire for

Rifle barrel and left Shotgun barrel.

ATTENTION-MANUAL SAFETY MECHANISM!

THE SAFETY PROVIDED ON MERKEL DRILLINGS IS MANUALLY

OPERATED AND DOES NOT OPERATE AUTOMATICALLY. THE

SHOOTER MUST MANUALLY MOVE THE SAFETY TO BOTH ITS

SAFE AND FIRE POSITIONS. FAILURE TO MANUALLY MOVE THE

SAFETY TO ITS DESIRED POSITION COULD CAUSE AN

ACCIDENTAL DISCHARGE!

Position 1- Safety slide is to the rear (red dot firing indicator is covered

by the safety selector). The trigger sears are blocked for the shotgun and

rifle barrels.

Position 2- The safety slide is indexed forward by depressing the the

safety button on the safety slide and pushing the safety slide forward

Figure 7 - Drilling Safety Mechanism

20

Safety Slide

Safety Button

until the red dot firing indicator is uncovered. Both shotgun barrels can

now be fired. The front trigger fires the right barrel and the rear trigger

the left barrel.

Position 3- The rifle barrel is selected by pushing the safety slide all the

way forward, the rifle is cocked when the safety button on the safety

slide pops up. The rifle barrel can now be fired by using the front trigger

and the rear trigger will fire the left shotgun barrel.

Uncockingthe Drillings Rifle Barrel - Depress the button on the safe-

ty slide and allow the the safety to slide rearward.

Movingto Safe position- Press the button on the safety slide and move

the slide completely to the rear. The firearm is now in its Safe position.

WARNING! SAFETIES ARE MECHANICAL DEVICES THAT MAY FAIL

OR MALFUNCTION LIKE ANY OTHER MECHANICAL DEVICE!

ALWAYS HANDLE THE DRILLING CAREFULLY AND DO NOT PER-

MIT THE DRILLING TO POINT IN AN UNSAFE DIRECTION!

ALWAYS TREAT THE DRILLING AS IF IT WERE LOADED AND

READY TO FIRE! ALWAYS OBSERVE SAFETY RULES WHEN HAN-

DLING THE DRILLING! THE SAFETY SHOULD ALWAYS BE IN THE

SAFE POSITION EXCEPT WHEN THE SHOOTER IS ACTUALLY

FIRING THE GUN. THE SAFETY SHOULD BE MOVED TO THE

SAFE POSITION , WHENEVER THE SHOOTER CEASES FIRING,

EVEN TEMPORARILY. KEEP THE MUZZLE OF THE FIREARM

POINTED IN A SAFE DIRECTION AT ALL TIMES!

When you are not using your firearm, be sure your gun is pointed in a safe

direction, avoid contact with the trigger and make sure the safety is in its

Safe position to prevent accidental discharge. Maintain the firearm safety

in the "Safe" position at all times, unless you are actually firing the gun.

DOUBLE TRIGGER OPERATIONS

All Drillings are equipped with two triggers, each trigger operates its own

barrel. The front trigger will fire 1) the

right barrel or 2) the rifle barrel when

the safety is indexed all the way forward

(see Position 3 above). The rear trigger

will fire the left shotgun barrel . Do not

pull both triggers at the same time in

order to avoid excessive recoil or kick

Set

Trigger

21

from simultaneous discharge of both barrels. The front trigger also can

function as a set (hair) trigger and can be set by pushing the trigger for-

ward. NEVERfire the rear trigger with the front trigger in the set

(hair) position as both barrels could fire simultaneously. Note: The

front trigger can be operated in its set (hair) mode for either the rifle

barrel or the right shotgun barrel.

TOP LEVER

The top lever operates the locking bolt, which securely aligns and clasps

the barrel assembly shut to the receiver for firing. The locking bolt and

barrel lugs are designed for gradual wear of locking surfaces and may

therefore exhibit tight fitting characteristics during initial use. The close

tolerances of these locking surfaces ensure that the breech of the firearm

remains tight throughout use.

