Professional Documents

Culture Documents

Environmental Characteristics and Derating Factors for MCCBs in Various Conditions

Uploaded by

Long LeoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Environmental Characteristics and Derating Factors for MCCBs in Various Conditions

Uploaded by

Long LeoCopyright:

Available Formats

66

8. ENVIRONMENTAL CHARACTERISTICS

Table 8.1 Abnormal Environments, and Countermeasures

8.1 Atmospheric Environment

Abnormal environments may adversely affect perfor-

mance, service life, insulation and other aspects of

MCCB quality. Where service conditions differ sub-

stantially from the specified range as below, derating

of performance levels may result.

1. Ambient temperature range 10C~+40C (Average

temperature for 24 hours,

however, shal l not be

higher than 35C.)

2. Relative humidity 85% max. with no dewing

3. Altitude 2,000m max.

4. Ambient No excessive water or oil

vapour, smoke, dust, salt

content, corrosive sub-

stance, vibration, and im-

pact

Expected servi ce l i fe

(MTTF) under the above

conditions is 15 years.

8.1.1 High Temperature Application

To comply with relevant standards, all circuit break-

ers are calibrated at 40C. If the circuit breaker is to

be used in an environment where the ambient tem-

perature is likely to exceed 40C please apply the de-

rating factor shown in table 8.2.

For example: To select a circuit breaker for use on a

system where the full load current is 70A in an ambi-

ent temperature at 50C then from table 8.2

0.9

70A

= 77.8A

Select a circuit breaker with a trip unit adjustable from

80-100A or fixed at 100A.

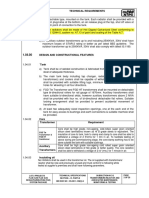

Table 8.2 MCCB Derating

Ambient Temperature (C)

50

55

60

Derating factor

0.9

0.8

0.7

High temperature

Low temperature

High humidity

High altitude

Dirt and dust

Corrosive gas, salt air

Environment Trouble Countermeasures

1. Nuisance tripping

2. Insulation deterioration

1. Condensation and freezing

2. Low-temperature fragility in shipping

(around 40C)

1. Insulation resistance loss

2. Corrosion

1. Reduced temperature, otherwise no

problem up to 2,000m

1. Contact discontinuity

2. Impaired mechanism movement

3. Insulation resistance loss

1. Corrosion

1. Reduce load current (derate).

2. Avoid ambients above 60C.

1. Install heater for defrosting and drying.

2. Ship tripped, or if not possible, OFF.

1. Use MCCB enclosure such as Type W.

2. Inspect frequently, or install high-

corrosion-resistant MCCBs.

1. See Low temperature, above.

1. Use Type MCCB enclosure.

1. Use Type W MCCB enclosure or install

high-corrosion-resistant MCCBs.

5:

67

8.1.2 Low Temperature Application

In conditions where temperatures reach as low as

5C special MCCBs are usually required. Mitsubishi,

however, have tested their standard MCCBs to tem-

peratures as low as 10C without any detrimental

effects.

For conditions where temperatures drop below

10C special MCCBs must be used.

If standard MCCBs experience a sudden change

from high temperature, high humidity conditions to low

temperature conditions, there is a possibility of ice

forming inside the mechanism. In such conditions we

recommend that some form of heating be made avail-

able to prevent mal-operation.

In conditions of low temperature MCCBs should

be stored in either the tripped or OFF position.

Low Temperature MCCBs

Special low temperature MCCBs are available that

can withstand conditions where temperatures fall to

as low as 40C. These special MCCBs are available

in sizes up to 1200A in the standard series and above

50A in the compact series.

8.1.3 High Humidity

In conditions of high humidity the insulation resistance

to earth will be reduced as will the electrical life.

For applications where the relative humidity ex-

ceeds 85% the MCCB must be specially prepared or

special enclosures used. Special preparation includes

plating all metal parts to avoid corrosion and special

painting of insulating parts to avoid the build up of

mildew.

There are two degrees of tropicalisation:

Treatment 1- painting of insulating material to avoid

build up of mildew plus special plating

of metal parts to avoid corrosion.

