Professional Documents

Culture Documents

Wagner Scooptrams Operator's Manual Preventive Maintenance: Master Switch Wheels and Tires

Uploaded by

Miguel Ruiz TatajeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wagner Scooptrams Operator's Manual Preventive Maintenance: Master Switch Wheels and Tires

Uploaded by

Miguel Ruiz TatajeCopyright:

Available Formats

Wagner Scooptrams Operators Manual Preventive Maintenance

5566071201 06-96 97

Master Switch

This switch isolates the battery from the electri-

cal circuits and should be set to OFF when the

vehicle is not in use or during maintenance and

repair to help prevent short circuits.

Circuit Breaker/Electrical Component

Box

The electrical component box is usually located

in the engine compartment, near the battery. This

box contains circuit breaker and fuses or resetta-

ble circuit breakers which provide first-line

protection for the electrical system. These break-

ers are equipped with an internal contact that

prohibits reset while the fault still exists, even if

the circuit breaker is manually held in the reset

position.

The lower amperage breakers in the instrument

panel are push-pull which allows for manually

isolating circuits for troubleshooting.

All breakers are manually reset. If an electrical

fault occur, try resetting the appropriate breaker.

If the breaker cannot be reset, contact mainte-

nance personnel to resolve the problem before

continuing operation.

Important: Do not run the engine with the bat-

tery terminals disconnected.

Important:

To prevent damage to the DDEC electronic con-

trol system, disconnect the battery ISO switch

and pull the main electrical circuit fuses before

welding. Failure to isolate the DDEC system

while welding can result in severe damage to the

DDEC computer.

Wheels and Tires

WARNING: Tires and wheels can

explode and cause injury or death.

Always keep yourself and others out of

the danger areas of the tires and wheels. Stand

on the tread side of a tire when you perform ser-

vice.

Servicing Tires

The vehicle must be empty before servicing the

tires.

Stand on the tread side of the tire when servic-

ing.

Check each tire for deep cuts, breaks or loose

tread. Look for exposed cord. Report any dam-

age to maintenance personnel for corrective

action.

Use a long hose and self-attaching air valve fit-

ting so that you can be outside of the danger

zone when inflating the tires.

If the tire and wheel assembly is removed from

the vehicle, always put it into the tire inflation

cage before adding air.

Always check tire pressures when the tire is

cold.

Always inflate tires to the recommended pres-

sure.

In extremely cold temperatures, inflation pres-

sures will vary from those listed in this manual.

Contact your Atlas-Copco Wagner sales com-

pany or dealer.

Avoid operation when the vehicles has been

parked for a long time in temperatures below -

40F (-40C).

Preventive Maintenance Operators Manual Wagner Scooptrams

98 06-96 5566071201

WARNING: Never mix different size

wheel parts. Never use damaged wheel

rims or parts. Incorrect modification or

rework to wheel rim or parts may result in fail-

ure, injury, or death.

Deflate the tire before attempting to repair tire

tread or removing foreign objects.

Wheel Lug Nuts

Make visual inspection of the wheels. Check for

loose, damaged, or missing lugnuts and studs.

Lubrication and Miscellaneous

Maintenance

Grease Points

Lubricate each grease point shown in the shift

maintenance diagram every shift or every 40

hours as indicated. Use a high pressure gun,

except as indicated on the lubrication checks.

On vehicles equipped with automatic central

lubrication, check the level of the grease reser-

voir every 100 hours.

Exhaust System

Your vehicle may be equipped with one or more

of the following components:

water exhaust scrubber

catalytic exhaust converter.

exhaust fume diluter

ECS purifilter

silencer

The water exhaust scrubber requires routine

operator maintenance. The remaining compo-

nents does not require operator maintenance.

(See the Service Manual for scheduled mainte-

nance instructions on these components.)

Water Exhaust Scrubber

The water exhaust scrubber must be flushed and

filled with clean water twice each shift.

