Professional Documents

Culture Documents

371 03

Uploaded by

Vinh Do ThanhOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

371 03

Uploaded by

Vinh Do ThanhCopyright:

Available Formats

Transactions of JWRI, Vol. 37 (2008), No.

1

13

Process Optimization to Prepare High-purity Amorphous Silica

from Rice Husks via Citric Acid Leaching Treatment

UMEDA Junko* and KONDOH Katsuyoshi**

Abstract

Rice husks or straws, one of the main agricultural wastes in South-east Asia, have a large possibility to be

employed as usefully renewable resources to produce energy and high-purity silica (SiO

2

), because they consist

of about 70% organics such as cellulose or hemi-cellulose, and 20% amorphous SiO

2

. The former is utilized as

bio-mass energy; for example, thermal or electric energy, and bio-mass ethanol. High-purity silica can be used

as raw materials in industrial application. It would be possible to extract silica elements from rice husks and

straws by burning them in air because their main contents are organics. In the previous studies, a strong acid

leaching treatment on rice husks before burning was carried out by using H

2

SO

4

, HCl and HNO

3

to prepare

high-purity silica materials. This was available to accelerate the hydrolysis of celluloses and hemicelluloses

contained in rice husks, and remove the above metallic impurities. A strong acid leaching treatment, however, is

significantly hazardous to environment and human life, and causes an increase of the process cost. In this study,

an environmentally benign, harmless to human and economically effective process to produce high-purity

amorphous SiO

2

materials from rice husks has been established without using strong acids. From a viewpoint of

being a harmless influence on the human body, carboxylic acids were used in the leaching treatment on rice

husks. TG-DTA measurement and GCMS analysis indicated that the leaching was effective for the hydrolysis of

celluloses and hemicelluloses contained in rice husks at 473K~873K, and produced the same results as using the

conventional sulfuric acid. The metallic impurities could be also removed from the husks via a chelate reaction

between carboxyl groups (-COOH) and the metal elements. In particular, it was clarified that cadmium (Cd) as

completely removed from rice straws by this reaction. Concerning the burning conditions of rice husks after the

acid leaching, it was necessary to supply a suitable amount of air to completely combust organics; for example it

required an air supplement of 50 ml/min. or more. The burning temperature should be less than 1273K to obtain

amorphous structured silica. High-purity amorphous silica materials with 99% or more purity were prepared

from rice husks by applying the citric acid leaching treatment and burning process at 1073K in air.

KEY WORDS: (High-Purity Silica) (Amorphous) (Rice Husks) (Citric Acid Leaching) (Chelate) (DTA)

(GCMS)

1. Introduction

Rice husks and straws are agricultural wastes

produced in a large amount, and their annual world

production amounts to about 80 million tons

1)

. The major

constituents of rice husks are ashes and organics such as

cellulose, hemi-cellulose and lignin. The former mainly

consists of silica and some metal impurities. The silicon

(Si) atoms exist in the protuberances and hairs on the

outer and inner epidermis of the rice husks

2)

. Extensive

researches have been carried out to extract SiO

2

elements

from rice husks

3-5)

, because high-purity silica is a useful

raw material for industrial application. In the previous

studies, the strong acid leaching treatment was carried out

on rice husks to remove metallic impurities and organics

contained in them. Sulfuric acid (H

2

SO

4

), hydrochloric

acid (HCl) and nitric acid (HNO

3

) solutions are

conventionally used in leaching

6,7)

. They are, however,

significantly hazardous to the environment and humans.

The strong acid leaching treatment also has an

economical problem due to a necessary use of expensive

materials with corrosion resistance to strong acids, water

rinsing of husks, and a special disposal treatment of used

strong acids. In this study, an environmentally benign,

harmless to humans and economical process to produce

high-purity amorphous SiO

2

from rice husks has been

established by using the carboxylic acid leaching

treatment. TG-DTA (Thermogravimetry-Differential

Received on July 11, 2008

* Specially Appointed Researcher

** Professor

Transactions of JWRI is published by Joining and Welding

Research Institute, Osaka University, Ibaraki, Osaka 567-0047,

Japan

Process Optimization to Prepare High-purity Amorphous Silica from Rice Husks

14

Thermal Analysis) measurement and GCMS (Gas

Chromatograph Mass Spectrometer) analysis were used

to clarify the effect of the hydrolysis of the organic

contents and its mechanism. The effect of air

supplements in burning acid-leached husks was

investigated to purify the silica element of ashes. XRD

analysis was carried out on rice husk ashes to optimize

the burning temperature and prepare amorphous

structured silica. For the evaluation of the carboxyl group

(-COOH) of organic acids in removing metallic

impurities via a chelate reaction, the citric acid leaching

treatment was applied to rice straws containing cadmium

(Cd), and the reduction effect was discussed.

