Professional Documents

Culture Documents

BR - HV Pass Family (En) D - 2gja708398 08.2013

Uploaded by

hansamvOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BR - HV Pass Family (En) D - 2gja708398 08.2013

Uploaded by

hansamvCopyright:

Available Formats

High voltage products

PASS Family

Plug and Switch System

PASS M00, PASS M0, PASS M0S

2

Focus factory

The ABB Focus Factory based in Lodi, Italy, is one of the facilities belonging to the

ABB Group. It produces High Voltage electrical equipment on a covered area of

more than 12,000 square metres.

It is a Global Focus Factory, and a centre of excellence for design and production

of high voltage hybrid circuit-breakers and switchgear. A market leader, it exports

approximately 80% of its products worldwide.

The factory is organized according to Lean Production criteria and is managed

by means of an integrated ERP system. The Quality System conforms to ISO 9001

standards, the Environmental Management System to ISO 14001 standards, and

the Health and Safety Management System to OHSAS 18001 standards.

Both quality and environmental management systems are certied by DNV

(SINCERT accredited).

3

the phase in which the products pass through the plant and

enabling ABB to achieve a much more flexible response to the

demands from the market.

To synchronize the physical flows, particular attention has

been paid to ensure that modern process techniques are

applied, namely: Just in Time, Lean Manufacturing and Theory

of Constraints. Use of these new techniques in the factory has

achieved sensible considerable improvements, such as:

a shorter throughput time;

a lower inventory value;

less space required in both the storage and production

departments;

total quality.

The ATO model (Assemble To Order) has been implemented

for management purposes, so assembly work can only begin

once the order has been acquired. Although an extensive mix

of finished product codes can be manufactured with certain

standard sub-assemblies in common, the management model

limits the stocks of semi-processed parts, subassemblies or

finished products to the WIP (Work In Progress) at the given

time.

The layout of the new plant is based on flows and no longer

on single stations. This has saved a great deal of space

and has improved and safety and quality of the work to a

considerable extent. The logic by which the components

are fed to the lines was modified at the same time, bills of

materials were organized differently so as to pilot the supplies

of components for each individual assembly phase.

Service

Thanks to its Service structure, the ABB plant provides a

full after-sales service for its customers needs: analysis and

modification of existing installations, diagnosis of module

conditions, solutions for reducing life cycle costs, upgrading

to achieve compliance with Standards and laws, retrofitting

and revamping interventions, training and updating of

maintenance personnel, as well as emergency interventions.

Production

The idea behind new plant of Lodi was that the development

process for new products must always be flanked by an

adequate and coordinated process for handling the physical

and computerized flows. To respond to the demands from

the market in the best possible way, it is consequently also

essential to plan the internal logics of the processes and

synchronize the flows. Criteria to achieve standardized and

common components are followed right from the time that

new products are engineered in order to comply with the need

to coordinate the operating flows. This makes supplies of

materials, the assembly processes and the general production

planning and programming process more fluid, speeding up

Laboratories

ABB plant has internal laboratories equipped with state-of-

the-art equipment in order to carry out material, experimental,

climatic, mechanical life, electromagnetic compatibility,

commissioning and dielectric tests. Type and routine tests

ascertain whether the components, construction stages

and finished products comply with the strict specification

requirements. The Test Laboratory is accredited by an

external independent organization and complies with UNI

CEI EN ISO/IEC 17025 Standards.

4

The Hybrid Switchgears

The arrival of the newly created PASS M0S switchgear for

voltages up to 420 kV has enlarged the PASS family: ABBs

hybrid Single-Phase, Encapsulated Plug And Switch System

solution. Starting with voltages of up to 100 kV with PASS

M00, through PASS M0, which can be used for voltages up to

170 kV and then to the above-mentioned PASS M0S used for

voltage values at 252 and 420 kV, almost all the transmission

and distribution voltage levels can be served by PASS modules.

The term Hybrid refers to the combination of both

conventional air insulated switchgear (AIS) and the newer

SF

6

metal-clad insulated switchgear (GIS), which takes

advantage of the two different technologies. The Hybrid

switchgear solution uses already existing, tried-and-tested

gas insulated switching components but also a conventional

Introduction

and very reliable AIS bus to connect the various hybrid

modules.

All the functions (except the ring type current transformers)

are sealed in a single SF

6

gas insulated housing:

circuit-breaker;

disconnectors;

earth switches;

cable sealing ends;

fast earthing switches;

SF

6

VTs or voltage sensor.

PASS could also be called Performance And Save Space

as it is possible to obtain any substation layout by making

efficient use of the available space.

PASS M0 145 kV SBB

5

electronic monitoring and on-line remote diagnostic

analysis.

8. Modularization of the substations:

savings during the design and construction stages;

minimal variations using standardized components;

less risk of design errors;

greater confidence in project estimation as costs are

predictable.