Catalytic Exhaust Converter

The converter consists of platinum coated pellets

or honeycomb mesh. When heated by the engine

exhaust gas the platinum acts to complete the

combustion and oxidize carbon monoxide and

hydro-carbons in the exhaust plume. Back pres-

sure should be checked periodically to prevent

carbon residue buildup.

Exhaust Fume Diluter

The diluter acts as a Venturi chamber, mixing a

large volume of ambient air in with the exhaust

gases. This helps to cool and dilute the exhaust

gas to an acceptable level. Back pressure should

be checked periodically to prevent carbon resi-

due buildup.

ECS Purifilter

The purifilter works like the catalytic converter,

with the additional feature of providing particu-

late filtering. When starting a cold engine, black

smoke or dark exhaust smoke will be visible. A

ceramic honeycomb structure in the purifilter

traps the carbon soot and other particles. The

smoke should disappear as the engine warms.

This means that the catalytic purifilter is effec-

tive and requires minimum maintenance.

Note: Do not idle the engine for more than five

minutes as this causes carbon buildup in the

purifilter. When carbon build-up is present dark

smoke will appear during low-speed operating.

If this happens, the system can be regenerated by

running the engine at governed speed for five

minutes (no load) until the exhaust becomes

clear. The time between regeneration depends on

use, condition of the engine and the grade of fuel

used.

You might also like

- Moocoowooodoo 987Document32 pagesMoocoowooodoo 987scribbedd55No ratings yet

- Mercury Maintenance ManualDocument27 pagesMercury Maintenance ManualJens Adam Hedegaard HansenNo ratings yet

- MAINTENANCE TIPS FOR YOUR OUTBOARDDocument20 pagesMAINTENANCE TIPS FOR YOUR OUTBOARDLahiru Chamara JayasingheNo ratings yet

- 5E-FE Engine and Engine RebuildDocument205 pages5E-FE Engine and Engine Rebuildjferrell4380100% (10)

- A32 GiDocument49 pagesA32 GiLevin Tan HtNo ratings yet

- 22hp FD661DDocument9 pages22hp FD661Dlen002No ratings yet

- Emission Control Systems: Chapter 4 Part DDocument2 pagesEmission Control Systems: Chapter 4 Part DstoicaNo ratings yet

- TGB Outback 425 - Service ManualDocument229 pagesTGB Outback 425 - Service ManualLau Tuijnman100% (5)

- General Information - General Service Information: Repairs and ReplacementsDocument24 pagesGeneral Information - General Service Information: Repairs and ReplacementsbledmikifrNo ratings yet

- Cat 966FDocument15 pagesCat 966FMohammed NADJIB DEBBALNo ratings yet

- Generator Preventive Maintenance and TroubleshootingDocument7 pagesGenerator Preventive Maintenance and Troubleshootingemmahenge100% (2)

- Maintenance ScheduleDocument16 pagesMaintenance ScheduleSiska0806No ratings yet

- KTM Training DIY CustomerDocument18 pagesKTM Training DIY Customerdushrox100% (1)

- 1998 Mercedes Benz SLK230 Workshop ManualDocument152 pages1998 Mercedes Benz SLK230 Workshop ManualMon Estocapio75% (4)

- Maintenance: Outboard CareDocument18 pagesMaintenance: Outboard Careshygal1981100% (1)

- Engine Manual Provides Operation and Maintenance TipsDocument48 pagesEngine Manual Provides Operation and Maintenance TipshassanHyro4350% (2)

- Jet Central Turbine Operation ManualDocument44 pagesJet Central Turbine Operation ManualholograghyNo ratings yet

- CAT Antes de Usar TH460BDocument4 pagesCAT Antes de Usar TH460Bmiguel0% (1)

- Catalogue ACDelco Steering PDFDocument32 pagesCatalogue ACDelco Steering PDFSelvin GalindoNo ratings yet

- 0911 Maintenance 15FSDocument23 pages0911 Maintenance 15FSemilio275655No ratings yet

- Gast 23 Series Oilless ManualDocument8 pagesGast 23 Series Oilless Manualclangbird210No ratings yet