When closing the breech of the action let the top lever move freely to

its locked (in line with the safety) position (see figure 8). Do not restrain

its travel with your thumb.

It is recommended that the top lever be indexed to the left with slight

finger or thumb pressure to make sure that the bolt is fully closed. If the

bolt does not fully close it is possible that dirt or debris has accumulated

to a level preventing full closure of the breech. In this condition open

the action and unload the firearm. Carefully inspect the action and

remove any dirt or foreign matter. Keep the polished breech surface

clean and lightly lubricated.

EXTRACTORS

Merkel Drillings are equipped with extractors. When the action is

opened, the round casings are elevated above the chamber for removal

by hand.

LOADING AND FIRING

Before loading the firearm, visually inspect your safety and make sure it

is in the Safe position. Never load the firearm with the safety in the

firing positions. Avoid contact with the trigger mechanism while loading

ammunition and at all times prior to firing.

22

To insert rounds in the chamber, move the top lever to the right with

the thumb of your firing hand and open the breech. Inspect the cham-

bers and barrel bores to be sure they are free of any obstruction. Insert a

round in each chamber and close the action. Be sure the round primer

and rim is facing rearward when inserting shells in the chamber. When

you close the breech of the action, let the top lever move freely to its

locked position. Do not restrain its travel with your thumb. It is

Figure 8-Closing the Breech

recommended that the top lever be indexed to the left with slight pres-

sure to make sure that the bolt is fully closed. (See figure 8).

The firearm is now ready to fire. Shots are discharged by indexing the

safety forward and pulling the trigger.

23

FIREARM ASSEMBLY

SIDE-BY-SIDE SHOTGUNS, DOUBLE RIFLES & DRILLINGS

Before assembly, be certain there is no ammunition in either chamber and

position the safety in the S or Safe position.

Remove all protective lubricants from your firearm before initial assembly.

Use a cleaning rod, patches and a light gun oil or solvent to clean the interi-

or of the firearm bore. Use a cleaning cloth and light gun oil to remove pro-

tective lubricants from metal parts on the receiver and barrel assemblies.

Figure 9-Removal of Forearm

Remove the forearm from the barrels by pulling the forearm latch out and

away from the underside of the forearm (See figure 9). Remove all protective

lubricants from the exposed metal surfaces with light gun oil and a cleaning

cloth. After cleaning, place a couple of drops of gun oil on the metal bearing

surfaces of the hinge, barrel lugs and on the forearm bracket (see figure 1).

The barrels are attached to the action by grasping the stock grip with the fir-

ing hand and supporting the buttstock in between the firing elbow and body

(See figure 10). Grasp the barrels with the non-firing hand and connect the

barrel lug hinge with the receiver hinge pin. Use the thumb of the firing

hand to move the top lever sideways to its most right position.

Maintain pressure on the barrels to keep the hinge pin aligned with the bar-

24

rel lug hinge pin recess, and rotate the barrels upward to close the action.

Release the top lever at this time.

Pivot the forearm assembly onto the barrels. Align the forearm in its proper

position on the barrels and push the forearm lever upward into its housing.

This locks the forearm back into its original position on the barrels.

Figure 10-Barrel Assembly

ATTENTION! While assembling your firearm, do not use excessive

force when closing the action! If the action and barrels are not aligned

properly, excessive force applied during assembly can deform or mar the

fitted surfaces of the firearm. If you perceive any interference while

installing the barrels to the receiver repeat the assembly procedures from

beginning, and be extra careful to align the barrel lug hinge pin recess

and the receiver hinge pin properly. If you continue to experience diffi-

culty in the assembly of your firearm, call GSI or seek assistance from a

qualified gunsmith.