That means:

very high reliability and availability of the substation;

drastic reductions in the time needed to install the

equipment;

much less space required;

simplified substation layout;

less maintenance required (maintenance on demand);

very good cost performance for purchasing, maintenance,

operation, outage and relocation;

environmentally friendly: recycling / disposal at end of life.

Versatile operation

PASS features versatile operation that knows no rivals in the

field of high voltage components.

PASS offers a series of modules for HV substations:

Single Bus Bar (SBB);

Double Bus Bar (DBB);

Double Circuit Breaker (DCB).

PASS can also be used as a high voltage bay on a mobile

truck, available for emergencies or if work has to be carried out

on already installed HV bays.

Advantages

PASS combines all the typical functions of a complete AIS bay

for electrical substations with voltage ratings of up to 420 kV

in a unit with a volume is comparable to that of a conventional

circuit-breaker of equal class.

It takes advantage and widens the scope of the operating philos-

ophy of the PASS series whose dominating factors - those that

have dictated the products success with a proven track record

and a global installed base - are briey outlined below:

1. Relatively inexpensive AIS bus bar:

yet traditionally highly reliable.

2. All live contacts in SF

6

:

experience has shown that AIS disconnector switch con-

tacts require relatively high levels of maintenance whereas

the experience with GIS has been exactly the opposite;

SF

6

technology means less ongoing maintenance;

highly reliable equipment leading to a lower global life

cycle cost.

3. Fewer switching elements:

use of highly reliable GIS style switches allows the

switching elements to be rationalized.

4. Pre-tested in the Factory, also for earthquakes.

5. Competitive installation cost:

time on site minimized;

less risk of delay due to adverse site conditions;

less demand for skilled resources at site.

6. High degree of factory assembly:

higher quality finished bay than one assembled under

on-site conditions.

7. Facilitates monitoring / on-line diagnostics:

integrated nature of the plant facilitates introduction of

Quick and easy erection and commissioning activities

6

Gas density control

Since the dielectric strength of the switchgear and the

breaking capacity of the SF

6

circuit-breaker depend on the

density of the SF

6

gas, a gas density relay is installed to

control gas density and detect leakage.

Voltage transformer

PASS can be equipped with conventional GIS inductive

voltage transformers. Similarly to Current Transformers,

several combinations of windings for protection and

measurements with different loads are available.

Over-pressure relief

A rupture diaphragm (rupture disk) is installed for protection

against excessive over-pressure due to internal arc faults.

When a predetermined overpressure is reached, the

rupture disk will break and relieve the pressure which would

otherwise cause the enclosure itself to break. Deflectors in

front of the diaphragms ensure the safety of personnel.

SF

6

Gas Insulated System

The compact design of the PASS module is due to the

excellent insulation qualities of SF

6

gas. Its dielectric strength

in a homogeneous field is about 2.5 times greater than that

of air at the same temperature and pressure. The design of

the live components is such that the distribution field is as

homogeneous as possible, allowing the intrinsic strength of

the insulating gas to be utilized more efficiently.

Combined disconnector / Earthing switch

PASS is equipped with combined disconnector/earthing

switches. The mechanism has a minimal number of

mechanical components, it is intrinsically reliable and

maintenance-free. All required combinations are possible.

In all PASS versions, the position of the combined

disconnector/earthing switch is clearly shown by an

indicator mechanically coupled to the shaft.

Moreover, visual confirmation can be obtained by means of an inspection

window in the enclosure. The disconnector/earthing switch can also be operated

manually by means of a crank.

Components

7

Circuit-breaker

The PASS circuit-breaker is a single-pressure

interrupter that operates by means of the

well-known self-blast principle. The energy for

breaking currents is partly supplied by the arc

itself, thereby reducing the energy the operating

mechanism has to provide by about 50%

compared with a conventional puffer type circuit-breaker.

Current transformer

PASS is equipped with conventional current transformers

to meet customers requirements. Several combinations of

cores for protection and measurements with different loads

are available.

Up to 5 cores can be fitted into the current transformers.

Bushings

The insulator consists of an epoxy impregnated fiberglass

tube with silicon rubber sheds. The main features are:

high degree of safety (crack and explosion resistant);

low weight;

excellent pollution and rain performance;

sandstorm-resistant;

maintenance-free.

Circuit-breaker drive

BLK is the spring-operated drive for the circuit-breaker,

designed with a minimum number of components.

BLK is available with 2 alternatives:

BLK 82 intended for a single-pole operation in line-bays

where single-phase auto-reclosing is foreseen

(*)

;

BLK 222 intended for three-pole operation

(**)

.

(*)

For PASS M00 version, the BLK82 can operate as for three-pole mechanism.

(**)

For PASS M0S BLK222, it can operate as a single-pole mechanism.

Transport

No special arrangements are needed for

shipping and transportation. PASS fits into

a standard truck container and does not

require any packaging. Once on site, a

simple 30 rotation of the outer poles is

required for the final layout of PASS. The

picture shows PASS 245 kV in the DCB

configuration in the transport position. Its compactness is self-evident.