- Instalaçaõ Dos InjetoresDocument20 pagesInstalaçaõ Dos InjetoresJoão JlmacaeNo ratings yet

- 350z Procharger Install ManualDocument52 pages350z Procharger Install Manualr3belzNo ratings yet

- TGB Blade 250 Service ManualDocument217 pagesTGB Blade 250 Service Manualyornletard100% (3)

- MaintenanceInformation 6CylVeradoDocument25 pagesMaintenanceInformation 6CylVeradocombaheeNo ratings yet

- FAMILIARISATION SEEING CLEARLY Lights WipersDocument121 pagesFAMILIARISATION SEEING CLEARLY Lights Wiperslsasha110No ratings yet

- 3116 MaintenanceDocument33 pages3116 MaintenanceCesar Gongora100% (8)

- d8k Tractor - Power Shift - 66v00001-02084 (Machine) (Hebp1007 - 01) - Sistemas y ComponentesDocument5 pagesd8k Tractor - Power Shift - 66v00001-02084 (Machine) (Hebp1007 - 01) - Sistemas y ComponentesJose MontalvoNo ratings yet

- 3 Service Manuals GTR250 0420Document159 pages3 Service Manuals GTR250 0420timawade100% (1)

- QuickServe en Línea - (4310736) ISX15 CM2250 SN Manual de ServicioDocument5 pagesQuickServe en Línea - (4310736) ISX15 CM2250 SN Manual de Serviciohamilton mirandaNo ratings yet

- Def 90 110 WSM Book4 PDFDocument102 pagesDef 90 110 WSM Book4 PDFPeter100% (1)

- Rev D 900FH and 1000FH Turbine FiltersDocument12 pagesRev D 900FH and 1000FH Turbine FiltersJan AhmedNo ratings yet

- Manual General Taller Motos Keeway 50cc (Idioma Ingles)Document64 pagesManual General Taller Motos Keeway 50cc (Idioma Ingles)CordobessaNo ratings yet

- GastDocument12 pagesGastiptNo ratings yet

- Lubrication and MaintenanceDocument18 pagesLubrication and MaintenanceRamon AcostaNo ratings yet

- David Control Idaan Doc Cat Inf 50004 A4 Cronograma de ActividadesDocument170 pagesDavid Control Idaan Doc Cat Inf 50004 A4 Cronograma de ActividadesAlby Enrique Cabrera HernandezNo ratings yet

- General Maintenance Procedures: Caution!Document14 pagesGeneral Maintenance Procedures: Caution!Henry HuayhuaNo ratings yet

- 967 0754Document75 pages967 0754Ryan Keith Kytle100% (1)

- Owner'S Manual: Air-Cooled Diesel Air Compressor Set DA011Document26 pagesOwner'S Manual: Air-Cooled Diesel Air Compressor Set DA011khomeinitjNo ratings yet

- Gts 250Document217 pagesGts 250Eduardo M. R. SousaNo ratings yet

- LEV80 Manual PDFDocument20 pagesLEV80 Manual PDFLee McDermottNo ratings yet

- KZ Slide Carb Tuning-1Document6 pagesKZ Slide Carb Tuning-1pertonpcNo ratings yet

- w202 PDFDocument130 pagesw202 PDFMixalis Diamantopoulos100% (2)

- Manual de Usuario Motor Picadoras PDFDocument160 pagesManual de Usuario Motor Picadoras PDFDavid Shiryū Red DragonNo ratings yet

- Yanmar BulletinsDocument10 pagesYanmar BulletinsBill Carter100% (2)

- Standard Workshop Practices for Discovery SportDocument34 pagesStandard Workshop Practices for Discovery SportFerhan SerdarogluNo ratings yet

- D6TMaintenance Interval ScheduleDocument12 pagesD6TMaintenance Interval Schedulepedro sanchezNo ratings yet