GAUGE, CALIBER, CHAMBER LENGTH

AND

CHOKE DESIGNATION

It is most important that the correct ammunition is used with your

firearm. Use of incorrect ammunition with your firearmcould cause

injury or death to the shooter and damage to the firearm. Never use

25

ammunition that does not match the correspondinggauge or caliber of

the firearm. For example, do not use 20 gauge ammunition in a 12 gauge

gun. In addition, do not use rounds with chamber lengths that exceed

the chamber length of the firearm barrel.

DANGER - AMMUNITION WARNING!

SERIOUS INJURY OR DEATH OR PROPERTY DAMAGE

MAY RESULT FROM ANY CONDITION WHICH CON-

TRIBUTES TO THE GENERATION OF EXCESSIVE PRES-

SURE, OR THE UNCONTROLLED RELEASE OF GAS,

WITHIN A FIREARM. THE FOREGOING ADVERSE CON-

DITIONS CAN BE CAUSED BY BORE OR CHAMBER

OBSTRUCTIONS, PROPELLANT POWDER OVERLOADS,

OR BY DEFECTIVE, INCORRECT CALIBER, GAUGE OR

LENGTH, OR IMPROPERLY LOADED AND ASSEMBLED

AMMUNITION COMPONENTS. IT IS EXTREMELY DAN-

GEROUS TO USE AMMUNITION WHOSE PRESSURE IS

GREATER THAN THAT DEVELOPED BY AMMUNITION

LOADED TO FACTORY STANDARDS. EVEN THE

STRONGEST FIREARM CAN BE BLOWN UP AS A

RESULT OF EXCESSIVE PRESSURE.

The following information describes the identification system used to

designate the gauge, chamber length and choke on your Merkel firearm.

Be sure you understand this identification system before loading your

firearm, and only use the correct ammunition. If there is any question in

regard to the proper ammunition for your firearm, feel free to call GSI at

205-655-8299 for assistance.

Firearm gauge, chamber and choke designations are engraved on the

underside of the barrels where they interface the breech block of the

receiver (See figure 11). A typical example of a gauge/chamber length

designation would be 12/76 which identifies a firearm bore diameter of

12 gauge and 76 mm (3 inch) chamber length. Bore diameters are

available in 12, 16, 20 and 28 gauge.

26

Figure 11-Gauge, Chamber Length and Choke Designation

Chamber lengths are identified by the numeral 70 or 76. The

numeral 76 designates a chamber length of 76mm which is equal

to the English measurement of 3 inches. A barrel marked with

the numeral 70 designates a chamber length of 70mm which is

equal to the English measurement of 2

3

/4 inches.

Use of shotgun rounds with chamber lengths shorter than the

shotgun chamber length is acceptable. However, never use rounds

with chamber lengths greater than the length of the shotgun

chamber. For example, do not use 3 inch shells in a shotgun

chambered for 2

3

/4 inch ammunition. In the rifle barrel of your

drilling always insure that you are using the proper caliber ammu-

nition. For example, do not use .270 Winchester ammunition in

a rifle barrel chambered for 30/06 Springfield.

Chokes are identified for each barrel below the designation for

gauge and chamber length on the underside of the barrels. Choke

designation indicates the dispersion pattern characteristics of the

shotgun bore. The chart on the following page provides identifi-

cation for choke and a pattern percentage within a 30 inch circle

at specified ranges.

Gauge or Caliber

Choke

Designation

Chamber Length

27

DrillingRifle Caliber

Choke

Identification Description Percentage Distance

1/1 Full Choke 70 - 75 35m

3/4 Improved 65 - 70 35m

Modified Choke

1/2 Modified Choke 60 -65 35m

1/4 Quarter Choke 55 - 60 35m

VZ Improved 45 - 50 35m

Cylinder Choke

S Skeet 70 - 75 20m

DRY FIRING

ATTENTION!!!!! Dry firing or pulling the triggers without live

ammunition is not recommended without the use of snap caps.

Snap caps absorb the inertia of the firing pins and protect inter-

nal parts from the full impact force of the hammers. Continuous

dry firing can potentially damage the internal parts and render

the gun inoperable.

