Professional Documents

Culture Documents

Sikadur 30 PDF

Uploaded by

Darwin SyahputraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sikadur 30 PDF

Uploaded by

Darwin SyahputraCopyright:

Available Formats

Technical Data Sheet

Edition 2, 2005

Identification no.

02 04 01 04 001 0 000001

Version no. 0010

Sikadur 30

Sikadur

30 1/5 1

C

o

n

s

t

r

u

c

t

i

o

n

Si k adur

30

Adhesive for Bonding Reinforcement

Description Solvent-free, thixotropic, epoxy-based on two-component adhesive mortar.

Use As an adhesive for bonding reinforcements, adhesive mortar and filler to :

Concrete, stone

Steel

Epoxy

For structural bonding of :

Sika CarboDur, brickwork , timber to concrete

Steel plates to concrete

Concrete elements

Bridge segments

Bonding of :

Starter bars

Wall anchors

Fixings, etc.

For vertical and overhead filling of :

Holes

Dimensional inaccuracies, etc

Advantages Easy to mix and apply

No primer needed

Non-sag in vertical and overhead applications

Solvent free

Hardening is not affected by high humidity

Hardens without shrinkage

High creep resistance under permanent load

High mechanical strength

High abrasion and shock resistance

Shrinkage-free curing

Impermeable to liquids and water vapour

Components come in different colors therefore homogeneity of mix is easy to

check

Test reports - IBMB, TU Braunschweig, test report No. 1871/0054, 1994 :

approval for Sikadur-30 Epoxy adhesive.

- IBMB, TU Braunschweig, test report No. 1734/6434, 1995:

Testing for Sikadur-41 Epoxy mortar in combination with Sikadur-30 Epoxy

adhesive for bonding of steel plates.

Table of Contents

Back

Sikadur

30 2/5 2

Technical Data

Colour Comp. A : white

Comp. B: black

Comp. A+B mixed: light grey

Consistency Comp. A+B mixed: creamy paste

Mix ratio Comp. A: B =3 : 1 by weight and volume

Storage

Store in dry condition at temperatures between +5C and +30C. Protect from direct

sunlight

Shelf life

24 months from date of production if stored in original unopened packing.

Packaging

- Pre-dosed units (Comp. A+B) at 6 kg

Physical Data

Density

~1.65 kg/l (mixed)

Pot life (to F.I.P.*)*

40 minutes (at +35C)

110 minutes (at +20C)

Open time (to F.I.P.*)*

30 minutes (at +35C)

Layer Thickness Max 30 mm layer thickness

Sag flow

(to F.I.P.*)

3-5 mm (at +35C) (on vertical surfaces)

Squeezability at 15 kg

(to F.I.P.*)

4000 mm (at +15C)

Shrinkage

(to F.I.P.*)

0.04%

Glass transition temperature

(to F.I.P.*)

62C

Heat deflection temperature

(ASTM 648)

Curing : HDT:

7d, 10C: 36C:

7d, 35C: 53C:

Modulus of elasticity

static (to F.I.P.*)

12800 N/mm

Compressi ve strength

(to DIN 53455)

>80 N/mm (at 35C)

Tensile strength

(to EN 196)

>25 N/mm

Shear strength

(to F.I.P.*)

Concrete failure (~15 N/mm)

Adhesive Tensile

strength on steel

>21 N/mm (to sandblasted substrate to Sa 2.5)

Coefficient of thermal

expansion

9 x 10

-5

per C (-10C to +40C)

Note The figures given may vary according to the mixing intensity and the amount of air

introduced.

* Fdration Internationale de la Prcontrainte

Sikadur

30 3/5 3

Sikadur

30 4/5 4

Application

Substrate Concrete, stone, brickwork :

- Clean, free from and grease, dry, no loose particles or laitance.

- Concrete age, depending on climate, 3 to 6 weeks.