- 4.3L GM Gas Engine Parts Manual PN 0D3749Document28 pages4.3L GM Gas Engine Parts Manual PN 0D3749Da GuruNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Ford Manual for Owners and Operators of Ford Cars and Trucks (1919)From EverandFord Manual for Owners and Operators of Ford Cars and Trucks (1919)No ratings yet

- Diesel Engine Care and Repair: A Captain's Quick GuideFrom EverandDiesel Engine Care and Repair: A Captain's Quick GuideRating: 5 out of 5 stars5/5 (1)

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003From EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Rating: 5 out of 5 stars5/5 (1)

- VW Transporter T4 (Petrol and Diesel - 1990-1995) Workshop Manual: Owners Edition (Owners' Workshop Manuals)From EverandVW Transporter T4 (Petrol and Diesel - 1990-1995) Workshop Manual: Owners Edition (Owners' Workshop Manuals)No ratings yet

- VW Transporter T4 Workshop Manual Diesel 2000-2004From EverandVW Transporter T4 Workshop Manual Diesel 2000-2004Rating: 5 out of 5 stars5/5 (5)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- Control AccountDocument3 pagesControl AccountMiguel Ruiz TatajeNo ratings yet

- STSMDocument278 pagesSTSMMiguel Ruiz TatajeNo ratings yet

- BacharachDocument2 pagesBacharachMiguel Ruiz TatajeNo ratings yet

- 3 - Comparativo AB - Jan.2014Document1 page3 - Comparativo AB - Jan.2014Miguel Ruiz TatajeNo ratings yet

- MSDS R134aDocument8 pagesMSDS R134aMiguel Ruiz TatajeNo ratings yet

- Specifications: Wagner Scooptrams Operator's Manual Preventive MaintenanceDocument1 pageSpecifications: Wagner Scooptrams Operator's Manual Preventive MaintenanceMiguel Ruiz TatajeNo ratings yet

- Camión MT 444Document3 pagesCamión MT 444José R. CastroNo ratings yet

- Power Train Service Manual Wagner Scooptrams: Inspection and MaintenanceDocument3 pagesPower Train Service Manual Wagner Scooptrams: Inspection and MaintenanceMiguel Ruiz TatajeNo ratings yet

- Operator Manual for Wagner Scooptram ST-6CDocument1 pageOperator Manual for Wagner Scooptram ST-6CMiguel Ruiz TatajeNo ratings yet

- R22 Refrigerant MSDS from Shandong Dongyue ChemicalDocument7 pagesR22 Refrigerant MSDS from Shandong Dongyue ChemicalMiguel Ruiz TatajeNo ratings yet

- Tire DesmountingDocument10 pagesTire DesmountingMiguel Ruiz TatajeNo ratings yet

- Ejc 130DDocument4 pagesEjc 130DMiguel Ruiz Tataje100% (1)

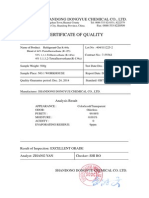

- R-404a Refrigerant Gas CertificateDocument1 pageR-404a Refrigerant Gas CertificateMiguel Ruiz TatajeNo ratings yet

- Certificado de Calidad R-134 (55566)Document1 pageCertificado de Calidad R-134 (55566)Miguel Ruiz TatajeNo ratings yet

- R-22 Refrigerant Gas CertificateDocument1 pageR-22 Refrigerant Gas CertificateMiguel Ruiz TatajeNo ratings yet

- Error Code For BeeDocument4 pagesError Code For BeeMiguel Ruiz TatajeNo ratings yet

- HEAT BALANCE BOILER UNIT 5Document18 pagesHEAT BALANCE BOILER UNIT 5hafidhrahadiyan2No ratings yet

- GMC Motorhome Service BulletinsDocument363 pagesGMC Motorhome Service Bulletinsbilly_gfroerer100% (1)

- M1 - Djonrae N. GalvezDocument5 pagesM1 - Djonrae N. GalvezDjonraeNarioGalvezNo ratings yet