8

PASS M0

PASS M0 is the best seller of the family:

PASS M0 was the first PASS designed (1999)

and, thanks to its features (compact design,

modularity and reliability), it was immediately

accepted by the electrical market. Since

then, more and more customers have decided

to include PASS M0 in their Distribution

Substation designs: the result is a reference list

of more than 6500 equivalent bays energized

around the world and in very different climatic

conditions. PASS M0 has, in fact, been installed

both in the desert (Saudi Arabia) and in the

Arctic (Russia), indoors and outdoors, on the

roof of buildings (Poland) and underground.

PASS M0 is extremely flexible and meets very

different final customer requirements. It may

therefore have the following configurations:

Single Bus Bar (SBB);

Double Bus Bar (DBB);

In and Out Substation (IOS);

Double Circuit Breaker (DCB).

9

Single Bus Bar, Australia

Double Bus Bar, Norway

Double Circuit Breaker, Italy

In and Out substation, Italy

10

ABB designed PASS M00 in 2003 in order to

meet the specific requirements of the fast-

expanding market for 66 kV and 100 kV systems.

In 2011 a completely new version was

introduced, increasing the short-time breaking

current up to 40 kV, and the maximum

continuous current up to 3150 A.

PASS M00 is smaller in size and weight

than PASS M0 and boasts many innovative

International Patents; the most important of

these is the Rotating breaking chamber

now also applied on PASS M0. In the rotating

breaking chamber the disconnector and

earthing switch moving contacts are installed

directly on the enclosure of the circuit-breaker,

which opens and closes the disconnector and

earthing switches by turning.

All functions of a complete bay are included in

one compact module. Thanks to its small size and

low weight (comparable to a conventional stand-

alone circuit-breaker), PASS M00 needs only one

steel supporting tube. Therefore its installation is

easy in both existing and new substations. Similarly

to PASS M0, PASS M00 can also have different

configurations:

Single Bus Bar;

Double Bus Bar.

PASS M00

11

Single Bus Bar, Italy

Single Bus Bar, Denmark

Double Bus Bar, France

12

PASS M0S 420 kV Double Bus Bar in transport position

PASS M0S 420 kV Double Bus Bar in service position

PASS M0S 252 kV Double Bus Bar

PASS M0S

13

252 kV Double Circuit Breaker, Italy

252 kV Double Bus Bar, Italy

PASS M0S has been designed with all the PASS features in

order to meet the market requirements at 252 and 420 kV.

PASS M0S is fully designed, assembled and tested in the

workshop, according to the PASS philosophy. In addition,

PASS M0S can be transported completely assembled to

the site. This means that no HV test need to be conducted

on site after erection and commissioning,

thus saving a time and money compared to all the other

252 and 420 kV switchgears (GIS, AIS or hybrid).

In the case of the 420 kV module, the goal of being shipped

completely assembled is reached by a simple, safe and

effective tool to perform the rotation of bushings from service

to transportable position, due to a robust sealing interface

capable ensuring tightness during and after rotations.

As usual, PASS M0S is extremely flexible and is available in

the following configurations:

Single Bus Bar (SBB);

Double Bus Bar (DBB);

In and Out Substation (IOS);

Double Circuit Breaker (DCB).

14

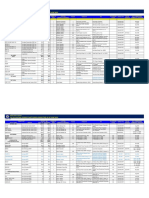

PASS M00 PASS M0 PASS M0S

Rated voltage kV 72.5 100 145 170 252 420

Frequency Hz 50 / 60 50 50 60 50 60 50 / 60

Rated current A 3150 3150 3150 3150 4000 5000

Breaking current kA 40 31.5 50 / 63 63 50 40 50 63

AC test voltage kV 160 185 275 325 460 650

Impulse test voltage BIL kV 350 450 650 750 1050 1425

Operation lightning impulse withstand voltage kV 1050

Altitude above sea level m 1000 1000 1000

Max air temperature C + 40

(1)

+ 40

(1)

+ 40

(1)

Min air temperature C - 40

(1)

- 30

(1)

- 30

(1)

- 25

(1)

Relative humidity % 100 100 100

Wind pressure Pa 700 700 700

Earthquake (IEC 1166) g 0.5 0.5 0.5

Pollution level (IEC 60815) III Heavy

(2)

IV Very Heavy IV Very Heavy

(1)

Different temperatures on request.

(2)

Level IV (very heavy) on request.

PASS Technical Data

15

Environmental impact

PASS is environmentally friendly. It has been designed

in compliance with the philosophy of the PASS project,

which combines functional and reliable systems with use

of highly recyclable, non-energy consuming materials with

low environmental impact. When materials with different

characteristics have to be used, the greatest care is taken

in order to obtain good performances while limiting the

impact on the environment.

The fact that several functions are integrated determines

an equally evident, drastic and global reduction in the

environmental impact. This is because all the materials

used for the typical conventional bay (such as the steel for

supports, the porcelain of the insulators, the concrete of the

foundations, the copper of the conductors and the aluminium

used to connect the components together, etc.) have been

completely eliminated.