2. Experimental Procedure

The raw materials of rice husks harvested in Niigata,

Japan are employed, and submitted to the carboxylic acid

leaching treatment using citric acid (C

6

H

8

O

7

). Sulfuric

acid solution is also used as the comparison in the

leaching treatment. 20g husks are sunk in the acid

solution of 500ml for 15min. Each concentration is 5%,

and temperature is controlled at 50 C. The waster rinsing

treatment on acid-leached husks was carried out to

remove the acid solution from rice husks. The repetition

number of the water rinsing after the leaching by citric

acid and sulfuric acid is three time and eight times,

respectively. The water-rinsed materials are dried at 100

C for 3.6s in the electric furnace. As mentioned above,

the main content of rice husks is cellulose and

hemicellulose. First of all, the thermal resolution

temperature of the cellulose powder, having a mean

particle size of 58m, was measured by TG-DTA

equipment (Shimadzu DTG-60). In the case of rice husks,

the same analysis was applied to evaluate the thermal

resolution behavior. In particular, from the viewpoint of

the hydrolysis of some organics in husks, its reactivity

can be discussed quantitatively by the comparison of the

exothermic heat in the TG-DTA profile. This indicates

that when the cellulose and hemicellulose have atomic

structure changes from the polysaccharide to

monosaccharide via a hydrolysis, the exothermic heat

was reduced. The optimization of the air supplement in

the burning process of rice husks was also evaluated by

the exothermic heat of the TG-DTA profiles. It was

controlled from 0 to 150 ml/min., and argon (Ar) gas is

used as the comparison in this analysis. It was measured

from 20C to 1000C with heating ratio of 10C/min. To

investigate the atomic structure changes of cellulose and

hemicellulose by the acid leaching, GCMS analysis

(Agilent 5973N) was applied to the specimens after

heating at 200C for 360s, 400C for 60s and 600C for 6s.

The hydrolysis behavior of the organics contained in the

acid-leached husks at each sampling temperature can be

also examined by the identification of the mass spectra

and their intensities. The burning process of dried husks

was conducted at 600~1150C in air to remove the

organics from rice husks. The dependence of the

crystallization of the silica elements on the burning

temperature was examined by X-ray Diffraction (XRD)

analysis (Shimadzu XRD-6100). The content of SiO

2

,

carbon and other metal impurities included in the rice

husk ashes were investigated by XRF (X-ray

fluorescence) and ICP (Inductively Coupled Plasma)

analysis.

3. Results and Discussion

3.1 Hydrolysis of organics by citric acid leaching

Rice husks and straws are comprised of cellulose,

hemicellulose and lignin. The previous work indicated

that hemicellulose and lignin are rapidly digested by a

short time acid leaching treatment while cellulose is only

partially digested

8)

. This means a high degree of

resistance of the residual cellulose in the husks towards

the acid digestion. Therefore, in this study, the hydrolysis

of cellulose of rice husks by citric acid leaching treatment

is discussed in detail. Figure 1 shows two DTA profiles

of the conventional cellulose powders under the air and

Ar gas flow condition with a flow ratio of both is 150

ml/min. In the air supplement, the profile indicates two

exothermic heats with the maximum peak temperature at

355C and 505C by the complete combustion, which

corresponds well to the previous results

8)

. At the same

time, the drastic weight loss occurs due to their thermal

degradation. On the other hand, when using Ar gas

atmosphere, it reveals an endothermic heat at the peak

temperature of 345C due to its carbonization without

combustion. Figure 2 reveals DTA profiles of rice husks

with the citric acid (a), sulfuric acid (b) leaching, and no

treatment (c). The initial temperature of the first

exothermic heat due to the thermal degradation of

organics in all materials is about 200~220C, and lower

than that of the cellulose (270C) shown in Fig.1 (a). This

may be attributed to the content of hemicellulose and

lignin elements in rice husks, that have significant

influences on the initial temperature of the thermal

degradation. They show two exothermic heat peaks,

which have the same maximum points at 335~350C and

450~470C, respectively. In comparing the heat values,

the difference between (a) and (b) is very little, but (c)

has a significantly small heat compared to another.

-100

-50

0

50

100

150

200

250

0 200 400 600 800 1000

(a) Air supplement

(b) Ar gas

Temperature, T /

D

T

A

/

V

-100

-50

0

50

100

150

200

250

0 200 400 600 800 1000

(a) Air supplement

(b) Ar gas

Temperature, T /

D

T

A

/

V

Fig.1 DTA profiles of cellulose measured in air (a) and

argon gas atmosphere (b).

