Professional Documents

Culture Documents

Part 15

Uploaded by

Vikas PatelOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Part 15

Uploaded by

Vikas PatelCopyright:

Available Formats

15 - 1

Texas Instruments Incorporated

European Customer Training Centre

University of Applied Sciences Zwickau (FH)

Module 15 : C28x Digital Motor Control

32-Bit-Digital Signal Controller

TMS320F2812

15 - 2

Electrical Motor families

Motor Classification:

Direct Current Motors (DC)

Alternating Current Motors (AC)

Asynchronous Induction Motor (ACI)

Permanent Magnet Synchronous Motor

(PMSM)

Synchronous Brushless DC Motor (BLDC)

15 - 3

3 Phase - Motor (PMSM)

For most three phase machines, the winding is stationery, and

magnetic field is rotating

Three phase machines have three stator windings, separated

120 apart physically

Three phase stator windings produce three magnetic fields,

which are spaced 120in time

=

=

=

3

4

3

2

.

.

.

t

e

t

e

e

t j

S c

t j

S b

t j

s a

e I i

e I i

e I i

=

=

=

O

O

O

3

4

3

2

.

.

.

t

t

t jp

c

t jp

b

t jp

a

e E e

e E e

e E e

N

S

a

c

b

i

a

i

c

i

b

15 - 4

-1,50

-1,00

-0,50

0,00

0,50

1,00

1,50

1 24 47 70 93 116 139 162 185 208 231 254 277 300 323 346

et

ia ib

ic

Phase currents

A`

A

Fa

B

C

`

C

B`

ia

Fb

Fc

Three stationary pulsating magnetic fields

The three phase winding

produces three magnetic

fields, which are spaced

120 apart physically.

When excited with three

sine waves that are a 120

apart in phase, there are

three pulsating magnetic

fields.

The resultant of the three

magnetic fields is a rotating

magnetic field.

3 Phase - Motor

15 - 5

Rotor is carrying a constant

magnetic field created either

by permanent magnets or

current fed coils

The interaction between the

rotating stator flux, and the

rotor flux produces a torque

which will cause the motor to

rotate.

The rotation of the rotor in this case will be at the same exact

frequency as the applied excitation to the rotor.

This is synchronous operation.

Rotor field

A`

B

C`

A

B`

C

N

S

|

Stator field

S

N

Synchronous Motor

phase per pair poles motor : p

(Hz) frequency supply AC :

(r.pm)

. 60

: (rad/s) speed Rotor

f

p

f

gives

p

e

= O

Example: a 2 poles pair

synchronous motor will

run at 1500 r.pm for a

50Hz AC supply

frequency

15 - 6

Both (typically) have permanent-magnet rotor and a

wound stator

BLDC (Brushless DC) motor is a permanent-magnet

brushless motor with trapezoidal back EMF

PMSM (Permanent-magnet synchronous motor) is a

permanent-magnet brushless motor with sinusoidal

back EMF

30

0

90

0

150

0

210

0

270

0

330

0

30

0

90

0

60

0

0

0

120

0

180

0

240

0

300

0

360

0

60

0

Phase A

Phase B

Phase C

i

a

i

b

i

c

u

e

u

e

u

e

E

a

Hall A

Hall B

Hall C

Back EMF of BLDC Motor

et

ea eb

ec

Back EMF of PMSM

A

`

B

C

`

A

B

`

C

N

S

F

F

Synchronous Motors: BLDC and PMSM

-1,50

-1,00

-0,50

0,00

0,50

1,00

1,50

1 24 47 70 93 116 139 162 185 208 231 254 277 300 323 346

15 - 7

Power

Switching

Devices

3 - phase

outputs to motor

terminals

+

Upper & lower

devices can not

be turned on

simultaneously

(dead band)

Six PWM signals

to control

Power Switches

DC - Voltage

3 Phase Voltage Inverter

15 - 8

Scalar Control Scheme ( V/f )

e*

PI

3-

Phase

Inverter

PWM

Command

E

+

PWM1

PWM2

PWM3

PWM5

PWM4

PWM6

V

f

V/f profile

Speed scaling

Speed calculator

+ Simple to implement: All you need is three sine

waves feeding the motor

+ Position information not required (optional).