Treatment 2- painting of insulating material to avoid

build up of mildew only.

8.1.4 Corrosive Atmospheres

In the environment containing much corrosive gas, it

is advisable to use MCCB of added corrosion resis-

tive specifications.

For the breakers of added corrosionproof type,

corrosion-proof plating is applied to the metal parts.

Where concentration of corrosive gas exceeds the

level stated below, it is necessary to use MCCB of

added corrosion resistive type being enclosed in a

water-proof type enclosure or in any enclosure of pro-

tective structure.

Allowable containment for corrosive gas.

H

2

S 0.01ppm SO

2

0.05ppm

NH

3

0.25ppm

8.1.5 Affecting of Altitude

When MCCBs are used at altitudes exceeding 2000m

above sea level, the effects of a drop in pressure and

drop in temperature will affect the operating perfor-

mance of the MCCBs. At an altitude of 2200m, the air

pressure will drop to 80% and it drops to 50% at

5500m, however interrupting capacity is unaffected.

The derating factors that are applicable for high alti-

tude applications are shown in table 8.3. (According

to ANSI C 37.29-1970)

Table 8.3 Derating Factors for High Altitude Appli-

cations

Altitude

3000m

4000m

5000m

6000m

Rated current

0.98

0.96

0.94

0.92

Rated voltage

0.91

0.82

0.73

0.65

For example: NF800-SEW on 4000m

1. Voltage

The rated operating voltage is AC690V. You should

derate by 690x0.82=565.8V. It means that you can

use this NF800-SEW up to AC565.8V rated voltage.

2. Current

The rated current is 800A. You should derate by

800x0.96=768A. It means that you can use this

NF800-SEW up to 768A rated current.

8.2 Vibration-Withstand Characteristics

8.2.1 The Condition of Test

1. Installation position and Direction of vibration

Every vertical and horizontal at vertical installed

(as shown in Fig. 8.1)

2. The position of MCCBs and vibration time

Forty minutes in each position (ON, OFF and TRIP)

3. Vibration criteria

Frequency 10~100Hz

Vibration acceleration 22 m/s

2

Period 10min./cycle

8.2.2 The Result of Test

The samples must show no damage and no change

of operating characteristic (200% release), and must

not be tripped or switched off by the vibration.

Vertical

Wire

connection

Horizontal

Fig. 8.1 Applied Vibration

68

8.3 Shock-Withstand Characteristics

8.3.1 The Condition of Test

1. MCCBs are drop-tested, as described in Fig. 8.2.

The arrows show the drop direction.

2. The samples are set to ON, with no current flow-

ing.

8.3.2 The Result of Test (as Shown in Table 8.4)

The samples must show no physical damage, and

the switched condition must not be changed by the

drop in any of the drop-attitudes tested.

The judgment of failure:

A case the switched condition changed from ON

to OFF

A case the switched condition changed from ON

to Trip

A case the sample shows physical damage

Table 8.4 Shock-Withstand Characteristics of Mitsubishi MCCB

Line terminals

Line terminals

Fig. 8.2 Drop-Test Attitudes

Type

BH-K BH-P, BH-S, BH-PS, BH-D

MB30-CS

MB30-SW MB50-CW MB50-SW

MB100-SW MB225-SW

NF32-SW NF63-HW NF63-SW NF125-SW

NF125-SGW NF125-HW NF125-HGW NF160-SW

NF160-SGW NF160-HW NF160-HGW NF250-SW

NF250-SGW NF250-HW NF250-HGW

NF400-SW NF400-SEW NF400-HEW NF400-REW

NF630-SW NF630-SEW NF630-HEW NF630-REW

NF800-SDW NF800-SEW NF800-HEW NF800-REW

NF1000-SEW NF1250-SEW

NF1600-SEW

NF30-CS

NF63-CW

NF125-CW NF250-CW NF400-CW NF630-CW

NF800-CW

NF125-RGW NF125-UGW NF250-RGW

NF250-UGW NF400-UEW NF800-UEW

No tripped

(m/s

2

)

147

147

196

196

147

196

196

196

No damage

(m/s

2

)