Transactions of JWRI, Vol. 37 (2008), No. 1

15

The measurement of the total exothermic heat of

each specimen is shown in Table 1. The reduction of the

exothermic heat in using acid-leached rice husks is about

17~28% against that of raw materials without any

leaching treatment. The color of every specimen after

TG-DTA analysis is completely white, that is, the ashes

are high-purity silica materials. These results mean that

the acid leaching treatment has the possibility of

accelerating the hydrolysis of organics contained in rice

husks. For the investigation of this reaction behavior,

GCMS analysis was carried out on each specimen. The

heating conditions before the analysis were 200C for

360s, 400C for 60s and 600C for 6s in air. Figure 3

shows GCMS results of rice husks after hot water rinsing

at 50C (a), and 5% citric acid leaching at 50C (b) when

using a heating condition of 200C for 360s. Spectra ,

and correspond to furfurals (C

4

H

3

O), and

levoglucosan, respectively. In both specimens, the

spectrum is very small, and no formation of

levoglucosan is detected by heating each material at 200C

for 360s. Table 2 indicates the ion intensity of peak

and of each rice husks. The maximum intensity of

both peaks in using the citric acid leached materials is

about 4~10 times those of hot water rinsed specimens. In

general, hemicelluloses, composing the cell wall, change

to D-xylose (C

5

H

10

O

5

) via a hydrolysis, and it forms

furfurals by a dehydration reaction. In the TG-DTA

profile of as-received raw rice husks, no weight reduction

and no heat was detected until 200C.

This means no effect of the heat treatment less than 200C

on the above hydrolysis of organics in rice husks.

Accordingly, the citric acid leaching treatment of husks is

effective in accelerating the atomic structure change of

their hemicellulose to furfural via the hydrolysis and

dehydration. Figure 4 indicates GCMS results of hot

water rinsed (a), and acid-leached materials (b) and (c)

after heating 400C for 60s. In all the specimens, the peaks

and are detected, and the difference of their ion

intensities is very small. That is, the above hydrolysis to

produce furfurals is carried out when heating rice husks at

400C. Concerning the peak , corresponding to the

formation of levoglucosan, (a) shows an extremely small

peak intensity, and very few products of levoglucosan.

On the other hand, the peak is clearly detected in the

specimen (b) and (c). The ion intensity, however, is not

Table 1 Comparison of exothermic heat values of DTA

profiles of each rice husks.

Citric acid

leached

Sulfuric acid

leached

As-received

(raw material)

N=1

N=2

39.5

38.0

31.4

33.3

27.3

28.9

28.1 32.4 38.8 Ave.

Citric acid

leached

Sulfuric acid

leached

As-received

(raw material)

N=1

N=2

39.5

38.0

31.4

33.3

27.3

28.9

28.1 32.4 38.8 Ave.

Table 2 Ion intensity of GCMS analysis on rice husks via

citric acid and hot water leaching.

Intensity of

total ion

Max. intensity

of peak

1.35*10

9

Max. intensity

of peak

Citric acid

N=2

Hot water

N=1 2.16*10

9

2.15*10

9

2.35*10

6

8.51*10

6

8.22*10

6

3.82*10

5

4.22*10

6

4.06*10

6

Intensity of

total ion

Max. intensity

of peak

1.35*10

9

Max. intensity

of peak

Citric acid

N=2

Hot water

N=1

Citric acid

N=2

Hot water

N=1 2.16*10

9

2.15*10

9

2.35*10

6

8.51*10

6

8.22*10

6

3.82*10

5

4.22*10

6

4.06*10

6

0

3

6

9

12

0 2 4 6 8 10 12 14 16

Retention time, t / min

(b) Citric acid leached

A

b

u

n

d

a

n

c

e

/

r

e

l

.

u

O

O

O

O

O

Furfural

0

3

6

9

12

0 2 4 6 8 10 12 14 16

A

b

u

n

d

a

n

c

e

/

r

e

l

.

u

Retention time, t / min

O

O

O

O

O

Furfural

(a) Hot water leached

0

3

6

9

12

0 2 4 6 8 10 12 14 16

Retention time, t / min

(b) Citric acid leached

A

b

u

n

d

a

n

c

e

/

r

e

l

.

u

O

O

O

O

O

Furfural

0

3

6

9

12

0 2 4 6 8 10 12 14 16

Retention time, t / min

(b) Citric acid leached

A

b

u

n

d

a

n

c

e

/

r

e

l

.

u

O

O

O

O

O

Furfural

O

O

O

O

O

Furfural

0

3

6

9

12

0 2 4 6 8 10 12 14 16

A

b

u

n

d

a

n

c

e

/

r

e

l

.

u

Retention time, t / min

O

O

O

O

O

Furfural

(a) Hot water leached

0

3

6

9

12

0 2 4 6 8 10 12 14 16

A

b

u

n

d

a

n

c

e

/

r

e

l

.

u

Retention time, t / min

O

O

O

O

O

Furfural

O

O

O

O

O

Furfural

(a) Hot water leached

Fig.3 GCMS results of rice husks via citric acid leaching

and hot water rinsing (200C for 360s).