- Preparation : Sandblasting, high-pressure water jetting, grinding

- Max. substrate moisture : 4% pbv

When applied to mat moisture concrete, brush Sikadur-30 well into substrate

- If the concrete surface has large uneven sections or holes after preparation, these

must first be filled with Sikadur-41 or a mixture of Sikadur-30 and quartz sand

Sikadur-501 (mixing ratio 1 : 1 by weight)

Timber :

- Clean, free from oil and grease

- Sandblast or grind

Structural steel 37, V2A-Steel (WN 1.4 301) :

- Free from grease and oil, free from rust, scale and rolling "skin"

- Preparation : Sandblast SA 2.5

- Beware of condensation (dew point), application only at >3C above dew point

- If the cleaned steel is not bonded immediately, the surface must be given one coat

of Sikagard-63 N or Icosit 277 to protect it from further corrosion.

Epoxy :

- Free from oil and grease

- Grind well using coarse abrasive

Mixing

Part A : part B = 3 : 1 by weight or volume

Pre-dosed packs :

Add component B to component A and stir with a mixing spindle fitted to an electric

low speed mixer (max. 500 rpm) to avoid entrapping of air. Mix thoroughly for about

3 minutes to uniform appearance. Then, pour the whole mix into a clean container

and

stir again for approx. 1 more minute at low speed to keep air entrapment at a

minimum.

Bulk packing, not pre-dosed:

Add the components in the correct proportion using a scale. Pour them into a

suitable mixing container and stir correctly using an electric low speed mixer as

indicated for ready to use pre-dosed packs.

The pot life begins when the resin and hardener are mixed. It is shorter at high

temperatures and longer at low temperatures. The greater the quantity mixed, the

shorter the pot life. To obtain longer workability at high temperatures, the mixed

adhesive may be divided into portions. Another method is to chill components A and

B before mixing them.

Sikadur

30 5/5 5

Application The homogeniously-mixed Sikadur-30 is applied with a spatula, trowel or float. When

bonding steel plates Sikadur-30 is applied to the strips in pitched-roof shape.

Within the open time the steel plates must be fixed in their final position.

Steel plates are being fixed to the concrete substrate with the aid of specially

prepared supporting scaffolding. since at normal ambient temperature sikadur-30

cures very fast, the scaffolding can be removed within 2-3 days (please refer to the

curing times at various temperatures).

For the application of Sika CarboDur laminates, please refer to the corresponding

product data sheet.

It is recommended to check the adhesive with regard to strength development by

producing cubes at site and to test them for compressive and flexural strength.

Cleaning Clean tools immediately with Colma cleaner. Wash hands and skin thoroughly in

warm soap water.

When uncured, Sikadur-30 components A+B, are water polllutants and should not

be discharged into drains, waterways or the ground.

Colma cleaner and Sikadur-30 residues must always be disposed of in accordance

with the regulations.

Cured material can only be removed mechanically.

Application

Limitations

Temperature Substrate and ambient: +10C to +35C

Material temperature Sikadur 30 must be applied at temperature between: +5C to +30C

Dew point Beware of condensation !

Ambient temperature during application must be at least 3 C above dew point

Safety Instructions

Safety precautions

Product can cause skin irritation. Wear protective clothing (gloves, safety glasses).

Cover hands with barrier cream before application. In contact with eyes or mucous

membranes, rinse thoroughly with clean warm water immediately and seek medical

attention without delay.

Ecology In a liquid state material contaminates water. Do not dispose into water or soil but

according to local regulations

Toxicity

Comp. A : Class 4 under the relevant Swiss Health and Safety Codes.

Observe warning on packing.

Comp. B : Non Toxic

Transport

Comp. A : Non hazardous

Comp. B : 8/65 c)

Legal Notes

The information, and, in particular, the recommendations relating to the application and end-use of Sika

products, are given in good faith based on Sikas current knowledge and experience of the product when

properly stored, handled and applied under normal conditions in accordances with Sikas

recommendations. In practice, the differences in materials, substrates and actual site conditions are such

that no warranty in respect of merchantability or of fitness for a particular purpose, nor any liability arising

out of any legal relationship whatsoever, can be inferred either from this information, or from any written

recommendations, or from any other advice offered. The user of the product must test the products

suitability for the intended application and purpose. Sika reserves the right to change the properties of its

products. The proprietary rights of third parties must be observed. All orders are accepted subject to our

current terms of sale and delivery. Users must always refer to the most recent issue of the local Product

Data Sheet for the product concerned, copies of which will be supplied on request.