Doesnt deliver good dynamic performance.

Torque delivery not optimized for all speeds

15 - 9

Field Oriented Control (FOC)

Field Oriented Control (FOC) or Vector

Control, is a control strategy for 3-phases

induction motors where the torque

producing and magnetizing components

of the stator flux are separately

controlled.

The approach consists in imitating the

DC motors operation

FOC will be possible with system

information: currents, voltages, flux and

speed.

15 - 10

FOC control scheme

Some key mathematical components are required!

e

PID

d,q

a,b,c

3-

Phase

Inverter

Space

Vector

PWM

E E

V

q

V

d

V

Q

V

D

i

a

i

b

I

q

I

d

I

Q

I

D

I

Q

I

D

+

+

+

e

r

q

r

i

c

: i

a

+ i

b

+ i

c

= 0

PWM1

D,Q

d,q

Park T

Clarke T

E

q

r

PWM2

PWM3

PWM5

PWM4

PWM6

Field Weakening

Controller

Speed

Calculator

Inverse Park

D,Q

d,q

PID

PID

15 - 11

PARK transform (1929):

(Vs): voltage vector applied

to motor stator (index s)

(

(

(

=

3

2

1

) (

S

s

s

S

v

v

v

V

Park transform is a referential change

| | | |

(

(

(

=

(

(

(

(

(

(

=

(

(

(

(

(

(

(

(

(

(

(

(

=

(

(

(

3

2

1

1

3

2

1

3

2

1

) ( and . ) (

1 )

3

4

sin( )

3

4

cos(

1 )

3

2

sin( )

3

2

cos(

1 sin cos

S

S

s

S

So

Sq

sd

so

sq

sd

S

S

S

s

So

Sq

sd

S S

S S

S S

s

s

s

v

v

v

P

v

v

v

v

v

v

P

v

v

v

v

v

v

v

v

v

u u

t

u

t

u

t

u

t

u

u u

1 s

v

3 s

v

2 s

v

sd

v

sq

v

0 =

so

v

t

S S

e u =

15 - 12

Park Transform key components

1 s

v

3 s

v

2 s

v

sd

v

sq

v

0 =

so

v

t

S S

e u =

(v

sd,

v

sq,

v

so

) are called the Park coordinates

v

sd

: direct Park component

v

sq

: squaring Park component

v

so

: homo-polar Park component

V

so

is null for a three-phases balanced system

Each pair of components is perpendicular to each other

=

=

=

= + +

0 .

0 .

0 .

system) balanced phases - (tri 0

3 2 1

So Sq

So Sd

Sq Sd

S S S

v v

v v

v v

v v v

15 - 13

CLARKE Transformation

Transform is usually split into CLARKE transform and one rotation

CLARKE converts balanced three phase quantities into balanced two

phase orthogonal quantities

t

S S

e u =

v

1

= v

o

v

3

v

2

v

|

3

. 2

1 2

1

v v

v

v v

+

=

=

|

o

v

d

v

q

(

(

(

(

(

(

(

(

(

=

|

o

u u

u u

v

v

S S

S S

q

v

d

v

) cos( ) sin(

) sin( ) cos(

CLARKE

+

Rotation

PARK TRANSFORM

15 - 14

PARK Transform summary

Clarke

v

1

v

2

v

3

v

o

v

|

Park

V

d

V

q

Three phase rotating

domain

Two phase rotating

domain

Stationary domain

1 s

i

3 s

i

2 s

i

0 =

so

i

t

S S

=e u

I

S

I

Sd

I

Sq

Stator phase current

example: I

s

is moving at

S

and its PARK coordinates

are constant in (d,q) rotating

frame.