Fig.2 DTA profile of rice husks with citric acid (a) and

sulfuric acid leaching (b) compared to as-received raw

materials (c).

-50

0

50

100

150

200

250

300

0 200 400 600 800 1000 1200

(c) As-received husks

(with no acid leaching)

(a) 5% citric acid leached

Air supplement150ml/min.

(b) 5% sulfuric acid leached

Temperature, T /

D

T

A

/

V

-50

0

50

100

150

200

250

300

0 200 400 600 800 1000 1200

(c) As-received husks

(with no acid leaching)

(a) 5% citric acid leached

Air supplement150ml/min.

(b) 5% sulfuric acid leached

Temperature, T /

D

T

A

/

V

Process Optimization to Prepare High-purity Amorphous Silica from Rice Husks

16

so different between these two values. This means that

the citric acid leaching is also effective for the hydrolysis

of the cellulose contained in husks to produce

levoglucosan, and its effect is almost same as that via the

sulfuric acid leaching. Figure 5 shows DTA profiles of

5% citric acid-leached rice husks when changing the air

supplement in the analysis. In the case of 50 ml/min. or

more, there is no change of the profile with the typical

two exothermic heats as mentioned above. When

reducing the air supplement to 20 ml/min., the

exothermic heat value is reduced. Finally, the profile

reveals the endothermic heat at 350C with no air

supplement in the analysis, and the color of the burned

specimen remaining in the alumina cup is black. The

others indicated pure white ashes. This result suggests

that a suitable air supplement with 50 ml/min. or more is

necessary to completely combust the organics of rice

husks, and insufficient air in burning causes the

carbonization of organics at 300~400C.

3.2 Reduction of metallic impurities by chelate

reaction of carboxyl groups

In general, rice husks and straws contain the

metallic impurities of about 0.8~1% such as Potassium

(K), Calcium (Ca), Sodium (Na), Phosphorus (P),

Aluminum (Al), etc. According to the soil contents, some

hazardous metal elements may be included in them. It is

reported that alkali metal impurities of K and Na cause

the remained carbons in ashes, which are originated in

organics of husks. This is because the eutectic reaction

between the alkali metals and SiO

2

element occurs in

burning, and the carbon remains in the melt SiO

2

9, 10)

. It

is well known the chelate reaction of carboxyl groups

(-COOH) with metal elements easily occurs, and their

metal complexes are formed

11)

. In this study, the effect of

the citric acid with carboxyl groups on the removal of

metal impurities contained in rice husks and straws was

investigated. Three kinds of rice straws, which included

Cadmium (Cd) contents of 0, 23ppm and 82ppm, were

prepared as raw materials. They were also submitted to

the citric acid leaching treatment at 50C for 900s. The

concentration of the acid solution was 5% and 20%. Cd

contents of acid leached straws and used solutions

measured by ICP optical emission spectrometer

(HORIBA, ULTIMA-2) are shown in Table 3. With

increasing the Cd content of raw straws that of used citric

acid solution after leaching gradually increases. The color

of the solutions changes to dark orange due to the eluted

Cd complexes. After the leaching treatment, the Cd

content of each straw is less than 0.001ppm, which is the

lowest limitation by ICP analysis when using 5% and

20% concentration. That is, the citric acid leaching is

significantly effective in removing Cd elements via a

chelate reaction from rice straws. By using the chelate of

carboxyl groups of organic acids, the metallic impurities

of rice husks are reduced. For example, the leaching

treatment by 5% citric acid and 5% oxalic acid solutions

is carried out at 50C on rice husks. After water rinsing

and drying in air, the acid leached materials are burned in

air at 800C for 3.6 ks. The air supplement is 150 ml/min.

Raw rice husks without any leaching treatment were also

used to prepare their ashes as a comparison. Table 4

indicates chemical compositions of rice husk ashes via

each leaching process. When using no acid leaching

treatment, a lot of metallic oxides remain in the ashes as

impurities. In particular, it is difficult to reduce K

2

O and

Table 3 Cd contents of raw materials, used citric acid solutions

and rice straw ashes by ICP analysis.