DISASSEMBLY

Remove loaded ammunition from the chamber before disassembling the

firearm. To disassemble the firearm, grasp the firearm barrel with the

non-firing hand and rest the buttstock against the upper leg. Pull the

forearm take down latch out and away from the forearm and pivot the

forearm away from the barrels.

Push the top lever to the right and carefully open the action to rotate

28

the barrel lug away from the receiver hinge pin and separate the barrels

from the receiver. The forearm can be reattached to the barrels for stor-

age.

Do not attempt further disassembly beyond barrel and forearm

removal!!! Further disassembly is not necessary for routine maintenance.

Any damage incurred due to further disassembly is not covered by your

service warranty.

FURTHER DISASSEMBLY BY UNQUALIFIED

PERSONS COULD CAUSE DAMAGE TO THE

FIREARM WHICH COULD RESULT IN

INJURY OR DEATH TO THE SHOOTER.

CLEANING

Merkel firearms require periodic maintenance and will perform more

reliably over a longer period of time if properly cleaned and serviced.

NEVER clean a loaded firearm. Remove ammunition from the cham-

bers before performing any cleaning procedures.

Always wipe the barrels and action with a lightly lubricated cloth to

remove fingerprints, dirt and moisture from the gun after handling. Keep

a light coat of gun oil on polished metal surfaces and moving parts.

Clean inside the barrels periodically to remove fouling and residue

caused by fired ammunition.

If the action seems unusually tight or if you are unable to close the breech

to its locked position, disassemble the firearm and give it a thorough

cleaning. If functional problems continue, call the GSI Service

Department or seek the assistance of a competent and qualified gunsmith.

A light cleaning consists of oiling and wiping down the firearm. This

can be accomplished without removing the barrels from the receiver. A

full detailed cleaning will require disassembly of the barrels and forearm.

29

General cleaning procedures are outlined as follows.

Make surethe chambers are unloadedon your firearm. Wear protective

safety glasses during assembly, disassembly and cleaning procedures. Keep

ammunition away from the cleaning area. NEVERtest the function of

your firearm with live ammunition.

Remove the barrels and forearm from the receiver according to disassem-

bly instructions provided in this manual.

Use a cleaning rod with a tip and patch suitable for use in firearm bores.

Lightly oil the patch and place it on the tip of the cleaning rod. Insert

the tip of the cleaning rod with the attached patch into the chamber

end of the barrels and push the patch back and forth through both bar-

rels several times. Inspect the bores from both ends of the barrels for

residue caused by leading and plastic shot cups. This residue will form

streaks that run parallel to the inside of the bore. Slight residue streaks

are common place and will not affect the performance of your firearm.

If lead or plastic residue appears to be excessive it can be removed by

brushing the bores with a brass brush attached to the cleaning rod.

First apply gunpowder solvent to the brush end of the cleaning brush.

Insert the cleaning rod into the chamber end of the bores. Push the

brush completely through the firearm bore before pulling it backwards to

avoid breaking the bristles on the brush. Continue this scrubbing action

until the bores are clean.

When all fouling and residue is removed, push a clean dry patch through

both bores with the cleaning rod to remove any remaining debris or sol-

vent. When the bores are free of all solvent and debris, insert a lightly

oiled patch and lubricate the bores.

Wipe the metal surfaces of the barrels, forearms and receiver with a

clean rag. Lightly oil the metal parts on the receiver hinge, and barrel

lugs and the forearm brackets.

30

Notes

31

Notes

32

Notes

33

QUICK REFERENCE

FOR YOUR MERKEL

MODEL NUMBER:________________________

GAUGE:_________________________________

BARREL LENGTH:_________________________

CHOKE:_________________________________

SERIAL NUMBER:_________________________

DATE PURCHASED:_______________________

34

U.S. IMPORTER

G SI I n corp orated , 1 08 M orrow Ave.,

P.O . B ox 1 29, Tru ssvi lle, Al 351 73.