Can be applied on any three-

phase balanced variables

(flux)

d

q

15 - 15

Texas Instruments Motor Control Solution

C2000 - Digital Motor Control Library (DMC) :

Single Phase ACI Motor Control Using Constant

V/Hz

3-Phase ACI Motor Constant V/Hz Control

3-Phase ACI Motor Field Oriented Control

3-Phase Sensored Field Oriented Control (PMSM)

3-Phase Sensorless Field Oriented Control

(PMSM)

3-Phase Sensored Trapezoidal Control (BLDC)

3-Phase Sensorless Trapezoidal Control (BLDC)

15 - 16

Digital Motor Control Library (DMC-Lib)

The DMC-Library is a collection of most

commonly used algorithms and function

blocks for motor control systems

For every algorithm and function:

Essential theoretical background information

Data types for input/output parameters with

numerical range and precision

Function prototypes and calling conventions

code size (program and data memory)

Build Level based code examples

15 - 17

Digital Motor Control Library (DMC-Lib)

The DMC-Lib contains

PID regulators,

Clarke transformers,

Park transformers,

Ramp generators,

Sine generators,

Space Vector generators,

Impulse generators,

and more

15 - 18

Laboratory: FOC for PMSM

TMS320F28x controller

v

os

*

v

|s

*

Inv.

Park

Space

Vector

Gen.

PWM

Driver

T

a

T

b

T

c

Voltage

Source

Inverter

PMSM

i

as

i

bs

Ileg2_

Bus

Driver

ADCIN1

ADCIN2

ADCIN3

i

|s

Park Clarke

i

os

QEP_A

SPEED

FRQ

dir

v

qs

*

v

ds

*

PI

i

qs

*

PI

u

r

v

ds

*

PI

e

r

i

qs

Encoder

QEP_B

QEP_inc

u

e

PWM1

PWM2

PWM3

PWM4

PWM5

PWM6

i

ds

i

ds

*

QEP

THETA

DRV

15 - 19

TI Library Solution PMSM 3-1 (sprc129)

Hardware for Laboratory setup:

Spectrum Digital eZdsp TMS320F2812

Spectrum Digital DMC550 drive platform

3-phase PMSM with a QEP encoder

Applied Motion 40mm Alpha Motor

Type: A0100-104-3-100

24V DC power supply ( DC bus voltage )

load , e.g. DC Motor as Generator

PC parallel port to JTAG

5V DC ( eZdsp )

RS232 ( optional )

Oscilloscope

15 - 20

TI Library Solution PMSM 3-1 (sprc129)

eZdsp

DMC 550

PMSM 3-1

Load

24V

PC- parallel port

5V DC

RS232

(optional)

15 - 21

PMSM 3-1 Laboratory

Student Workbench

15 - 24

Build Level 1

TMS320F28x controller

v

os

*

v

|s

*

Inv.

Park

Space

Vector

Gen.

PWM

Driver

T

a

T

b

T

c

Vq_testing

rmp_out

Vd_testing

PWM1

PWM2

PWM3

PWM4

PWM5

PWM6

speed_ref

Ramp

Gen.

Ramp

control

key modules under test

15 - 25

Code Composer Studio with

Real Time Mode

1. Load a workspace file pmsm3_1.wks

2. In build.h, #define BUILDLEVEL LEVEL1

3. Rebuild all

4. Load program to target

(..\pmsm3_1.out)

15 - 26

5. In Debug menu, Reset CPU and then set

Real-time Mode. Then, click Yes when the

message box pops up.

6. Click Run icon

Code Composer Studio with

Real Time Mode

15 - 27

8. Set enable_flg to 1 in watch window.

(to enable T1UF interrupt and PWM drive on DMC550)

7. Right click on watch window. Then, check

Continuous Refresh.

Code Composer Studio with

Real Time Mode

15 - 28

Changing !!

watch window

for build 1

Code Composer Studio Level 1

15 - 29

Results: Build Level 1

rmp_out

Ta

15 - 30

Build Level 2 Current verification

TMS320F28x controller

v

os

*

v

|s

*

Inv.

Park

Space

Vector

Gen.

PWM

Driver

T

a

T

b

T

c

Voltage

Source

Inverter

PMSM

i

a

i

b

Ileg2_

Bus

Driver

ADCIN1

ADCIN2

ADCIN3

i

|s

Park Clarke

i

os

Vq_testing

Vd_testing

i

qs

Encoder

PWM1

PWM2

PWM3

PWM4

PWM5

PWM6

i

ds

Ramp

Gen.