C

o

n

s

t

r

u

c

t

i

o

n

PT. Sika Indonesia

J l. Raya Cibinong- Bekasi km. 20

Limusnunggal- Cileungsi

BOGOR 16820 - Indonesia

Tel. +62 21 8230025

Fax +62 21 8230025

Website : www.sika.co. id

e-mail: sikacare@id.sika.com

Branches

Surabaya :

Puri Niaga Blok G No. 29, J l. Raya Rungkut Menanggal 11, Surabaya

Tel : 031-8690202 ; Fax : 031-8682123

Medan :

Kawasan Industrial " Medan Star ", Tanjung Morawa Km.19,2

J l. Pelita Raya Blok R No.32, Deli Serdang 20362

Tel : 061-7941200 ; Fax : 061-7940822

Batam :

J l. Laksamana Bintan,Komp. Bumi Riau Makmur Blok E No.3,

Sungai Panas, Batam

Tel : 0778-424928 ; Fax : 0778-450189

You might also like

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- Mechanical Properties and Performance of Engineering Ceramics and Composites XIFrom EverandMechanical Properties and Performance of Engineering Ceramics and Composites XIJonathan SalemNo ratings yet

- Sikadur 30Document3 pagesSikadur 30Hakiki SaputraNo ratings yet

- Sikadur 31 CFDocument4 pagesSikadur 31 CFRonald MassoraNo ratings yet

- Sikadur 31 CF NormalDocument4 pagesSikadur 31 CF Normaldepi_rachmanNo ratings yet

- Sikadur - 31 CF Rapid: 2-Part Thixotropic Epoxy AdhesiveDocument6 pagesSikadur - 31 CF Rapid: 2-Part Thixotropic Epoxy AdhesivevladodjuNo ratings yet

- Sikadur - 31 SBA S-02 MYDocument4 pagesSikadur - 31 SBA S-02 MYsamitha505No ratings yet

- Sikadur 31 CF Normal PDS (CE)Document5 pagesSikadur 31 CF Normal PDS (CE)Satria AdityaNo ratings yet

- SikaWrap Hex - 230CDocument3 pagesSikaWrap Hex - 230CHakiki SaputraNo ratings yet

- Sikadur - 32 Normal: 2-Part Structural Epoxy Bonding AgentDocument4 pagesSikadur - 32 Normal: 2-Part Structural Epoxy Bonding AgentFarhanSyarifNo ratings yet

- SikaWrap Hex - 430G - VPDocument3 pagesSikaWrap Hex - 430G - VPHakiki SaputraNo ratings yet

- Sikadur 31 CF Normal: 2-Part Thixotropic Epoxy AdhesiveDocument4 pagesSikadur 31 CF Normal: 2-Part Thixotropic Epoxy Adhesiverahayu59No ratings yet

- Sikadur-31 2-part epoxy adhesiveDocument4 pagesSikadur-31 2-part epoxy adhesivecamelia_pirjan5776No ratings yet

- Sikadur31 TdsDocument4 pagesSikadur31 TdsFrederick Linsangan CruzNo ratings yet

- Sikadur 53Document2 pagesSikadur 53the pilotNo ratings yet

- Sikaflex Pro 3 WF Pds enDocument4 pagesSikaflex Pro 3 WF Pds enrydocNo ratings yet

- Sikatop Armatec 110 EpoCem PDFDocument2 pagesSikatop Armatec 110 EpoCem PDFDarwin SyahputraNo ratings yet

- Sikadur-330: 2-part epoxy impregnation resin for fabric reinforcementDocument6 pagesSikadur-330: 2-part epoxy impregnation resin for fabric reinforcementDarwin SyahputraNo ratings yet

- Sikafloor - 325: 2-Part PUR Resin Self Smoothing Screed and Seal CoatDocument6 pagesSikafloor - 325: 2-Part PUR Resin Self Smoothing Screed and Seal Coatthe pilotNo ratings yet

- Sikadur - 42: Epoxy Resin Castable GroutDocument2 pagesSikadur - 42: Epoxy Resin Castable Groutthe pilotNo ratings yet

- Icosit KC 330-2MDocument4 pagesIcosit KC 330-2MNelu IvascuNo ratings yet

- Sikadur - 53 (UF) : Moisture Insensitive Injection ResinDocument3 pagesSikadur - 53 (UF) : Moisture Insensitive Injection Resinpramod kumarNo ratings yet