490

Series

BH

MB

NF

C

U

S

You might also like

- PC8AHXS Buyers GuideDocument6 pagesPC8AHXS Buyers GuidekkrishnamoorthyNo ratings yet

- 3089-99 RCCB F660Document16 pages3089-99 RCCB F660Nguyen SonNo ratings yet

- Technical Description Td-95/3 400 KV, 30 Mvar or 50 Mvar or 60 Mvar Shunt ReactorsDocument25 pagesTechnical Description Td-95/3 400 KV, 30 Mvar or 50 Mvar or 60 Mvar Shunt ReactorsK Vijay Bhaskar ReddyNo ratings yet

- Finder General Technical Information enDocument14 pagesFinder General Technical Information enenerconNo ratings yet

- FRS LED Indoor Lighting Specifications EOIDocument10 pagesFRS LED Indoor Lighting Specifications EOIManish GuptaNo ratings yet

- 1-04-012-11 - 0 TrafoDocument9 pages1-04-012-11 - 0 TrafonishantpsbNo ratings yet

- Gold Capacitors: Electric Double Layer CapacitorsDocument28 pagesGold Capacitors: Electric Double Layer Capacitorsgiapy0000No ratings yet

- Low voltage air-breaker 600V below Molded Case Circuit BreakerDocument19 pagesLow voltage air-breaker 600V below Molded Case Circuit BreakeronyekaNo ratings yet

- Motor Protection Circuit BreakersDocument25 pagesMotor Protection Circuit Breakersrajpre1213No ratings yet

- 011 - 2008 - Medium Voltage (36 Ka) Surge ArrestersDocument10 pages011 - 2008 - Medium Voltage (36 Ka) Surge Arresterse09341No ratings yet

- L&T MPCBDocument25 pagesL&T MPCBjoydeep_d3232No ratings yet

- Surge Arrest Test ProceduresDocument11 pagesSurge Arrest Test Proceduresmarevey100% (3)

- HF2100 enDocument4 pagesHF2100 enBhakti PermanaNo ratings yet

- AMS-24kV-En Instruction ManualDocument10 pagesAMS-24kV-En Instruction ManualLê Nguyên TríNo ratings yet

- Motor Protection Circuit BreakersDocument24 pagesMotor Protection Circuit Breakerschirags_99No ratings yet

- Accutrim™ 1240 (RJ26 Style) : Vishay Foil ResistorsDocument5 pagesAccutrim™ 1240 (RJ26 Style) : Vishay Foil ResistorsSlavaSH2No ratings yet

- Electrical SpecificationDocument40 pagesElectrical SpecificationChandrasekar KaruppasamyNo ratings yet

- 33mva TransformerDocument6 pages33mva TransformerJoule BarkNo ratings yet

- Off Load Tap Changer - Part 1Document20 pagesOff Load Tap Changer - Part 1Moncoz Aye100% (3)

- Oil-Filled Transformer Guide for Steel IndustryDocument9 pagesOil-Filled Transformer Guide for Steel IndustryRAPRATSINNo ratings yet

- Technical Specification For 20 MVA Transformer PDFDocument21 pagesTechnical Specification For 20 MVA Transformer PDFamulya00428100% (10)

- Reference Specification: 175 C Operation Leaded MLCC For Automotive With AEC-Q200 RHS SeriesDocument17 pagesReference Specification: 175 C Operation Leaded MLCC For Automotive With AEC-Q200 RHS SeriesDanish Ur RahmanNo ratings yet

- K2Series DS 1015370 5 20141104Document4 pagesK2Series DS 1015370 5 20141104曾乙申No ratings yet

- MV Distribution TransformersDocument11 pagesMV Distribution TransformerswaseemsamsodienNo ratings yet

- Hermetically Sealed RelayDocument12 pagesHermetically Sealed RelayTejas JasaniNo ratings yet

- G9EB-1-B-AQ: Capable of Interrupting High-Voltage, High-Current LoadsDocument2 pagesG9EB-1-B-AQ: Capable of Interrupting High-Voltage, High-Current LoadsNandam SrinivasNo ratings yet

- Breaker Basics: MCCB Technology and Enhanced ProtectionDocument65 pagesBreaker Basics: MCCB Technology and Enhanced ProtectionArunachalam Nagarajan100% (1)