- 1 9 77 KW Tdi PD EngineDocument209 pages1 9 77 KW Tdi PD Engine19crysti100% (2)

- Acumen: Myanmar B2B Management MagazineDocument80 pagesAcumen: Myanmar B2B Management MagazineACUMEN Business MagazineNo ratings yet

- Guidelines For The Avoidance of Vibration Induced Fatigue in Process PipeworkDocument0 pagesGuidelines For The Avoidance of Vibration Induced Fatigue in Process Pipeworkviv01020% (1)

- Nexus 250 I.E. UPUTSTVO - 1559729845Document96 pagesNexus 250 I.E. UPUTSTVO - 1559729845Aleksandar RakićNo ratings yet

- Process Design Basis RevA - PLLSG CommentsDocument7 pagesProcess Design Basis RevA - PLLSG CommentschemjojoNo ratings yet

- Hydrochloric Acid Plant Design: The Copperbelt University School of Technology Chemical Engineering DepartmentDocument86 pagesHydrochloric Acid Plant Design: The Copperbelt University School of Technology Chemical Engineering DepartmentAndre Winata100% (1)

- Fans in Fire SafetyDocument58 pagesFans in Fire SafetyMohammed Majeed Ali100% (1)

- Gas Pipe SizingDocument17 pagesGas Pipe Sizingcentaury2013100% (2)

- JH4 Om 05june08 PDFDocument158 pagesJH4 Om 05june08 PDFramsi17No ratings yet

- Determinant of Global Crude Oil Pricing Theoretical ReviewDocument10 pagesDeterminant of Global Crude Oil Pricing Theoretical ReviewibidaboNo ratings yet

- Datatherm 715 PDFDocument2 pagesDatatherm 715 PDFSH1961No ratings yet

- Dacia Sandero BrochureDocument8 pagesDacia Sandero BrochurechechumenendezNo ratings yet

- An Analysis of The Relationship Between Petroleum Prices and Inflation in NigeriaDocument7 pagesAn Analysis of The Relationship Between Petroleum Prices and Inflation in NigeriaChidinma Glory EjikeNo ratings yet

- Methane vs Propane as Fuel Sources: A ComparisonDocument11 pagesMethane vs Propane as Fuel Sources: A Comparisonjubatus.libroNo ratings yet

- Maintenance Manual 1T-4T (LPG) - EN 英语Document128 pagesMaintenance Manual 1T-4T (LPG) - EN 英语Jose Luis LavinNo ratings yet

- PDFDocument181 pagesPDFkoki100% (2)

- Gottwald ProductsDocument4 pagesGottwald ProductsPedroNo ratings yet

- EPS Employment Application FormDocument10 pagesEPS Employment Application FormLiviu Crăciun50% (2)

- Flow Behind Casing DetectionDocument18 pagesFlow Behind Casing Detectiontaufiq01100% (1)

- Carbon LandscapeDocument137 pagesCarbon Landscapem_danmNo ratings yet

- EMS-2 Engine Monitoring System ManualDocument20 pagesEMS-2 Engine Monitoring System Manualcristian crespoNo ratings yet

- Six stroke engine types and designsDocument13 pagesSix stroke engine types and designskarthiksubramanian94No ratings yet

- ECOSOC - Syria Position PaperDocument2 pagesECOSOC - Syria Position PaperAnish BanerjeeNo ratings yet

- Lesson 1 Fossil FuelsDocument17 pagesLesson 1 Fossil Fuelstashnee pillayNo ratings yet

- Acoustics AACTx R150 L01 Introduction To AcousticsDocument71 pagesAcoustics AACTx R150 L01 Introduction To AcousticsPercy Romero MurilloNo ratings yet

- Waste Cook Oil To BiodieselDocument7 pagesWaste Cook Oil To Biodieselandri yulianyiNo ratings yet

- Fluid SaturationDocument14 pagesFluid SaturationHarry JakeNo ratings yet

- Red Max G2500TS PDFDocument36 pagesRed Max G2500TS PDFKevinNo ratings yet