- Sikadur - 42 HES: Castable Epoxy Resin Based GroutDocument4 pagesSikadur - 42 HES: Castable Epoxy Resin Based GroutAjay SastryNo ratings yet

- B220 SikadurCombiflexSGSystem UsDocument3 pagesB220 SikadurCombiflexSGSystem Usengsam777No ratings yet

- Sikadur PFDocument2 pagesSikadur PFthe pilotNo ratings yet

- Icosit Steel ProtectDocument2 pagesIcosit Steel Protectthepilot2No ratings yet

- Sikadur - 42 HS: High Strength Pourable Epoxy GroutDocument4 pagesSikadur - 42 HS: High Strength Pourable Epoxy GroutMuhammad Azlan AhmadNo ratings yet

- Sikagard Wallcoat PdsDocument5 pagesSikagard Wallcoat PdscharlessimoNo ratings yet

- Sikadur - 52 inDocument3 pagesSikadur - 52 inRavi Kumar KadivetiNo ratings yet

- Flex 68wDocument2 pagesFlex 68wYasher Meera SaibNo ratings yet

- My Con Pds Sikafloor 220 W ConductiveDocument7 pagesMy Con Pds Sikafloor 220 W ConductivelaurenjiaNo ratings yet

- Sikafloor 357Document6 pagesSikafloor 357Jessica CaldwellNo ratings yet

- Sikadur-31 CF Normal 2012-05 - 1 PDFDocument5 pagesSikadur-31 CF Normal 2012-05 - 1 PDFNyu123456No ratings yet

- Sikadur 32Document2 pagesSikadur 32the pilotNo ratings yet

- Sikadur-31 SBA S-02 2012-05 - 1 PDFDocument4 pagesSikadur-31 SBA S-02 2012-05 - 1 PDFNyu123456No ratings yet

- Sikadur - 41CF: Epoxy Resin Patching MortarDocument2 pagesSikadur - 41CF: Epoxy Resin Patching Mortarthe pilotNo ratings yet

- Sikafloor - 2430: 2-Part Epoxy Coloured CoatingDocument4 pagesSikafloor - 2430: 2-Part Epoxy Coloured Coatingthe pilotNo ratings yet

- Sikagard - 670W: Emulsion Type Protective Coating For ConcreteDocument2 pagesSikagard - 670W: Emulsion Type Protective Coating For Concretethe pilotNo ratings yet

- Sikadur 32Document3 pagesSikadur 32Matteo BreveglieriNo ratings yet

- Sikafloor - 2530 W: 2-Part Water Based Epoxy CoatingDocument5 pagesSikafloor - 2530 W: 2-Part Water Based Epoxy Coatingthe pilotNo ratings yet

- Sikadur 42 MP Normal PDFDocument5 pagesSikadur 42 MP Normal PDFDarwin SyahputraNo ratings yet

- 2-part water based epoxy sealer coatDocument5 pages2-part water based epoxy sealer coatazheminNo ratings yet

- Sikadur 732Document2 pagesSikadur 732Alfiady Reza Putu ArgaNo ratings yet

- Sika CarbodurDocument3 pagesSika CarbodurHakiki SaputraNo ratings yet

- Sikadur 42 HSDocument2 pagesSikadur 42 HSthe pilotNo ratings yet

- High-performance cementitious groutDocument2 pagesHigh-performance cementitious groutGuillermo Garcia50% (2)

- Sikagrout - 295: Cement-Base Fluid Expanding Mortar, With High Mechanical ResistanceDocument2 pagesSikagrout - 295: Cement-Base Fluid Expanding Mortar, With High Mechanical Resistancethe pilotNo ratings yet

- Sikagrout - 200: High Strength, Non-Shrink, None Oxidized Cementitious GroutDocument2 pagesSikagrout - 200: High Strength, Non-Shrink, None Oxidized Cementitious Groutthe pilot100% (1)

- High-Strength Epoxy Grouting SystemDocument6 pagesHigh-Strength Epoxy Grouting SystemGihasAbdNo ratings yet