Material A Material B Material C

Raw materials

Used citric

acid solution

5%

20%

Rice straw

ashes

5%

20%

~0 23 82

~0 0.085 0.383

~0 0.087 0.411

~0

~0

~0

~0

~0

~0

Material A Material B Material C

Raw materials

Used citric

acid solution

5%

20%

Rice straw

ashes

5%

20%

~0 23 82

~0 0.085 0.383

~0 0.087 0.411

~0

~0

~0

~0

~0

~0

A

b

u

n

d

a

n

c

e

/

r

e

l

.

u

Retention time, t / min

0

1

2

3

4

0 2 4 6 8 10 12 14 16

(b) Citric acid leached

O

OH

OH

OH

O

Levoglucosan

0 2 4 6 8 10 12 14 16

A

b

u

n

d

a

n

c

e

/

r

e

l

.

u

1

2

3

4

0

(a) Hot water leached

O

OH

OH

OH

O

Levoglucosan

Retention time, t / min

0 2 4 6 8 10 12 14 16

A

b

u

n

d

a

n

c

e

/

r

e

l

.

u

1

2

3

4

0

Retention time, t / min

O

OH

OH

OH

O

Levoglucosan

(c) Sulfuric acid leached

A

b

u

n

d

a

n

c

e

/

r

e

l

.

u

Retention time, t / min

0

1

2

3

4

0 2 4 6 8 10 12 14 16

(b) Citric acid leached

O

OH

OH

OH

O

Levoglucosan

A

b

u

n

d

a

n

c

e

/

r

e

l

.

u

Retention time, t / min

0

1

2

3

4

0 2 4 6 8 10 12 14 16 0 2 4 6 8 10 12 14 16

(b) Citric acid leached

O

OH

OH

OH

O

Levoglucosan

0 2 4 6 8 10 12 14 16

A

b

u

n

d

a

n

c

e

/

r

e

l

.

u

1

2

3

4

0

(a) Hot water leached

O

OH

OH

OH

O

Levoglucosan

Retention time, t / min

0 2 4 6 8 10 12 14 16 0 2 4 6 8 10 12 14 16

A

b

u

n

d

a

n

c

e

/

r

e

l

.

u

1

2

3

4

0

(a) Hot water leached

O

OH

OH

OH

O

Levoglucosan

Retention time, t / min

0 2 4 6 8 10 12 14 16

A

b

u

n

d

a

n

c

e

/

r

e

l

.

u

1

2

3

4

0

Retention time, t / min

O

OH

OH

OH

O

Levoglucosan

(c) Sulfuric acid leached

0 2 4 6 8 10 12 14 16 0 2 4 6 8 10 12 14 16

A

b

u

n

d

a

n

c

e

/

r

e

l

.

u

1

2

3

4

0

Retention time, t / min

O

OH

OH

OH

O

Levoglucosan

(c) Sulfuric acid leached

Fig.4 GCMS results of rice husks via citric acid leaching

and hot water rinsing (400C for 60s).

-200

-150

-100

-50

0

50

100

150

200

0 200 400 600 800 1000

150ml/min. 50ml/min.

20ml/min.

0ml/min. 0ml/min.

Temperature, T /

D

T

A

/

V

5%citric acid leached rice husks

-200

-150

-100

-50

0

50

100

150

200

0 200 400 600 800 1000

150ml/min. 50ml/min.

20ml/min.

0ml/min. 0ml/min.

Temperature, T /

D

T

A

/

V

5%citric acid leached rice husks

Fig.5 DTA profiles of citric acid leached rice husks measured

under various air supplement flow rate.

Transactions of JWRI, Vol. 37 (2008), No. 1

17

CaO, which cause the remaining carbon after burning as

mentioned above, from rice husk ashes. As a result, the

SiO

2

content of ashes is 94.6%, and their color is black

and dark gray. On the other hand, both citric and oxalic

acid leaching treatments are significantly better at

removing these impurities and remaining carbon. The

white ashes have a high-purity of silica with 99% or

more.

3.3 Combustion temperature of rice husks

It is important to prepare high-purity SiO

2

ashes

with amorphous structures from rice husks, because

IARC (International Agency for Research on Cancer),

one part of WHO (World Health Organization), strongly

points that the crystal SiO

2

particles have carcinogenic

risks to humans

12)

, and belong to Group 1. The structure

of rice husk ash strongly depends on the burning

temperature. Figure 6 shows XRD profiles of the ashes

of citric acid leached rice husks after burned at various

temperatures in air. It indicates that the changes from

originally amorphous structures to crystal ones occur by

burning the husks at 1323K or more. The rice husk ashes

include crystallized silica materials with trydymite and

cristobalite structures

13)

.