Global life cycle costs and impact on the environment were

considered right from the very beginning, when PASS was

designed. Compared to a conventional air insulated solution

which implements the same functions, PASS meets the

following targets:

SF

6

reduced by 80%;

maintenance costs reduced by 38%;

space reduced by 70%;

total life cycle costs less than 60%.

Compared to a conventional 5-bay H layout air insulated

substation, the global life cycle cost for PASS is estimated to

be more than 30% lower.

Moreover, PASS M0 has been subjected to LCA (Life Cycle

Assessment), a study that covers all environmental aspects

during the whole life of the product. In relation to this, the EDP

(Environmental Product Declaration) provides a quantitative

and assessed description of the environmental performance of

PASS, viewed from a comprehensive life cycle perspective.

Complete double busbar substation with PASS M0

16

Life Cycle Cost

The CEI 56-13 Standards that relate to the IEC300-3

Standard act as guidelines when calculating the Life Cycle

Cost (LCC) of a product.

Since 1999, ABB has also been using a calculation

method that allows the cost of the entire life cycle

of an installation to be evaluated (initial cost of the

investment, fixed charges for management and

preventive maintenance, variable costs due to corrective

maintenance following faults).

People who need to compare performances and relative

costs throughout the entire life cycle of the actual product,

and not just the technical aspects, can better understand the

philosophy of PASS: products are no longer considered as

a technological end in themselves, but become part of the

operating context of a process and are strongly linked to its

profitability.

As an example, lets take a conventional bay installed in an

HV/MV substation in an operating cement works: the cost for

lack of production when the system is out of service would be

about 3 times higher than the cost of installing PASS.

Similarly, PASS is more reliable since it is less liable to

become faulty. Moreover, it needs servicing less frequently

throughout the life of the installation and maintenance

work can be carried out much faster. If these features are

considered in relation to the process on the load side of

the installation, it is evident that PASS is able to achieve

remarkably interesting financial savings.

PASS M0 double busbar

17

New features

Motor drive

A motor drive is a digitally controlled motor that

directly moves the circuit-breaker contacts.

ABB has developed a servomotor system with

digital control, able to directly drive the circuit-

breaker contacts in a highly accurate and reliable

way.

The number of moving parts in the drive is reduced

to just one, i.e. the rotating motor shaft.

Description of main functions

Operation of the motor drive can be summarized

in a few simple operations: the rotor is connected

directly to the circuit-breaker drive shaft. The

integrated resolver in the motor continuously

monitors the rotor position.

This information is fed back directly to the

Control Unit. The Control Unit verifies the position

measured, compares it to the position required

at that moment by the pre-programmed travel

curve, and sends further control signals to the

Converter Unit to continue the movement of the

circuit-breaker. This means the circuit-breaker

contacts are precisely controlled during their entire

movement by comparing the feedback data with

the pre-programmed travel curve stored in the

Control Unit memory.

Extensive type test

The motor drive is type tested in accordance with

IEC and ANSI Standards. In view of the largely

electronic nature of the motor drive, the EMC

tests conducted in accordance with IEC and EN

standards are of particular interest.

Simple erection

Installation and commissioning are easy. Each

motor drive is pre-tested and shipped to the

installation site in the form of a few pre-assembled

units.

18

Protection and control

Integration of the protection relay inside the control

cubicle

The idea is to integrate station monitoring with the circuit-

breaker and disconnector control functions into one

commercial high performance protection and control IED.

Voltage and current signals used by the protection unit are

also supplied to the control system without the need for any

additional wiring.

Integration of most of the required functions into one

compact unit is considered a key factor for improving cost/

performance, cubicle/station layout, etc.

Communication (or links) with a remote PC (for supervision

and configuration) or with a remote control room operator is

based on IEC 61850 Standards.

disconnector control functions can be integrated into one

commercial high performance protection and control IED.

The local panel interface is large with robust pushbuttons

and bright signalling lamps for full control and status check.

Each part (command, single line diagram and indication) is

configurable to provide high flexibility and capability.

Installation and commissioning are easy, the cubicle is deliv-

ered already configured, tested and ready to be operative.

UniWire

The UniWire cubicle is designed to replace the traditional

wired logic using electromechanical components with a

programmable logic controller, while maintaining the same

circuit-breaker operating mechanism, DS drive, etc.

The wiring diagrams are simple, the cubicle tidy and mainly

consisting of standardized parts, with a lot of space for the

wiring duct, terminal blocks, and customer equipment.

In addition, station monitoring with the circuit-breaker and

Control unit

I/O rack

Panel

Intended for:

- wiring duct

- terminal blocks

- customer equipment...

New features

19

Quality

ABB designs, manufactures, installs, commissions and services equipment

and Systems for SF

6

insulated High Voltage products.

As part of one of the worlds leading engineering companies, it helps

customers to use electrical power efficiently, to increase industrial

productivity and to lower environmental impact in a sustainable way.