Speed_ref

Ramp

control

u

e

key module under test

rmp_out

15 - 31

Instructions: Build Level 2

1. Tune the 24V Power Supply to 10 Volts with 1 Amp limit

2. Load a workspace file pmsm3_1.wks

3. In build.h, #define BUILDLEVEL LEVEL2

4. Reset CPU, Compile, Load, start RTM and Run

5. Switch on 24V Power Supply

6. Set variable enable_flg to 1 in watch window.

7. Try to change motor speed by setting speed_ref (p.u.)

in watch window. Then, motor should change its speed

accordingly.

15 - 32

Results: Build Level 2

1. PMSM should run open-loop smoothly

2. The currents in the motor phases should be

sinusoidal.

15 - 33

Build Level 3 - Tuning of dq-axis current closed loops

TMS320F28x controller

Ramp

Gen.

Speed_ref

Ramp

control

Iq_ref

key modules under test

v

os

*

v

|s

*

Inv.

Park

Space

Vector

Gen.

PWM

Driver

T

a

T

b

T

c

Voltage

Source

Inverter

PMSM

i

a

i

b

Ileg2_

Bus

Driver

ADCIN1

ADCIN2

ADCIN3

i

|s

Park Clarke

i

os

i

ds

*

PI

PI

rmp_out

i

qs

Encoder

PWM1

PWM2

PWM3

PWM4

PWM5

PWM6

i

ds

Id_ref

v

qs

*

v

ds

*

15 - 34

Instructions: Build Level 3

1. In build.h, #define BUILDLEVEL LEVEL3

2. Compile, Load, start RTM and Run

3. Set enable_flg to 1 in watch window.

4. Tune-up the PI

Observe dq-axis current regulations at PI inputs (i.e., reference and feedback). For

example, pid1_iq.pid_ref_reg3 and pid1_iq.pid_fdb_reg3.

Try to change motor speed by setting speed_ref (p.u.) in watch window . Then,

observe dq-axis current regulations.

P

I

D

out

ref

fdb

15 - 35

Build Level 4 Encoder verification

TMS320F28x controller

v

os

*

v

|s

*

Inv.

Park

Space

Vector

Gen.

PWM

Driver

T

a

T

b

T

c

Voltage

Source

Inverter

PMSM

i

a

i

b

Ileg2_

Bus

Driver

ADCIN1

ADCIN2

ADCIN3

i

|s

Park Clarke

i

os

QEP_A

dir

v

qs

*

v

ds

*

PI

rmp_out

v

ds

*

PI

Theta_elec

i

qs

Encoder

QEP_B

QEP_inc

u

m

PWM1

PWM2

PWM3

PWM4

PWM5

PWM6

i

ds

QEP

THETA

DRV

Ramp

Gen.

Speed_ref

Ramp

control

Iq_ref

Id_ref

15 - 36

Instructions: Build Level 4

1. In build.h, #define BUILDLEVEL LEVEL4

2. Compile, Load, start RTM and Run

3. Set the DC-bus to 24 Volts 1 Amp

4. Set enable_flg to 1 in watch window.

15 - 37

Results: Build Level 4

Emulated angle VS sensed angle

15 - 38

Results: Build Level 4

Speed reference VS real speed

15 - 39

Build Level 5 close speed loop

TMS320F28x controller

v

os

*

v

|s

*

Inv.

Park

Space

Vector

Gen.

PWM

Driver

T

a

T

b

T

c

Voltage

Source

Inverter

PMSM

i

as

i

bs

Ileg2_

Bus

Driver

ADCIN1

ADCIN2

ADCIN3

i

|s

Park Clarke

i

os

QEP_A

SPEED

FRQ

dir

v

qs

*

v

ds

*

PI

i

qs

*

PI

u

r

v

ds

*

PI

e

r

i

qs

Encoder

QEP_B

QEP_inc

u

e

PWM1

PWM2

PWM3

PWM4

PWM5

PWM6

i

ds

i

ds

*

QEP

THETA

DRV

15 - 40

Instructions: Build Level 5

1. In build.h, #define BUILDLEVEL LEVEL5

2. Compile, Load, start RTM and Run

3. Set the DC-bus to 24 Volts

4. Set enable_flg to 1 in watch window.

15 - 41

Results: Build Level 5

Fastest response time with

the closed loop!