4. Conclusion

The recycling process of rice husks with a high

safety and economical benefits was developed to produce

high purity amorphous silica materials. It consists of a

citric acid leaching and an air-combustion process. The

acid leaching treatment is effective in accelerating the

hydrolysis of cellulose of rice husks and reducing

metallic impurities by the chelate action of the carboxyl

groups. A suitable air supplement from 200 to 600C is

important to completely combust the organics of husks.

The optimized burning temperature of acid leached rice

husks is less than 1073K to prepare amorphous silica

materials.

Acknowledgement

This study was supported by Research &

Technology Development on Waste Management

Research Grant, Ministry of the Environment.

References

1) N. Yelcin and V. Sevinc: Ceramics International 27

(2001), 219.

2) B. D. Park, S. G. Wi, K. H. Lee, A. P. Singh, T. H. Yoon

and Y. S. Kim: Biomass and Bioenergy 25 (2003), 319.

3) M. Nehdi, J. D. Quette and A. E. Damatty : Cement

Concrete Res. 33 (2003), 1203.

4) R. V. Krishnarao and M. M. Godkhindi: Ceramics

International 18 (1992), 185.

5) M. K. Naskar and M. Chatterjee: J. Eu. Ceramics Soc. 24

(2004), 3499.

6) A. Chakraverti, P. Mishra and H. D. Banergee: J.

Materials Science 23 (1988), 21.

7) N. Yalcin and V. Sevinc: Ceramics International 27

(2001), 219.

8) I. A. Rahman, J. Ismail and H. Osman: Journal of Material

Chemistry, 7 (1997), 1505-1509.

9) Concha Real, Maria D. Alcala and Jose M. Criado:

Journal of the American Ceramic Society, 79 (1996),

2012-2016.

10) A. M. Venezia and V. La Parola: Journal of Solid State

Chemistry, 161 (2001), 373-378.

11) G. R. Lenz and A. E. Martell: Biochemistry, 3 (1964),

750-753.

12) IARC Monographs on the Evaluation of Carcinogenic

Risks to Humans, Vol58 (1993), pp.41-61.

13) Y. Shinohara and N. Kohyama: Industrial Health, 42

(2004), 277-285.

Table 4 Chemical compositions of rice husk ashes burned at 800C via carboxylic acid leaching and without any treatment.

SiO

2

Al

2

O

3

MgO Na

2

O P

2

O

5

S K

2

O CaO Mn Fe

2

O

3

BaO Carbon

Without leaching 94.58 0.02 0.31 0.11 0.41 0.11 3.69 0.56 0.08 0.04 0.04 0.61

Citric acid leaching 99.14 0.03 0.08 0.06 0.29 0.03 0.12 0.16 0.01 0.03 0.03 0.09

Sulfuric acid leaching

90.99 0.01 0.06 0.07 0.31 0.05 0.11 0.37 0.01 0.02 0.03 0.12

SiO

2

Al

2

O

3

MgO Na

2

O P

2

O

5

S K

2

O CaO Mn Fe

2

O

3

BaO Carbon

Without leaching 94.58 0.02 0.31 0.11 0.41 0.11 3.69 0.56 0.08 0.04 0.04 0.61

Citric acid leaching 99.14 0.03 0.08 0.06 0.29 0.03 0.12 0.16 0.01 0.03 0.03 0.09

Sulfuric acid leaching

90.99 0.01 0.06 0.07 0.31 0.05 0.11 0.37 0.01 0.02 0.03 0.12

1150

1100

1000

20 30 40 50 60

I

n

t

e

n

s

i

t

y

(

a

.

u

.

)

Diffraction Angle, 2/

SiO

2

5% citric acid leached husk

900

800

700

600

1150

1100

1000

20 30 40 50 60

I

n

t

e

n

s

i

t

y

(

a

.

u

.

)

Diffraction Angle, 2/

SiO

2

5% citric acid leached husk

900

800

700

600

Fig.6 XRD profiles of rice husk ashes of citric acid leached

rice husks after burned at various temperatures in air.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- SBI - Certificate To Be Submitted by Pensioner - ChandigarhDocument1 pageSBI - Certificate To Be Submitted by Pensioner - ChandigarhMsinghNo ratings yet

- Medical PhysicsDocument81 pagesMedical Physicsroni roniNo ratings yet

- Ansi B16-104Document1 pageAnsi B16-104Monica Suarez100% (1)

- 5 S Principles ExplainedDocument30 pages5 S Principles Explainedamaresh nkNo ratings yet

- Isolation and Characterization of Galactomannan From Sugar PalmDocument4 pagesIsolation and Characterization of Galactomannan From Sugar PalmRafaél Berroya Navárro100% (1)