Telep h on e 205) 655-8299

F ax 205) 655-7078

www.G SI fi rearm s.com

You might also like

- Practical Guide to the Operational Use of the PK/PKM Machine GunFrom EverandPractical Guide to the Operational Use of the PK/PKM Machine GunRating: 5 out of 5 stars5/5 (4)

- Smith Wesson Revolvers Owners ManualDocument32 pagesSmith Wesson Revolvers Owners ManualRob TomsicNo ratings yet

- Accurate Load Data 3.5Document20 pagesAccurate Load Data 3.5Dale FundakNo ratings yet

- User Manual Savage 64FXPDocument7 pagesUser Manual Savage 64FXPtlvetter50% (2)

- Pump Action ShotgunDocument16 pagesPump Action ShotgunJustin0% (1)

- M88 ManualDocument16 pagesM88 Manualbalkanmonitor100% (1)

- Metallic Pistol Manual PDFDocument36 pagesMetallic Pistol Manual PDFWallace LimaNo ratings yet

- Maxus ManualDocument27 pagesMaxus Manualklipschthx0No ratings yet

- Ascension Lily: Hippeastrum reginae Flower FactsDocument1 pageAscension Lily: Hippeastrum reginae Flower Factsdannyjan5080No ratings yet

- Kac Sr-25 Operator's ManualDocument109 pagesKac Sr-25 Operator's Manualraiderkilo100% (3)

- USMC OrdnanceEquipmentDocument160 pagesUSMC OrdnanceEquipmentWilliam James Abercrombie100% (1)

- plr-16 Manual PDFDocument11 pagesplr-16 Manual PDFwytboi420No ratings yet

- Humorous Comparison of An AK47 An AR15 and A MosinDocument3 pagesHumorous Comparison of An AK47 An AR15 and A Mosintinkshot4759No ratings yet

- Steyr Scout User ManualDocument46 pagesSteyr Scout User ManualpozolabNo ratings yet

- IZHMSH Baikel ManualDocument26 pagesIZHMSH Baikel ManualtiberiansonNo ratings yet

- EAA WindicatorDocument15 pagesEAA WindicatorJustinNo ratings yet

- EAA Witness Warnings and Instruction ManualDocument26 pagesEAA Witness Warnings and Instruction ManualMichael SmithNo ratings yet

- Walther Pps Pistols: Safety & Instruction ManualDocument32 pagesWalther Pps Pistols: Safety & Instruction ManualFlatstalkerNo ratings yet

- Saiga12 ManualDocument21 pagesSaiga12 ManualjfmanNo ratings yet

- Db15 Db10 Db9r-ManualDocument40 pagesDb15 Db10 Db9r-ManualTony MitchellNo ratings yet

- MP94 Manual PDFDocument25 pagesMP94 Manual PDFvuklisNo ratings yet

- M4 Carbine Instruction/Safety ManualDocument52 pagesM4 Carbine Instruction/Safety ManualTaKTiKiLLNo ratings yet

- Manual Colt M4 M16 22 Rimfire 10R11Document32 pagesManual Colt M4 M16 22 Rimfire 10R11Mike Cannady0% (1)

- Rem 1911 r1Document18 pagesRem 1911 r1Mark PlattnerNo ratings yet

- Sigma Pistols: Safety & Instruction ManualDocument32 pagesSigma Pistols: Safety & Instruction ManualVictorNo ratings yet

- Izh 43 2004Document26 pagesIzh 43 2004grugnirNo ratings yet

- Rem402833 Model1911 - 2015-10-08Document36 pagesRem402833 Model1911 - 2015-10-08blbecekNo ratings yet

- Beretta Stampede PDFDocument0 pagesBeretta Stampede PDFmrek68No ratings yet

- IZH 27 ManualDocument28 pagesIZH 27 ManualgzapasNo ratings yet

- IZH 43 ManualDocument26 pagesIZH 43 ManualAnonymous vKD3FG6RkNo ratings yet

- Millennium g2 Manual PDFDocument36 pagesMillennium g2 Manual PDFWallace LimaNo ratings yet