- My Con Pds Sikadur 31 LPDocument3 pagesMy Con Pds Sikadur 31 LPmcwong_98No ratings yet

- Sikadur - 42 HES (VP) : 3-Part, High Performance, Low Exothermic, Pourable Epoxy Grouting SystemDocument4 pagesSikadur - 42 HES (VP) : 3-Part, High Performance, Low Exothermic, Pourable Epoxy Grouting SystemAjay SastryNo ratings yet

- Sikadur 31, Hi-Mod Gel 1 1 Mix Ratio-UsDocument2 pagesSikadur 31, Hi-Mod Gel 1 1 Mix Ratio-Usgrats_singcoNo ratings yet

- Sikadur 732Document2 pagesSikadur 732Iskandar AlamsyaNo ratings yet

- Sikadur - 53 Uf GroutDocument3 pagesSikadur - 53 Uf GroutJU SHUANGNo ratings yet

- Sikadur - 32 N: Wet To Dry Epoxy Resin Bonding AgentDocument4 pagesSikadur - 32 N: Wet To Dry Epoxy Resin Bonding AgentjxvichoNo ratings yet

- PDS - Sikaflex®-11 FC+ PDFDocument5 pagesPDS - Sikaflex®-11 FC+ PDFblancogonzalosNo ratings yet

- SikaTop Seal-109 MY 2012-08 - 1Document3 pagesSikaTop Seal-109 MY 2012-08 - 1Mashithah AhmadNo ratings yet

- Advanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials IIFrom EverandAdvanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials IITatsuki OhjiNo ratings yet

- Sika - Waterbars: Flexible PVC WaterstopsDocument5 pagesSika - Waterbars: Flexible PVC WaterstopsRonald MassoraNo ratings yet

- Plastiment VZ PDFDocument2 pagesPlastiment VZ PDFDarwin SyahputraNo ratings yet

- Sikagard 700 S ID PDFDocument2 pagesSikagard 700 S ID PDFDarwin SyahputraNo ratings yet

- Sikadur 42 MP Normal PDFDocument5 pagesSikadur 42 MP Normal PDFDarwin SyahputraNo ratings yet

- SikaTile Grout PDFDocument2 pagesSikaTile Grout PDFDarwin SyahputraNo ratings yet

- Sikadur-330: 2-part epoxy impregnation resin for fabric reinforcementDocument6 pagesSikadur-330: 2-part epoxy impregnation resin for fabric reinforcementDarwin SyahputraNo ratings yet

- SikaWrap-231 C PDFDocument3 pagesSikaWrap-231 C PDFDarwin SyahputraNo ratings yet

- Plastiment V105 PDFDocument2 pagesPlastiment V105 PDFDarwin SyahputraNo ratings yet

- Sikatop Armatec 110 EpoCem PDFDocument2 pagesSikatop Armatec 110 EpoCem PDFDarwin SyahputraNo ratings yet

- Sikacrete W: High - Performance Mineral Admixture For Underwater-Cast ConcreteDocument2 pagesSikacrete W: High - Performance Mineral Admixture For Underwater-Cast ConcreteDarwin SyahputraNo ratings yet

- Sikadur 42 MP Normal PDFDocument5 pagesSikadur 42 MP Normal PDFDarwin SyahputraNo ratings yet

- BOQ of Sylhet RCC 01.07.19 OldDocument98 pagesBOQ of Sylhet RCC 01.07.19 OldAtiq R Rafi100% (1)

- 07 Rawlbolts Plugs AnchorsDocument1 page07 Rawlbolts Plugs AnchorsLincolnNo ratings yet

- Aerospace Material SpecificationDocument7 pagesAerospace Material SpecificationdaNo ratings yet

- Metric ISO thread size chart 6g/6HDocument2 pagesMetric ISO thread size chart 6g/6HJose AndresNo ratings yet

- Module 6 (Materials & Hardware) SubModule 6.5 (Fasteners)Document75 pagesModule 6 (Materials & Hardware) SubModule 6.5 (Fasteners)daniaNo ratings yet

- Henderson, Johnson & Wood 2002 Enhancing The Whole Life Structural Performance of Multi-Storey Car ParksDocument50 pagesHenderson, Johnson & Wood 2002 Enhancing The Whole Life Structural Performance of Multi-Storey Car ParksRm1262No ratings yet