Its mission is to help customers improve their operating performance, grid

reliability and productivity while saving energy and lowering environmental impact.

Our Integrated Management System, in accordance with ISO 9001:2008,

ISO 14001:2004 and OHSAS 18001:1999, states our commitment to providing

Customer satisfaction in a Safe and Environmentally friendly work atmosphere for

employees, customers and neighbours.

To achieve this, operational and supporting processes are constantly monitored

and improved in terms of input/output data, responsibilities, description of

activities and performance indicators.

Through the Quality Control Plan and in accordance with customer specifications,

ABB defines technical references, responsibilities and prescribed controls for each

phase of production, from Incoming Quality Control to Commissioning.

By means of the Environmental Product Declarations (EPD), ABB provides the

necessary information about the environmental performance of the products

during their whole Life Cycle, in compliance with the Standards (Specific Product

Requirements).

20

Activities

Incoming Control

Supplier qualification process

Supplier performance monitoring

Incoming inspection

Statistical process control

Defect monitoring and reporting

Involvement in preventive and corrective actions

Periodical and systematic calibration of all instruments and

equipment

Process Control

Definition of procedures for assembling and testing activities

Monitoring of compliancy with procedures

Defect monitoring and reporting

Involvement in preventive and corrective actions

Final Testing

Testing activities, according to IEC Standards (IEC62271

for HV switchgears, IEC60044 for Instrument Transformers)

or other standards (Gost, ANSI, GB) and, if this is the case,

additional Customer requirements and specifications

Issuing documentation: Routine Test Report, Factory

Acceptance Test Report, Declaration of Conformity

Quality Documentation Management for traceability

Outbound Control

Visual check e completeness of delivery

Monitoring of packing adequacy

Customer Claim Management

Involvement in preventive and corrective actions

Quality

Contact us

For more information please contact:

ABB S.p.A.

Power Products Division

Unit Operativa Adda-HV

Via dei Ceramisti, snc

I-26900 Lodi

Tel: +39 0371 452.1

Fax: +39 0371 452.222

www.abb.com/highvoltage

2

G

J

A

7

0

8

3

9

8

R

e

v

.

D

,

e

n

B

r

o

c

h

u

r

e

P

A

S

S

F

a

m

i

l

y

2

0

1

3

.

0

8

(

m

t

)

Data and illustration without engagement. We reserve

the right to make changes in the course of technical

development.

Copyright 2013 ABB.

All rights reserved.

You might also like

- Pass Family Brochure PDFDocument20 pagesPass Family Brochure PDFdabic_zoranNo ratings yet

- PASS FAMILY Brochure PDFDocument20 pagesPASS FAMILY Brochure PDFHarry RincónNo ratings yet

- Hybrid SwitchgearDocument3 pagesHybrid SwitchgearMahendra KammaNo ratings yet

- Compass: Compact Prefabricated Air Insulated SubstationDocument16 pagesCompass: Compact Prefabricated Air Insulated Substationcarlose_123No ratings yet

- BR Service Onefit CBR (En) - 1vcp000510-1310Document12 pagesBR Service Onefit CBR (En) - 1vcp000510-1310vdaNo ratings yet

- Hybrid Switchgear: Plug and Switch System (PASS)Document2 pagesHybrid Switchgear: Plug and Switch System (PASS)anjes1No ratings yet

- ABB PASS M0S 420kV For Transmission Substation: CIGRE 2016Document8 pagesABB PASS M0S 420kV For Transmission Substation: CIGRE 2016Marko KojicNo ratings yet

- High Voltage Circuit Breakers: For Applications Up To 800 KVDocument12 pagesHigh Voltage Circuit Breakers: For Applications Up To 800 KVnikolalukovicNo ratings yet

- ELK-14C 245 1HC0078221AIEnDocument20 pagesELK-14C 245 1HC0078221AIEnJoel PalomaresNo ratings yet

- Catalogue 1VDD006104 SafeRing - SafePlus 12-24kV - 0912Document82 pagesCatalogue 1VDD006104 SafeRing - SafePlus 12-24kV - 0912Dimitris Zeimpekis100% (1)

- PASS M0S 252 KV: Innovative Solution For Transmission Substation Up To 252 KVDocument8 pagesPASS M0S 252 KV: Innovative Solution For Transmission Substation Up To 252 KVtomquirozNo ratings yet

- Abb RmuDocument88 pagesAbb RmumarkfoyNo ratings yet

- SafeRing SafePlus 12-24kV May 2013 EnglishDocument88 pagesSafeRing SafePlus 12-24kV May 2013 EnglishDubravko100% (1)

- 1VDD006114 Catalogue SR-SP 36kV-EN 12-2019Document100 pages1VDD006114 Catalogue SR-SP 36kV-EN 12-2019ArturNo ratings yet

- ABB Product Note - Condensers - Lowres PDFDocument2 pagesABB Product Note - Condensers - Lowres PDFbudituxNo ratings yet