- Izh18 Single Barrel ShotgunDocument17 pagesIzh18 Single Barrel ShotgunJustin0% (1)

- Smith and Wesson Modelo 22a y 22sDocument32 pagesSmith and Wesson Modelo 22a y 22sbrass.pissNo ratings yet

- Windicator Series: Warnings and Instruction ManualDocument24 pagesWindicator Series: Warnings and Instruction ManualDustin PearmanNo ratings yet

- Owner'S Manual: Read This Manual in Its Entirery Before Using Your FirearmDocument24 pagesOwner'S Manual: Read This Manual in Its Entirery Before Using Your Firearmspan codNo ratings yet

- Over & Under: ShotgunDocument40 pagesOver & Under: ShotgunjovanNo ratings yet

- Pringfield Rapdoor: by Davide PedersoliDocument31 pagesPringfield Rapdoor: by Davide PedersoliradiumgalaxyNo ratings yet

- SW Model - 41Document32 pagesSW Model - 41winshooterNo ratings yet

- EAA Izh43KDocument17 pagesEAA Izh43KJustinNo ratings yet

- Remington 1100, 11-87 & Super Mag Auto ShotgunsDocument26 pagesRemington 1100, 11-87 & Super Mag Auto ShotgunsPlainNormalGuy2No ratings yet

- Walther PPK PpksDocument28 pagesWalther PPK PpksTravis JohnsonNo ratings yet

- Taurus 38Document32 pagesTaurus 38Diego Velásquez AscuyNo ratings yet

- Owner'S Manual: 802 Plinkster™ and 801 HALF-PINT™Document20 pagesOwner'S Manual: 802 Plinkster™ and 801 HALF-PINT™Ramon BrazNo ratings yet

- S&W Metal Frame PistolsDocument32 pagesS&W Metal Frame Pistolsapi-3840428100% (2)

- FNAR ManualDocument25 pagesFNAR ManualdmanisgnarlyNo ratings yet

- Metallic Pistol ManualDocument36 pagesMetallic Pistol ManualAdmir BorovicNo ratings yet

- Bar Browning ManualDocument52 pagesBar Browning ManualGriguta AlexNo ratings yet

- WALTHER P99 Pistols: Safety & Instruction ManualDocument36 pagesWALTHER P99 Pistols: Safety & Instruction ManualSpyros PrasinosNo ratings yet

- 800 Series ManualDocument36 pages800 Series ManualWallace LimaNo ratings yet

- Manuale Di Istruzione Instruction Manual Mode D'emploi Manual de InstruccionesDocument47 pagesManuale Di Istruzione Instruction Manual Mode D'emploi Manual de Instruccionesdannyjan5080No ratings yet

- Baikal Izh 18mh ManualDocument24 pagesBaikal Izh 18mh ManualMet AfuckNo ratings yet

- A400 Users ManualDocument35 pagesA400 Users ManualbjmooseNo ratings yet

- M&P12_Manual_091520_3013381Document48 pagesM&P12_Manual_091520_3013381Marco AnnoniNo ratings yet

- Owners Manual WebDocument24 pagesOwners Manual WebwassimNo ratings yet

- Firearms Safety Code: Guide for the safe use of firearmsFrom EverandFirearms Safety Code: Guide for the safe use of firearmsNo ratings yet

- Gun Digest's Defensive Handguns Firearm Safety Course eShort: Must-know handgun safety techniques, shooting tips, certificate courses & combat drills. Discover the top firearm safety skills, rules & questions.From EverandGun Digest's Defensive Handguns Firearm Safety Course eShort: Must-know handgun safety techniques, shooting tips, certificate courses & combat drills. Discover the top firearm safety skills, rules & questions.No ratings yet

- HOME AND FAMILY DEFENSE: Safeguarding Your Loved Ones and Property (2023 Guide for Beginners)From EverandHOME AND FAMILY DEFENSE: Safeguarding Your Loved Ones and Property (2023 Guide for Beginners)No ratings yet