- Guidelines for selecting aluminium electrolytic capacitorsDocument4 pagesGuidelines for selecting aluminium electrolytic capacitorsHenry PalNo ratings yet

- Technical Data and Applications of RCCBsDocument16 pagesTechnical Data and Applications of RCCBsfndprojectNo ratings yet

- Circuit Breakers PresentationDocument108 pagesCircuit Breakers PresentationMAHMOUD MOHAMEDNo ratings yet

- 19th Electrical Engineering Safety Seminar Nov.09 - Arc Fault ContainmentDocument36 pages19th Electrical Engineering Safety Seminar Nov.09 - Arc Fault ContainmentramtgemNo ratings yet

- Maintaining Industrial Sector Electricity SupplyDocument36 pagesMaintaining Industrial Sector Electricity SupplyAvi OjhaNo ratings yet

- Ee Full Catalogue PDFDocument19 pagesEe Full Catalogue PDFDaya SagarNo ratings yet

- Instruction Manual: 5COR469100 - BR25AT - REV00Document8 pagesInstruction Manual: 5COR469100 - BR25AT - REV00Javier SalaNo ratings yet

- OPzV 3000 - High performance lead-acid battery for renewable energy applicationsDocument2 pagesOPzV 3000 - High performance lead-acid battery for renewable energy applicationscandaruchoNo ratings yet

- Maintenance-Free Design 8DABDocument5 pagesMaintenance-Free Design 8DABrjk941-1No ratings yet

- Sensor de Temperatura LM50Document8 pagesSensor de Temperatura LM50Erick Dos SantosNo ratings yet

- NTPC SpecsDocument2 pagesNTPC SpecsxiaomiNo ratings yet

- RFL 9550 Line TrapDocument12 pagesRFL 9550 Line TrapSINU0607IITEEENo ratings yet

- TFR CommissioningDocument24 pagesTFR CommissioningKrishna DNo ratings yet

- Motores Norma VDE-530 para AislamientosDocument9 pagesMotores Norma VDE-530 para Aislamientosjcorona71No ratings yet

- (New Models) : New Super MK Relays. Models With Latching Lever Added To The SeriesDocument9 pages(New Models) : New Super MK Relays. Models With Latching Lever Added To The SeriesCak AndiNo ratings yet

- Siemens - Tyco V23084 C2001 A303Document5 pagesSiemens - Tyco V23084 C2001 A303meda меда100% (1)

- Schneider Releu NivelDocument8 pagesSchneider Releu NivelDan MircescuNo ratings yet

- Protective Devices & MaintenanceDocument77 pagesProtective Devices & MaintenanceAbin Paul67% (3)

- Finder CatalogueDocument18 pagesFinder CatalogueGeorge GeorgeNo ratings yet

- Distribution Transformer Maintenance and ProtectionDocument77 pagesDistribution Transformer Maintenance and ProtectionAbin PaulNo ratings yet

- Ampacity of 230kV Taungoo-Loikaw LineDocument6 pagesAmpacity of 230kV Taungoo-Loikaw Line정상진No ratings yet

- Sharp 25KM100 TV Service ManualDocument48 pagesSharp 25KM100 TV Service ManualferdialvascribdNo ratings yet

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Boat Maintenance Companions: Electrics & Diesel Companions at SeaFrom EverandBoat Maintenance Companions: Electrics & Diesel Companions at SeaNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- 1SAJ520000R0101 Umc100 FBP 0 Universal Motor Controller Replaces 1saj520000r0100Document3 pages1SAJ520000R0101 Umc100 FBP 0 Universal Motor Controller Replaces 1saj520000r0100Long LeoNo ratings yet

- Equipment Damage Curves CapacitorsDocument2 pagesEquipment Damage Curves CapacitorsLong LeoNo ratings yet

- Comm Vs Industrial Ups Tech PaperDocument8 pagesComm Vs Industrial Ups Tech PaperssatgrNo ratings yet

- Ge Critical Power Ep Ups DatasheetDocument2 pagesGe Critical Power Ep Ups DatasheetLong LeoNo ratings yet