- ABB TransformersDocument18 pagesABB TransformersEng HamiedNo ratings yet

- 3 High Voltage SwitchgearDocument2 pages3 High Voltage SwitchgearriogadNo ratings yet

- Elk-14 252kv BLKDocument20 pagesElk-14 252kv BLKmaruf048No ratings yet

- HIS 8DQ1 DS e en PDFDocument20 pagesHIS 8DQ1 DS e en PDFTerefe TadesseNo ratings yet

- ABB Cast Resin Dry Type Transformer CATDocument16 pagesABB Cast Resin Dry Type Transformer CATTruong Minh Rang50% (2)

- ELK-14 245S 1HC0078221AAEnDocument24 pagesELK-14 245S 1HC0078221AAEndwas1314No ratings yet

- ABB Ring Main Unit sf6Document8 pagesABB Ring Main Unit sf6Eric SuttonNo ratings yet

- 2600T Pressure Transmitters: Pressure Measurement Made EasyDocument8 pages2600T Pressure Transmitters: Pressure Measurement Made EasyWathroni IndratnoNo ratings yet

- ABB Ring Main Unit Chirag TechnoDocument8 pagesABB Ring Main Unit Chirag TechnoEric SuttonNo ratings yet

- HIS - An Innovative Substation Concept: Special EditionDocument6 pagesHIS - An Innovative Substation Concept: Special EditionMartin HroudnýNo ratings yet

- Abb Pass CompassDocument51 pagesAbb Pass Compassanand_girgaonkar100% (1)

- Siemens MV Gas Insulated Switch GearDocument14 pagesSiemens MV Gas Insulated Switch GearSajesh Thykoodan T VNo ratings yet

- Generator Step Up and System Intertie Power TransformersDocument8 pagesGenerator Step Up and System Intertie Power TransformershansamvNo ratings yet

- Distribution Transformer BrochureDocument8 pagesDistribution Transformer Brochureshashank11No ratings yet

- ALSTOM Gas Insulated Switchgear Solutions Up to 800kVDocument12 pagesALSTOM Gas Insulated Switchgear Solutions Up to 800kVgovindarulNo ratings yet

- Hybrid Substation PDFDocument20 pagesHybrid Substation PDFJayadevDamodaran75% (4)

- (Gas Insulated Switchgear) : Pittsburgh Office: Head OfficeDocument12 pages(Gas Insulated Switchgear) : Pittsburgh Office: Head OfficessappanNo ratings yet

- More Flexibility For The Manufacturing Industry: LI, LD and BD2 Busbar Trunking SystemsDocument8 pagesMore Flexibility For The Manufacturing Industry: LI, LD and BD2 Busbar Trunking Systemscc_bauNo ratings yet

- HYpact Compact HybridDocument24 pagesHYpact Compact HybridMateo Alvez100% (1)

- Disjuntor SiemenesDocument15 pagesDisjuntor SiemenesDaviMiattelloRFNo ratings yet

- 72 - 800 Gas Insulated Switchgear SiemensDocument10 pages72 - 800 Gas Insulated Switchgear Siemensamir17012076No ratings yet

- Catalogue SafeRing - SafePlus 36kV 1VDD006114 GB May 2012Document66 pagesCatalogue SafeRing - SafePlus 36kV 1VDD006114 GB May 2012Natanael HernandezNo ratings yet

- Gas Insulated Switchgear For High Voltage Substations SiemensDocument10 pagesGas Insulated Switchgear For High Voltage Substations SiemenspcelisNo ratings yet

- Abb BrochureDocument12 pagesAbb BrochurewindaidenNo ratings yet

- Hypact: Hybrid Compact Switchgear AssemblyDocument24 pagesHypact: Hybrid Compact Switchgear AssemblyVICTORMARCENo ratings yet

- Abb Reb500Document24 pagesAbb Reb500GuiNo ratings yet

- Hico GisDocument12 pagesHico GisAlejandro UshiñaNo ratings yet

- Reel Direction Spring 2011Document8 pagesReel Direction Spring 2011gl3d3kNo ratings yet

- We Keep Your Motors Running: ABB's New Control and Protection DevicesDocument12 pagesWe Keep Your Motors Running: ABB's New Control and Protection DevicesTagno Miguel MacedoNo ratings yet

- Highly Integrated Gate Drivers for Si and GaN Power TransistorsFrom EverandHighly Integrated Gate Drivers for Si and GaN Power TransistorsNo ratings yet

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Practical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneFrom EverandPractical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneNo ratings yet

- High-Performance D/A-Converters: Application to Digital TransceiversFrom EverandHigh-Performance D/A-Converters: Application to Digital TransceiversNo ratings yet

- The Maplin Electronic Circuits HandbookFrom EverandThe Maplin Electronic Circuits HandbookRating: 4.5 out of 5 stars4.5/5 (6)