15 - 42

Application of PMSM 3-1:

img GmbH Nordhausen

You might also like

- First Course On Power System SlidesDocument243 pagesFirst Course On Power System Slidessavannah78No ratings yet

- 1705 10196Document28 pages1705 10196Vikas PatelNo ratings yet

- 300gk QuestionsDocument20 pages300gk QuestionsPraveen SinghNo ratings yet

- Research PaperDocument10 pagesResearch PaperVikas PatelNo ratings yet

- Math Assignment - Complex Numbers: 1 Theoretical BackgroundDocument2 pagesMath Assignment - Complex Numbers: 1 Theoretical BackgroundVikas PatelNo ratings yet

- 1 s2.0 S136403211401048X MainDocument17 pages1 s2.0 S136403211401048X MainVikas PatelNo ratings yet

- Abdullah 2013Document6 pagesAbdullah 2013Vikas PatelNo ratings yet

- Mail SelfDocument6 pagesMail SelfVikas PatelNo ratings yet

- Faculty 152Document4 pagesFaculty 152Vikas PatelNo ratings yet

- PMSMDocument10 pagesPMSMVikas PatelNo ratings yet

- Fluid DynamicsDocument6 pagesFluid DynamicsVikas PatelNo ratings yet

- ISM JRF BrochureDocument37 pagesISM JRF BrochureVikas Patel100% (1)

- Recruitment NISEDocument8 pagesRecruitment NISErahul93anNo ratings yet

- Dynamic Modeling and Analysis of A Synchronous Generator in A Nuclear Power PlantDocument6 pagesDynamic Modeling and Analysis of A Synchronous Generator in A Nuclear Power PlantAmar SwamiNo ratings yet

- Notice ESE-2014 EngDocument7 pagesNotice ESE-2014 EngaquibzafarNo ratings yet

- List of candidates selected as Management TraineesDocument15 pagesList of candidates selected as Management TraineesVikas PatelNo ratings yet

- Optimization of Solar Power ChalegesDocument31 pagesOptimization of Solar Power ChalegesVikas PatelNo ratings yet

- Guidelines To AuthorsDocument2 pagesGuidelines To AuthorsBIJAY KRISHNA DASNo ratings yet

- TTP 2014 List ElectricalDocument1 pageTTP 2014 List ElectricalVikas PatelNo ratings yet

- Non LinearDocument7 pagesNon LinearjyotiblossomsNo ratings yet

- Device To Device CommunDocument9 pagesDevice To Device CommunwhatisgoingonNo ratings yet

- PR LGP 29 43 2014Document3 pagesPR LGP 29 43 2014nishantk1No ratings yet

- Free E Book Samsamyiki 2012 NationalDocument44 pagesFree E Book Samsamyiki 2012 NationalVikas PatelNo ratings yet

- Browser Settings For The StudentsDocument12 pagesBrowser Settings For The StudentsdvagrawalNo ratings yet

- College Name Subject-WiseDocument32 pagesCollege Name Subject-WiseLawanda ShafferNo ratings yet

- Power System Stabilizers For The Synchronous Generator: Tuning and Performance EvaluationDocument78 pagesPower System Stabilizers For The Synchronous Generator: Tuning and Performance EvaluationVikas PatelNo ratings yet

- Time-Frequency Toolbox GNU TutorialDocument150 pagesTime-Frequency Toolbox GNU Tutorialglebkarmi0% (1)

- List of candidates selected as Management TraineesDocument15 pagesList of candidates selected as Management TraineesVikas PatelNo ratings yet

- Madan Mohan Malaviya University of Technology, Gorakhpur M.Tech./Ph.D. Counseling (Admission Test-2014)Document3 pagesMadan Mohan Malaviya University of Technology, Gorakhpur M.Tech./Ph.D. Counseling (Admission Test-2014)Vikas PatelNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