- Sporting Guns: Weapons, Skills and Techniques for Competitive Shooting SportsFrom EverandSporting Guns: Weapons, Skills and Techniques for Competitive Shooting SportsNo ratings yet

- Bullet Mold EnlargementDocument4 pagesBullet Mold Enlargementdannyjan5080No ratings yet

- DIY Soldering For A Whiskey StillDocument2 pagesDIY Soldering For A Whiskey Stilldannyjan5080No ratings yet

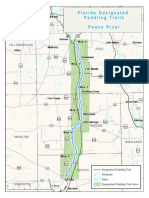

- Peace River Guide-FloridaDocument10 pagesPeace River Guide-Floridadannyjan5080No ratings yet

- Bumping Up A BulletDocument3 pagesBumping Up A Bulletdannyjan5080No ratings yet

- 2012 Infiniti Navigation Manual PDFDocument251 pages2012 Infiniti Navigation Manual PDFdannyjan5080No ratings yet

- History of Moonshine - Learn To MoonshineDocument7 pagesHistory of Moonshine - Learn To Moonshinedannyjan5080No ratings yet

- 2021 Camp Florida DirectoryDocument35 pages2021 Camp Florida Directorydannyjan5080No ratings yet

- Reloading-Attention To DetailDocument2 pagesReloading-Attention To Detaildannyjan5080No ratings yet

- How To Make A Still - Learn To Moonshine PDFDocument7 pagesHow To Make A Still - Learn To Moonshine PDFdannyjan5080100% (1)

- How To Make Moonshine: 21 Easy Steps Using A Pressure Cooker StillDocument17 pagesHow To Make Moonshine: 21 Easy Steps Using A Pressure Cooker Stilldannyjan5080No ratings yet

- Beginning Leatherworking Class PDFDocument69 pagesBeginning Leatherworking Class PDFdannyjan5080No ratings yet

- Copper Sheet Thickness GuideDocument6 pagesCopper Sheet Thickness Guidedannyjan5080No ratings yet

- DIY Soldering For A Whiskey StillDocument2 pagesDIY Soldering For A Whiskey Stilldannyjan5080No ratings yet

- Types of Stills - Learn To MoonshineDocument7 pagesTypes of Stills - Learn To Moonshinedannyjan508050% (2)

- Moonshine RecipesDocument7 pagesMoonshine Recipesdannyjan5080No ratings yet

- Pure Blend Pro Tri FoldDocument2 pagesPure Blend Pro Tri Folddannyjan5080No ratings yet

- Cupper Tube HandbookDocument56 pagesCupper Tube HandbookGustavo SuarezNo ratings yet

- Ch.3 Growing Cocoa BeansDocument5 pagesCh.3 Growing Cocoa BeanssuryasanNo ratings yet

- Pico Manual PDFDocument103 pagesPico Manual PDFdannyjan5080No ratings yet

- Pico Manual PDFDocument103 pagesPico Manual PDFdannyjan5080No ratings yet

- Barbados Beach GuideDocument7 pagesBarbados Beach Guidedannyjan5080No ratings yet

- Florida Peach and Nectarine Varieties MG37400 PDFDocument17 pagesFlorida Peach and Nectarine Varieties MG37400 PDFdannyjan5080No ratings yet

- Two Canoes and A Crazy Idea PDFDocument24 pagesTwo Canoes and A Crazy Idea PDFdannyjan5080No ratings yet

- 4 Diamond Buying Guide Under 90 PtsDocument1 page4 Diamond Buying Guide Under 90 Ptsdannyjan5080No ratings yet

- Brake Drum ForgeDocument12 pagesBrake Drum Forgedannyjan5080No ratings yet

- Humbucker 4 WireDocument1 pageHumbucker 4 Wiredannyjan5080No ratings yet

- Humbucker Braided 2 WireDocument1 pageHumbucker Braided 2 Wiredannyjan5080No ratings yet