- Modelling of Vibrations of Overhead Line Conductors: Assessment of the TechnologyFrom EverandModelling of Vibrations of Overhead Line Conductors: Assessment of the TechnologyGiorgio DianaNo ratings yet

- Automated Broad and Narrow Band Impedance Matching for RF and Microwave CircuitsFrom EverandAutomated Broad and Narrow Band Impedance Matching for RF and Microwave CircuitsNo ratings yet

- Overcurrent Relay Advances for Modern Electricity NetworksFrom EverandOvercurrent Relay Advances for Modern Electricity NetworksNo ratings yet

- Millimeter-Wave Digitally Intensive Frequency Generation in CMOSFrom EverandMillimeter-Wave Digitally Intensive Frequency Generation in CMOSNo ratings yet

- Arduino Measurements in Science: Advanced Techniques and Data ProjectsFrom EverandArduino Measurements in Science: Advanced Techniques and Data ProjectsNo ratings yet

- SG5 Power Switch Gears AssembliesDocument13 pagesSG5 Power Switch Gears AssemblieshansamvNo ratings yet

- Stds 19 0004 00 PUBS 3002 8Document79 pagesStds 19 0004 00 PUBS 3002 8Leander ChuaNo ratings yet

- Nema Ics 6Document24 pagesNema Ics 6hansamv100% (1)

- Luzon Committed 2019 Jan DecemberDocument7 pagesLuzon Committed 2019 Jan DecemberhansamvNo ratings yet

- PhotoDocument1 pagePhotohansamvNo ratings yet

- SPCS Order 758 Sudden Pressure Report Final 02132014 PDFDocument34 pagesSPCS Order 758 Sudden Pressure Report Final 02132014 PDFhansamvNo ratings yet

- Iec60364 PDFDocument105 pagesIec60364 PDFMircea Murar60% (5)

- TextDocument2 pagesTexthansamvNo ratings yet

- White PaperDocument16 pagesWhite PaperhansamvNo ratings yet

- C57 19 100 1995 PDFDocument30 pagesC57 19 100 1995 PDFhansamvNo ratings yet

- Eliminate Problematic and Momentary Relay Actions: Qualitrol 909Document4 pagesEliminate Problematic and Momentary Relay Actions: Qualitrol 909AbdulJabbarSethar50% (2)

- PAGASADocument1 pagePAGASAhansamvNo ratings yet

- Ansi C 119.4 PDFDocument28 pagesAnsi C 119.4 PDFIngJGMNo ratings yet

- Write Up 2 AttachmentDocument2 pagesWrite Up 2 AttachmenthansamvNo ratings yet

- Buy AirPods With Wireless Charging Case - Apple (PH)Document1 pageBuy AirPods With Wireless Charging Case - Apple (PH)hansamvNo ratings yet

- Appendixe 1 STR 1386 TestsDocument7 pagesAppendixe 1 STR 1386 TestshansamvNo ratings yet

- PhotoDocument1 pagePhotohansamvNo ratings yet

- Luzon Committed Oct 2018Document6 pagesLuzon Committed Oct 2018hansamvNo ratings yet

- Development of Natural EsterDocument15 pagesDevelopment of Natural Esterrdwchy100% (1)

- White PaperDocument16 pagesWhite PaperhansamvNo ratings yet

- Ansi C 119.4 PDFDocument28 pagesAnsi C 119.4 PDFIngJGMNo ratings yet

- Battery Room Ventilation and SafetyDocument62 pagesBattery Room Ventilation and SafetyingatvNo ratings yet

- Solar TechDocument31 pagesSolar TechhansamvNo ratings yet

- Solar TechDocument31 pagesSolar TechhansamvNo ratings yet

- SPCS Order 758 Sudden Pressure Report Final 02132014 PDFDocument34 pagesSPCS Order 758 Sudden Pressure Report Final 02132014 PDFhansamvNo ratings yet

- Itce16 Mohammad TariqDocument41 pagesItce16 Mohammad TariqhansamvNo ratings yet

- SPCS Order 758 Sudden Pressure Report Final 02132014 PDFDocument34 pagesSPCS Order 758 Sudden Pressure Report Final 02132014 PDFhansamvNo ratings yet

- List of Existing Power Plants (Grid-Connected) As of June 2019Document5 pagesList of Existing Power Plants (Grid-Connected) As of June 2019hansamvNo ratings yet

- PGC Inquiries Chapter 7 Grid ProtectionDocument7 pagesPGC Inquiries Chapter 7 Grid ProtectionhansamvNo ratings yet

- Mercalco PDFDocument33 pagesMercalco PDFBethylGoNo ratings yet

- Engg Multiple Choice Questions - Instruments and MeasurementDocument21 pagesEngg Multiple Choice Questions - Instruments and MeasurementVishwanath Brungi100% (1)

- Bushing Test ErrorsDocument7 pagesBushing Test ErrorsKarthik SriramakavachamNo ratings yet