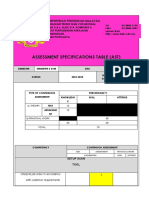

- Assessment Specifications Table (Ast) : Kementerian Pendidikan MalaysiaDocument6 pagesAssessment Specifications Table (Ast) : Kementerian Pendidikan MalaysiaMohd raziffNo ratings yet

- PDADocument38 pagesPDASaima NazNo ratings yet

- Access Token Stealing On WindowsDocument11 pagesAccess Token Stealing On Windows@4e4enNo ratings yet

- LivewireDocument186 pagesLivewireBlessing Tendai ChisuwaNo ratings yet

- Assignment 4Document2 pagesAssignment 4SARISHA BIDAWATKANo ratings yet

- Tieng Anh 10 Friends Global - Unit 8 - Test 2Document8 pagesTieng Anh 10 Friends Global - Unit 8 - Test 2haminhpham1708No ratings yet

- Data Guard PerformanceDocument39 pagesData Guard Performancesrevenco srevencoNo ratings yet

- Megaplex2100 ManualDocument326 pagesMegaplex2100 Manualashraf.rahim139No ratings yet

- Experiment No - Ripple Carry Full AdderDocument3 pagesExperiment No - Ripple Carry Full AdderNikhil PawarNo ratings yet

- CD KEY Untuk PerusahaanDocument30 pagesCD KEY Untuk PerusahaanAriagus BjoNo ratings yet

- Integration of Struts, Spring and Hibernate For An University Management SystemDocument8 pagesIntegration of Struts, Spring and Hibernate For An University Management SystemDrajan LamaNo ratings yet

- Proportional/Servo Valve Automatic Test Bench: Hangzhou Rebotech Co.,LtdDocument20 pagesProportional/Servo Valve Automatic Test Bench: Hangzhou Rebotech Co.,LtdCuneytNo ratings yet

- Visi Misi Ketos 20Document11 pagesVisi Misi Ketos 20haidar alyNo ratings yet

- Billing Invoice Payment PlanDocument7 pagesBilling Invoice Payment PlanyogeshNo ratings yet

- LCD TV: Service ManualDocument36 pagesLCD TV: Service ManualВладислав РусинNo ratings yet

- Allwinner H5 DatasheetDocument68 pagesAllwinner H5 DatasheetSuperFly SmithNo ratings yet

- Threats Analysis On VoIP SystemDocument9 pagesThreats Analysis On VoIP SystemIJEC_EditorNo ratings yet

- Math 10 Learning PlanDocument11 pagesMath 10 Learning PlanmichaelNo ratings yet

- Oracle Financial FaqDocument259 pagesOracle Financial FaqAndrea NguyenNo ratings yet

- TopSURV 7 3 Release NotesDocument55 pagesTopSURV 7 3 Release NotesChilo PerezNo ratings yet

- Date Sheet (MST-I)Document12 pagesDate Sheet (MST-I)Tauqeer AhmadNo ratings yet

- Hive Tutorial PDFDocument14 pagesHive Tutorial PDFbewithyou2003No ratings yet

- How Would You Describe The Telecommunication IndustryDocument3 pagesHow Would You Describe The Telecommunication Industryvinay kumarNo ratings yet

- FLS DemonstrationDocument30 pagesFLS DemonstrationLeah UljerNo ratings yet

- Write For Us Digital MarketingDocument6 pagesWrite For Us Digital MarketingSumit PrajapatiNo ratings yet

- Surbhi Sharma: at HCL Pvt. LTDDocument1 pageSurbhi Sharma: at HCL Pvt. LTDJaskiran KaurNo ratings yet

- AWUS036EW User Guide PDFDocument29 pagesAWUS036EW User Guide PDFFelipe GabrielNo ratings yet

- Java Network ProjectDocument20 pagesJava Network ProjectabbasmulaniNo ratings yet

- Literature Review of Online Registration SystemDocument8 pagesLiterature Review of Online Registration Systemzepewib1k0w3100% (1)

- Transport Layer: Unit - IVDocument19 pagesTransport Layer: Unit - IVHarishmaNo ratings yet