- Ovation ManualDocument13 pagesOvation Manualdannyjan5080100% (1)

- Coat Hanger Machine Gun DIASDocument8 pagesCoat Hanger Machine Gun DIASRoddy Pfeiffer100% (1)

- Combat Handguns - June 2015 USADocument100 pagesCombat Handguns - June 2015 USAJohan100% (1)

- CoC 7e Character SheetDocument12 pagesCoC 7e Character SheetAlejandro CastañedaNo ratings yet

- M36 Tank Field Manual FM 18-18 (1944)Document49 pagesM36 Tank Field Manual FM 18-18 (1944)Tane67100% (1)

- Pistolsmithing-John M Browning PDFDocument5 pagesPistolsmithing-John M Browning PDFiron juqueNo ratings yet

- Borderlands 1 Loot ListDocument6 pagesBorderlands 1 Loot Listap0lly0n1990No ratings yet

- The History of WeaponryDocument2 pagesThe History of WeaponryBlue RainNo ratings yet

- Instructor Guide Pilot PDFDocument630 pagesInstructor Guide Pilot PDFArendra WahyudiNo ratings yet

- Quiz On OutdoorDocument13 pagesQuiz On OutdoorvinaykajlaNo ratings yet

- How Weapons Have Changed Since ww1 1Document19 pagesHow Weapons Have Changed Since ww1 1api-329578408No ratings yet

- Acculite 22 Caliber Graphite Barrel System 5-21-08Document4 pagesAcculite 22 Caliber Graphite Barrel System 5-21-08TNT1842No ratings yet

- Whitetail Deer HuntingDocument124 pagesWhitetail Deer Huntingarmymedic7100% (1)

- Scuba Ringer Instruction ManualDocument11 pagesScuba Ringer Instruction ManualJesus PulidoNo ratings yet

- PNN Af DMDDocument119 pagesPNN Af DMDCitroNo ratings yet

- WWII German OrganizationsDocument9 pagesWWII German OrganizationsAndrew SmithNo ratings yet

- 5080 308 Win. SWISS P AP 12.7 G - 196 GR ENDocument2 pages5080 308 Win. SWISS P AP 12.7 G - 196 GR ENVirgin Owl Oldman100% (1)

- Chapter ViDocument4 pagesChapter ViBrielle Shai CruzNo ratings yet

- Manual cz630 631 - enDocument16 pagesManual cz630 631 - enPeter SakeNo ratings yet

- 264 Winchester Magnum load data from Hodgdon Powder CompanyDocument2 pages264 Winchester Magnum load data from Hodgdon Powder Companyengine33rNo ratings yet

- 39th Zone Shooting Championship Results: Standard Pistol 25m Men Individual QualificationDocument15 pages39th Zone Shooting Championship Results: Standard Pistol 25m Men Individual QualificationjayakumaraNo ratings yet

- Lyman 2012 CatalogDocument96 pagesLyman 2012 CatalogMichael SchreiberNo ratings yet

- M16A4 Rifle SpecificationDocument57 pagesM16A4 Rifle Specificationcjnjr1No ratings yet

- Battlesight Zero Updated Nov 2013 RWSDocument12 pagesBattlesight Zero Updated Nov 2013 RWSplanetoftheafpNo ratings yet

- Cuervos Sangrientos Señor Del Capítulo: Gabriel Angelos Hiende Dioses Armadura Gravis Primera CompañíaDocument6 pagesCuervos Sangrientos Señor Del Capítulo: Gabriel Angelos Hiende Dioses Armadura Gravis Primera CompañíaDaniel Padilla MartínezNo ratings yet

- Lithgow Arms - F90 (Operator Manujal)Document6 pagesLithgow Arms - F90 (Operator Manujal)Ricardo C TorresNo ratings yet

- M1 Garand New Barrel InstallationDocument35 pagesM1 Garand New Barrel InstallationToschanoNo ratings yet