- CoreTen Brochure PDFDocument2 pagesCoreTen Brochure PDFRashid MohammedNo ratings yet

- Presentazione Inox Maket Service Group 2018 PDFDocument33 pagesPresentazione Inox Maket Service Group 2018 PDFAnonymous thurQ1QydLNo ratings yet

- Introduction to Prestressed Concrete in 40 CharactersDocument15 pagesIntroduction to Prestressed Concrete in 40 Charactersyosef gemessaNo ratings yet

- Certificate of Conformity Number # 241413C: ContaminantDocument2 pagesCertificate of Conformity Number # 241413C: ContaminantAdrian HolotteNo ratings yet

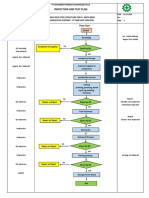

- Inspection and Test Plan: Flow Chart Start IncomingDocument1 pageInspection and Test Plan: Flow Chart Start IncomingSinden AyuNo ratings yet

- NSCP 2010Document758 pagesNSCP 2010Chelle Sujetado De Guzman95% (21)

- Module 1 FundamentalsDocument90 pagesModule 1 Fundamentalshari0118No ratings yet

- Fairfield Atlas Limited: 6.1 - Minimum 5 Samples Per Heat Batch To Be CheckedDocument3 pagesFairfield Atlas Limited: 6.1 - Minimum 5 Samples Per Heat Batch To Be CheckedAndras StegerNo ratings yet

- Incoloy 825 Pipe Price Alloy 825 Tubing Price: USD 12/KGSDocument10 pagesIncoloy 825 Pipe Price Alloy 825 Tubing Price: USD 12/KGSGonzalo MazaNo ratings yet

- KORVISIT A: Durable Refractory Lining for Reheating FurnacesDocument1 pageKORVISIT A: Durable Refractory Lining for Reheating FurnacesMaximoJrOtadoyNo ratings yet

- Technical Catalog Sandwich Panels Paneltech 2020.1Document88 pagesTechnical Catalog Sandwich Panels Paneltech 2020.1cheikh ahmed Mohamed NagimNo ratings yet

- Certification 3g Dan 4g Aws d1Document12 pagesCertification 3g Dan 4g Aws d1AvebFrederiksenNo ratings yet

- Design Your Baseplate Using Supplimentary ReinforcementDocument52 pagesDesign Your Baseplate Using Supplimentary ReinforcementCretu RazvanNo ratings yet

- Polyflor Global Approved AdhesivesDocument24 pagesPolyflor Global Approved AdhesivesRatna Ayu K 201102No ratings yet

- Bug Holes in PrecastDocument5 pagesBug Holes in PrecastMichel DaoustNo ratings yet

- Instructions For Welding The Cat Advansys™ Adapters On Excavator and Wheel Loader S (0679, 6001, 6800)Document1 pageInstructions For Welding The Cat Advansys™ Adapters On Excavator and Wheel Loader S (0679, 6001, 6800)arfa ujiantoNo ratings yet

- Marshall Stability Test ProcedureDocument9 pagesMarshall Stability Test ProcedurePurshottam SharmaNo ratings yet

- Redi - Rainwater Gullies - Dexterton Corporation PhilippinesDocument8 pagesRedi - Rainwater Gullies - Dexterton Corporation PhilippinesMonami Imanom100% (1)

- Chemical Composition AluminiumDocument3 pagesChemical Composition AluminiumEmreNo ratings yet

- Lec2 PDFDocument24 pagesLec2 PDFKiran Kumar AatyamNo ratings yet

- Logan Clay: ASTM C 700 Spec and DimensionsDocument2 pagesLogan Clay: ASTM C 700 Spec and DimensionsMohamed AdelNo ratings yet

- BOQ for Road and Drainage WorksDocument20 pagesBOQ for Road and Drainage WorksVenkatesha Hebbar50% (2)

- AUTOMATIC WELDING OF STORAGE TANKSDocument8 pagesAUTOMATIC WELDING OF STORAGE TANKSJimmy RodriguesNo ratings yet

- Laying of DWC PipesDocument56 pagesLaying of DWC Pipessatyam50% (2)