- Diploma Pharmacy First Year - Hap - MCQSDocument13 pagesDiploma Pharmacy First Year - Hap - MCQSAnitha Mary Dambale91% (33)

- Review On Development of Polypropylene Manufacturing ProcessDocument11 pagesReview On Development of Polypropylene Manufacturing ProcessShweta Yadav100% (1)

- Proper Air-Fuel Ratios for Starting, Idling, Accelerating & MoreDocument9 pagesProper Air-Fuel Ratios for Starting, Idling, Accelerating & MoreVinh Do ThanhNo ratings yet

- Modeling and Simulation of A Co-Current Rotary Dryer Under Steady ConditionsDocument8 pagesModeling and Simulation of A Co-Current Rotary Dryer Under Steady ConditionsVinh Do ThanhNo ratings yet

- Air-Fuel Ratio, Lambda and Engine Performance: AFR M MDocument12 pagesAir-Fuel Ratio, Lambda and Engine Performance: AFR M MVinh Do ThanhNo ratings yet

- Dryer CalculationsDocument4 pagesDryer CalculationsVinh Do Thanh0% (1)

- Effects of Drying Parameters On Heat Transfer During DryingDocument13 pagesEffects of Drying Parameters On Heat Transfer During DryingVinh Do ThanhNo ratings yet

- Studies On Drying Kinetics of Solids in A Rotary DryerDocument6 pagesStudies On Drying Kinetics of Solids in A Rotary DryerVinh Do ThanhNo ratings yet

- Modelling and Simulation of A Direct Contact Rotary DryerDocument16 pagesModelling and Simulation of A Direct Contact Rotary DryerVinh Do ThanhNo ratings yet

- 4244 12672 1 PB PDFDocument15 pages4244 12672 1 PB PDFVinh Do ThanhNo ratings yet

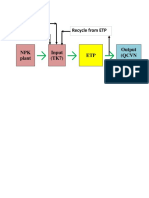

- Recycle From ETP Make Up H2O DAP, UreaDocument1 pageRecycle From ETP Make Up H2O DAP, UreaVinh Do ThanhNo ratings yet

- The Heart of Operations - World Cement - 02-2015Document4 pagesThe Heart of Operations - World Cement - 02-2015fetniNo ratings yet

- 4244 12672 1 PB PDFDocument15 pages4244 12672 1 PB PDFVinh Do ThanhNo ratings yet

- Aoac - Methods.1.1990. MoistureDocument2 pagesAoac - Methods.1.1990. MoistureVinh Do ThanhNo ratings yet

- NPK-15 8 15Document5 pagesNPK-15 8 15Vinh Do ThanhNo ratings yet

- Multi-Use Chair DesignDocument7 pagesMulti-Use Chair DesignVinh Do ThanhNo ratings yet

- PEP Report 267A: Ihs ChemicalDocument8 pagesPEP Report 267A: Ihs ChemicalVinh Do ThanhNo ratings yet

- Tinh Luong Nuoc Bay HoiDocument22 pagesTinh Luong Nuoc Bay HoiVinh Do ThanhNo ratings yet

- DRS 279-2015 Organic Fertilizer - SpecificationDocument17 pagesDRS 279-2015 Organic Fertilizer - SpecificationVinh Do ThanhNo ratings yet

- Natural Evaporation RateDocument16 pagesNatural Evaporation RateVinh Do ThanhNo ratings yet

- Equivalent Grades of Cast IronsDocument2 pagesEquivalent Grades of Cast IronsVinh Do ThanhNo ratings yet

- How To Calculate Heat Load - 5 StepsDocument1 pageHow To Calculate Heat Load - 5 StepsVinh Do ThanhNo ratings yet

- Mau Giay Uy Quyen Bang Tieng AnhDocument3 pagesMau Giay Uy Quyen Bang Tieng AnhVinh Do ThanhNo ratings yet

- Metal Price IndexDocument1 pageMetal Price IndexVinh Do ThanhNo ratings yet

- CRACKER A PC Based Simulator For Industr PDFDocument6 pagesCRACKER A PC Based Simulator For Industr PDFVinh Do ThanhNo ratings yet

- 1 0ProjectManagementProceduresDocument8 pages1 0ProjectManagementProceduresRamiesRahmanNo ratings yet

- Estimating Evaporation From Water SurfacesDocument27 pagesEstimating Evaporation From Water SurfacesVinh Do ThanhNo ratings yet

- Optimization of Wall Thickness For Minimum Heat LossesDocument9 pagesOptimization of Wall Thickness For Minimum Heat LossesVinh Do ThanhNo ratings yet

- How To Calculate Heat Load - 5 StepsDocument1 pageHow To Calculate Heat Load - 5 StepsVinh Do ThanhNo ratings yet