- Equipment Damage Curves ConductorsDocument4 pagesEquipment Damage Curves ConductorsLong LeoNo ratings yet

- 1SVR405651R3400 CR m4sfb Standard Socket Fork Type For 2c o or 4c o CR M RelayDocument1 page1SVR405651R3400 CR m4sfb Standard Socket Fork Type For 2c o or 4c o CR M RelayLong LeoNo ratings yet

- GJH1213001R7221 k6s 22z 1 7 71 Mini Contactor Relay 24vdc 1 7wDocument3 pagesGJH1213001R7221 k6s 22z 1 7 71 Mini Contactor Relay 24vdc 1 7wLong LeoNo ratings yet

- Sade-5tnrjr r2 enDocument10 pagesSade-5tnrjr r2 enlostris234No ratings yet

- 41 2131 0212Document10 pages41 2131 0212sachin_vjtiNo ratings yet

- Vigirex Installaiton GuideDocument23 pagesVigirex Installaiton GuideLong LeoNo ratings yet

- 1SFA611100R1002 mp1 10g PushbuttonDocument2 pages1SFA611100R1002 mp1 10g PushbuttonLong LeoNo ratings yet

- Equipment Damage Curves Generators PDFDocument4 pagesEquipment Damage Curves Generators PDFLong LeoNo ratings yet

- 2gcs301013b0030 CLMD BrochureDocument12 pages2gcs301013b0030 CLMD BrochureLong LeoNo ratings yet

- 1SFA611605R1101 MCBH 10 Contact BlockDocument3 pages1SFA611605R1101 MCBH 10 Contact BlockLong LeoNo ratings yet

- ANGEN - En006 Restricted Earth Fault ProtectionDocument5 pagesANGEN - En006 Restricted Earth Fault Protectionriddler_007No ratings yet

- TGN Restricted Earth Fault v1 - 0Document40 pagesTGN Restricted Earth Fault v1 - 0Anonymous dqbb02DUhNo ratings yet

- Overcurrent Coordination Basics CablesDocument3 pagesOvercurrent Coordination Basics CablesLong LeoNo ratings yet

- Using Utility Data Performing Arc Flash Hazard Analysis (SKM)Document8 pagesUsing Utility Data Performing Arc Flash Hazard Analysis (SKM)RudanekNo ratings yet

- Overcurrent Coordination Basics ConductorsDocument5 pagesOvercurrent Coordination Basics ConductorsLong LeoNo ratings yet

- Overcurrent Coordination Basics CapacitorsDocument3 pagesOvercurrent Coordination Basics CapacitorsLong LeoNo ratings yet

- Equipment Damage Curves MotorsDocument4 pagesEquipment Damage Curves MotorsLong LeoNo ratings yet

- Equipment Damage Curves GeneratorsDocument4 pagesEquipment Damage Curves GeneratorsLong LeoNo ratings yet

- Equipment Damage Curves TransformersDocument6 pagesEquipment Damage Curves TransformersLong LeoNo ratings yet

- Overcurrent Coordination Basics GeneratorsDocument3 pagesOvercurrent Coordination Basics GeneratorsLong LeoNo ratings yet

- MNF VJ160Document1 pageMNF VJ160Long LeoNo ratings yet

- Overcurrent Coordination Basics MotorsDocument6 pagesOvercurrent Coordination Basics MotorsLong LeoNo ratings yet

- Account Manager LD DF PDDocument1 pageAccount Manager LD DF PDLong LeoNo ratings yet

- Arc Flash Considerations For Data Center IT SpaceDocument12 pagesArc Flash Considerations For Data Center IT SpaceLong LeoNo ratings yet

- Diversifying The Tech BoomDocument5 pagesDiversifying The Tech BoomLong LeoNo ratings yet

- A New Method of Voltage Sag and Swell Detection: Raj Naidoo, Member, IEEE, and Pragasen Pillay, Fellow, IEEEDocument8 pagesA New Method of Voltage Sag and Swell Detection: Raj Naidoo, Member, IEEE, and Pragasen Pillay, Fellow, IEEEjcrodriguez83No ratings yet