- Summer TrainingDocument33 pagesSummer TrainingRUCHI JAISWALNo ratings yet

- Mineral Insulating Oils in Electrical Equipment-Supervision and Maintenance Guidance (IEC 60422, Ed. 4.0 (2013) MOD)Document10 pagesMineral Insulating Oils in Electrical Equipment-Supervision and Maintenance Guidance (IEC 60422, Ed. 4.0 (2013) MOD)Quality Assurance Team APTranscoNo ratings yet

- Study of 220kv Network in Visakhapatnam Steel PlantDocument19 pagesStudy of 220kv Network in Visakhapatnam Steel Plantsudhialamanda100% (1)

- Impact of Slot Discharges and Vibration Sparking On Stator Winding Life in Large GeneratorsDocument8 pagesImpact of Slot Discharges and Vibration Sparking On Stator Winding Life in Large GeneratorsShanjiNo ratings yet

- REF Stabilizing Resistor CalculationsDocument8 pagesREF Stabilizing Resistor CalculationsmaheshNo ratings yet

- Logical Node Classes & DataDocument47 pagesLogical Node Classes & Datank1224No ratings yet

- 600W PFC Power Supply For Audio AmplifierDocument37 pages600W PFC Power Supply For Audio Amplifierpgamez833No ratings yet

- Nyeri Solar PV Project Grid Study - Report PDFDocument87 pagesNyeri Solar PV Project Grid Study - Report PDFAmos NabaalaNo ratings yet

- How To Build A Simple But Powerful Flyback DriverDocument8 pagesHow To Build A Simple But Powerful Flyback DriverGabriel Droguett OleaNo ratings yet

- Understanding The TV Horizontal Output Stage: Key ComponentsDocument4 pagesUnderstanding The TV Horizontal Output Stage: Key ComponentsakulimeNo ratings yet

- PSCAD IntroductionDocument72 pagesPSCAD IntroductionksbwingsNo ratings yet

- Basic Electronics, Volumes 1-5, (1955) - Text PDFDocument570 pagesBasic Electronics, Volumes 1-5, (1955) - Text PDFfrankNo ratings yet

- Type FEC Epoxy Encapsulated, Copper-Wound Industrial Control TransformersDocument12 pagesType FEC Epoxy Encapsulated, Copper-Wound Industrial Control TransformersTOLENTINONo ratings yet

- BIRLA INSTITUTE OF TECHNOLOGY MESRA, DEOGHAR Campus Assignment SheetDocument27 pagesBIRLA INSTITUTE OF TECHNOLOGY MESRA, DEOGHAR Campus Assignment SheetDevansh PratapNo ratings yet

- Sverker 900: Relay and Substation Test SystemDocument7 pagesSverker 900: Relay and Substation Test SystemchinnathambijNo ratings yet

- National Grid Malaysia Power SystemDocument10 pagesNational Grid Malaysia Power SystemDa Harlequin GalNo ratings yet

- Guideline For Adoption of CMEN Earthing System: Purpose and ScopeDocument14 pagesGuideline For Adoption of CMEN Earthing System: Purpose and ScopeTerex14253No ratings yet

- Simple RF Remote Control Circuit Without Microcontroller - Electronic Circuit ProjectsDocument8 pagesSimple RF Remote Control Circuit Without Microcontroller - Electronic Circuit Projectserbc111No ratings yet

- r7210102 Electrical and Electronics EngineeringDocument1 pager7210102 Electrical and Electronics EngineeringsivabharathamurthyNo ratings yet

- Simulation of Parallel Resonance Condition in ElectricalDocument6 pagesSimulation of Parallel Resonance Condition in ElectricalyaoNo ratings yet

- STR2A100 Series Application Note (Rev.0.3) : Sanken Electric Co., LTDDocument18 pagesSTR2A100 Series Application Note (Rev.0.3) : Sanken Electric Co., LTDАлександр АндриановNo ratings yet

- 15 Dinora 115557 PDFDocument91 pages15 Dinora 115557 PDFMadhur GuptaNo ratings yet

- ABB High Voltage Testing TechquniesDocument101 pagesABB High Voltage Testing Techquniescisnatel100% (1)

- TManual Chapter 01Document23 pagesTManual Chapter 01abhayambujNo ratings yet

- ABB NI 40 Relay Operation Manual Datasheet & Applicatoin Notes - Datasheet ArchiveDocument16 pagesABB NI 40 Relay Operation Manual Datasheet & Applicatoin Notes - Datasheet ArchiveUjjal ChakmaNo ratings yet

- Type SSM Medium Voltage 2300 - 13,800V: SoftstartersDocument5 pagesType SSM Medium Voltage 2300 - 13,800V: SoftstartersJavier AffifNo ratings yet

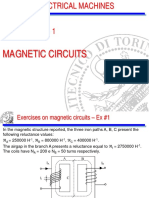

- Exercises On ELECTRICAL MACHINESDocument29 pagesExercises On ELECTRICAL MACHINESDavide100% (1)

- Induction HeatingDocument33 pagesInduction Heatingdallisrinivas14No ratings yet