- Investigation of Sensible Heat Storage and Heat Insulation in The Exploitation of Concentrated Solar EnergyDocument5 pagesInvestigation of Sensible Heat Storage and Heat Insulation in The Exploitation of Concentrated Solar EnergyradanpetricaNo ratings yet

- Undas Deployment PadsDocument15 pagesUndas Deployment PadsVic NairaNo ratings yet

- Energy-Exergy Performance Evaluation of New HFO Refrigerants in The Modified Vapour Compression Refrigeration SystemsDocument9 pagesEnergy-Exergy Performance Evaluation of New HFO Refrigerants in The Modified Vapour Compression Refrigeration SystemsIjrei JournalNo ratings yet

- Schneider - Cptg010 en (Print)Document16 pagesSchneider - Cptg010 en (Print)el_koptan00857693No ratings yet

- The Truth About EtawahDocument4 pagesThe Truth About EtawahPoojaDasgupta100% (1)

- (9F) Ankle - Bones, Joints, Tendons and LigamentsDocument4 pages(9F) Ankle - Bones, Joints, Tendons and LigamentsJeffrey RamosNo ratings yet

- Chambal Cable Stayed Bridge Connecting ShoresDocument6 pagesChambal Cable Stayed Bridge Connecting Shoresafzal taiNo ratings yet

- T1D Report September 2023Document212 pagesT1D Report September 2023Andrei BombardieruNo ratings yet

- EMI InstructionsDocument2 pagesEMI InstructionsAKSHAY ANANDNo ratings yet

- H1 Revision Notes DNA and GenomicsDocument6 pagesH1 Revision Notes DNA and GenomicsJiaLi XieNo ratings yet

- Jamec Air FittingsDocument18 pagesJamec Air Fittingsgoeez1No ratings yet

- Rainer M. Holm-Hadulla, Alina Bertolino: Use of Drugs by Jazz MusiciansDocument3 pagesRainer M. Holm-Hadulla, Alina Bertolino: Use of Drugs by Jazz MusiciansTitikshaNo ratings yet

- Personal Chiller 6-Can Mini Refrigerator, Pink K4Document1 pagePersonal Chiller 6-Can Mini Refrigerator, Pink K4Keyla SierraNo ratings yet

- Vastra Grah .Pvt. LTD: In-House Manufacturing FacaltyDocument2 pagesVastra Grah .Pvt. LTD: In-House Manufacturing FacaltySaurabh JainNo ratings yet

- Density of Aggregates: ObjectivesDocument4 pagesDensity of Aggregates: ObjectivesKit Gerald EliasNo ratings yet

- Role of Homeostasis in Human Physiology A ReviewDocument5 pagesRole of Homeostasis in Human Physiology A ReviewNathaly ZiékteNo ratings yet

- Presente Continuo Present ContinuosDocument4 pagesPresente Continuo Present ContinuosClaudio AntonioNo ratings yet

- Cement Evaluation CAST-CBL HalliburtonDocument36 pagesCement Evaluation CAST-CBL HalliburtonrezaNo ratings yet

- Assessing Inclusive Ed-PhilDocument18 pagesAssessing Inclusive Ed-PhilElla MaglunobNo ratings yet

- Myofascial Release for Piriformis MyalgiaDocument14 pagesMyofascial Release for Piriformis MyalgiaApoorvNo ratings yet

- Lesson 5 - The Problem of EvilDocument10 pagesLesson 5 - The Problem of Evilsemmerson4896No ratings yet

- Multiple Sentences and Service of PenaltyDocument5 pagesMultiple Sentences and Service of PenaltyAngelNo ratings yet

- PGAU - BOHC2018-05 - 20pg - Lowres - Leader Cable AAC Conductor Data PDFDocument20 pagesPGAU - BOHC2018-05 - 20pg - Lowres - Leader Cable AAC Conductor Data PDFKelly chatNo ratings yet

- Homework 5 - 2020 - 01 - v3 - YH (v3) - ALV (v2)Document5 pagesHomework 5 - 2020 - 01 - v3 - YH (v3) - ALV (v2)CARLOS DIDIER GÓMEZ ARCOSNo ratings yet

- Mimosa-by-Airspan-C5c Hoja de EspecificacionesDocument2 pagesMimosa-by-Airspan-C5c Hoja de EspecificacionesJuan atzinNo ratings yet

- Rundingan Perdagangan Antara Malaysia Dan Indonesia Di Wisma Putra, Kuala Lumpur 1967Document15 pagesRundingan Perdagangan Antara Malaysia Dan Indonesia Di Wisma Putra, Kuala Lumpur 1967nixyingboNo ratings yet